Centering supporting mechanism, car coupler buffering device adopting centering supporting mechanism and centering method

A technology of support mechanism and buffer device, which is applied in the field of coupler buffer device and centering support mechanism, can solve the problems of inconvenient regulation and complex structure, and achieve the effect of automatic vehicle coupling and roller force dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

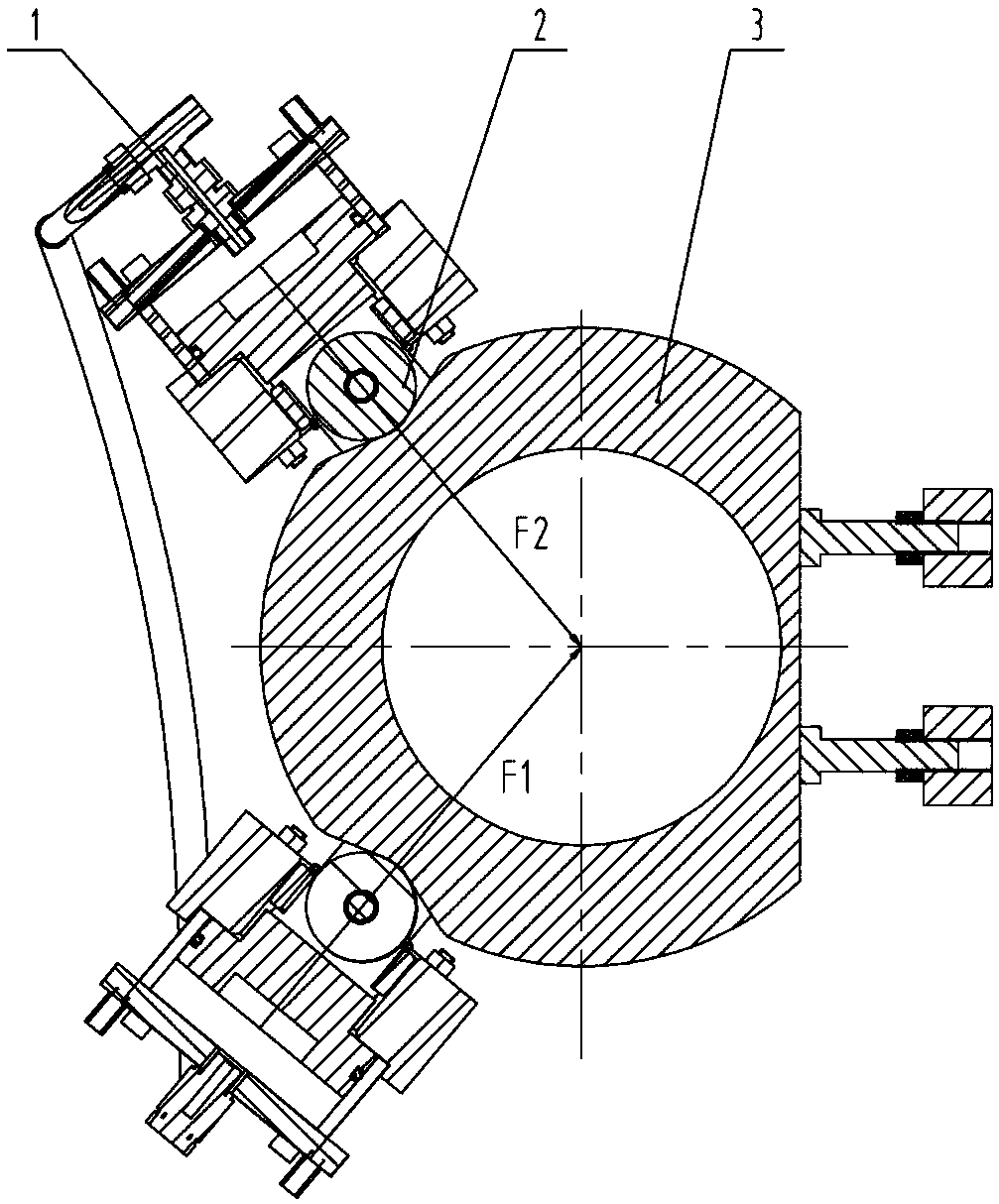

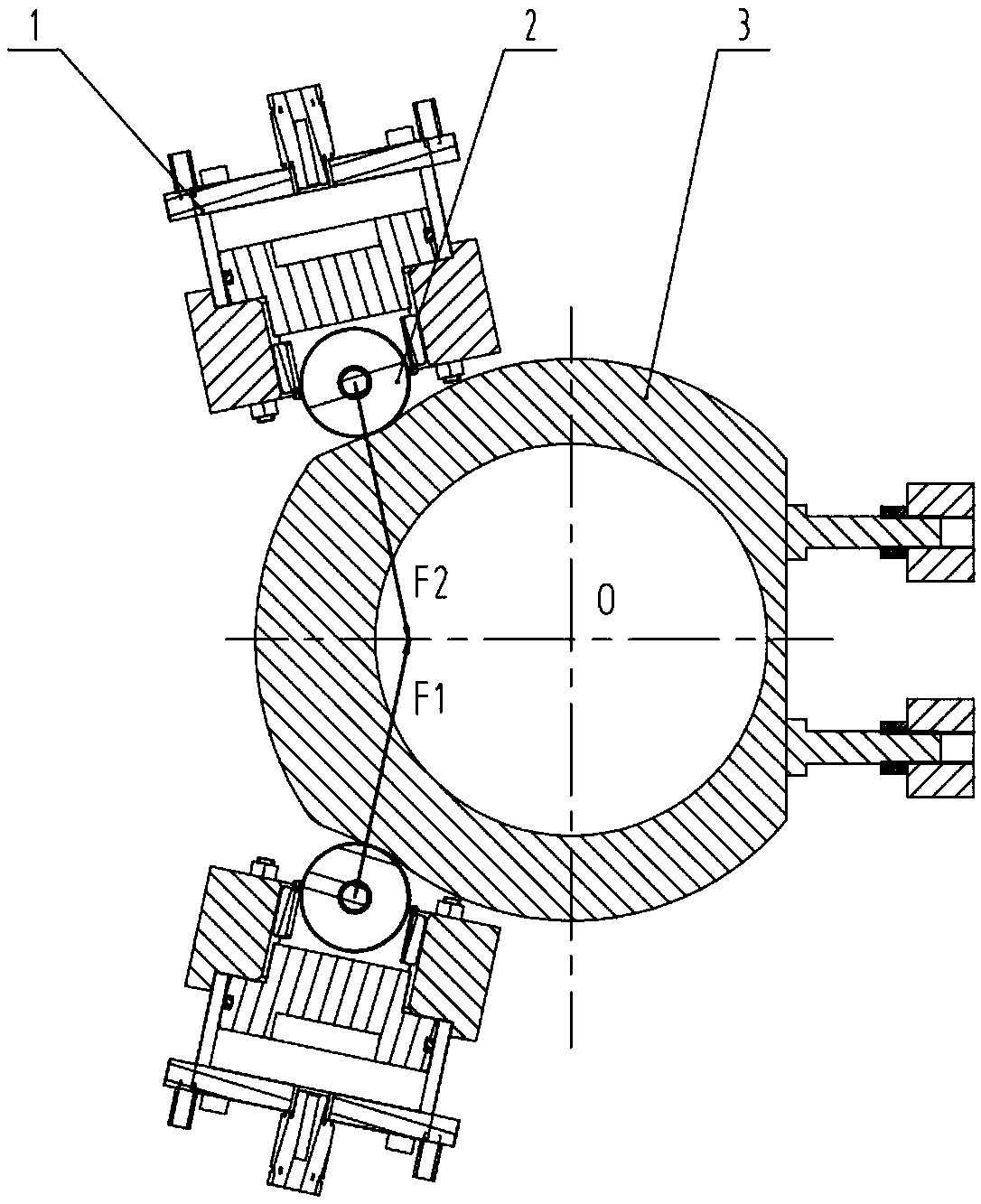

[0031] The basic structure of the centering support mechanism of this embodiment is as follows: figure 2 shown (see image 3 , Figure 4 ), the hinged hole in the center of the center plate 3 forms the coupler swing center O, and the two sides of the coupler extension direction (horizontal direction through the swing center in the figure) are symmetrically placed on both sides of the pneumatic pressure device 1, and the piston of the pneumatic pressure device 1 The cam pair is formed by the circular arc recess of the roller 2 and the centering disc 3 .

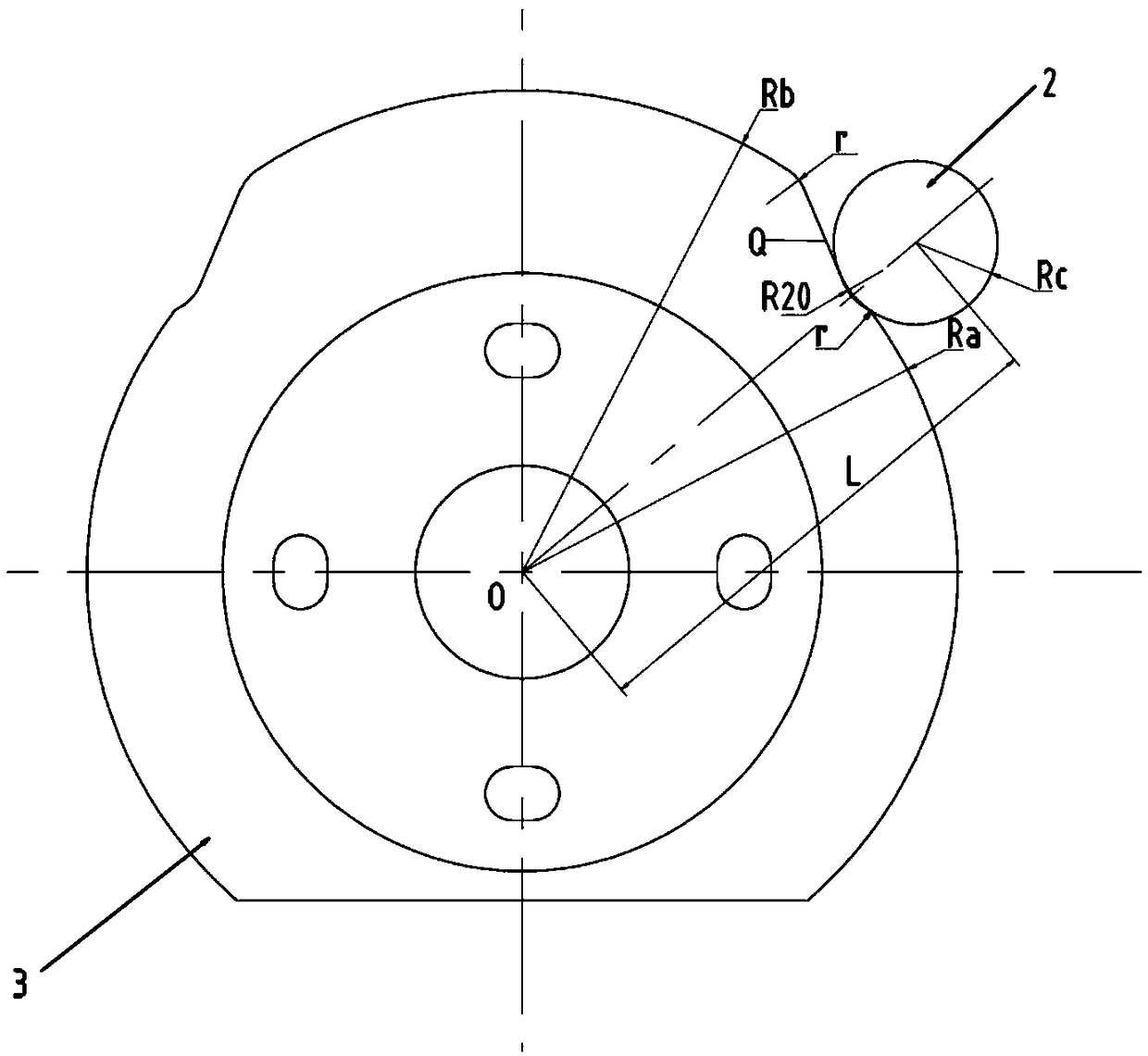

[0032] Such as image 3 As shown, the outer profile of the centering plate 3 has a large-diameter section corresponding to the space between the two pneumatic pressure-applying devices 1 with a radius of Rb, and a small-diameter section corresponding to the outside of the two pneumatic pressure-applying devices 1 with a radius of Ra and a radius of R20 The circular arc depression of the centering disc 3 is adjacent to the ...

Embodiment 2

[0041] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference lies in that the outline curve of the middle plate 3 is optimized.

[0042] The outline of the centering plate 3 of the centering support mechanism is constituted as follows: Figure 7 As shown, as in Embodiment 1, there is a large-diameter section corresponding to two pneumatic pressure-applying devices 1 with a radius of Rb and a small-diameter section corresponding to the outside of the two pneumatic pressure-applying devices 1 with a radius of Ra, and a radius of R20 The arc sag, the optimization point is that the tangent between the arc sag and the large-diameter section of the centering plate 3 is the diameter-increasing arc Q' of the radius RQ (2000mm in this embodiment), and its center is in the centering The position is on the line of the force direction of the pressing device passing the center of the roller circle. In this way, it is easier to perceive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com