Composite material grid conical shell fiber placing and winding integrated molding device

A composite material and forming device technology, which is applied in the field of composite mesh cone shell wire laying and winding integrated forming device, can solve the problems of difficult to accurately design the shell thickness and layup angle, and difficult to accurately control the layup thickness, etc. Achieve the effect of favorable molding quality control, convenient loading and unloading, and controllable winding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

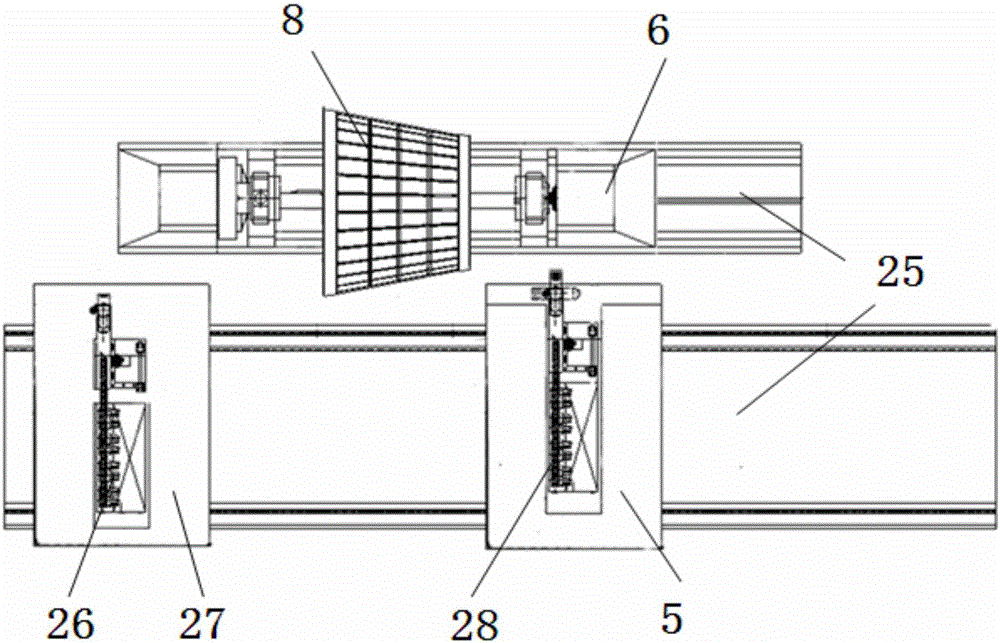

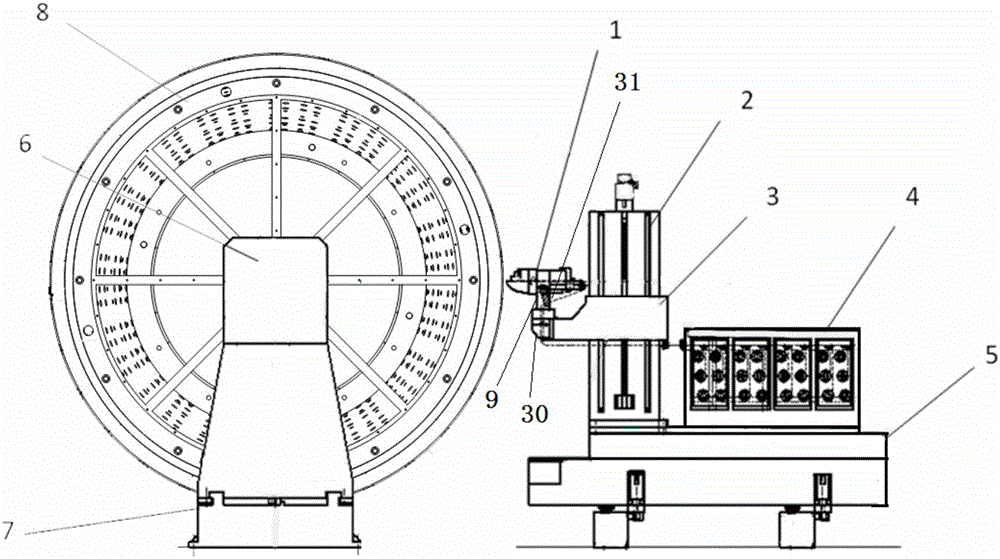

[0040] The integrated wire laying and winding forming device of the composite grid cone shell member includes a machine tool, a grid cone shell member mold, a spindle, an automatic wire laying device, a winding device, a wire laying trolley and a winding trolley; the machine bed is located on the foundation , the main shaft of the machine tool is installed on the bed; during the forming process, the grid cone shell component mold is clamped on the main shaft; the automatic wire laying device is installed on the wire laying trolley platform, and the winding device is installed on the winding trolley. Both the trolley and the winding trolley are seated on the foundation, and each can move horizontally and laterally.

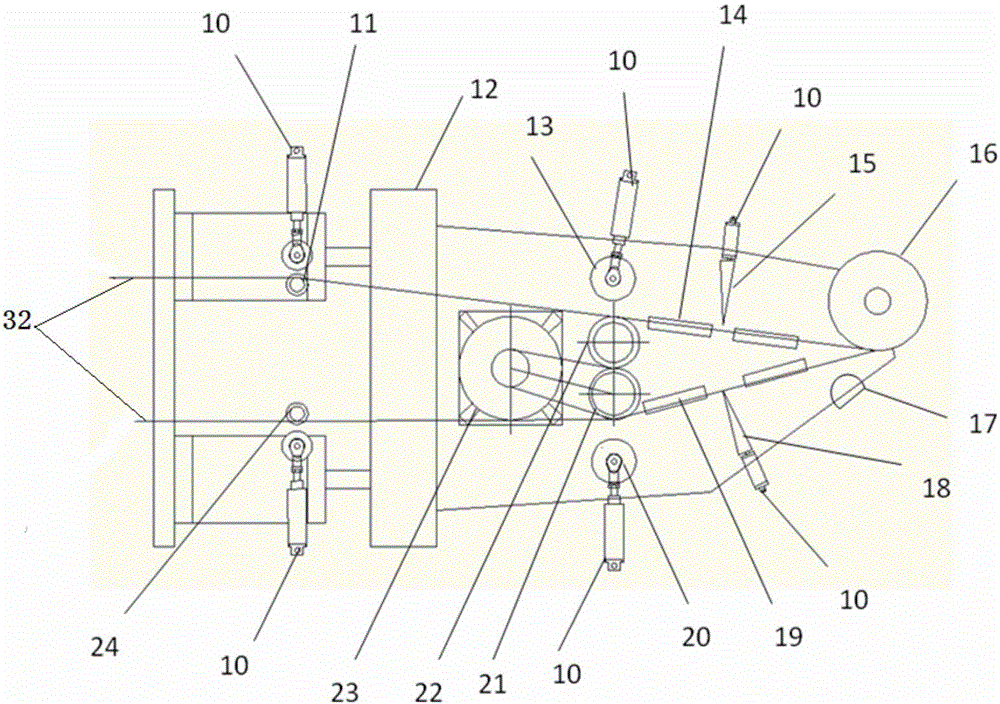

[0041] The automatic laying device includes automatic laying head, laying head rotation mechanism, laying pitching mechanism, laying head yaw mechanism, vertical mechanism, outrigger mechanism and yarn box; the vertical mechanism and yarn box are directly installed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com