High-precise preparation method of micro-nano structure on flexible film substrate

A technology of micro-nano structure and flexible film, applied in the direction of micro-structure technology, micro-structure device, manufacturing micro-structure device, etc. The effect of high-precision preparation, reduction of production cost and processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

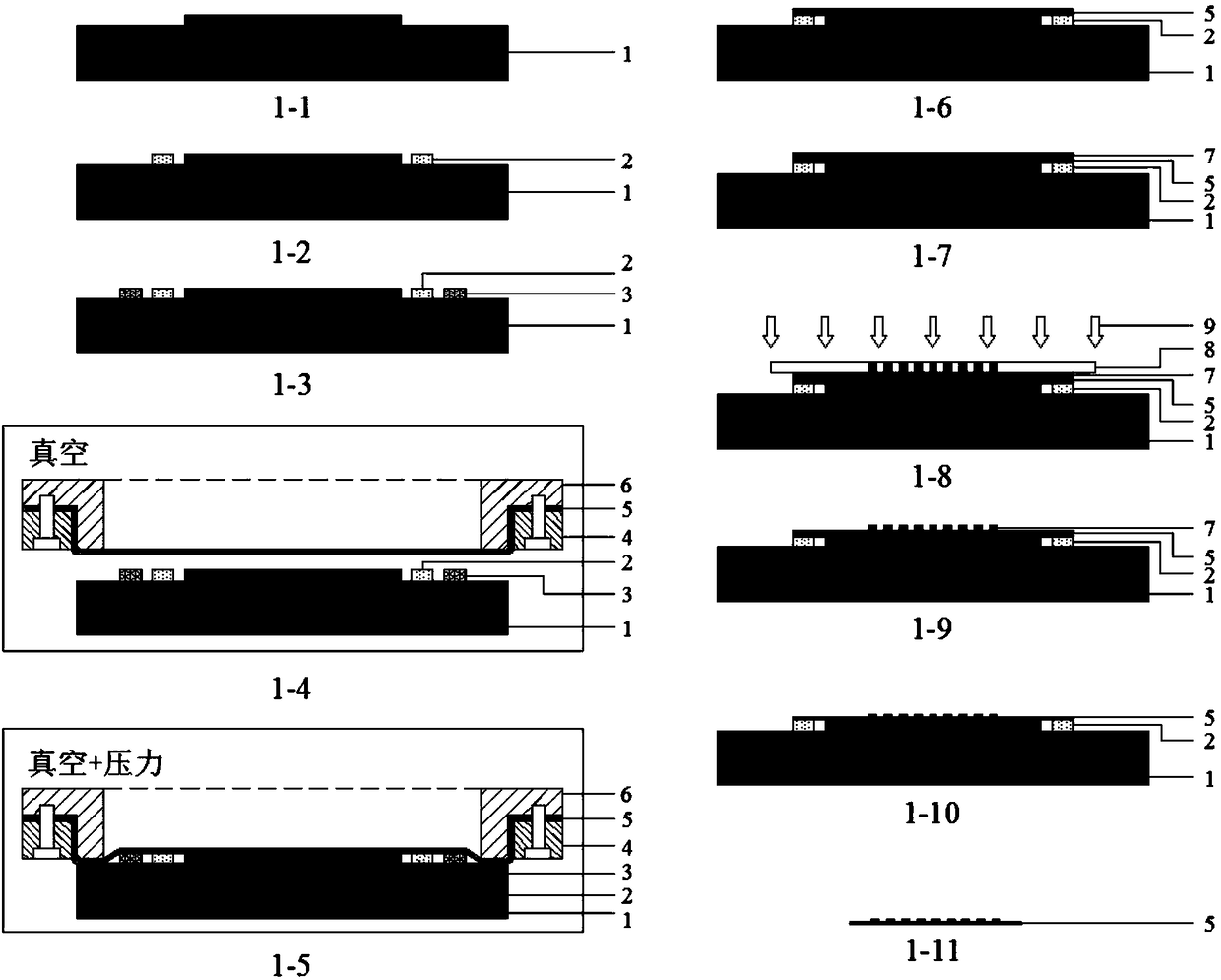

example 1

[0031] Such as figure 1 As shown in 1-1, the upper surface edge of a quartz substrate 1 (size φ500mm*5mm) with relatively high flatness (PV=200nm, RMS=50nm) is thinned by 0.5mm from φ440mm to φ500mm to form a relatively An annulus with a reduced height at the center;

[0032] Such as figure 1 As shown in middle 1-2, apply the adhesive polyurethane 2 evenly on the inner side of the thinning ring (range φ450mm to φ470mm) with a brush, and leave a gap of 5mm between the quartz boss to avoid the adhesive Squeezed to reach the upper surface of the boss;

[0033] Such as figure 1 As shown in 1-3, place an annular silicone rubber sealing ring 3 with a size of φ(480-490)mm*0.5mm on the outside of the adhesive polyurethane, and the outer edge of the sealing ring should not exceed the scope of the quartz substrate 1;

[0034] Such as figure 1 As shown in middle 1-4, the flexible polyimide film 5 is fixed by two aluminum fixtures, the upper fixture 4 and the lower fixture 6, and pla...

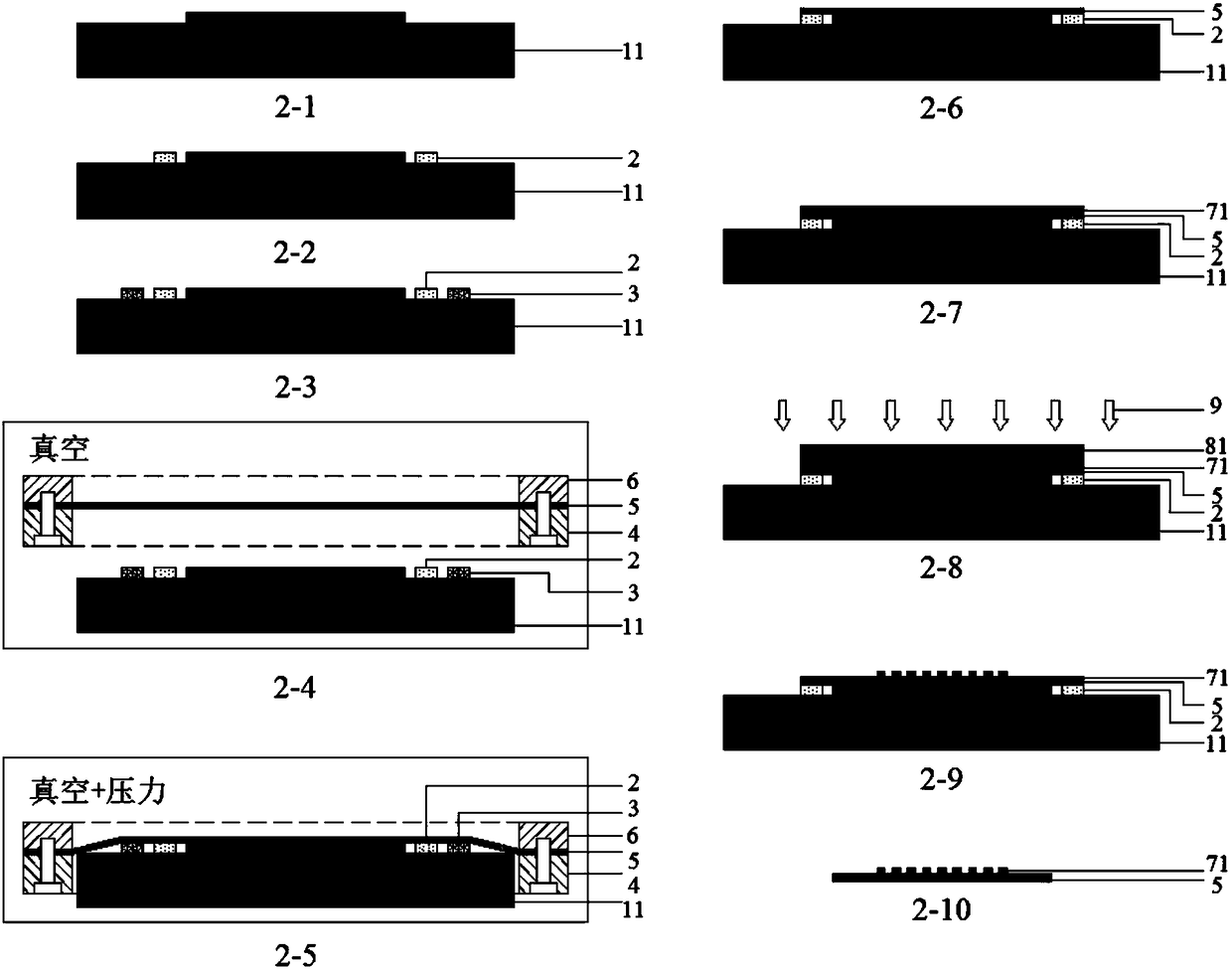

example 2

[0043] Such as figure 2 As shown in 2-1, the upper surface edge of a circular carbon fiber substrate 11 (size φ500mm*10mm) with a relatively high flatness (PV=4um, RMS=1um) is thinned by 1mm from φ440mm to φ500mm to form a phase An annulus with a lower height than the central position;

[0044] Such as figure 2 As shown in 2-2, apply the adhesive polyurethane 2 evenly on the inner side of the thinning ring (range φ450mm to φ470mm) with a brush, and leave a gap of 5mm between the boss of the carbon fiber base to avoid glue The adhesive is squeezed to reach the upper surface of the boss;

[0045] Such as figure 2 As shown in middle 2-3, place an annular silicone rubber sealing ring 3 with a size of φ(480~490)mm*0.5mm on the outside of the adhesive polyurethane, and the outer edge of the sealing ring should not exceed the scope of the carbon fiber substrate 1;

[0046] Such as figure 2 As shown in middle 2-4, the flexible polyimide film 5 is fixed by two aluminum fixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com