Rotary steam distillation equipment

A steam distillation and rotary technology, applied in the direction of steam distillation, etc., can solve the problems of low extraction efficiency, long heating time, long production time, etc., and achieve the effects of less loss of aroma components, increased contact area, and high-efficiency distillation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

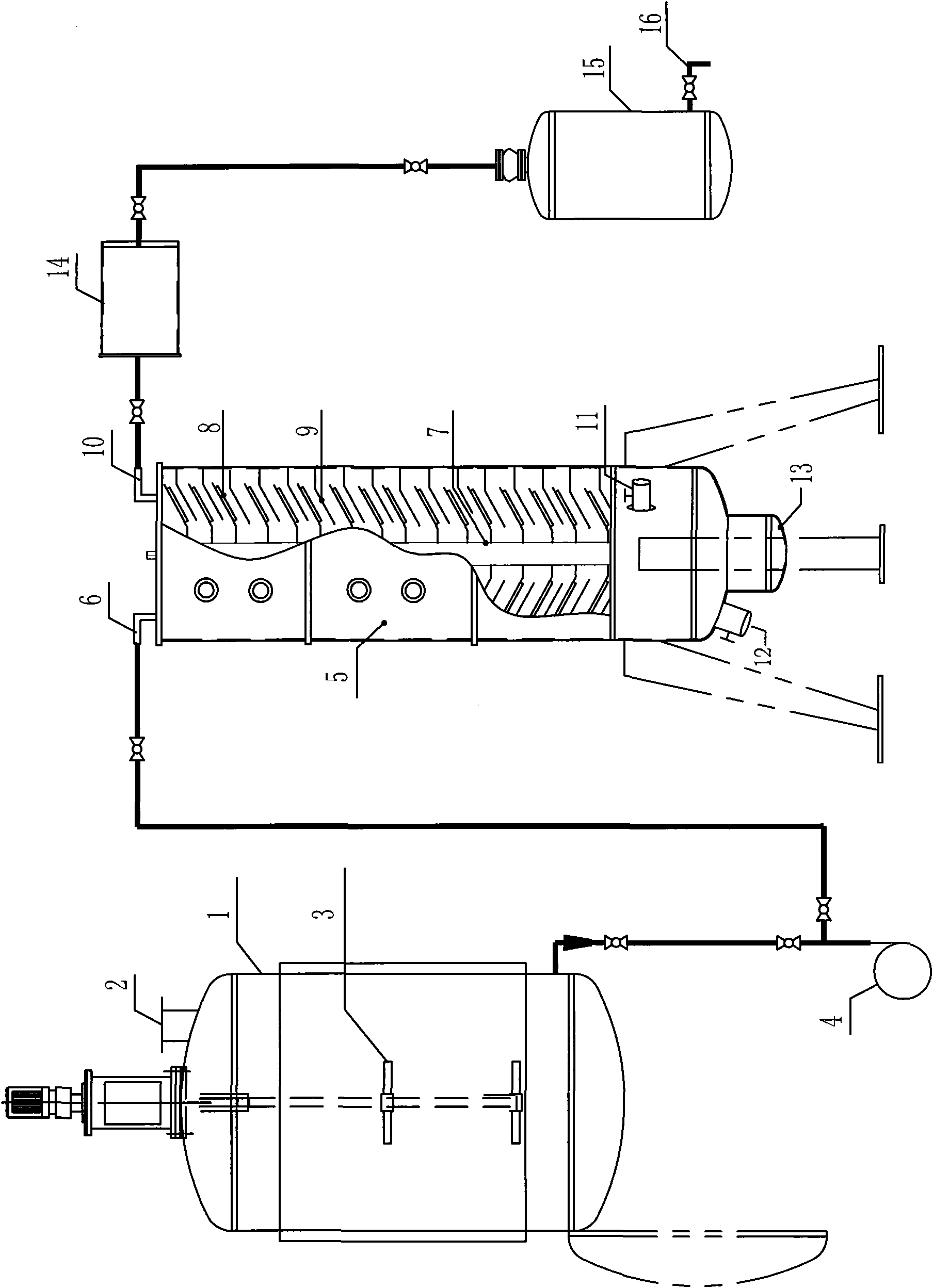

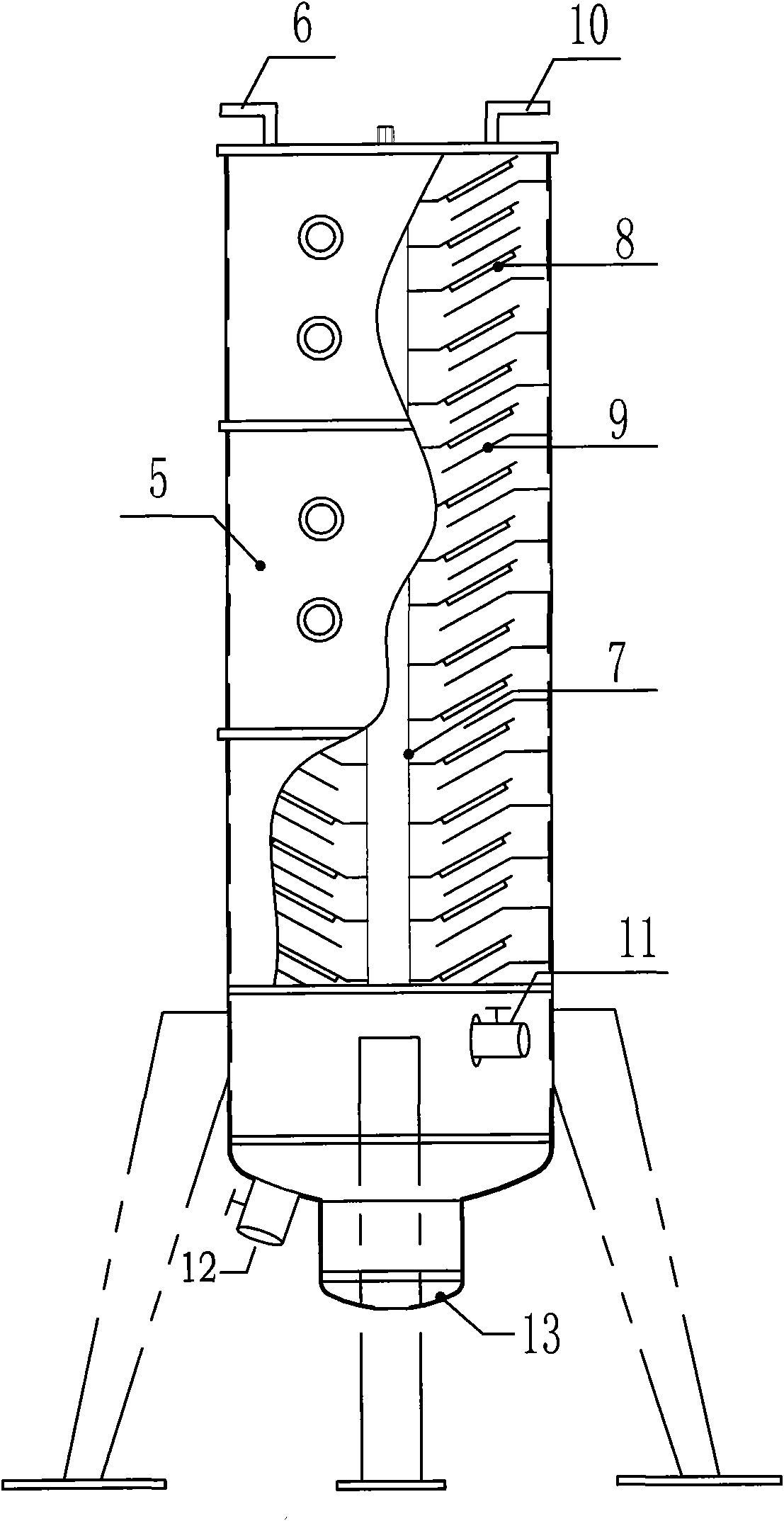

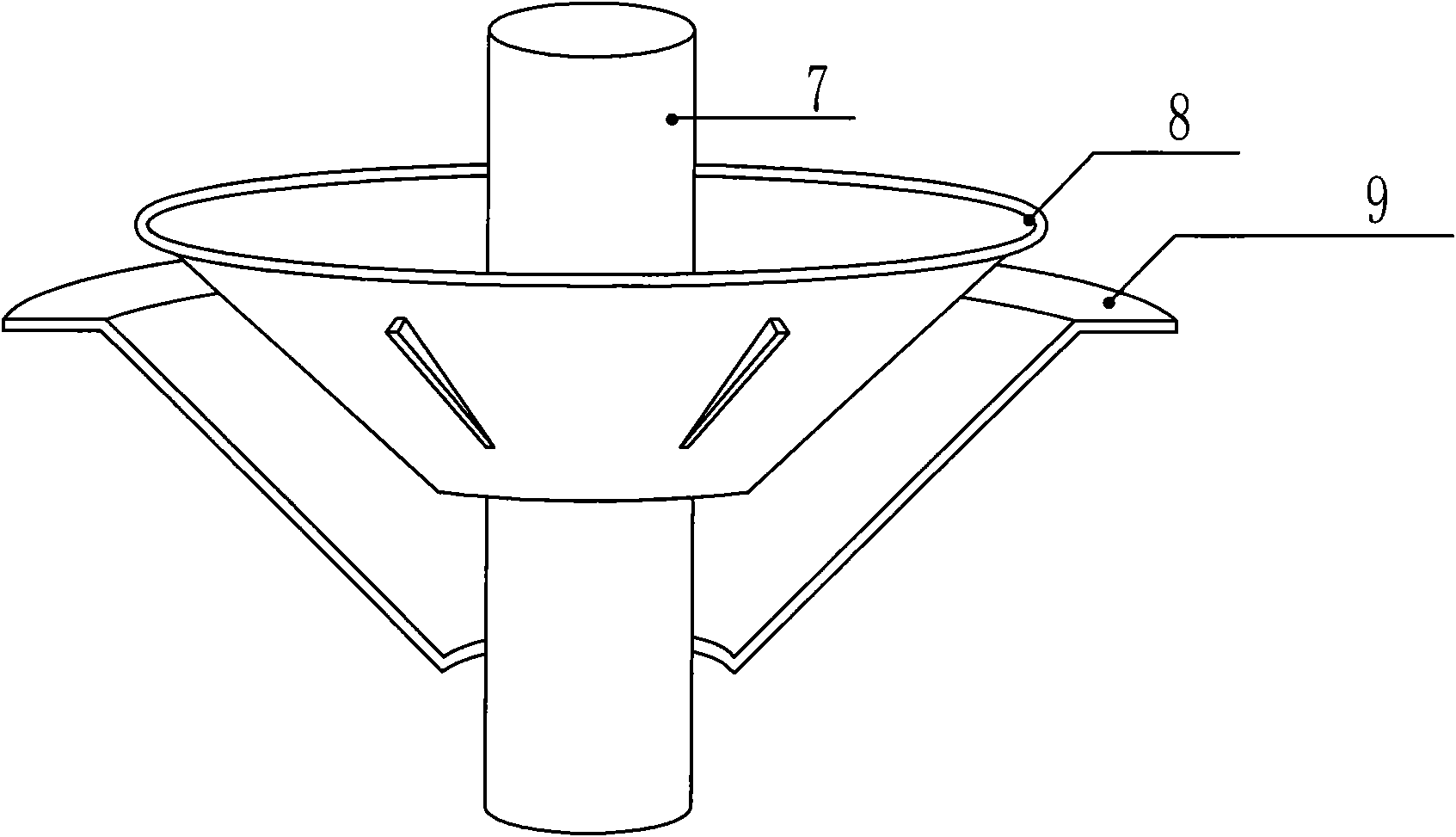

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. The rotary steam distillation equipment of the present invention is used in connection with external equipment feeding equipment, condensing equipment and collecting equipment. The material is added to the material storage tank 1 through the material inlet 2 of the storage tank. After the material is stirred evenly by the agitator 3, it enters the shell 5 of the rotary steam distillation equipment through the pump 4 through the inlet 6 of the distillation equipment for distillation. The mixture with the fragrance substance enters the condenser 14 to condense from the gaseous substance outlet 10, and the recovered fragrance obtained is stored in the collecting tank 15. The added material can be solid or liquid. The solid material can be crushed to 60-80 mesh and then fed into the material storage tank 1 from the feed port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com