Integral lifting reconstruction method for high-span overweight continuous box girder

An integral jacking, large-span technology, used in bridges, bridge parts, bridge maintenance, etc., can solve the problems of difficulty in distributing beams and the bottom of box girder with uniform force, low cost performance and safety, and limited location of the bearing platform. To achieve the effect of high cost performance, high safety, high safety and clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

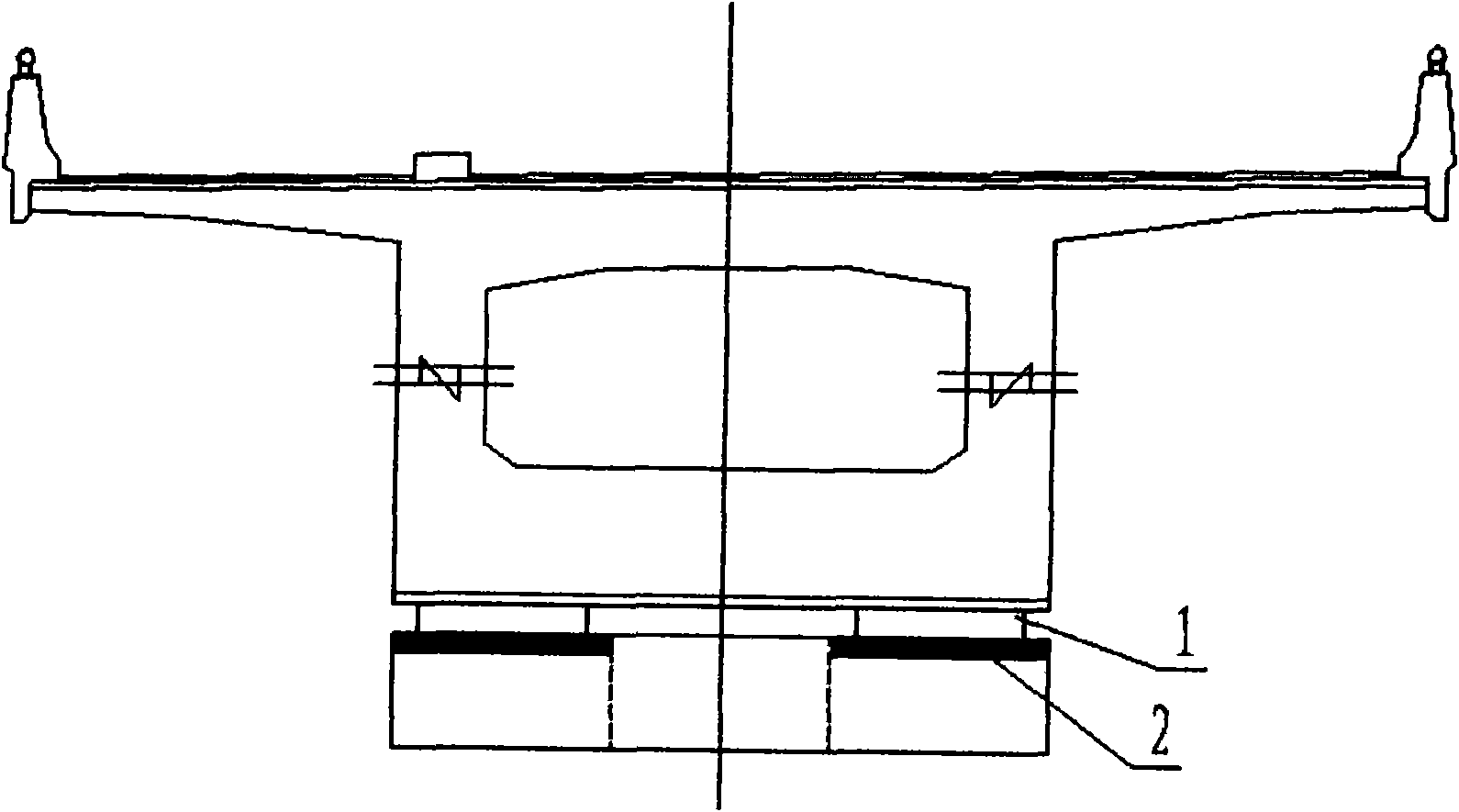

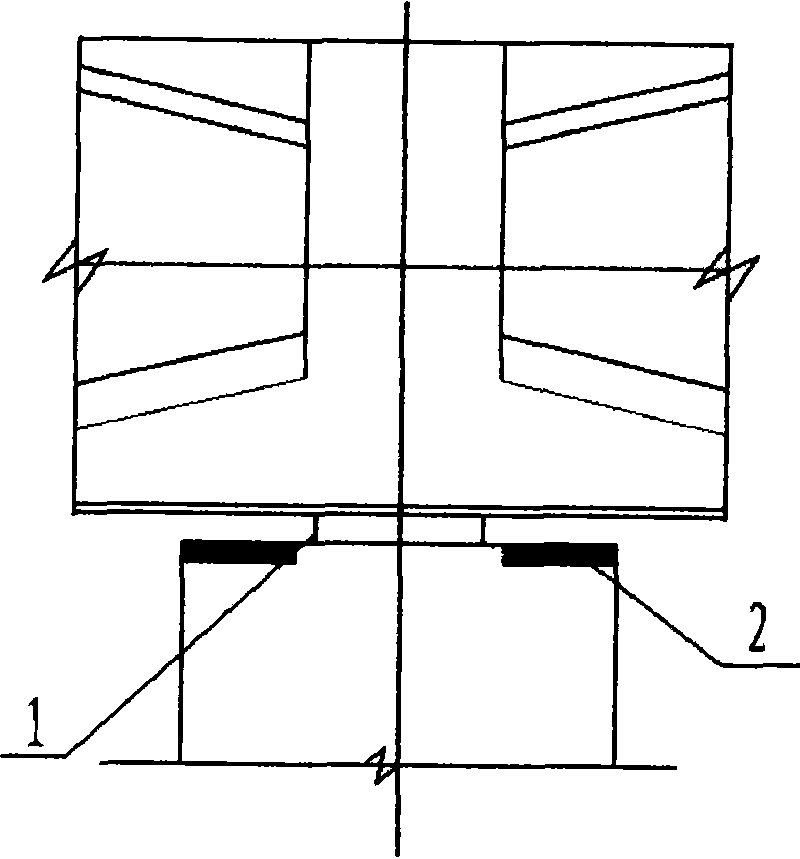

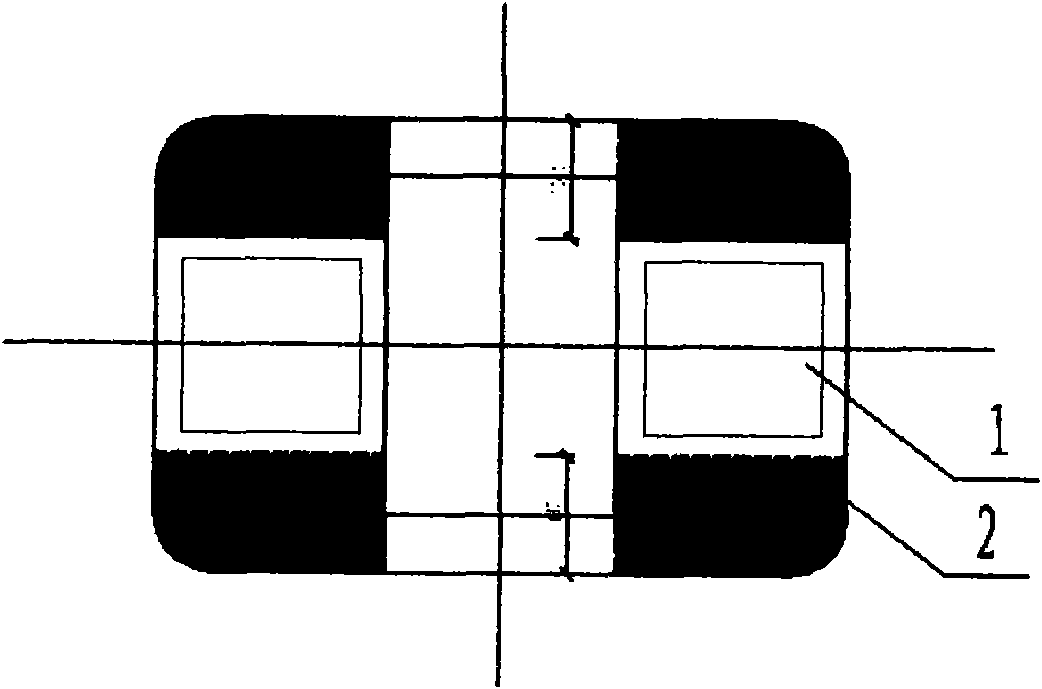

[0033] like Figure 1 to Figure 18 Shown, the present invention a kind of long-span super-heavy continuous box girder overall jacking modification method, this method comprises the following construction steps:

[0034] (1) Cutting the top of the pier (take the pier as an example, such as Figure 1 to Figure 3 As shown, cutting range 2, as shown in the figure), the reason is that the top of the pier is cut to facilitate the installation of the jacking jack in consideration of the small clearance between the side pier and the upper part of the box girder, which is not conducive to the installation and operation of the jacking jack And follow the jack to form the jacking reaction foundation. Before the construction, the pressure calculation of the top of the pier column is carried out. If the pressure value meets the jacking requirements, the top of the pier is directly cut. If the pressure value does not meet the jacking requirements, the pier’s After thickening the concrete of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com