Small volume low loss superconductor CICC connector structure

A joint structure, low-loss technology, applied in superconducting devices, clamping/spring connections, electrical components, etc., can solve the problems of large volume, large AC loss, and large contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

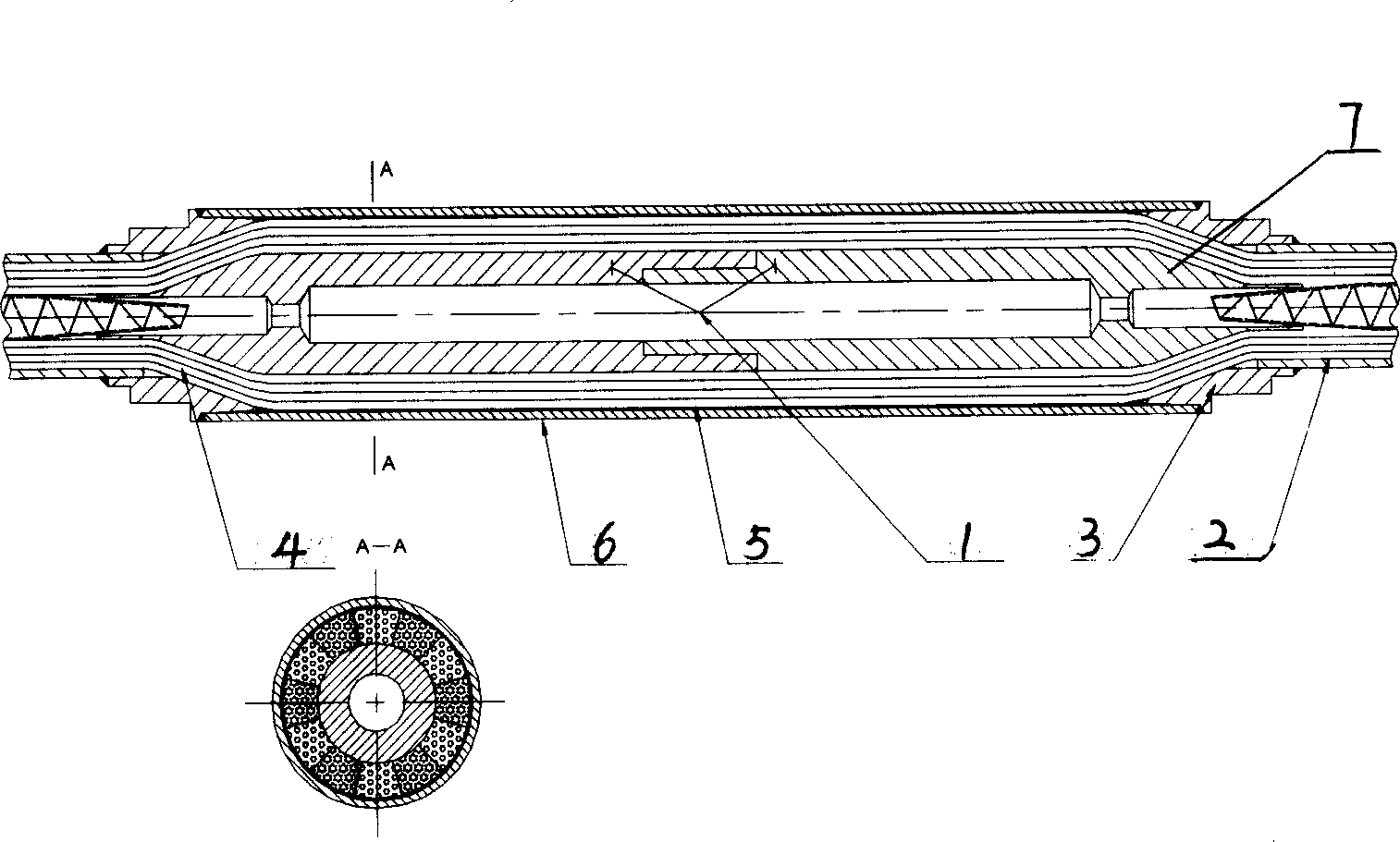

[0019] Small volume and low loss superconducting CICC joint structure (see figure 1 ), including a wiring shaft 1 with a cold mass flow channel 8 in the middle, superconducting sub-cables 4 protruding from the two superconducting conductor shells 2 at the left and right ends are fixed outside the wiring shaft 1 through spiral winding, and the sub-cable joints The wiring shaft 1 is distributed with a plurality of through holes or interspersed through grooves, which are used for cold mass flow and cooling of the sub-cable. The sub-cable 4 has an inner shell 5 outside, and an outer shell 6 outside the inner shell 5. The wiring shaft 1. The two ends form a conical body 7. The superconducting sub-cable 4 is close to the two ends of the wiring shaft. The conical body 7 is covered with a tapered sleeve 3. The taper sleeve 3, the outer shell 6 and the superconducting conductor shell 2 are squeezed and sealed. . The wiring shaft 1 is divided into two sections, left and right, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com