Wet static cyclone dust collector

A wet electrostatic and dust collector technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode structure, etc., can solve the problems of cyclone dust collector application limitation, cyclone dust collector cannot be removed, etc., to improve particle removal efficiency, The effect of improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

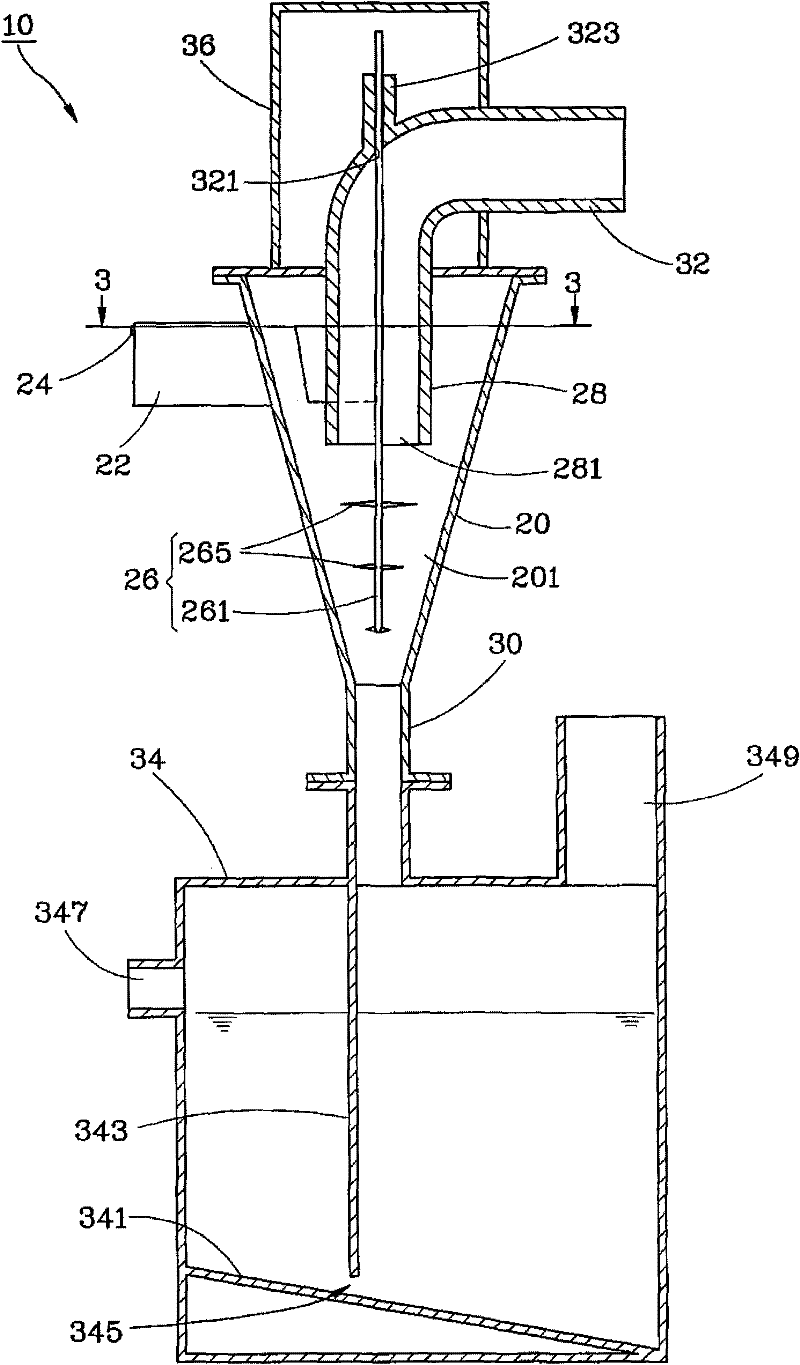

[0023] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

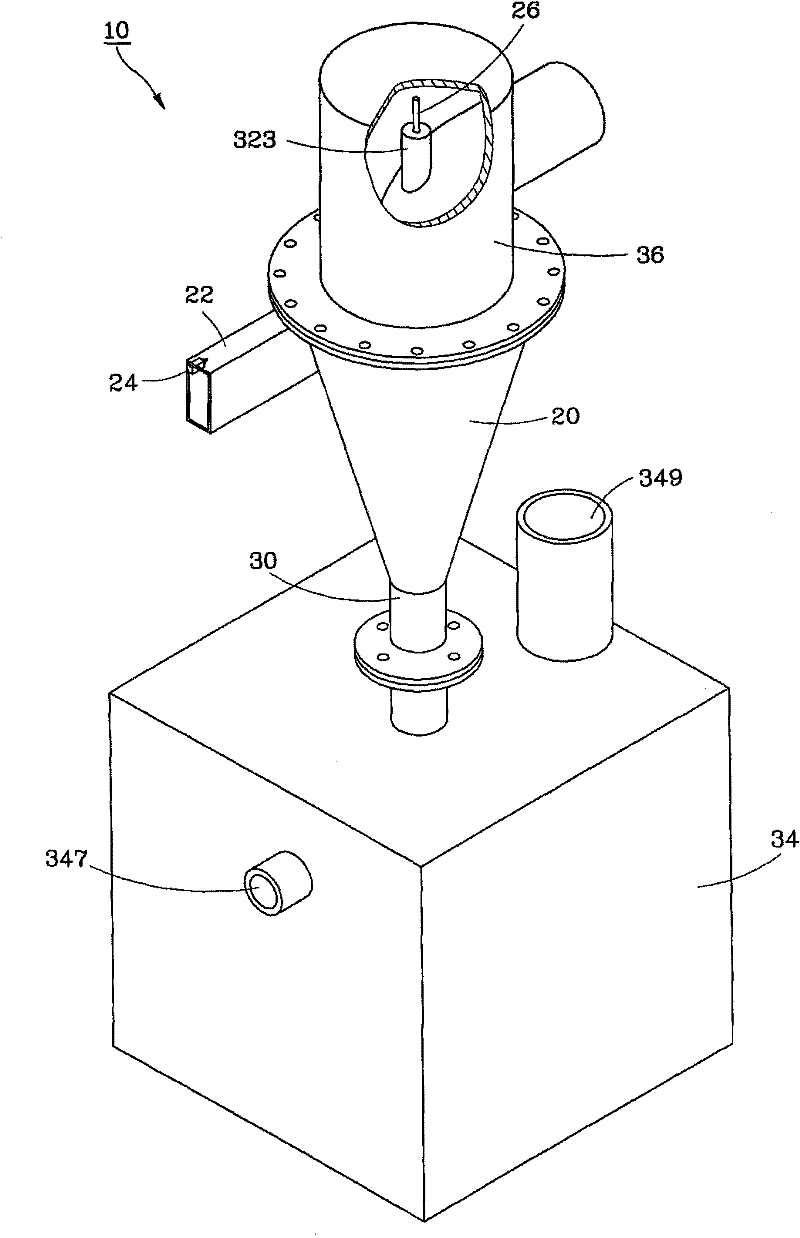

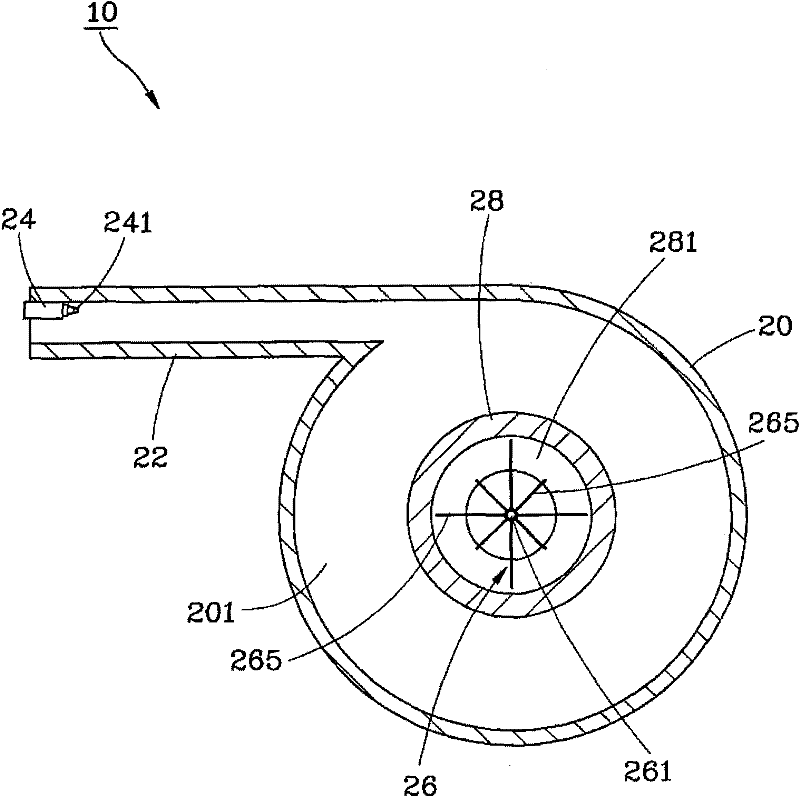

[0024] Such as Figure 1 to Figure 3 As shown, the wet electrostatic cyclone dust collector 10 provided by the first preferred embodiment of the present invention includes a casing 20, an air inlet pipe 22, a water supply member 24, a discharge electrode tube 26, an annular wall 28, A drain pipe 30 , an exhaust pipe 32 , a liquid storage tank 34 and an insulating cover 36 .

[0025] The shell 20 is in the shape of an inverted cone, and a cavity 201 is formed in a hollow inside. The shell 20 is made of conductive material.

[0026] The intake pipe 22 is connected to the casing 20 and extends along a tangential direction of the casing 20 .

[0027] The water supply part 24 is arranged inside the air intake pipe 22 and is connected with a water supply pipeline (not shown in the figure). The water supply part 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com