Tank body assembling electric lifting system by flip chip method and hoisting method thereof

A lifting system and method of tank body technology, which is applied in the field of electric lifting system and lifting field of flip-chip method tank body assembly, can solve the problems of inaccurate positioning of cylinder body lifting, low assembly efficiency, poor molding quality, etc., and achieves increased convenience and efficiency. Safety, Avoiding scratches and abrasions, Guaranteed quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

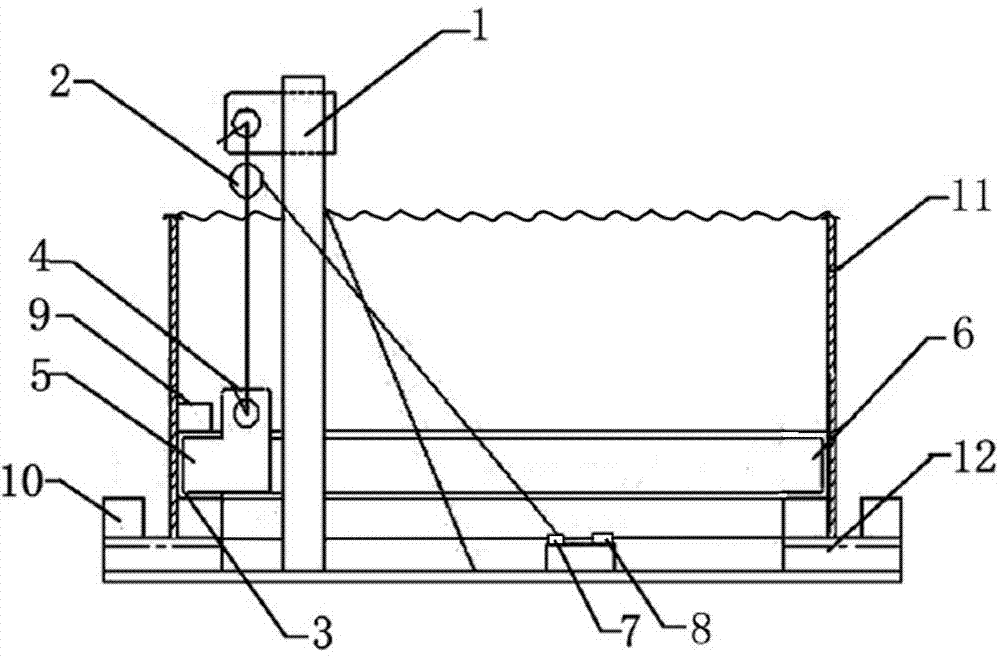

[0022] Such as figure 1 As shown, a cylinder 11 with an inner diameter of 12.6 m and a mass of 95 tons is placed on the base 12, and a square outer baffle 10 is arranged on the outside of the cylinder 11, and the outer baffle 10 is welded on the base 12. The bottom of the inner wall of 11 is welded with an annular expansion ring 3 whose outer diameter is equal to the inner diameter of the cylinder 11. The expansion ring 3 is a closed metal ring, one side of which is a sliding surface, which is closely attached to the inner wall of the cylinder 11, and the other There is a concave slot 6 on the side for engaging with the engaging body 5 of the electric lifting device; a square inner baffle 9 that is close to the inner wall of the cylinder 11 is welded on the top surface and the ground of the expansion ring 3 respectively. 10 electric lifting devices are evenly distributed on the circumference of the inner side of the cylinder 11.

[0023] Each electric lifting device includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com