Cross box transfer structure and processing method thereof

A technology for converting structure and box shape, applied in the direction of building structure and building, can solve problems such as the design of connecting nodes of rods, and achieve the effect of avoiding laminar tearing and reducing cutting deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

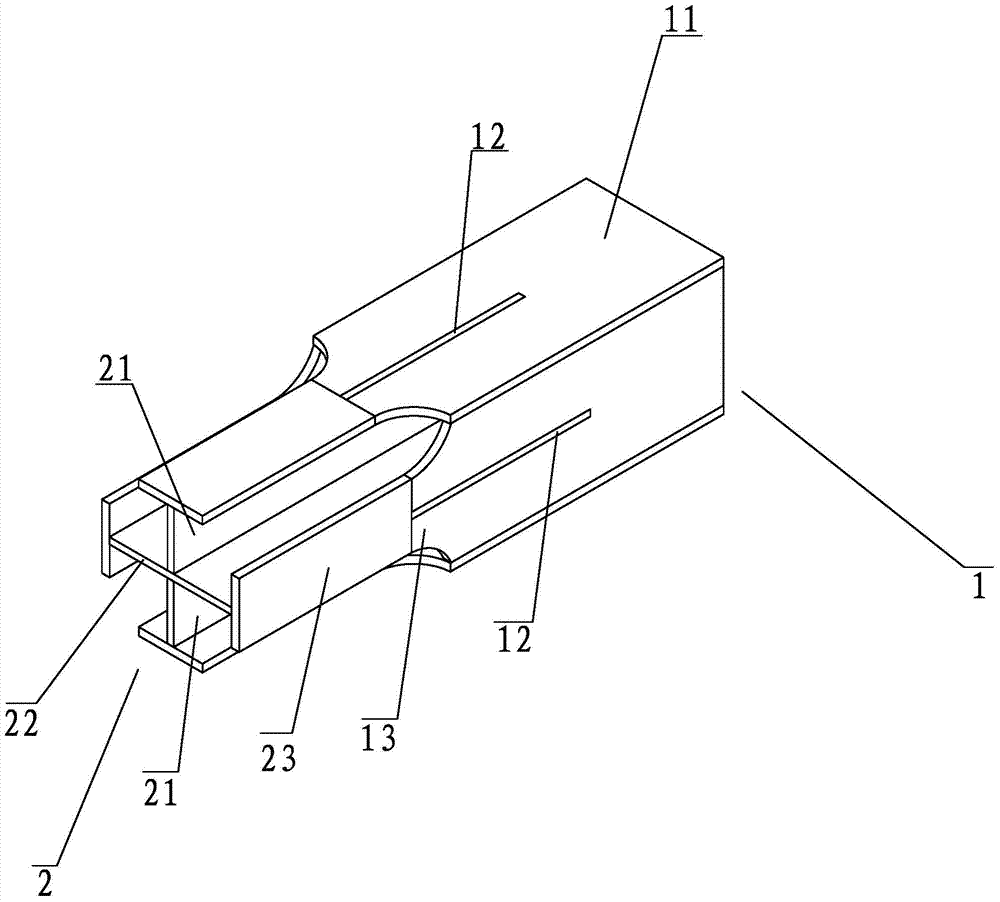

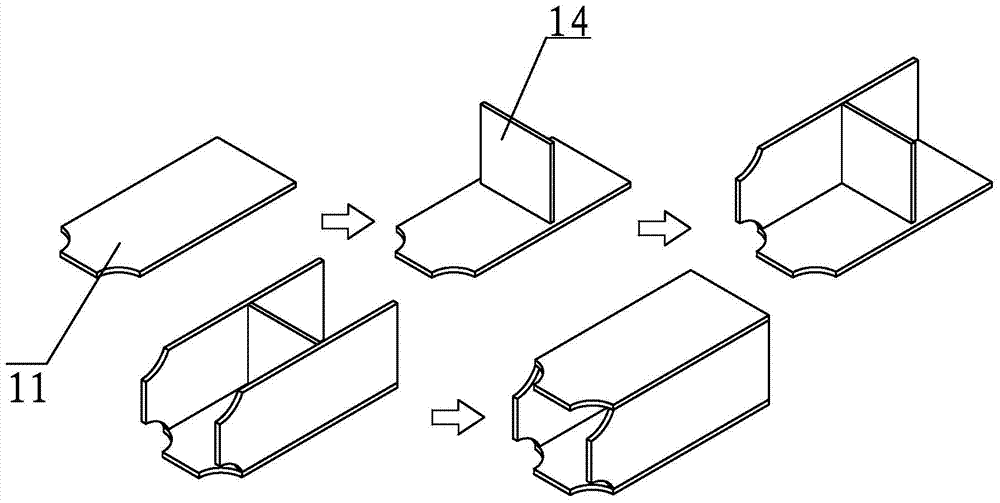

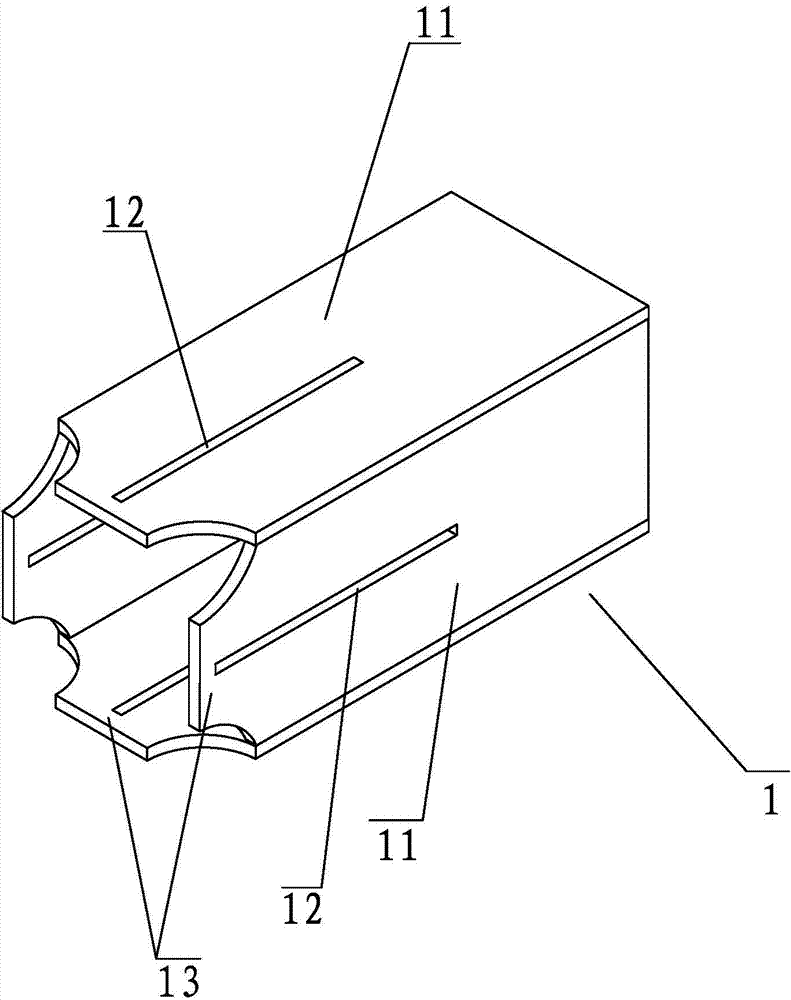

[0025] like figure 1 , 2 , 3, 4, 5, and 6, what the present invention discloses is a cross box-type conversion structure, which includes a box-shaped column 1 enclosed by four box-shaped panels 11 and a cross-shaped column installed in the box-shaped column 1. Column 2, the cross column 2 is welded by two cross column small webs 21 and a cross column large web 22, a part of the cross column 2 is exposed outside the box column 1; each box panel 11 is provided with There is a cut groove 12, and each side of the cross column 2 is correspondingly inserted and welded in the cut groove 12; each side of the cross column 2 is welded with a cross column wing plate 23, and the cross column wing plate 23 is connected with the box panel 11 connected and located at the same level.

[0026] Further, the cross column 2 is provided with a rib 24 on the edge in the cut groove 12, and the rib 24 is a pointed rib 24, and the rib 24 and the cut groove 12 form a W-shaped cut groove; the cross co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com