Pile machine having drilling function and drilling static pressure method

A drilling method and pile driver technology, which is applied to drilling equipment and methods, rotary drilling rigs, drill pipes, etc., and can solve problems such as pressure explosion of pipe piles and destructive cracks in buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

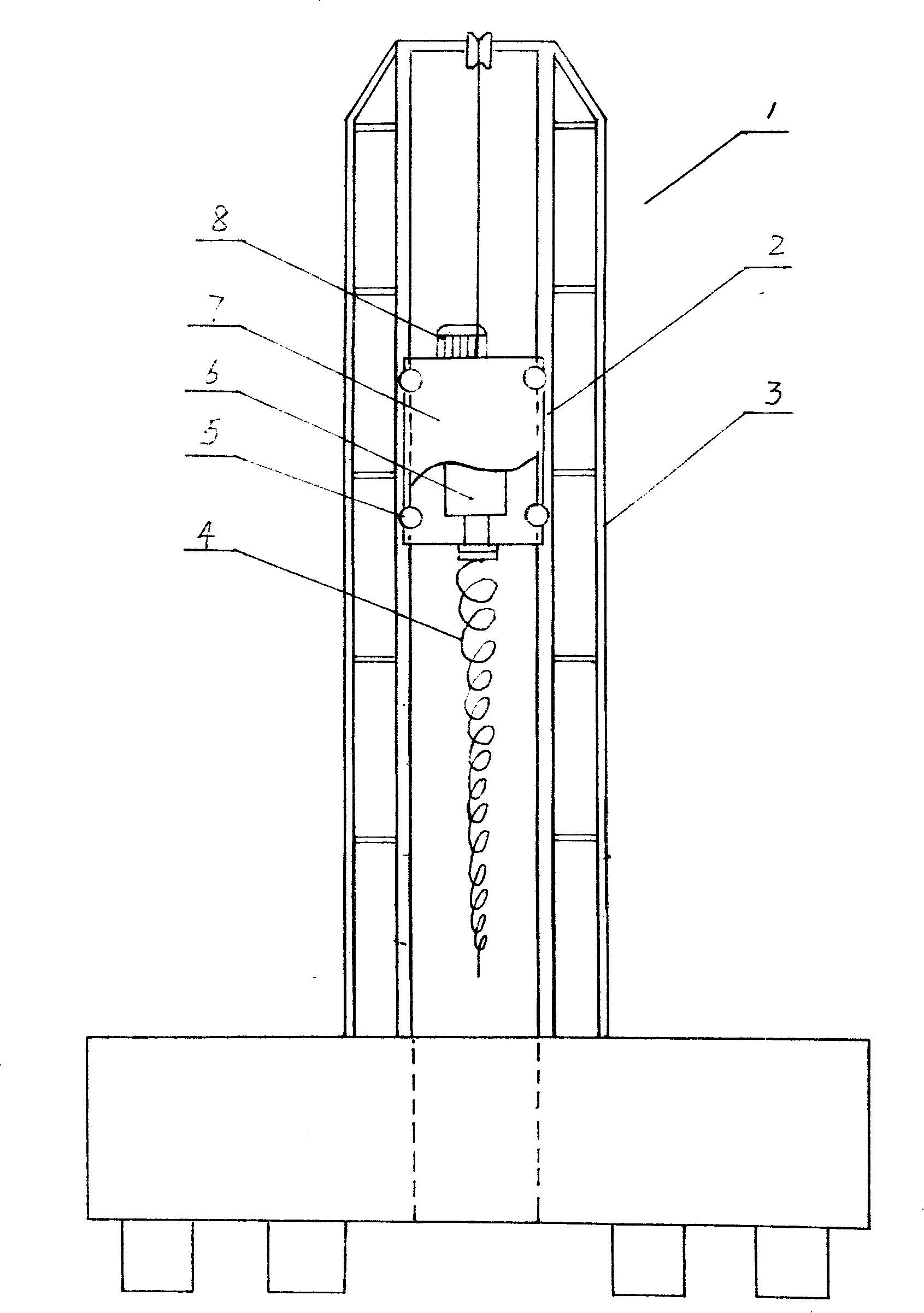

[0009] Embodiment 1: with reference to attached figure 1 . A pile driver with a drilling function, which includes a static pressure pipe pile machine 1, a drilling device 2 is located between the vertical frames of the static pressure pipe pile machine and is connected to the traction mechanism on the top of the static pressure pipe pile machine frame by a traction rope , move up and down along the vertical frame under the traction of the traction mechanism, that is to say, the guide pulley in the drilling device 2 is located between the vertical frame rails 3 in the static pressure pipe pile machine, and the drilling device 2 is connected to the vertical frame by the traction rope The traction mechanism on the top of the static pressure pipe pile machine frame is connected and moves up and down along the vertical frame rail 3 under the traction of the traction mechanism. Erection frame rail 3 is I-shaped steel track or channel steel track or angle steel track. Drilling devi...

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, the drilling method of the static pressure pipe pile machine with drilling function, the guide pulley in the drilling device (the guide pulley is a groove structure) is stuck in the static pressure pipe pile machine Between the vertical frame rails in the static pressure pipe pile machine, the traction mechanism located at the top of the static pressure pipe pile machine frame drives the drilling device to move down along the vertical frame frame rails in the static pressure pipe pile machine through the traction rope (wire rope, etc.), Make the drill bit contact with the ground to be drilled, then start the power machine, the power machine drives the drill bit to drill, the soil drilled by the drill bit is automatically transported to the ground along the spiral soil extraction drill, when the drilling device is under the action of its gravity, the drill bit When the required depth is reached, the drill bit device stops workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com