Patents

Literature

32results about How to "Realize automatic molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

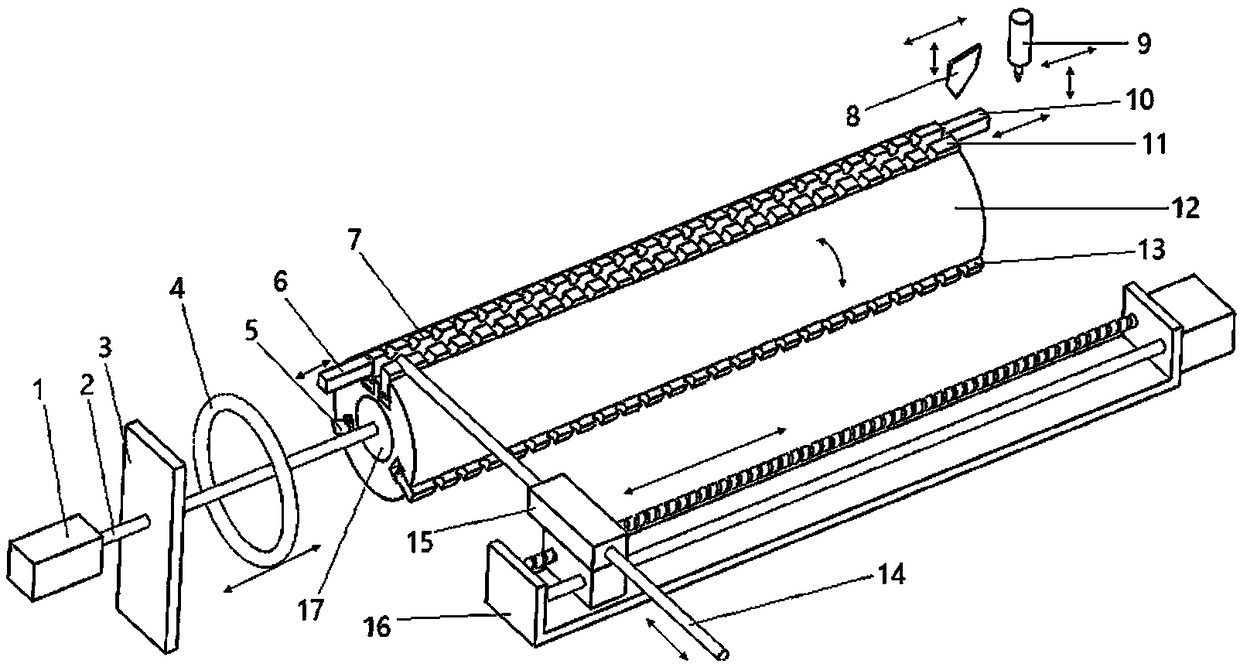

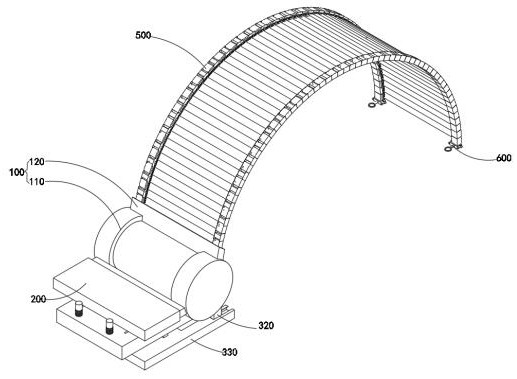

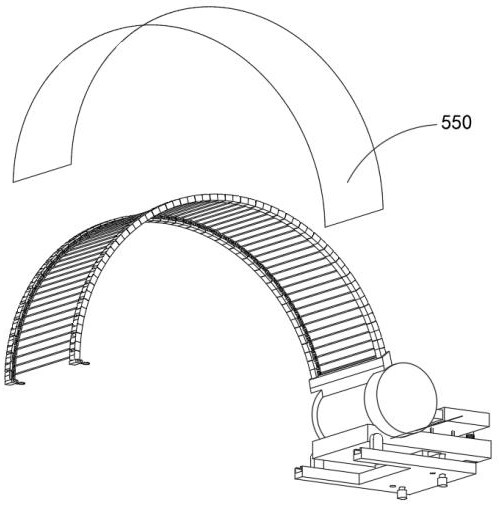

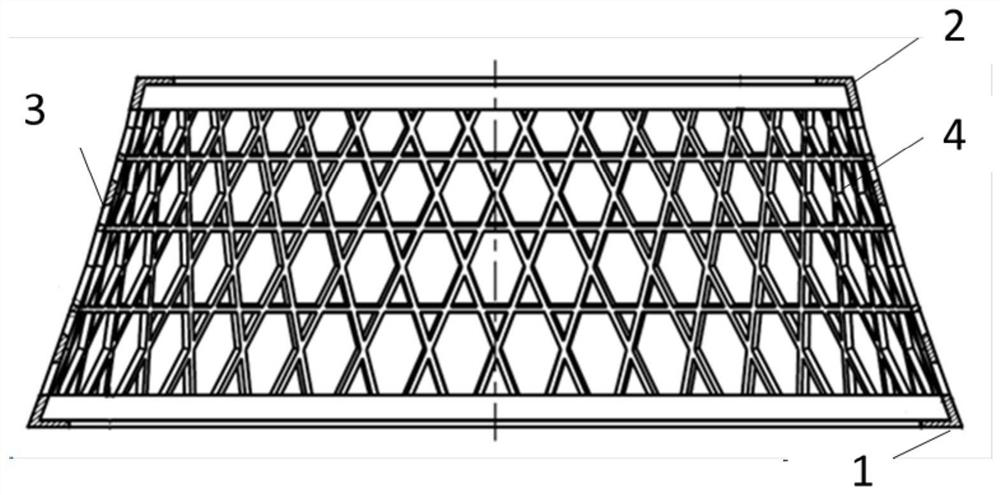

Composite material grid conical shell fiber placing and winding integrated molding device

ActiveCN105799187AImprove molding qualityImprove product qualityTemperature controlMaterials preparation

The invention discloses a composite material grid conical shell fiber placing and winding integrated molding device, and relates to the technical field of composite material preparation. The device comprises a grid conical shell component mold, a winding device, a winding trolley, a fiber placing device and a fiber placing trolley. The integrated molding device not only can be used for finishing the winding of grid ribs, but also can be used for finishing the fiber placement molding of stressed-skin constructions, and has a tow resin temperature control ability to realize control over the prepreg tow viscosity in the transmission process; a heating system is configured in a placing head to enable prepreg tows to be heated, so that the prepreg tows have a certain viscosity and then the process requirements are satisfied. The device disclosed in the invention can be applied to composite material grid conical shell components, and is good in molding quality, high in placing precision, good in product quality and high in manufacture efficiency; an automatic fiber placing system and a grid rib winding system are integrated in a set of equipment, so that the high-efficiency and high-quality composite integrated molding of the composite material grid conical shell components is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

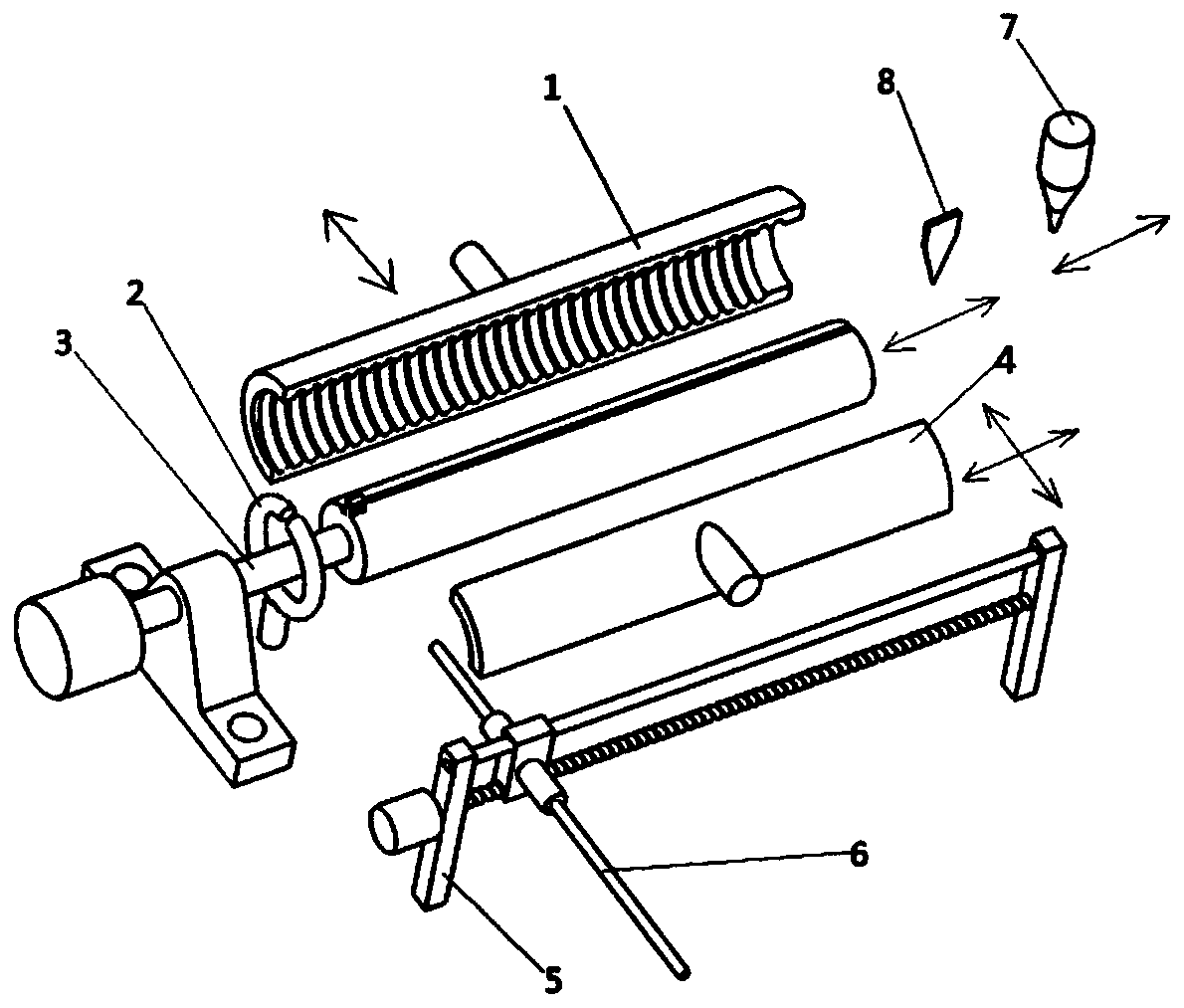

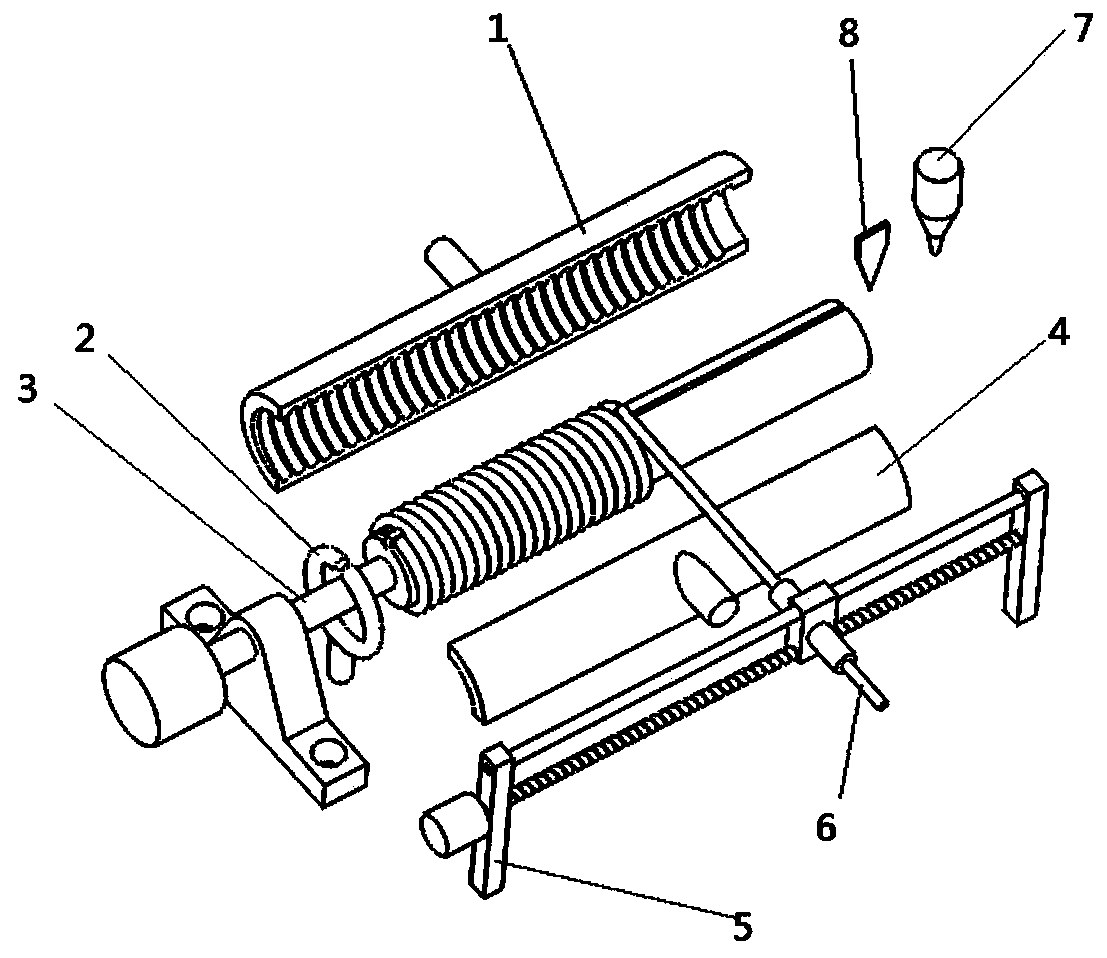

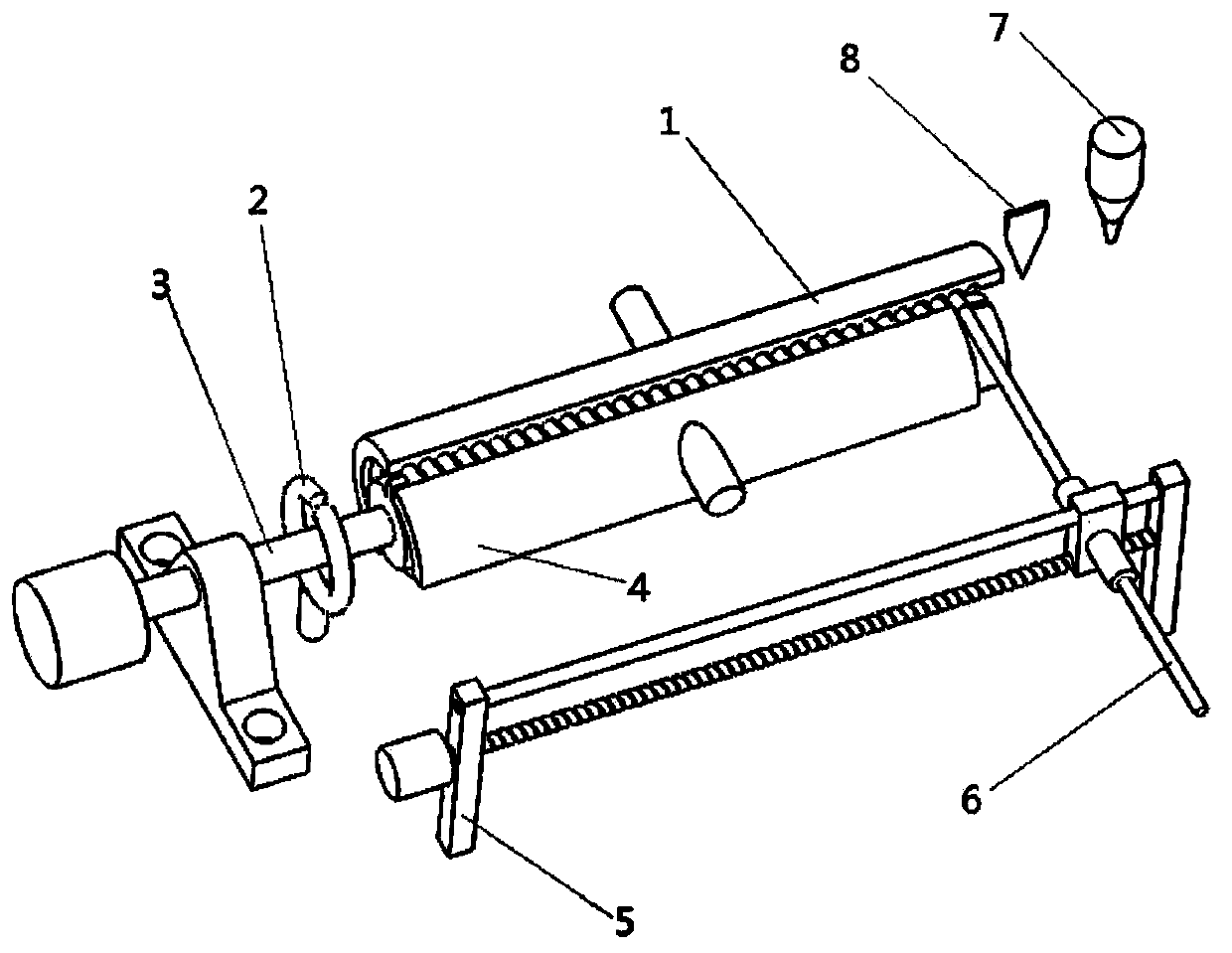

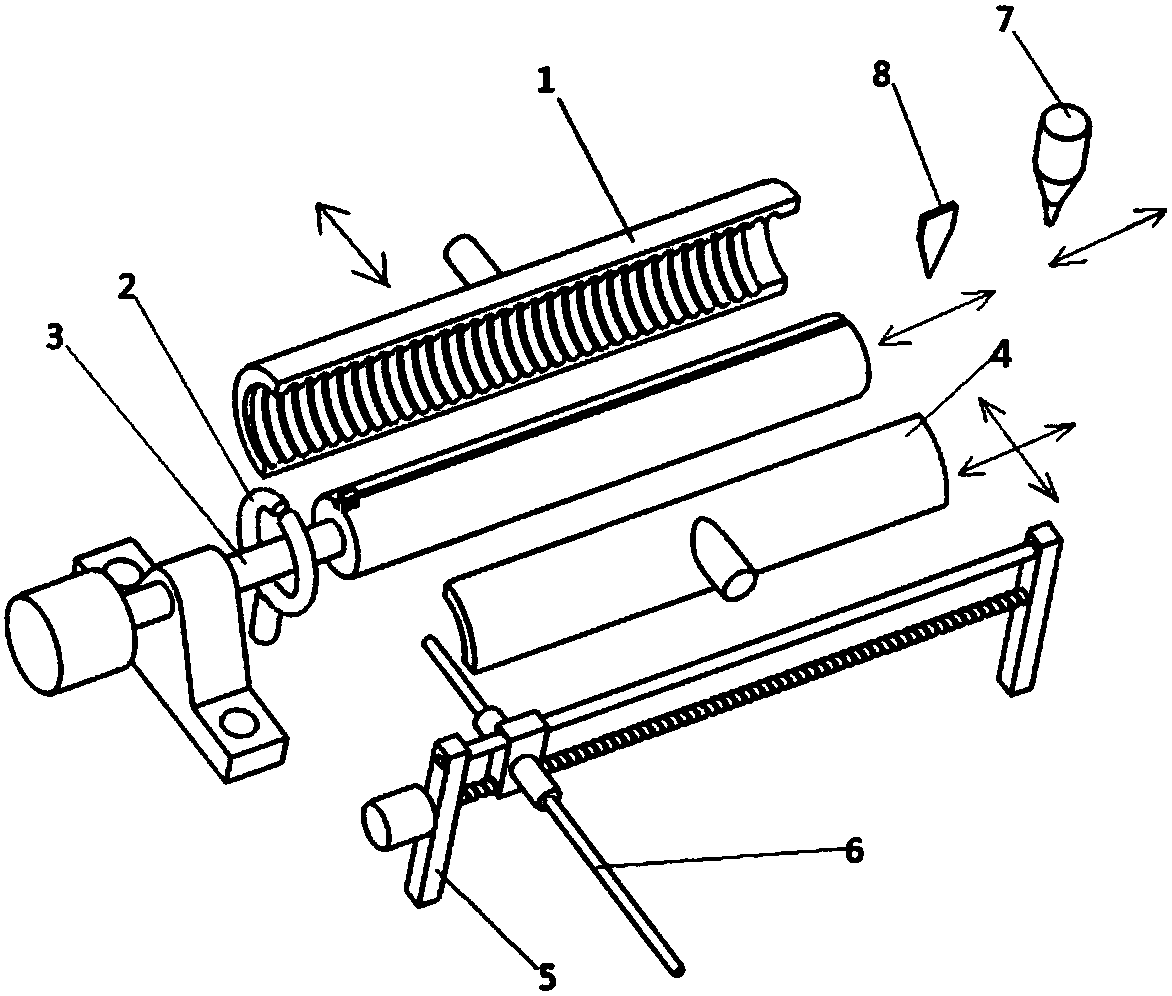

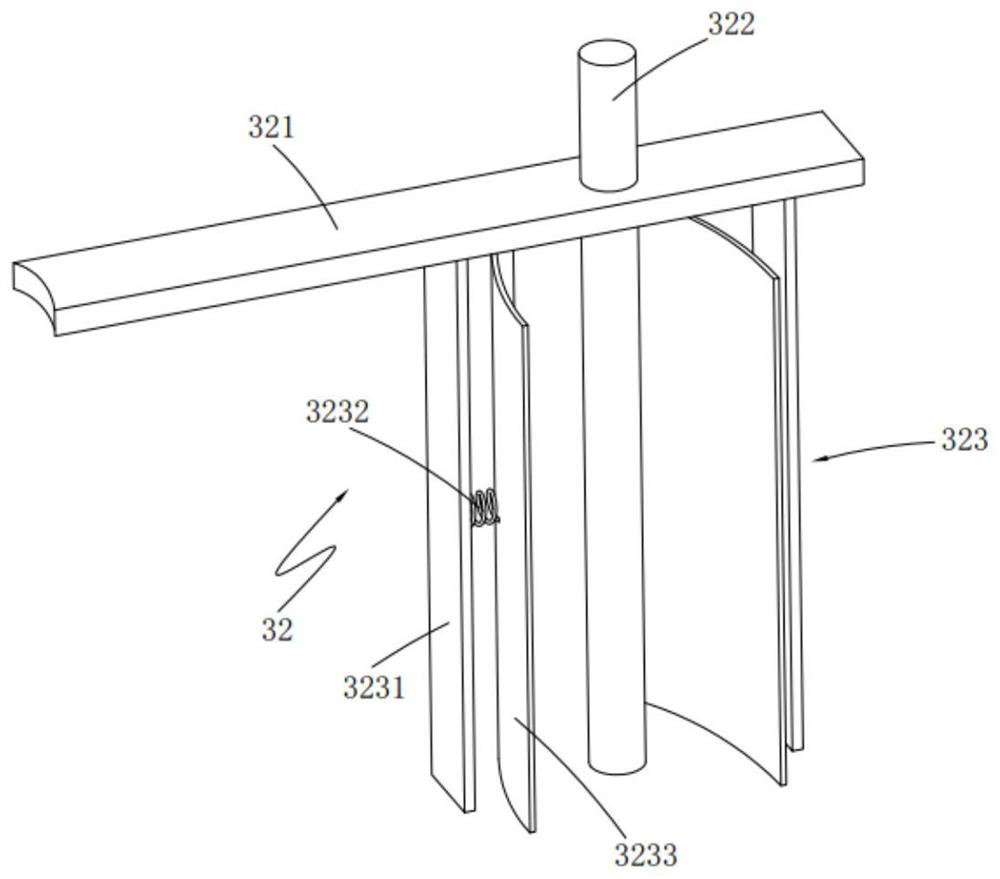

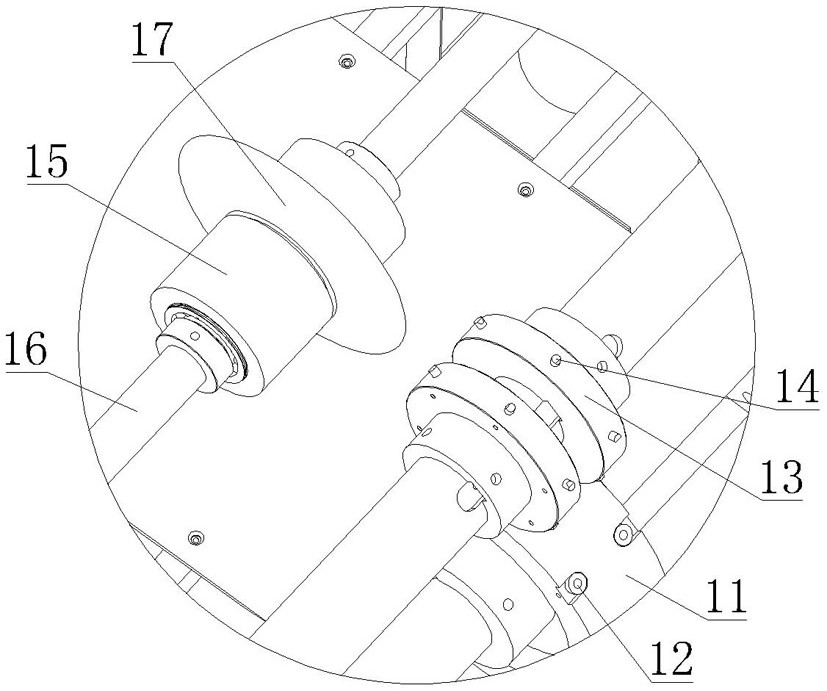

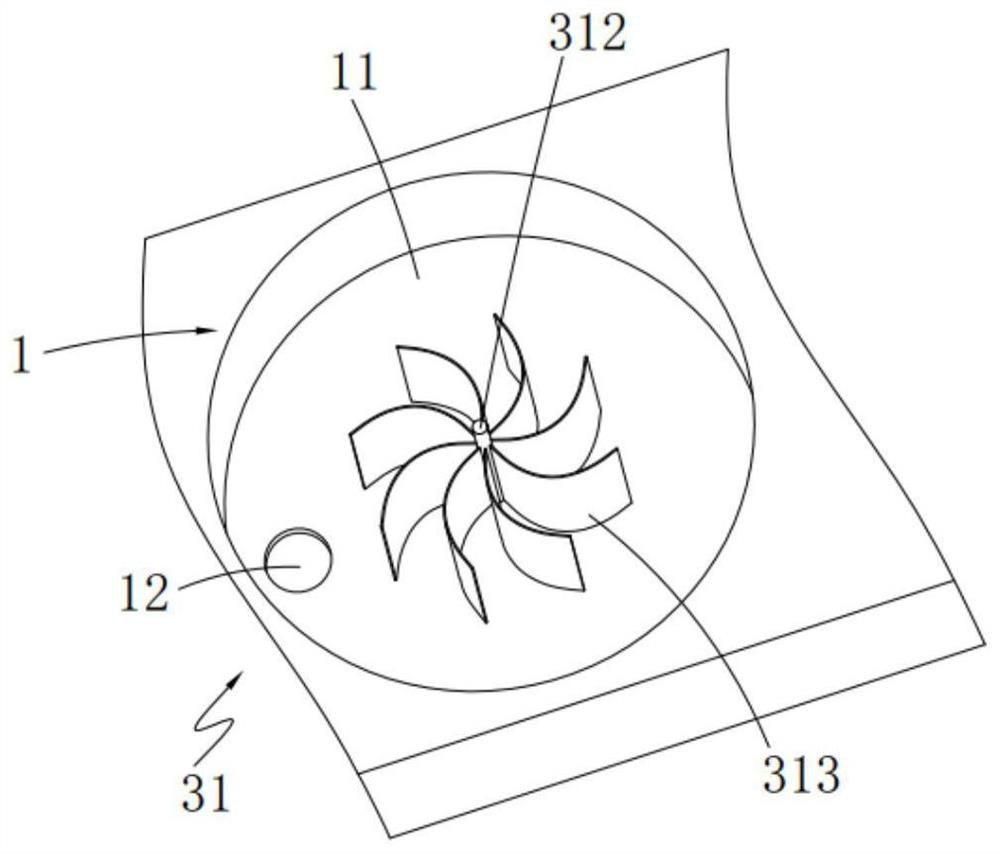

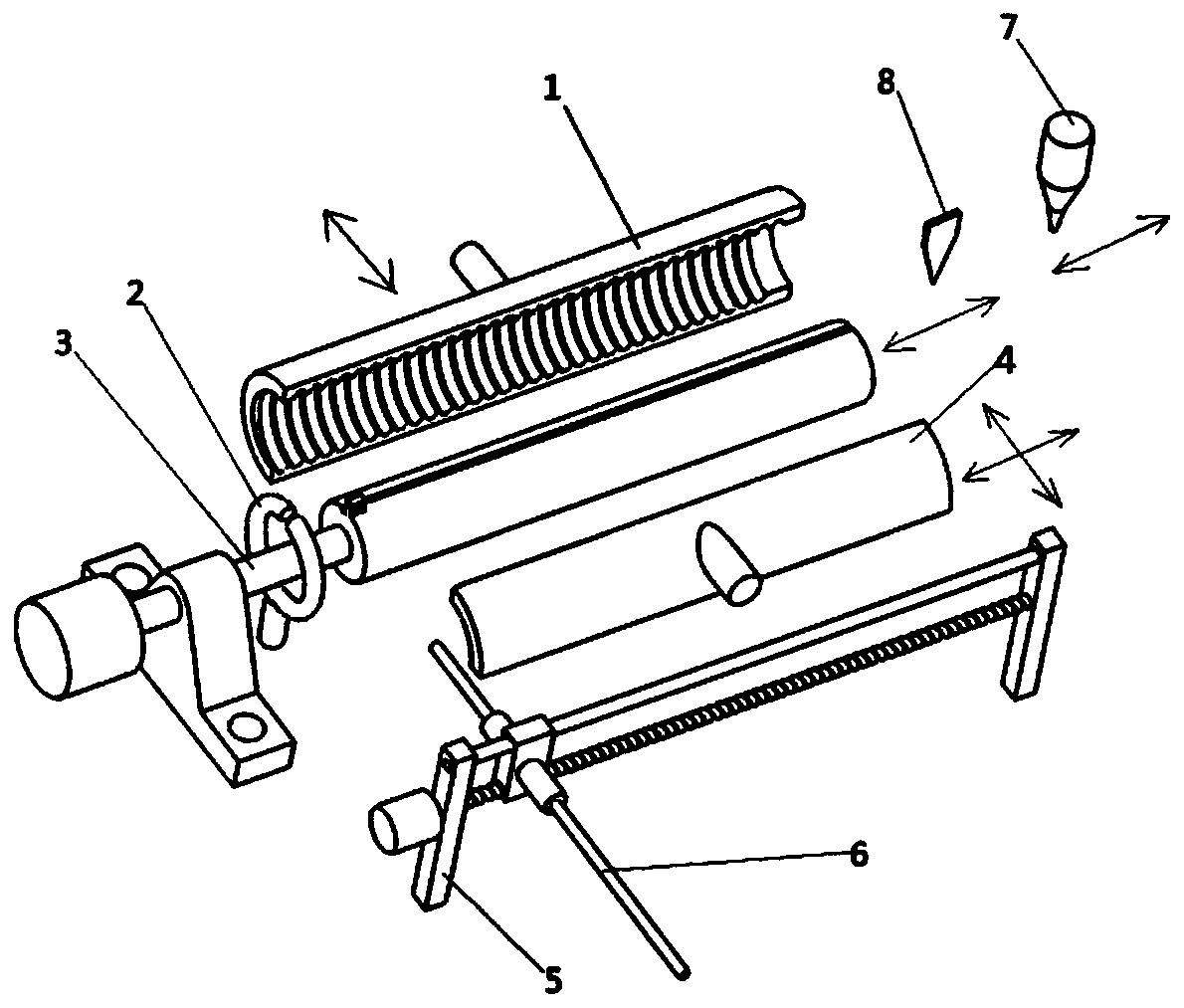

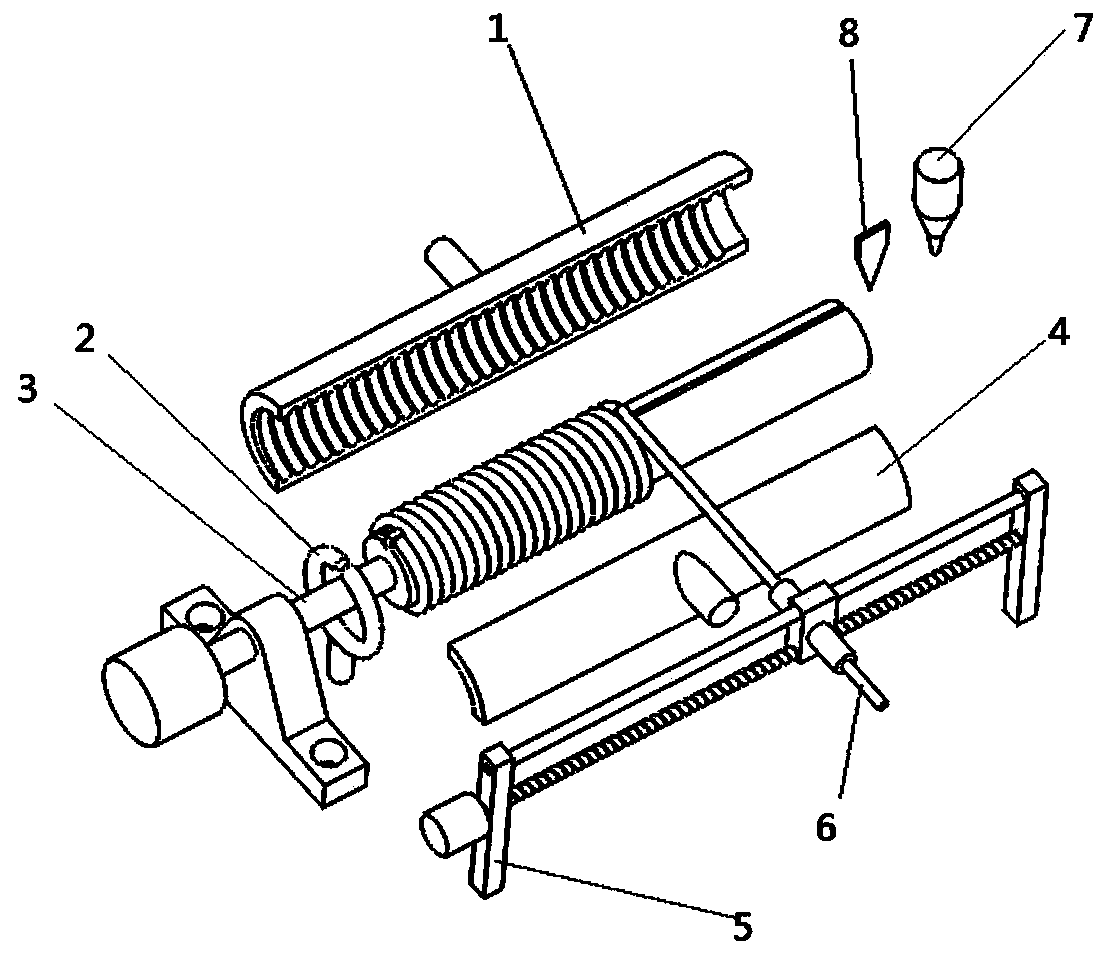

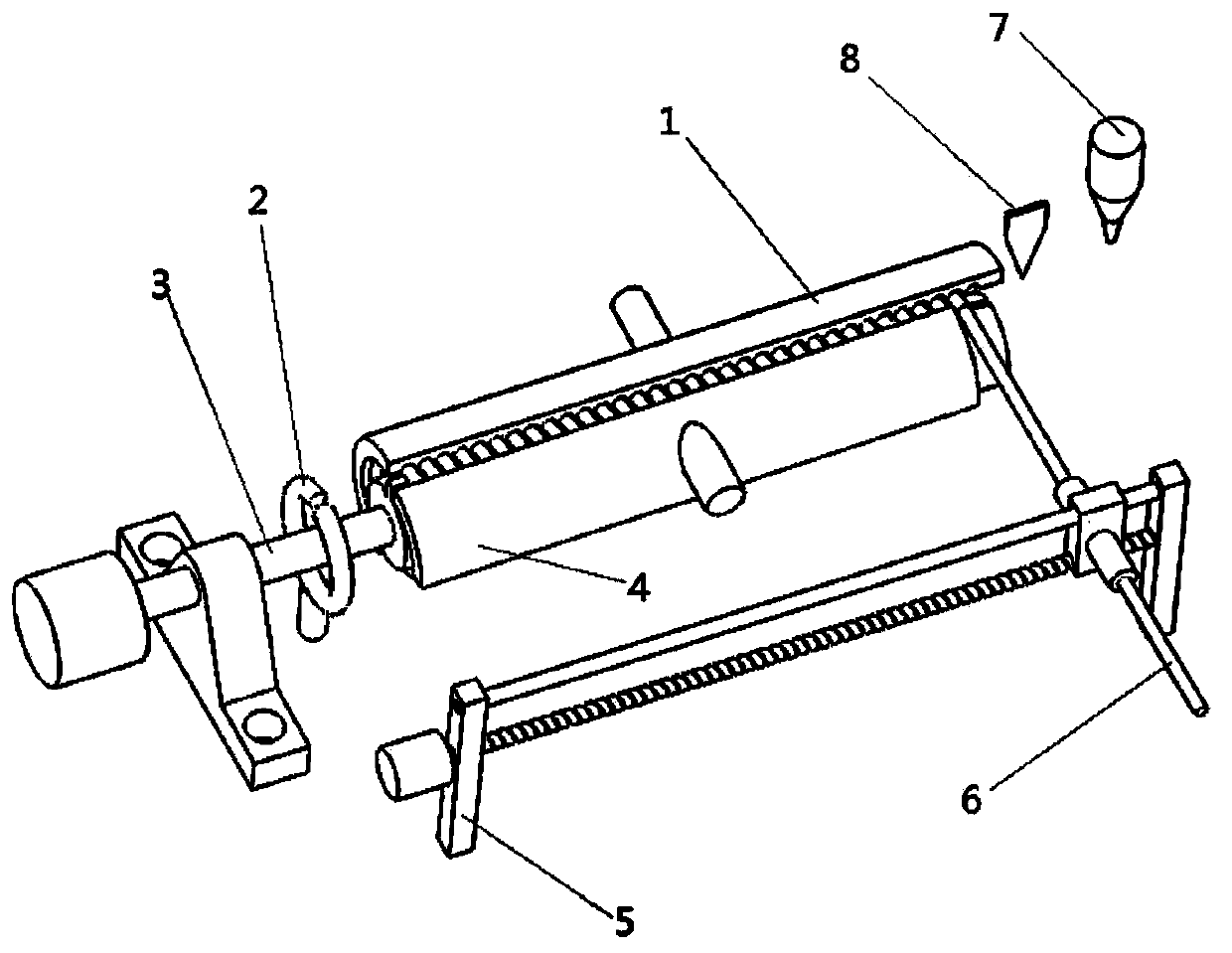

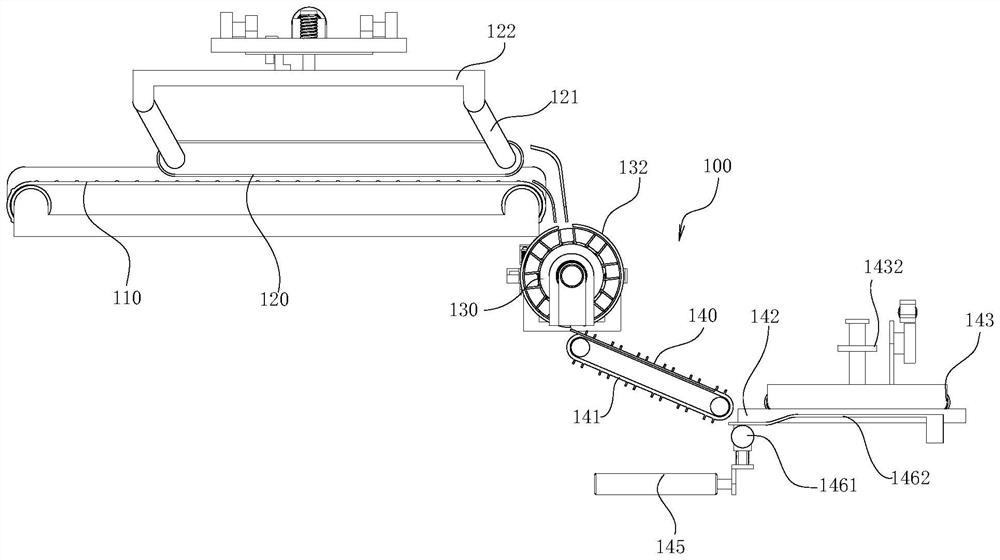

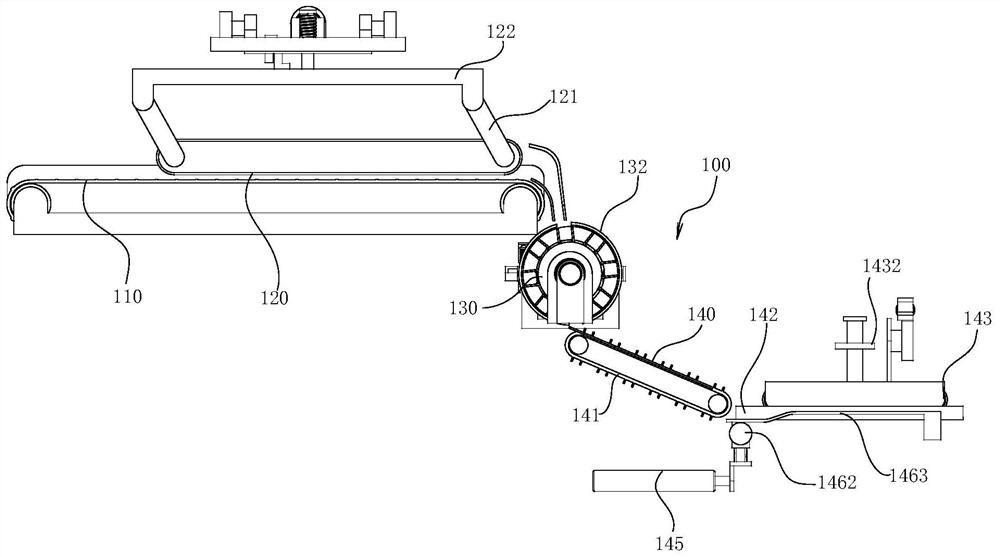

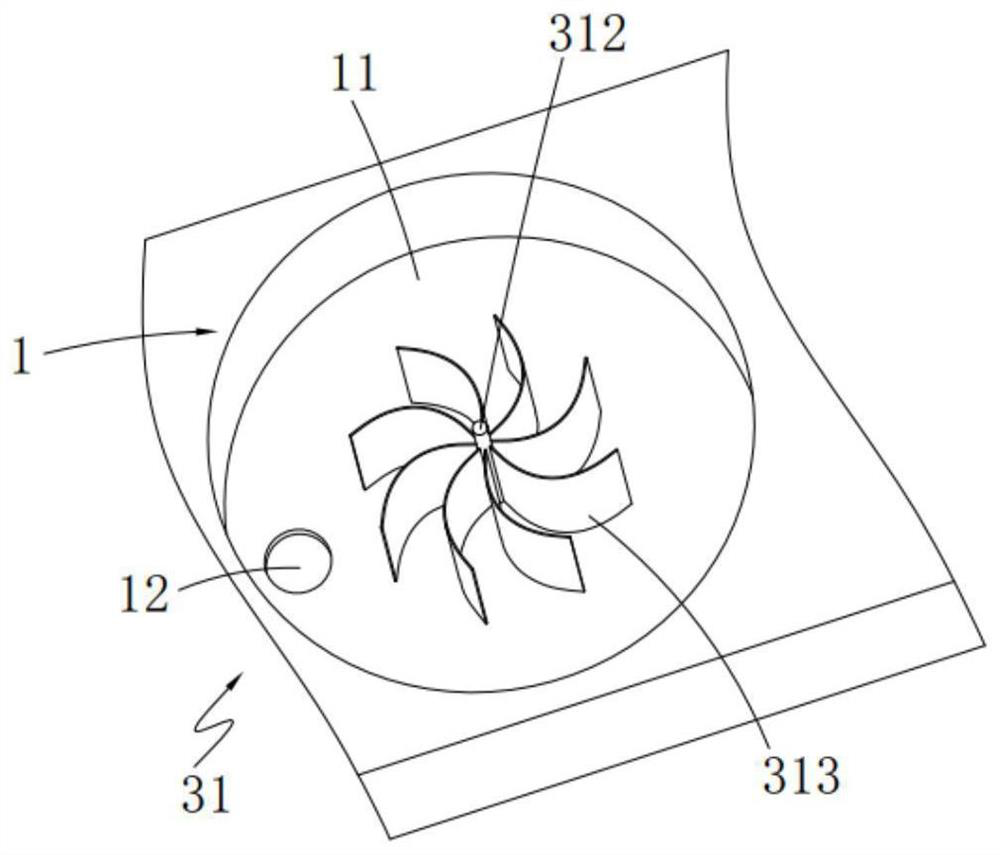

Rubber hair ring automatic forming machine

InactiveCN108162427BRealize automatic moldingIncrease productivityDomestic articlesRubber ringMechanical engineering

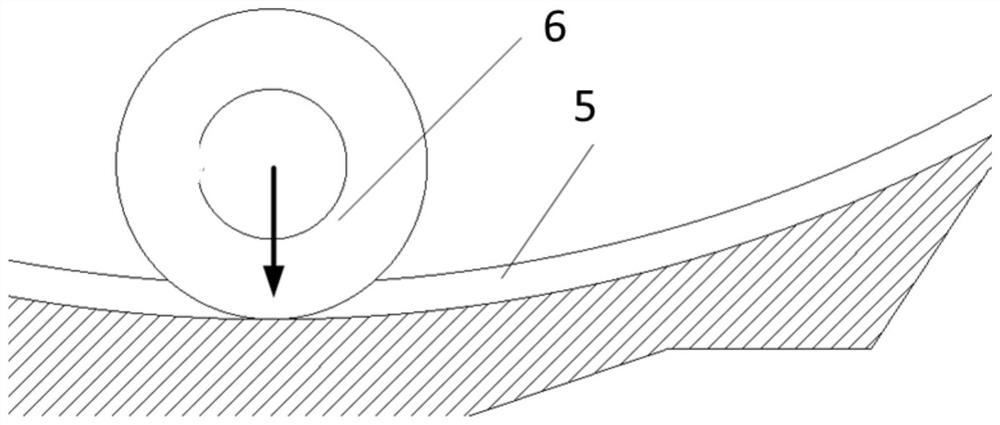

The invention discloses an automatic rubber hair ring forming machine. The automatic rubber hair ring forming machine comprises a wire winding mechanism (5), a forming shaft (3), a cutting mechanism (8), a staggering mechanism and a dispensing mechanism (7). A rubber wire (6) is wound around the forming shaft 3 through the wire winding mechanism (5) and is spirally arranged on the forming shaft (3). The rubber wire (6) is wound around the forming shaft (3) through rotation. The cutting mechanism (8) cuts the spiral rubber wire (6) wound into the spiral shape in the axial direction. Through thestaggering mechanism, the cut rubber wire is staggered at the breaking position of each circle, the staggered rubber wire is in linkage in an end-to-end manner, and a plurality of rubber rings are formed. Through the dispensing mechanism (7), dispensing operation is conducted at the connector positions of the rubber rings, and head-tail fixed connection of the rubber rings is achieved. By means of the automatic rubber hair ring forming machine, automatic rubber hair ring forming can be achieved, the production efficiency is high, and the product quality and consistency are improved.

Owner:CHINA JILIANG UNIV

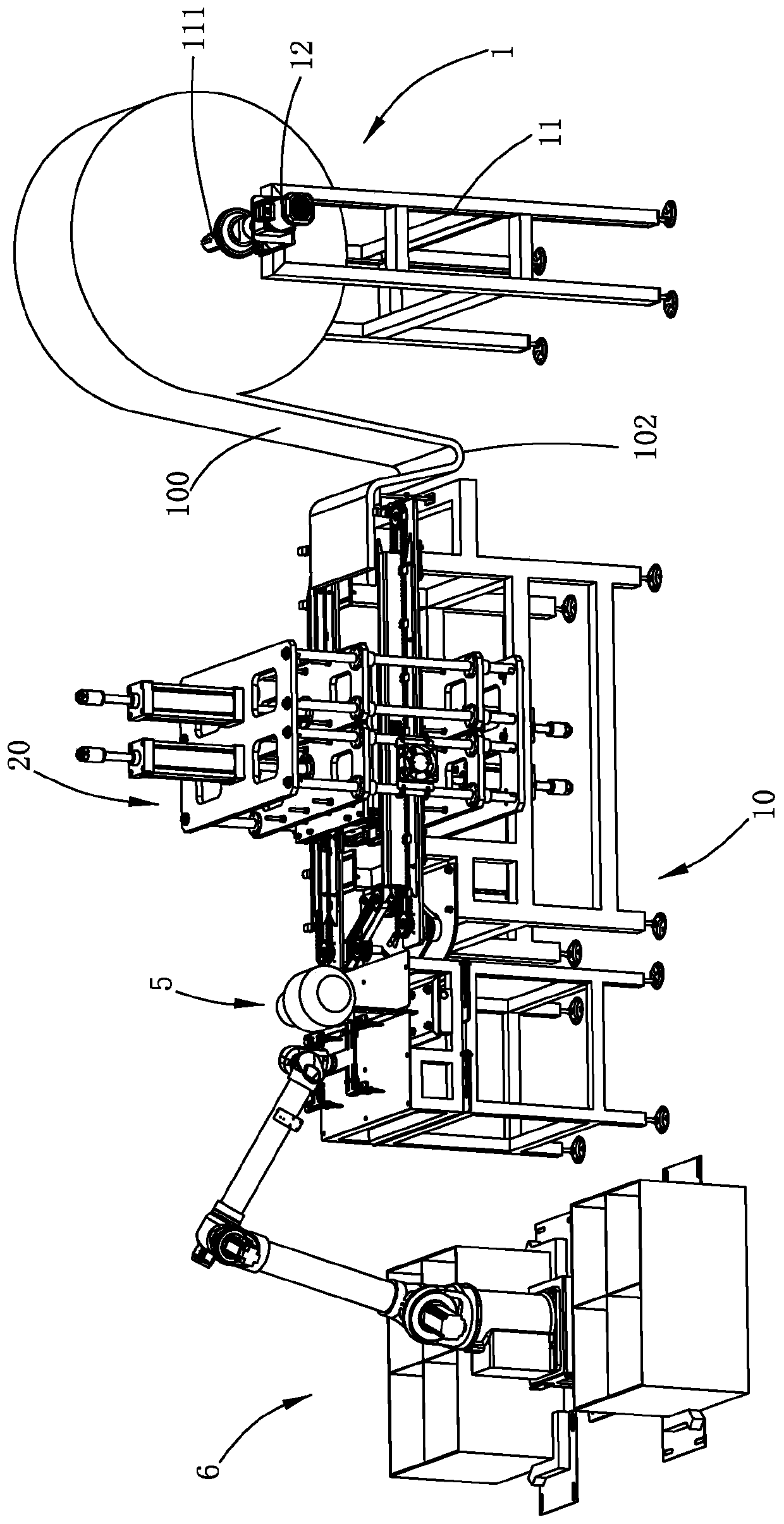

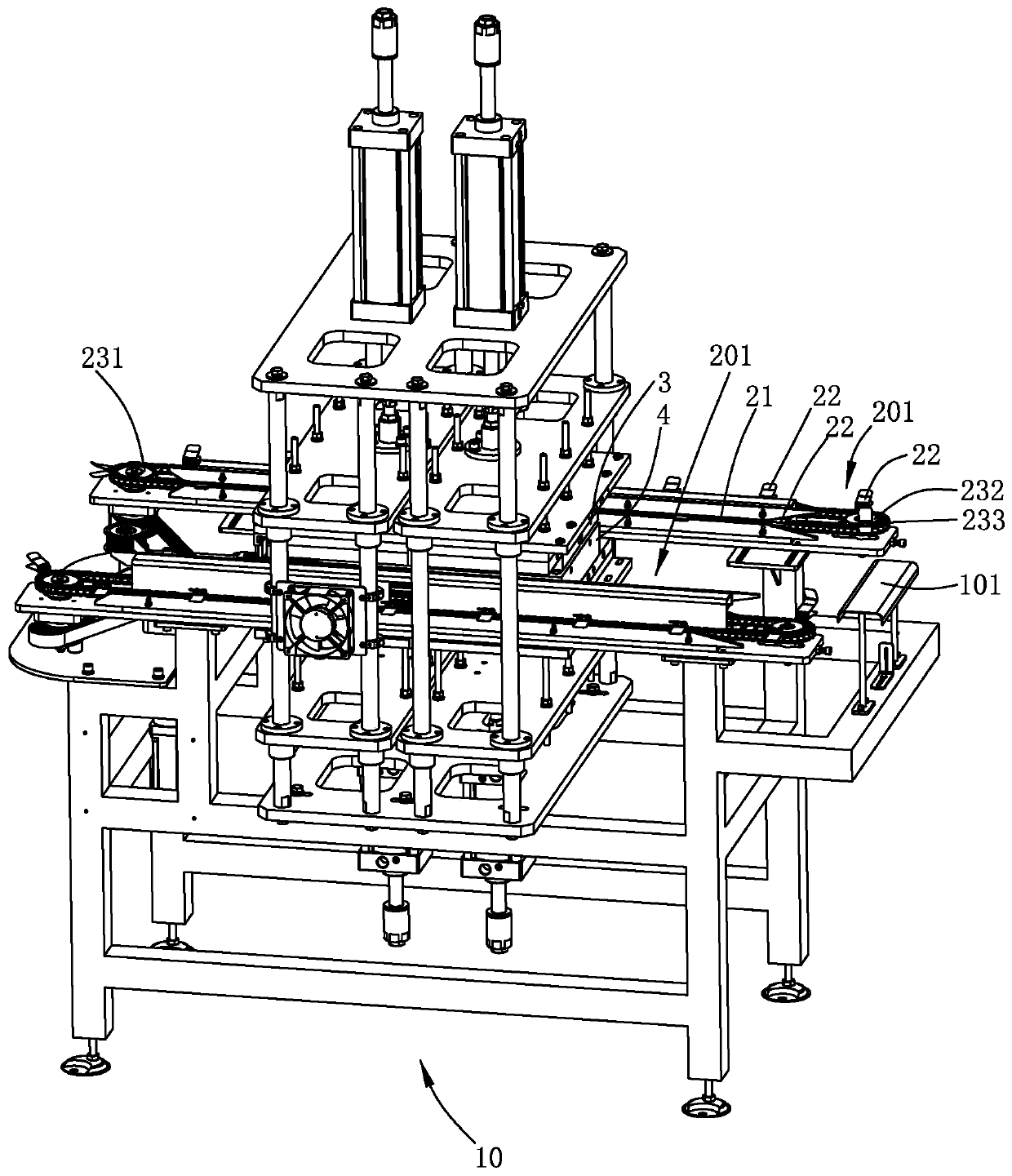

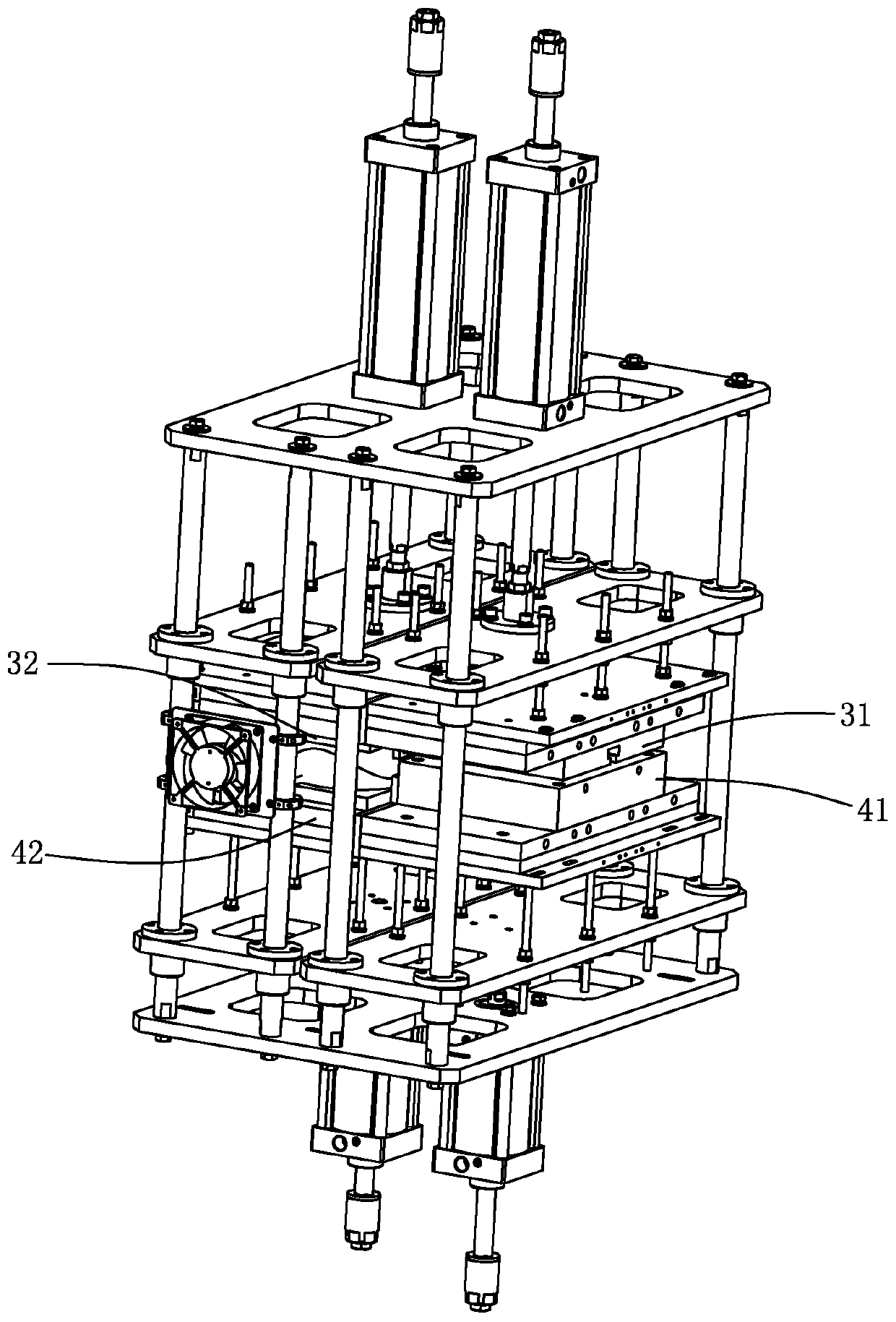

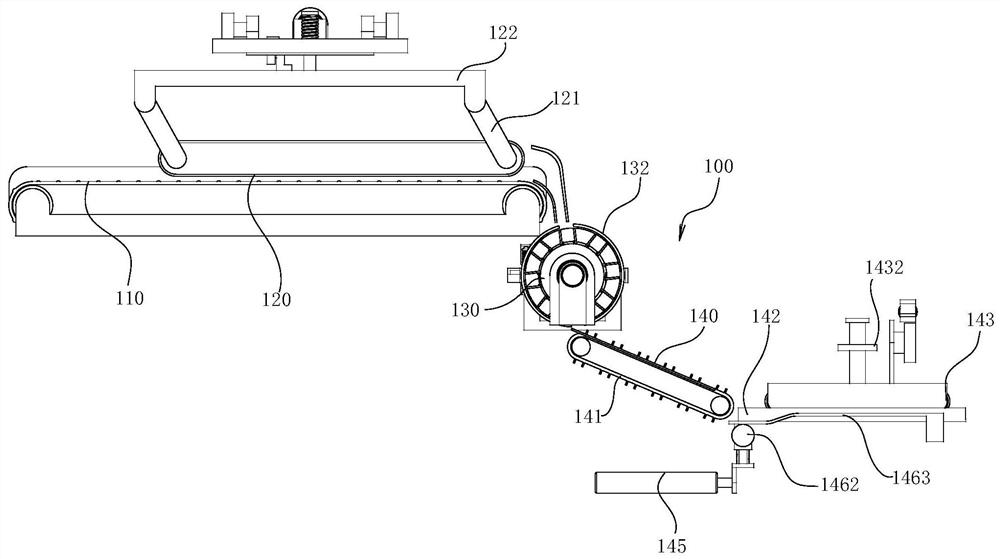

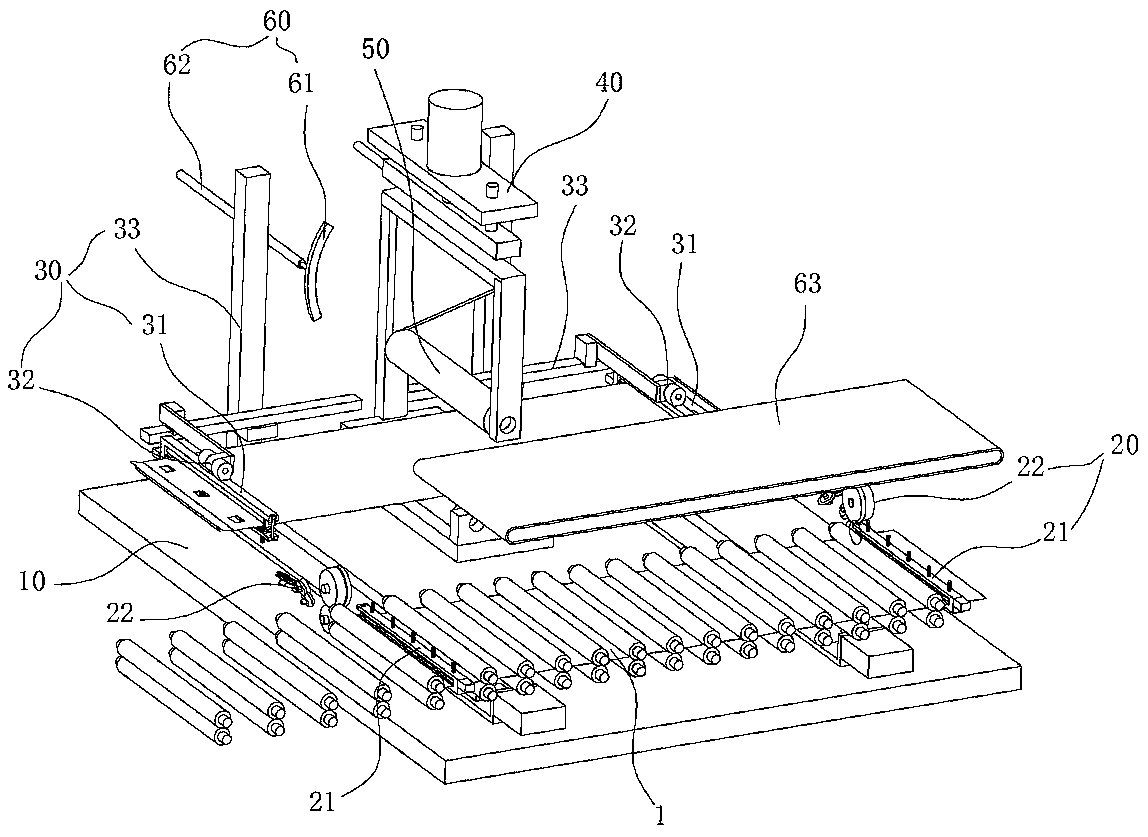

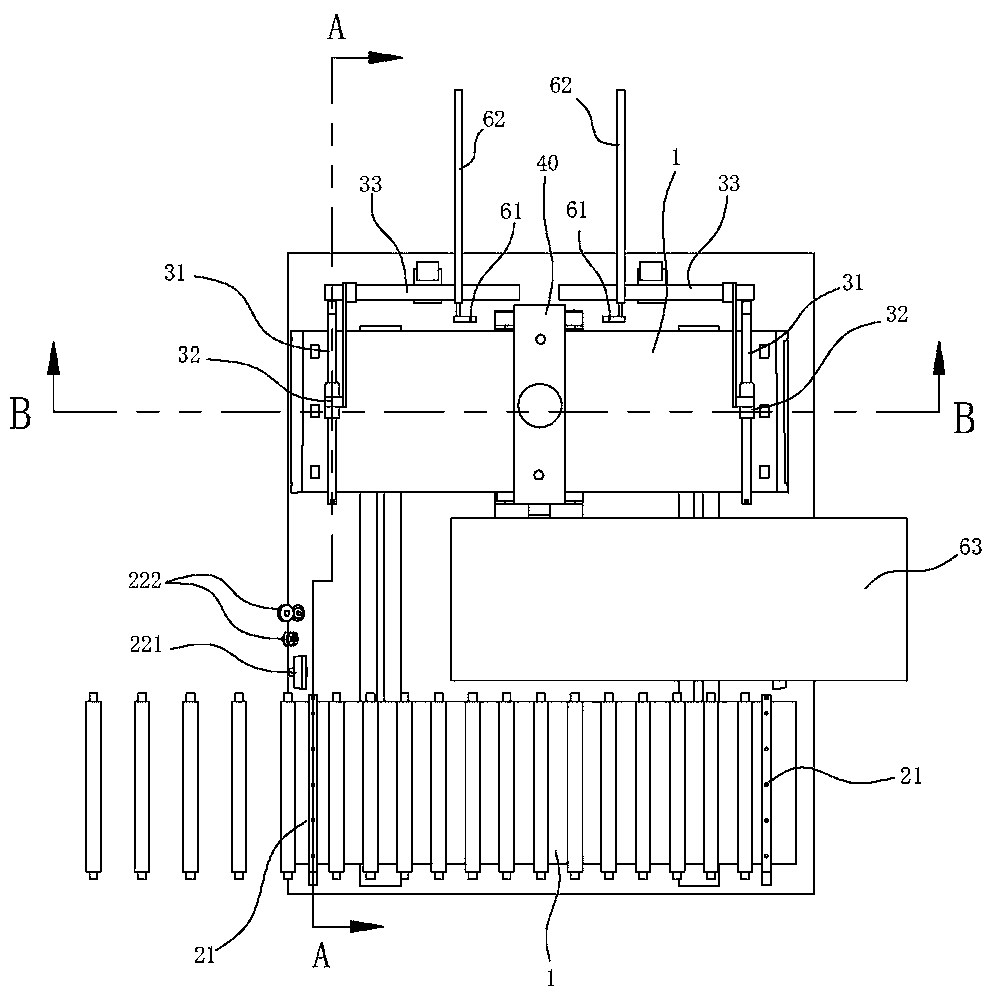

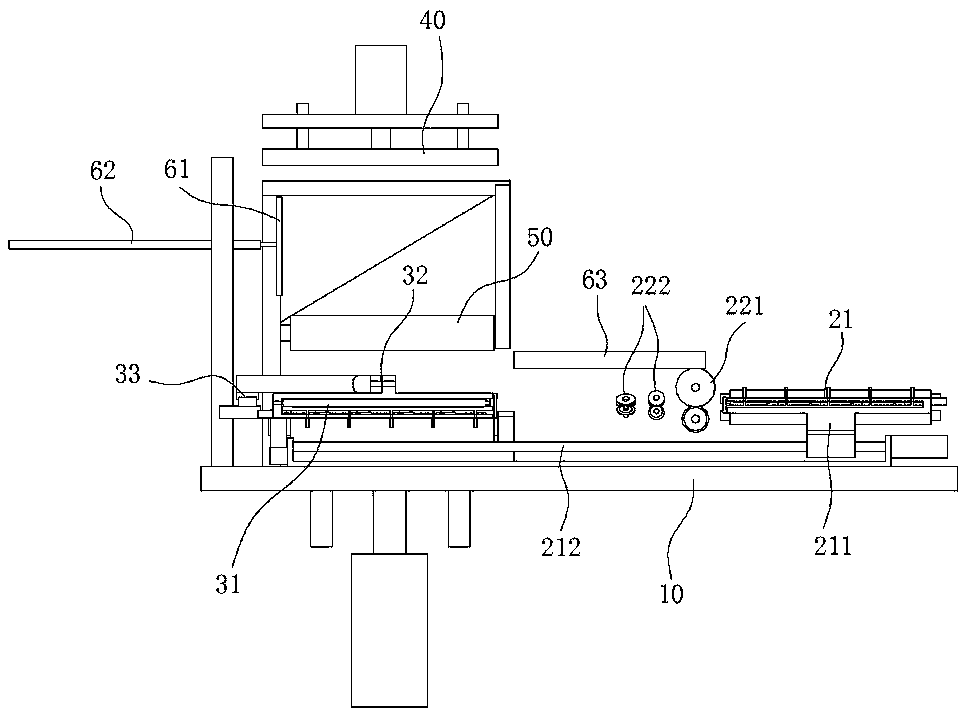

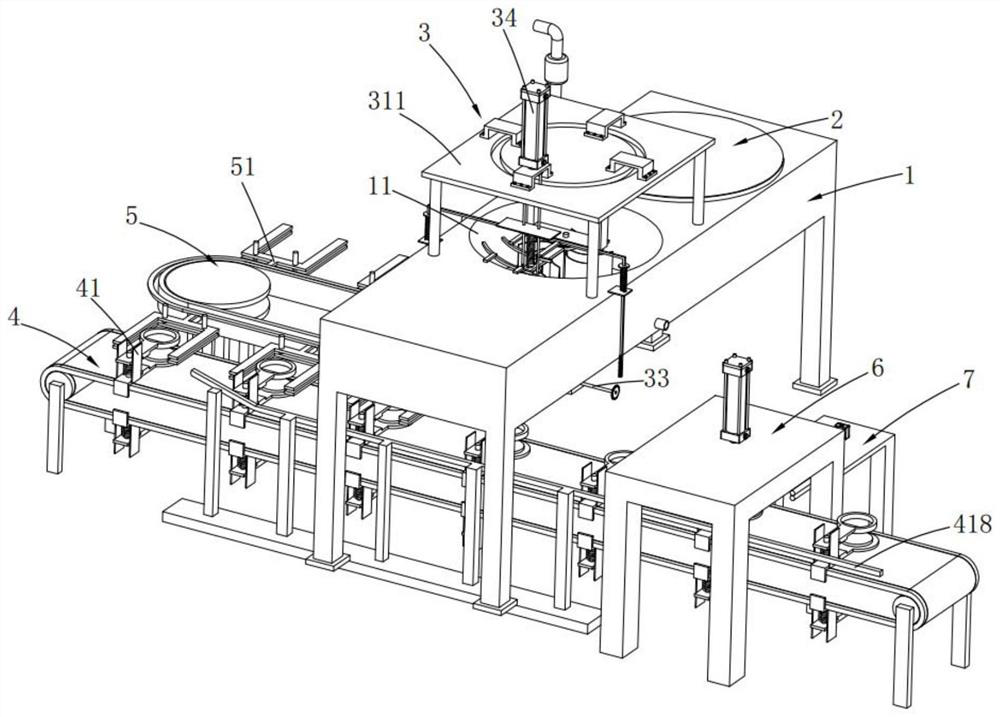

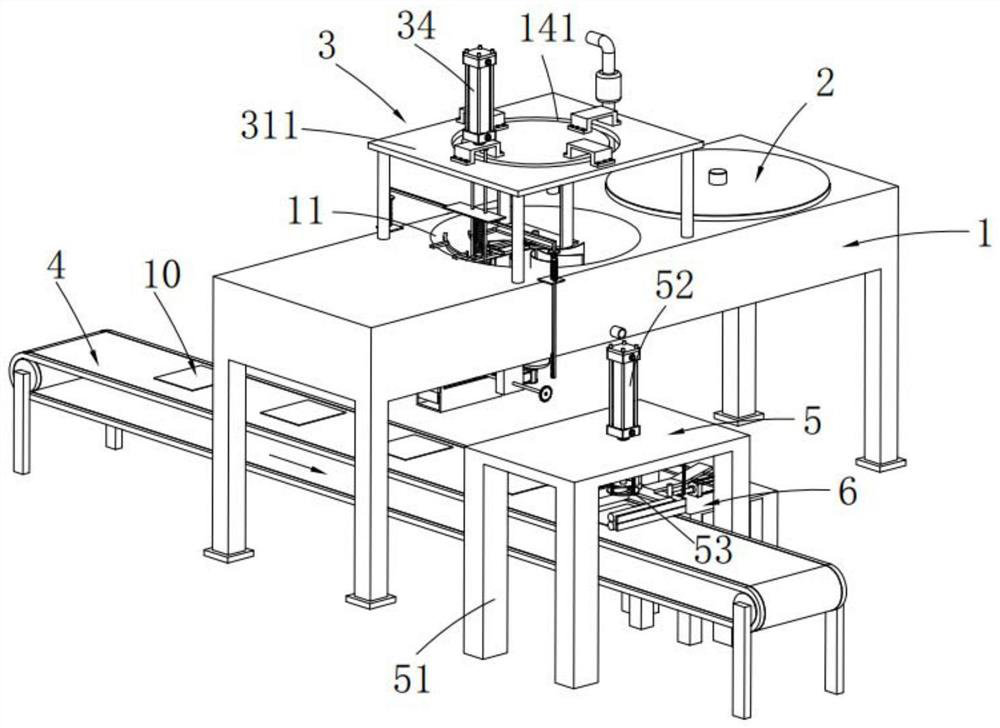

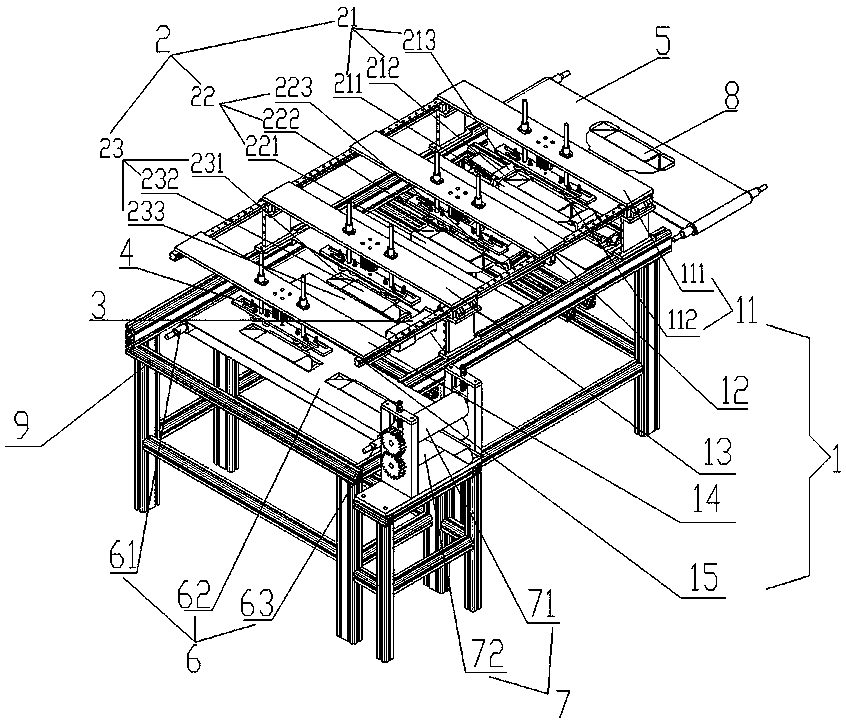

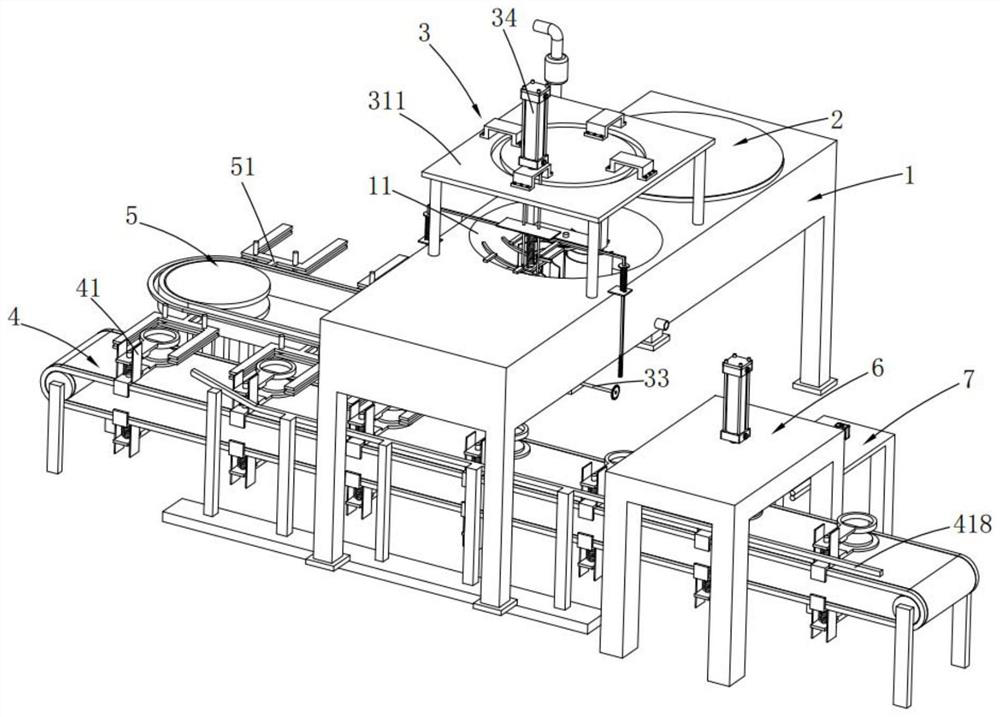

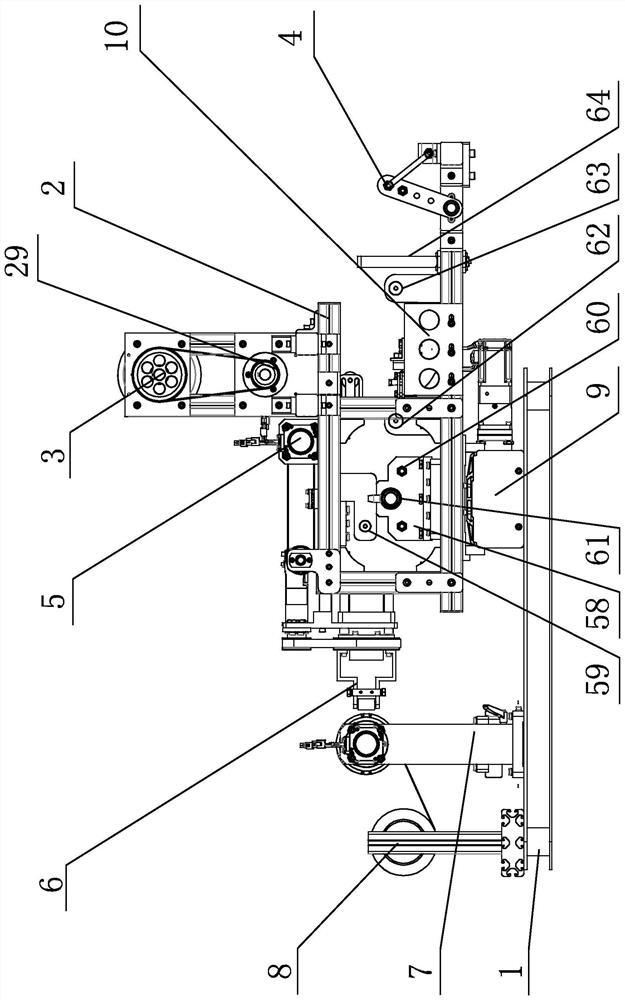

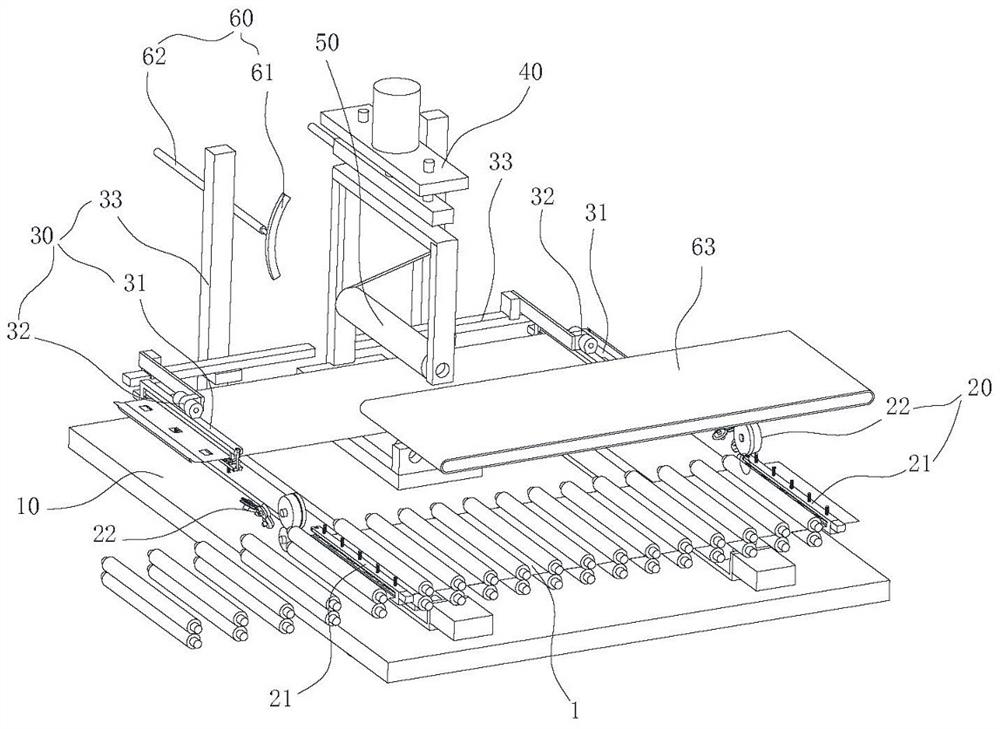

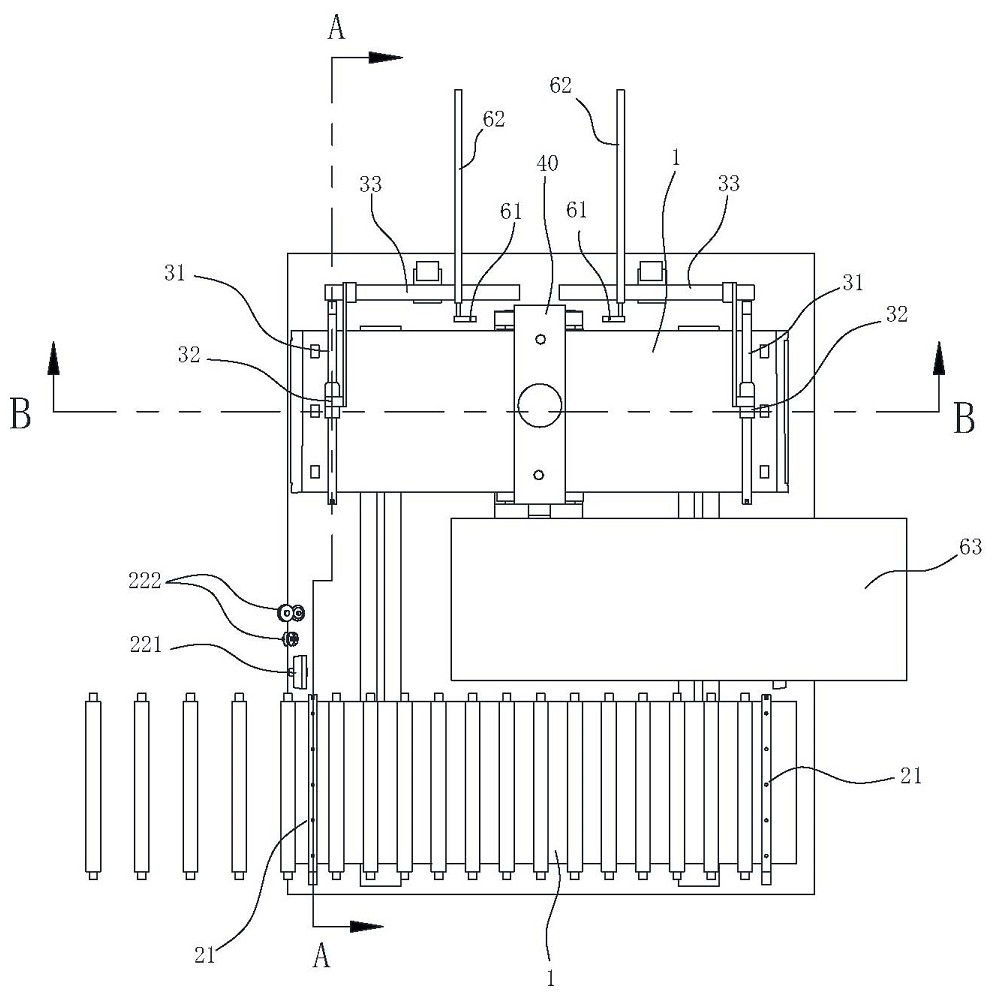

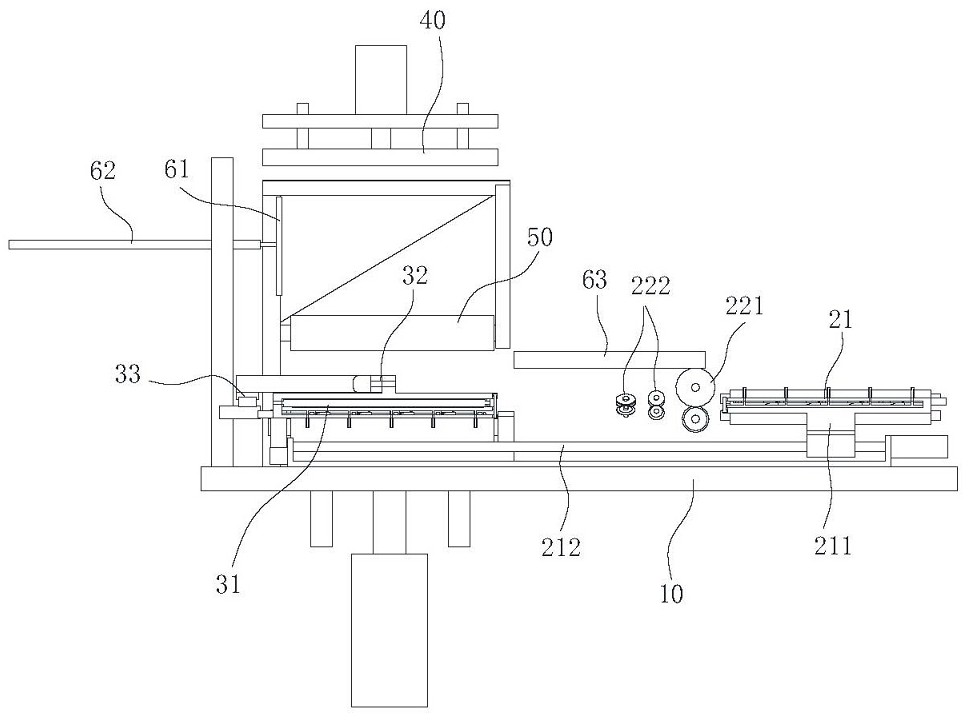

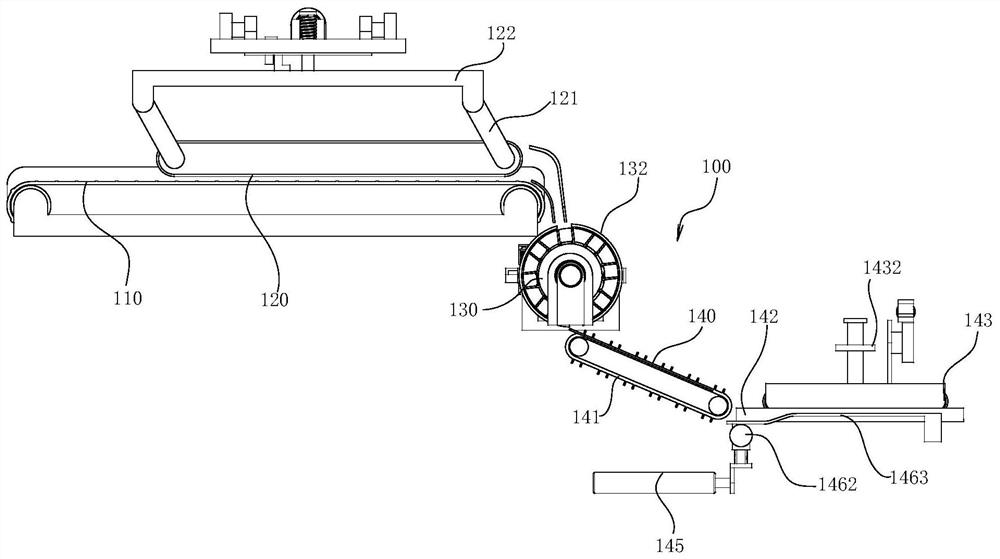

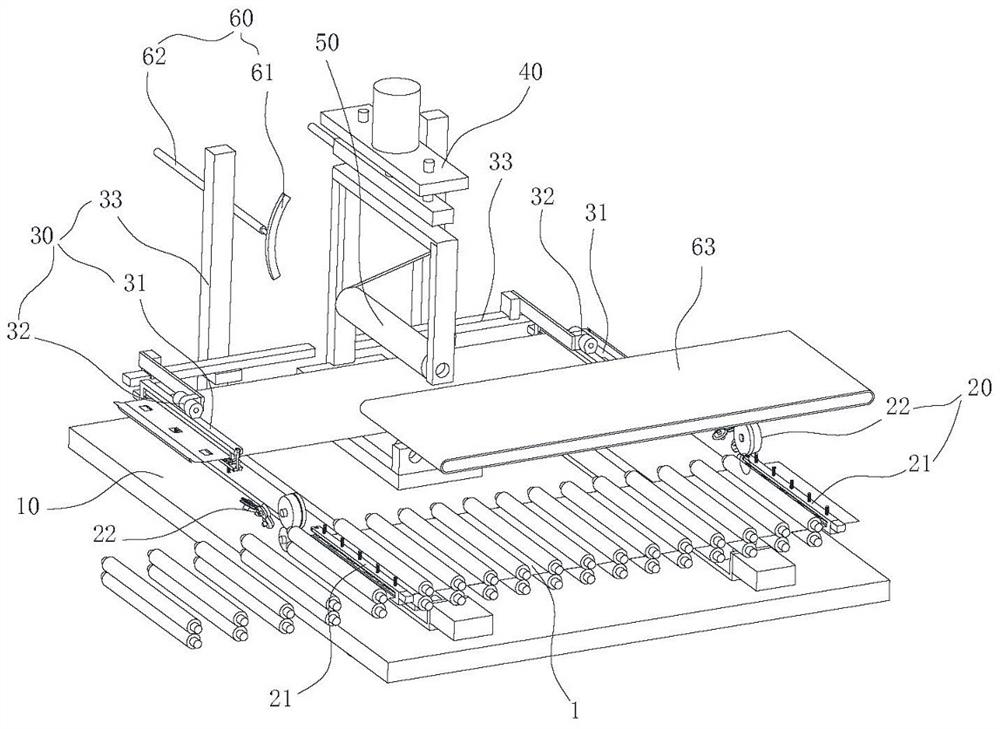

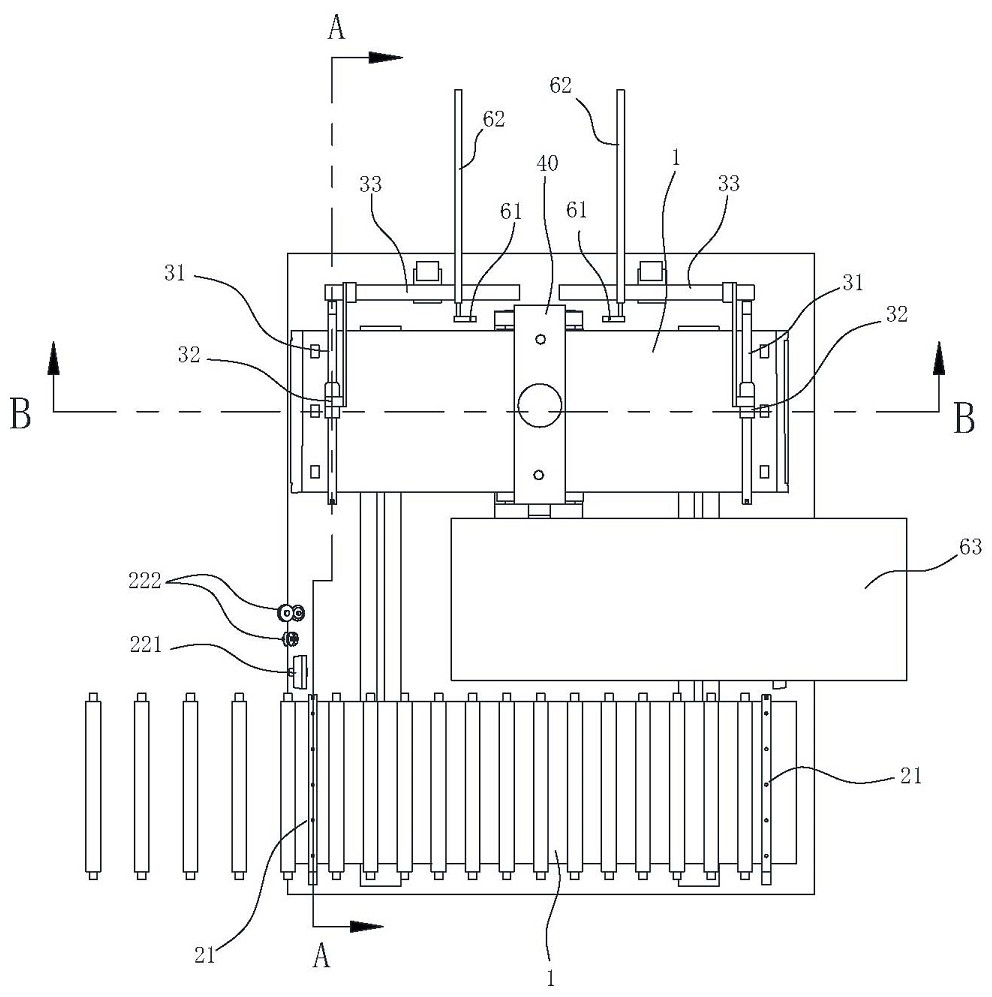

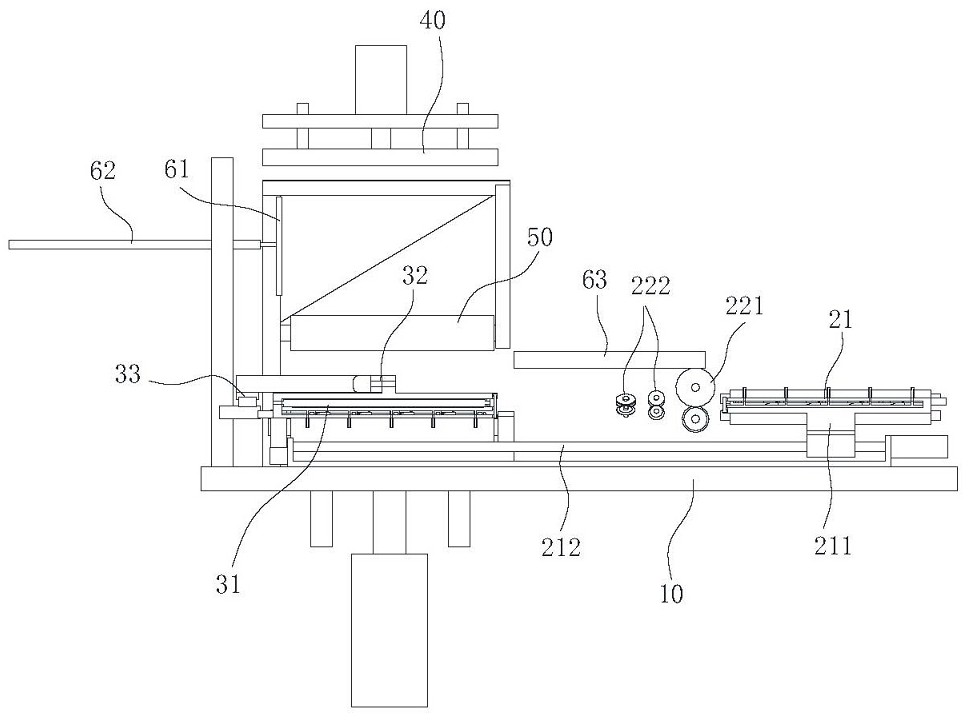

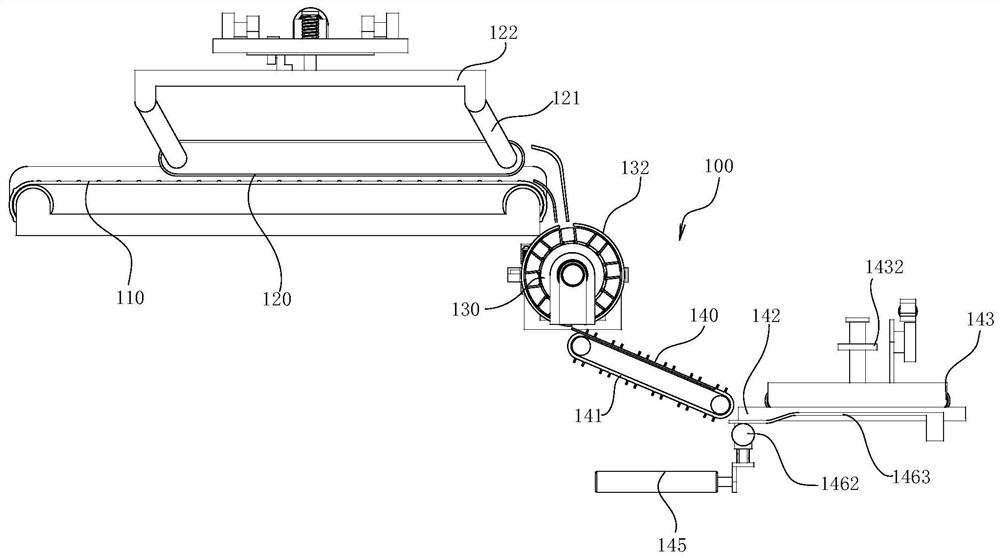

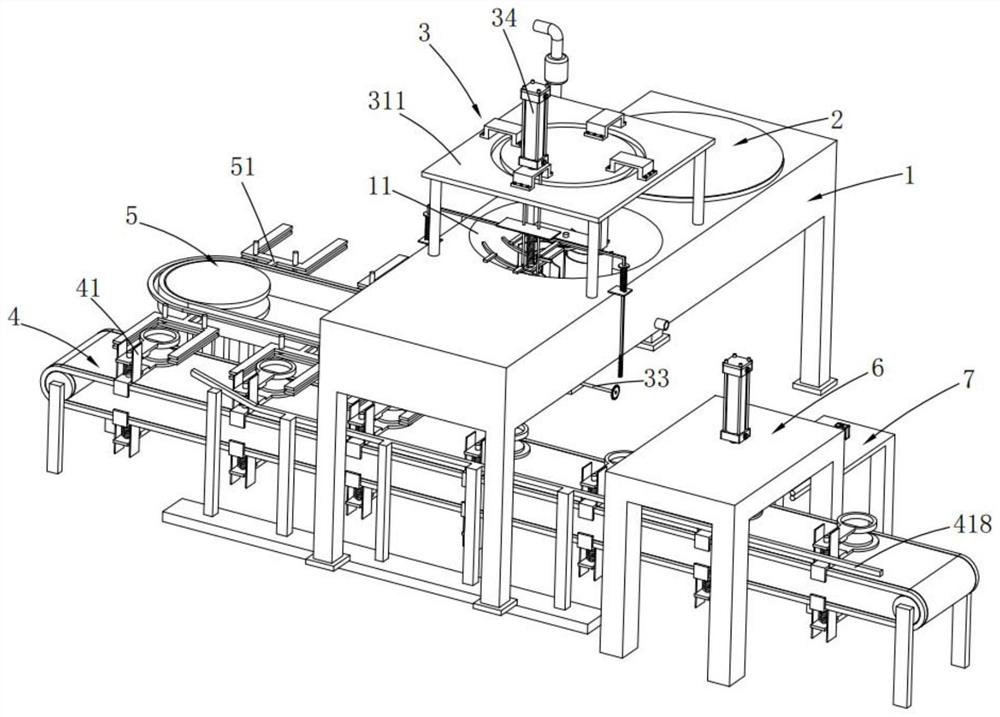

Bra cup automatic molding production line

PendingCN110250601ARealize automatic moldingReduce labor intensityBrassieresCorsetsProduction lineEngineering

The invention relates to the technical field of bra cup production, and in particular to a bracup automatic molding production line which includes a machine frame. The machine frame is provided with a molding device, and the molding device comprises anupper molding mold and a lower molding mold which are arranged up and down and can realize pressing molding;themachine frame is further provided with a blank conveying mechanism for conveying roll materials to pass through the position between the upper molding mold and the lower molding mold, whereina hot pressing portion and a cold pressing portion aresequentially formed between the upper molding mold and the lower molding mold in the conveying direction of the blank conveying mechanism; an automatic unwinding mechanism for unwinding the roll materials to enable theroll materials to enter the inlet end of the blank conveying mechanism is arranged onthe rear side of the machine frame; and a cutting mechanism for cutting the molded parts of the roll materials is arranged on the front side of the machine frame. According to thebra cup automatic molding production line, through the mutual cooperation of the automatic unwinding mechanism, the blank conveying mechanism and the cutting mechanism, automatic molding of bra cups isrealized, the labor intensity is greatly reduced, and the production efficiency isimproved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

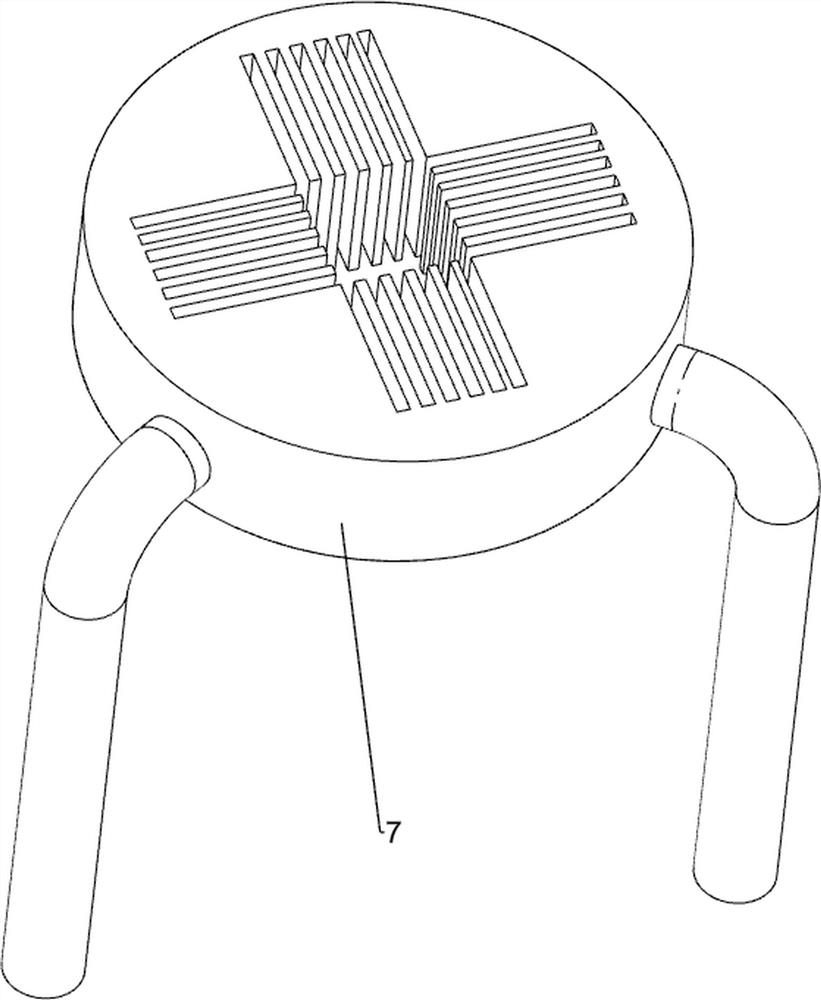

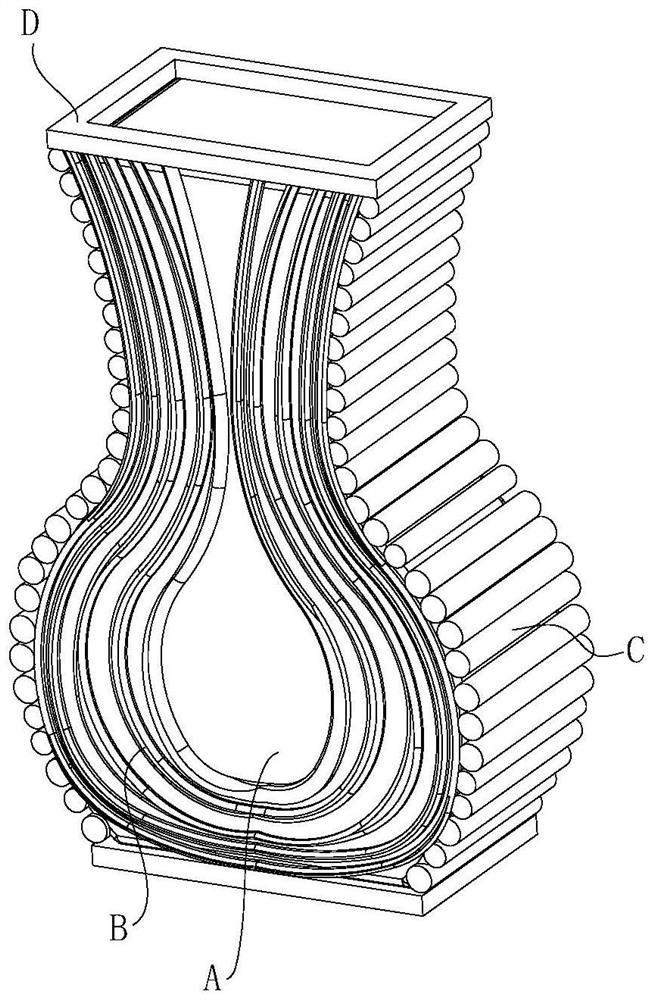

Artware automatic forming system

ActiveCN112519471AImprove molding efficiencyRealize automatic moldingWood compressionSpecial ornamental structuresPositioning equipmentEngineering

The invention relates to an artware automatic forming system which comprises an elastomer feeding device, a discharging port of the elastomer feeding device is connected with a feeding port of an elastomer forming device, an outlet of the elastomer forming device is connected with a feeding port of a green body positioning device, the elastomer forming device is used for guiding elastomers connected into a whole to the positions of the two sides of a green body in the green body positioning device and fixing the elastomers, and an end cover feeding device is further arranged beside the green body positioning device and used for guiding end covers to the positions of the two ends of the green body and fixing the end covers to the green body and the two ends of the elastomers. When artware is automatically processed, the forming system can effectively improve the forming efficiency of the artware.

Owner:合肥迈亚家具有限公司

Inner cylinder wall forming machine

ActiveCN111001725ARealize automatic moldingSolve defects that are not suitable for transportationMetal-working feeding devicesOther manufacturing equipments/toolsMolding machineEngineering

The invention belongs to the technical field of assembling and manufacturing, and particularly relates to an inner cylinder wall forming machine. The inner cylinder wall forming machine comprises an edge folding mechanism, an overturning mechanism, a seam buckling mechanism and a shaping mechanism; the edge folding mechanism is used for bending the two ends of a planar sheet into V-shaped bayonetsand conveying the planar sheet to the overturning mechanism; the overturning mechanism is used for overturning the two ends of the planar sheet by 180 degrees and enabling the two ends to be in buttjoint at the seam buckling mechanism; the seam buckling mechanism is used for pressing and fixing the two ends of the planar sheet to enable the sheet to be connected into an annular cylinder; and theshaping mechanism is used for rolling the annular cylinder into a cylindrical shape. According to the inner cylinder wall forming machine, the rolling and seam buckling mechanisms of the cylindricalpart are integrated, the machining sequence is adjusted, that is, seam buckling is conducted firstly and then shaping is conducted, the defect that the thin-wall part is not suitable for being conveyed after being rolled is overcome, automatic forming of the thin-wall cylindrical part is achieved, the machining process is simplified, and the production efficiency is improved.

Owner:长丰吾道智能光电科技有限公司

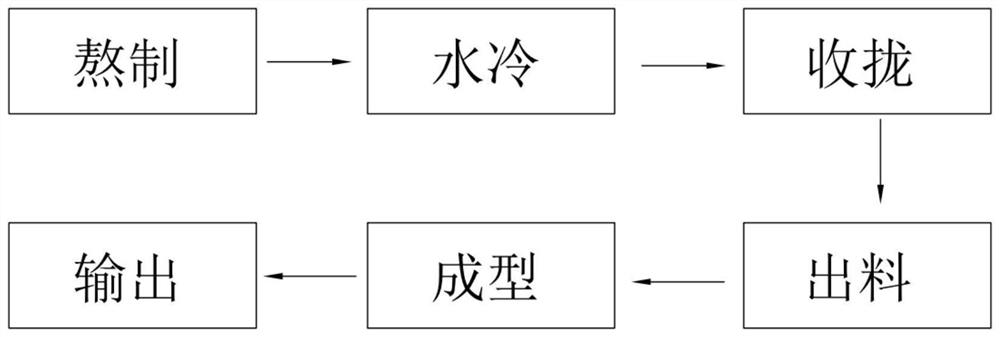

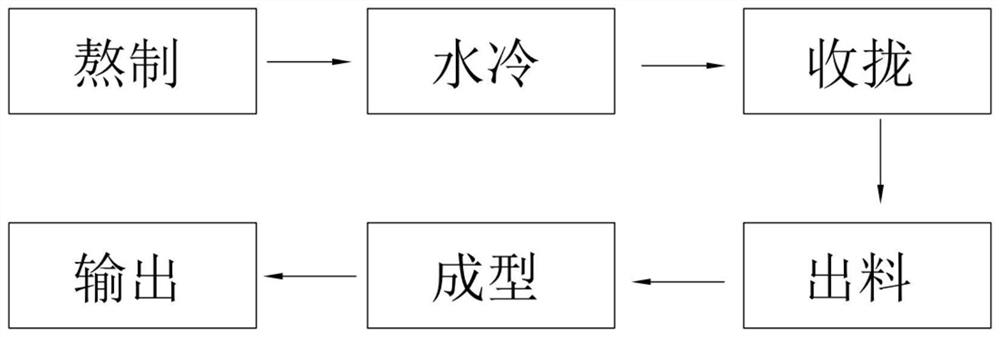

Medicinal patch forming process

ActiveCN112137887ARealize automatic moldingReduce manual laborPharmaceutical product form changeDomestic articlesPharmacy medicinePoultice

The invention relates to the technical field of traditional Chinese medicine production, in particular to a medicine patch forming process which comprises the following steps: step 1, decocting process; Step 2, water cooling process: removing fire toxin from the plaster in cold water in a water cooling tank; Step 3, discharging process: pushing the rod to push out the plaster slurry on the secondrotating shaft; Step 5, forming process, a first air cylinder drives a pressing part to press the base cloth, the plaster slurry and the film into shape; Step 6, outputting process, the traditional Chinese medicine patch is taken out from the top of the annular hoop manually or through a mechanical arm. According to the invention, the plaster slurry in the decocting equipment is poured into the water cooling tank, after the plaster slurry is gathered through cooperation of a gathering assembly and a stirring assembly, the plaster slurry is cut into small parts and conveyed to a clamping assembly on the second conveying mechanism through cutters acting at intervals, and the thin film is conveyed to the pressing station through the film conveying mechanism; the base cloth, the plaster slurryand the film are pressed into shape by a pressing mechanism, so that the traditional Chinese medicine patch is formed automatically, and the manual labor force is reduced.

Owner:安徽美邸康药业有限公司

Automatic rubber hair ring forming method

InactiveCN108162419ARealize automatic moldingIncrease productivityDomestic articlesRubber ringEngineering

The invention discloses an automatic rubber hair ring forming method. The automatic rubber hair ring forming method comprises the following steps that a rubber wire is wound around a forming shaft, and the rubber wire is spirally arranged on the forming shaft; in the winding process, the rubber wire is wound around the forming shaft through rotation of the forming shaft; the rubber wire wound intoa spiral shape is cut in the axial direction of the forming shaft; the cut rubber wire is staggered at the breaking position of each circle, the staggered rubber wire is in linkage in an end-to-end manner, and a plurality of rubber rings are formed; and dispensing operation is conducted at the connector positions of the rubber rings, and head-tail fixed connection of the rubber rings is achieved.By means of the automatic rubber hair ring forming method, automatic rubber hair ring forming can be achieved, the production efficiency is high, and the product quality and consistency are improved.

Owner:CHINA JILIANG UNIV

Automatic traditional Chinese medicine patch forming equipment

ActiveCN112274427AGuaranteed flatnessImprove flatnessPharmaceutical product form changeMetal working apparatusPoulticeMechanical engineering

The invention relates to the technical field of traditional Chinese medicine production, in particular to automatic traditional Chinese medicine patch forming equipment. The equipment comprises a first base and decocting equipment arranged on the first base, and a forming mechanism comprises a stirring assembly, a gathering assembly, a discharging assembly and a first driving part; a first conveying mechanism evenly conveys base cloth in the conveying direction of the first conveying mechanism; and a profiling mechanism comprises a second base, a first air cylinder and a profiling assembly. After plaster slurry is subjected to fire toxin removal and gathering in a water cooling tank through cooperation of the gathering assembly and the stirring assembly, the plaster slurry is cut into small parts through cutters acting at intervals, the small parts are conveyed to base cloth on a second conveying mechanism, a thin film is conveyed to a pressing station through a film conveying mechanism, when the base cloth, the plaster slurry and the thin film are pressed and formed by a pressing mechanism, the flatness of the thin film is guaranteed by a film feeding mechanism, automatic formingof a traditional Chinese medicine patch is achieved, the flatness of the thin film is improved, and therefore the forming quality of the traditional Chinese medicine patch is improved.

Owner:安徽美邸康药业有限公司

Bicycle carrying frame forming machine

ActiveCN112044998AReduce the difficulty of operationImprove work efficiencyMetal-working feeding devicesCycle equipmentsStructural engineeringIndustrial engineering

The invention relates to a forming machine, in particular to a bicycle carrying frame forming machine. According to the technical purposes of the bicycle carrying frame forming machine, it is to provide the bicycle carrying frame forming machine which is simple to operate, high in efficiency and capable of bending and forming a carrying frame iron stand at a time. In order to achieve the technicalpurposes, the bicycle carrying frame forming machine is provided and comprises a bottom plate, a long rod, a rotating mechanism, a pressing bending mechanism, a press-down mechanism and a dischargingblock, wherein one side of the top of the bottom plate is connected with an electromotor; the long rod is connected to the bottom plate; the rotating mechanism is installed in the middle of the top of the bottom plate; the pressing bending mechanism is installed on the long rod; the press-down mechanism is connected between the pressing bending mechanism and the rotating mechanism; and the discharging block is connected to the side, close to the electromotor, of the top of the bottom plate. According to the bicycle carrying frame forming machine, through cooperative work of the rotating mechanism, the press-down mechanism and the pressing bending mechanism, the continuity of the forming work of the carrying frame iron stand can be guaranteed, and therefore automatic forming of the carrying frame iron stand is achieved.

Owner:朱明昌

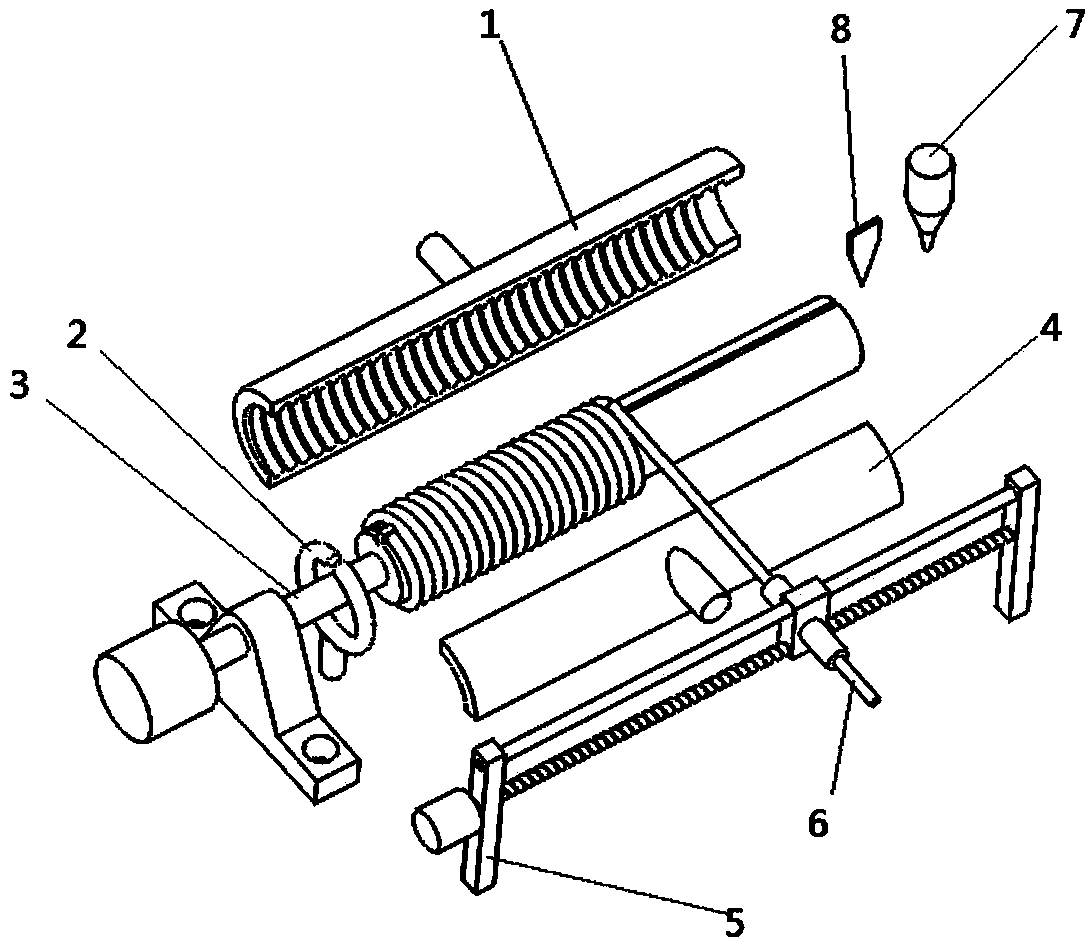

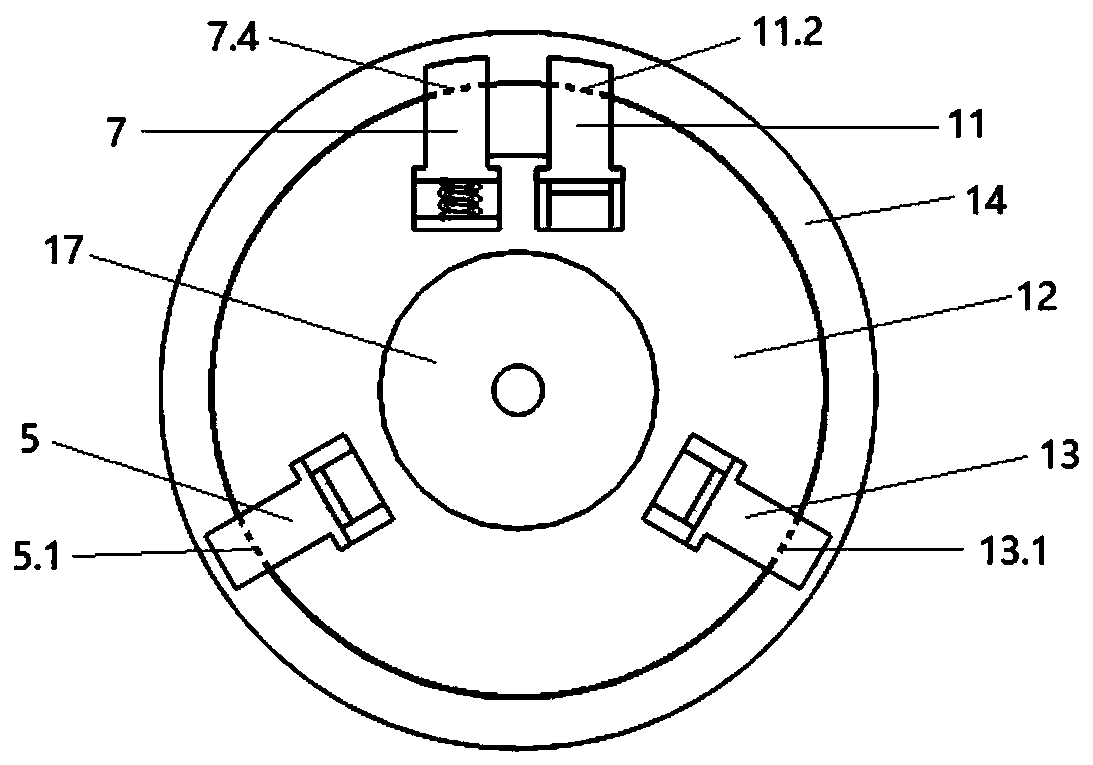

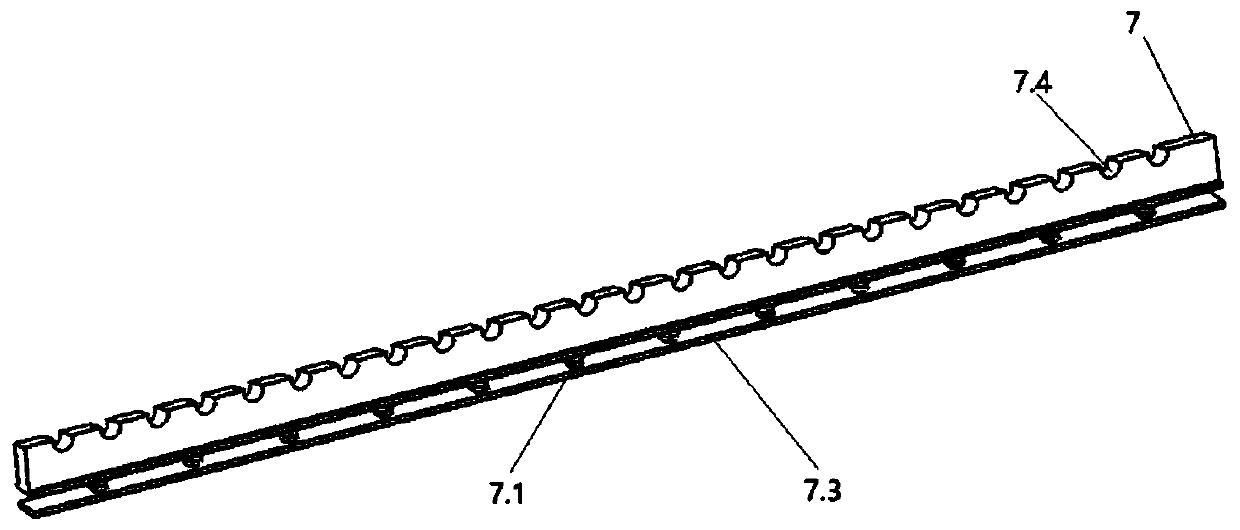

Electromagnetic rubber hair band automatic forming device

InactiveCN108127930AIncrease productivityImprove product quality and consistencyDomestic articlesEngineeringRubber band

The invention discloses an electromagnetic rubber hair band automatic forming device. The device comprises a thread outlet mechanism, a forming drum, a status switching mechanism, a cutting mechanismand a glue dispensing mechanism. A left side forming strip, a right side forming strip and a combined forming strip are mounted in the forming drum. An electromagnet is arranged in the forming drum. Aplurality of notches allowing rubber threads to be wound therein are formed in each forming strip. The electromagnet drives the left side forming strip, the right side forming strip and the combinedforming strip to stretch out of and retract from corresponding mounting grooves. After thread winding is completed, the cutting mechanism cuts the rubber threads, at this time, the combined forming strip is staggered, the broken position of each ring of the cut rubber threads is staggered, the staggered rubber threads are connected end to end, and a plurality of rubber bands are formed; and the glue dispensing mechanism is used for performing glue dispensing work at joints of the rubber bands. According to the electromagnetic rubber hair band automatic forming device, the rubber hair bands canbe automatically formed, the production efficiency is high, and the product quality and consistency are improved.

Owner:CHINA JILIANG UNIV

Automatic forming method of electromagnetic rubber hair ring

InactiveCN109624336BRealize automatic moldingIncrease productivityCurling devicesRubber ringMechanical engineering

The invention discloses an automatic forming method of electromagnetic type rubber hair rings. The automatic forming method of the electromagnetic type rubber hair rings is based on an automatic forming device of the electromagnetic rubber hair rings, and comprises a line discharging mechanism, a forming cylinder, a state switching mechanism, a cutting mechanism and an adhesive dispensing mechanism. A left forming strip, a right forming strip and a combined forming strip are installed in the forming cylinder, an electromagnet is arranged in the forming cylinder, and a plurality of notches forrubber line involving are arranged on each forming strip. The left forming strip is driven by the electromagnet, and the right forming strip and the combined forming strip extend and retract from corresponding installation grooves. After the winding is completed, the cutting mechanism cuts rubber lines, at the moment, the combined forming strip is mispositioned, so that the cut rubber lines are mispositioned at the broken place of each ring, and the rubber lines after dislocation are connected at the beginning and end of the rubber lines to form a plurality of rubber rings; and the adhesive dispensing mechanism performs the adhesive dispensing operation at the interfaces of the rubber rings. The automatic forming method of the electromagnetic type rubber hair rings can realize the automatic forming of the rubber hair rings, the production efficiency is high, and the product quality and consistency are improved.

Owner:CHINA JILIANG UNIV

Edgefold type packaging box molding equipment

PendingCN108312615ARealize automatic moldingIncrease productivityPaper-makingBox making operationsManufacturing cost reductionControl system

The implementation method of the invention relates to the technical field of intellectualized packaging box production equipment and discloses edgefold type packaging box molding equipment. The packaging box molding equipment comprises a paper fetching device, an edge folding device, a first driving device, a second driving device and a main control system, the first driving device drives the paper fetching device to move between a paper inlet position and a paper outlet position, the main control system controls the paper fetching device to absorb paper at the paper inlet position and move towards the paper outlet position after absorbing the paper, when the paper fetching device moves to an edge folding position, the main control system closes the first driving device and starts the second driving device, the second driving device drives the paper fetching device to move towards the edge folding device after being started, after the paper is fed into the edge folding device, the maincontrol system closes the second driving device and starts the edge folding device to perform edge folding on the paper, and the main control system controls the paper fetching device to discharge the paper after edge folding is finished. By means of the edgefold type packaging box molding equipment, automation molding of edgefold type packaging boxes is realized, the production efficiency of thepackaging boxes is improved, and the fabricating cost is lowered.

Owner:上海隽韬创意设计发展有限公司

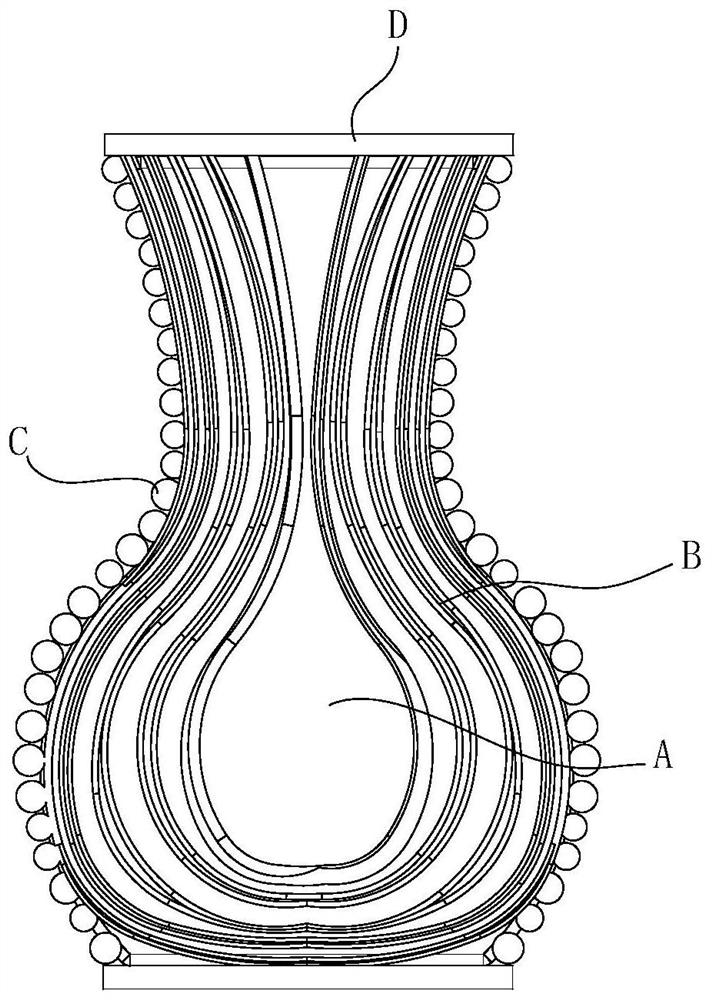

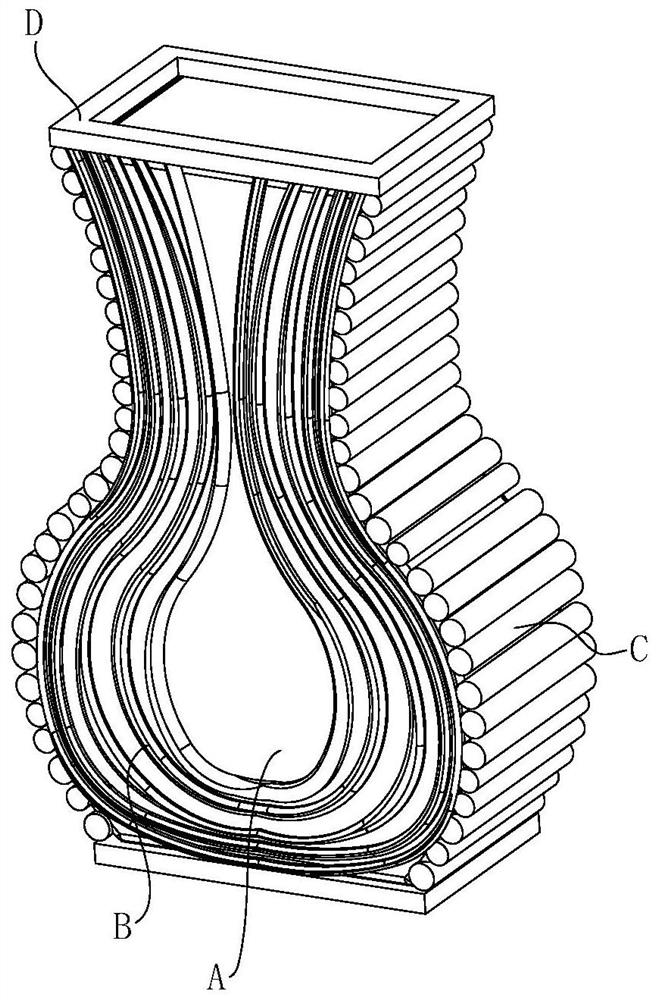

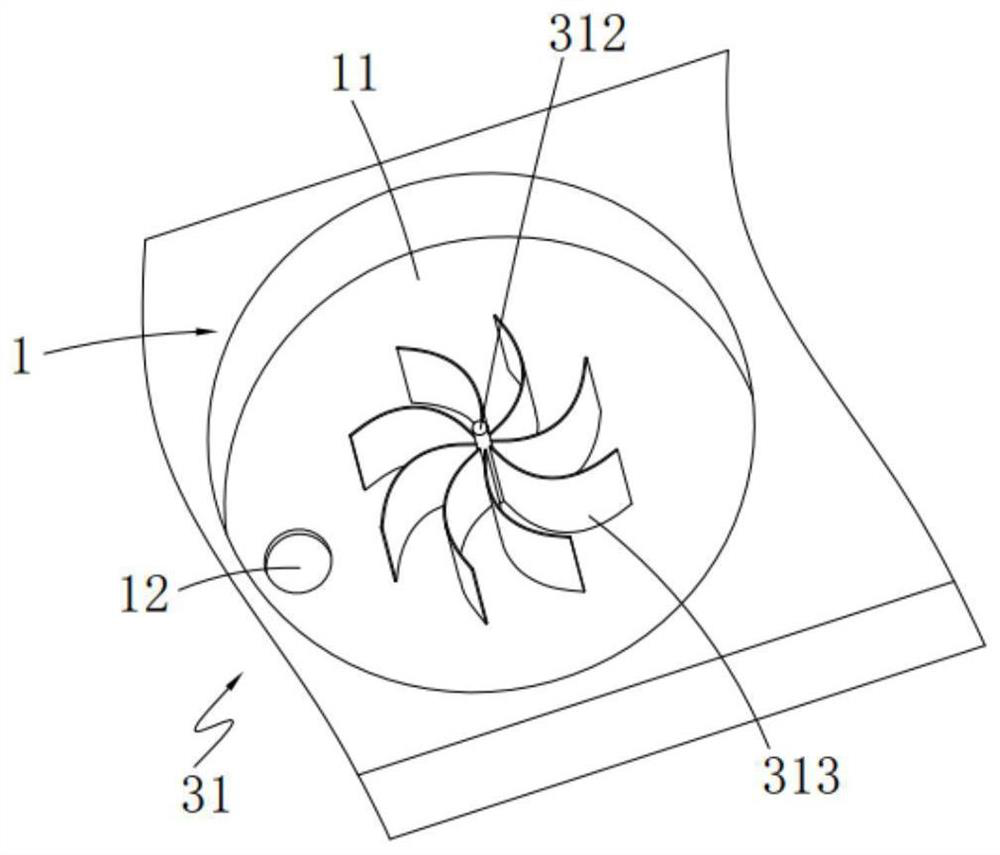

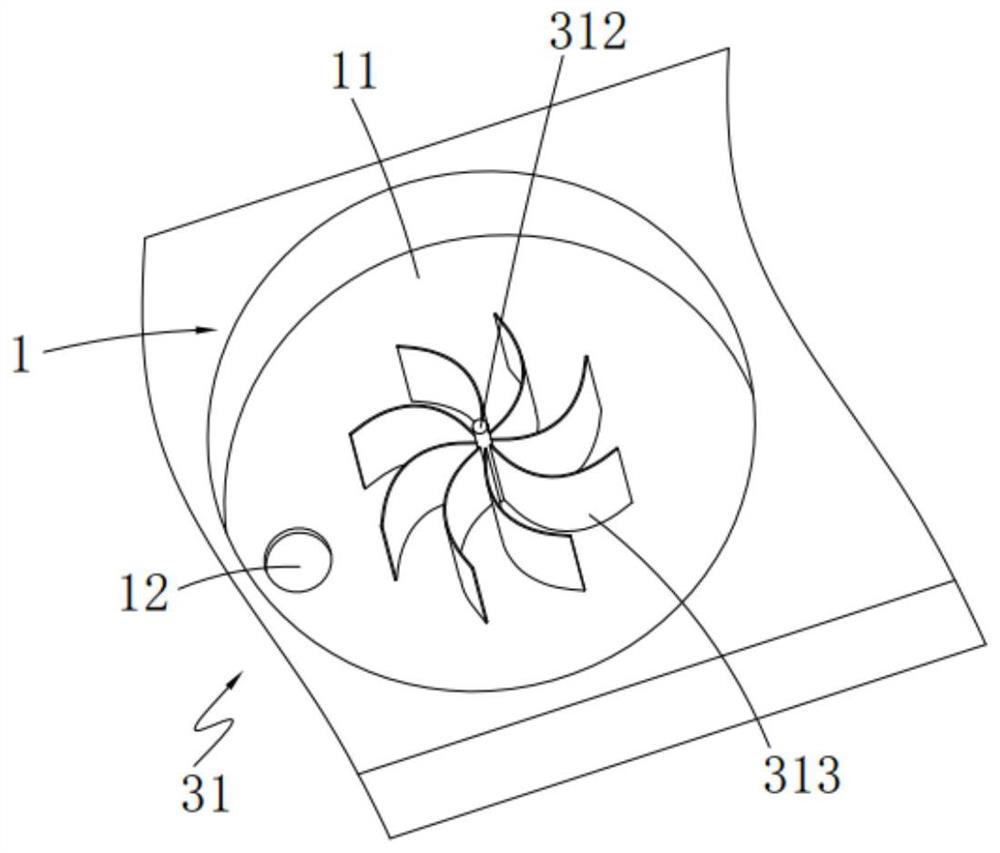

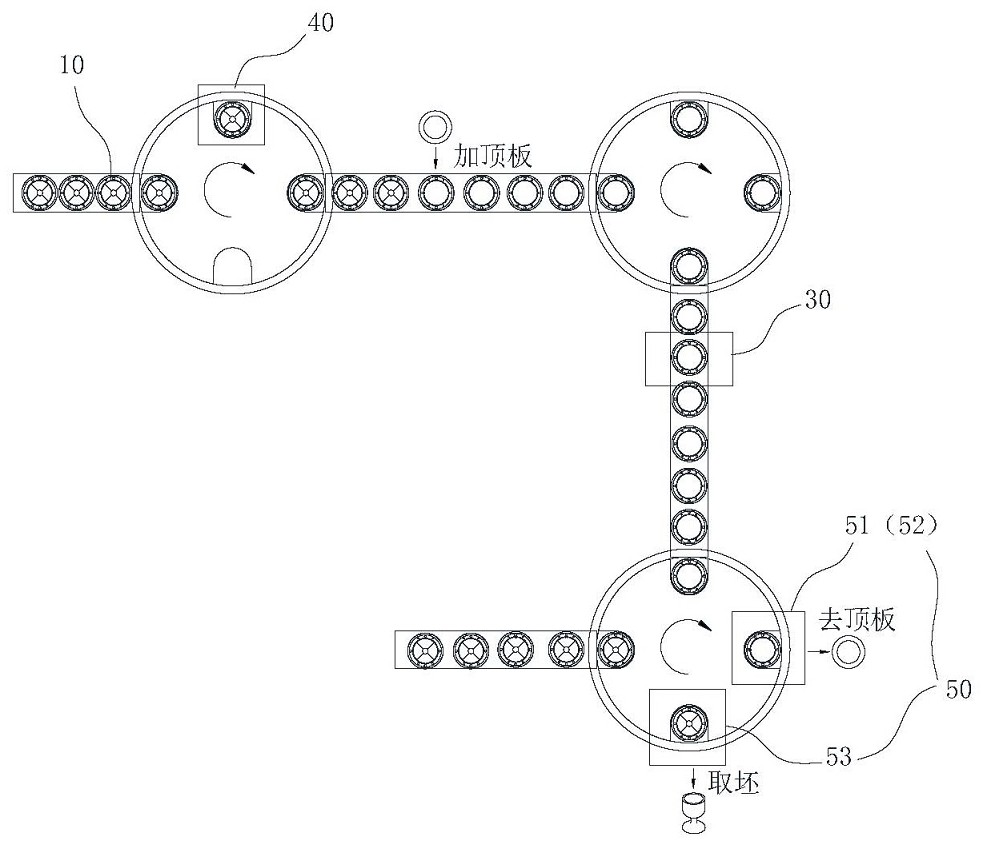

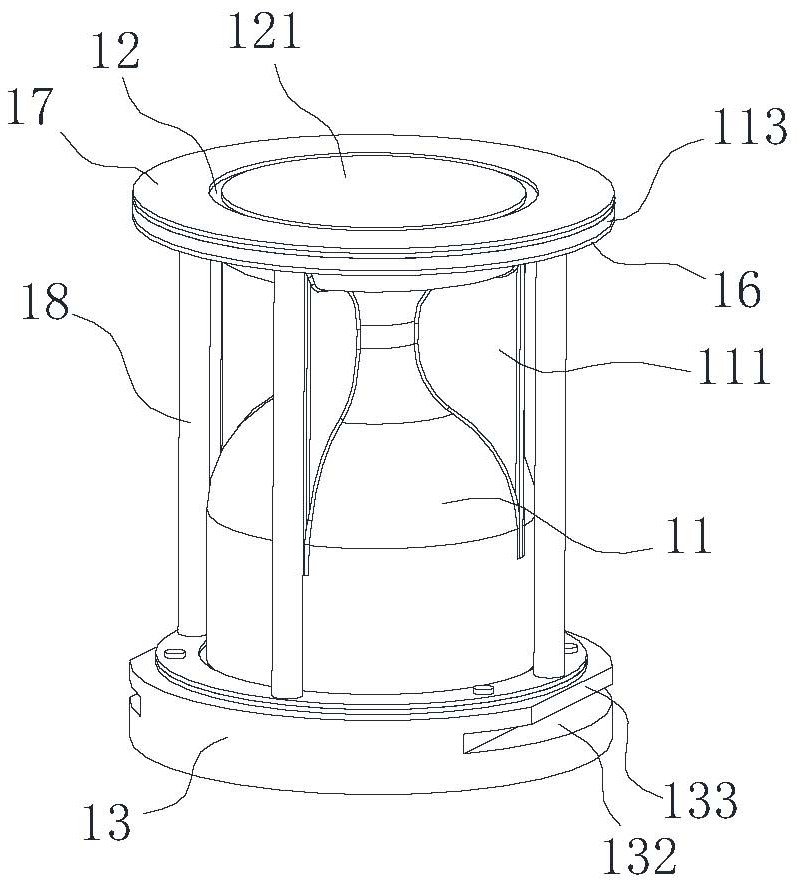

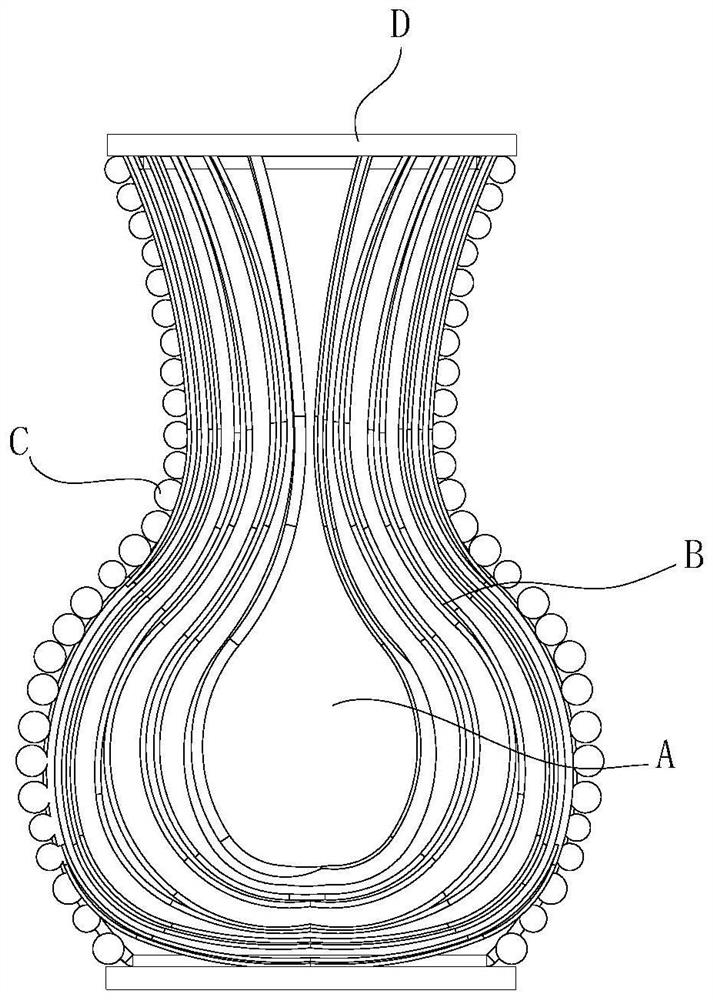

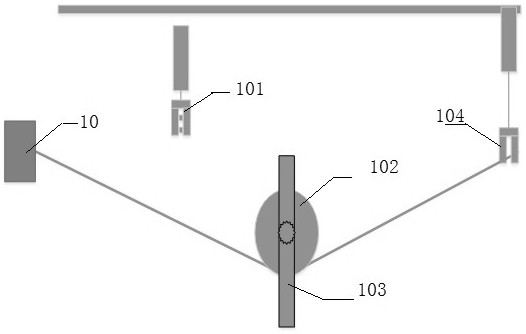

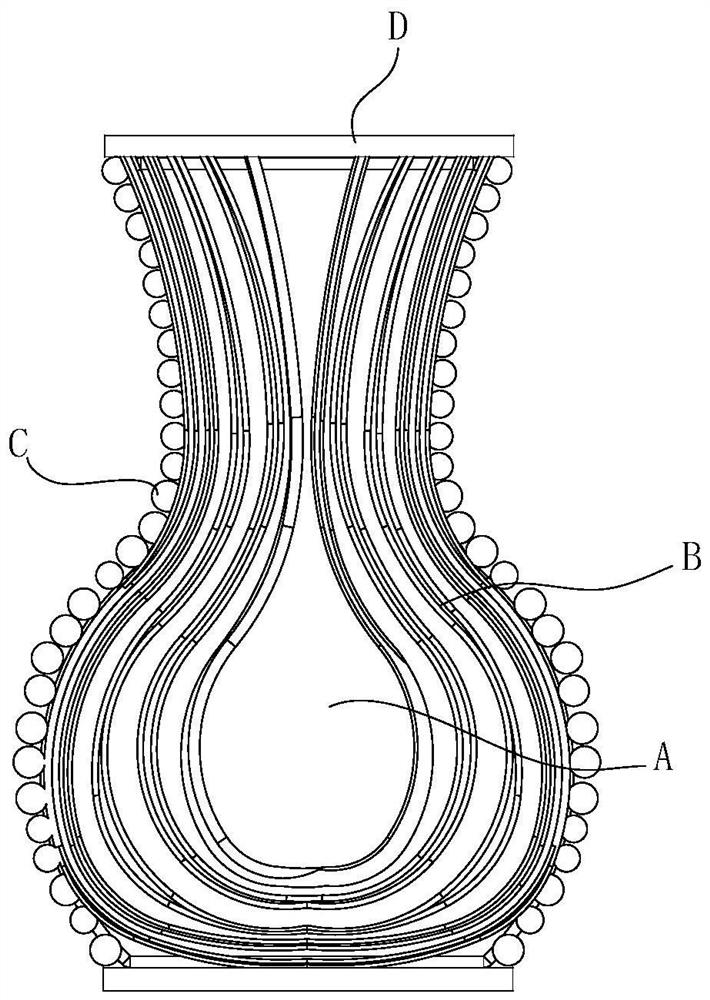

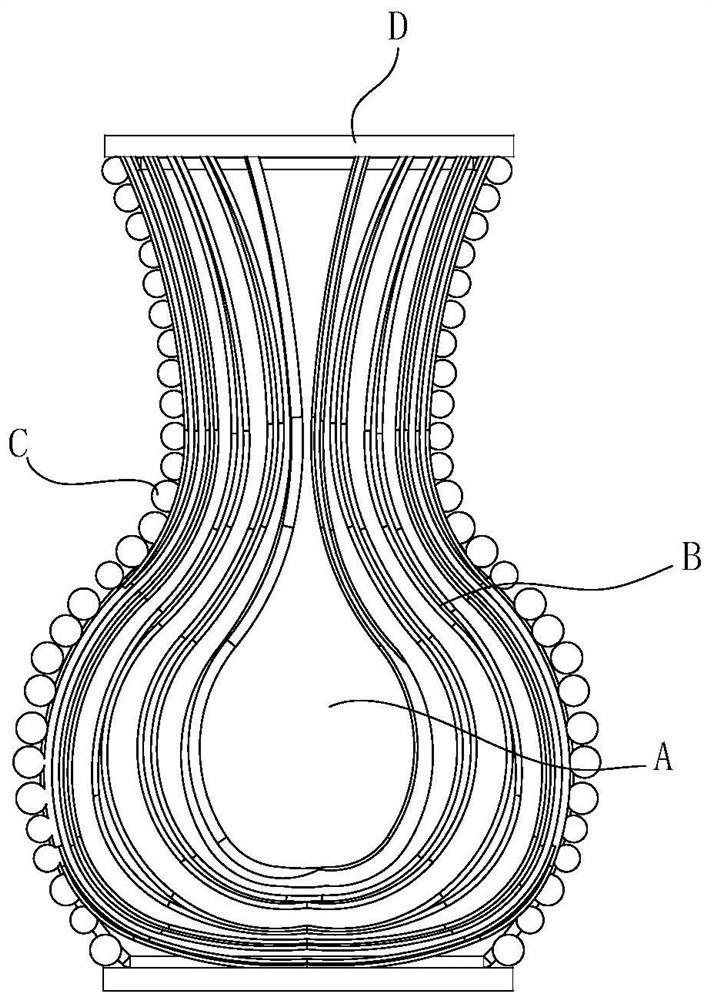

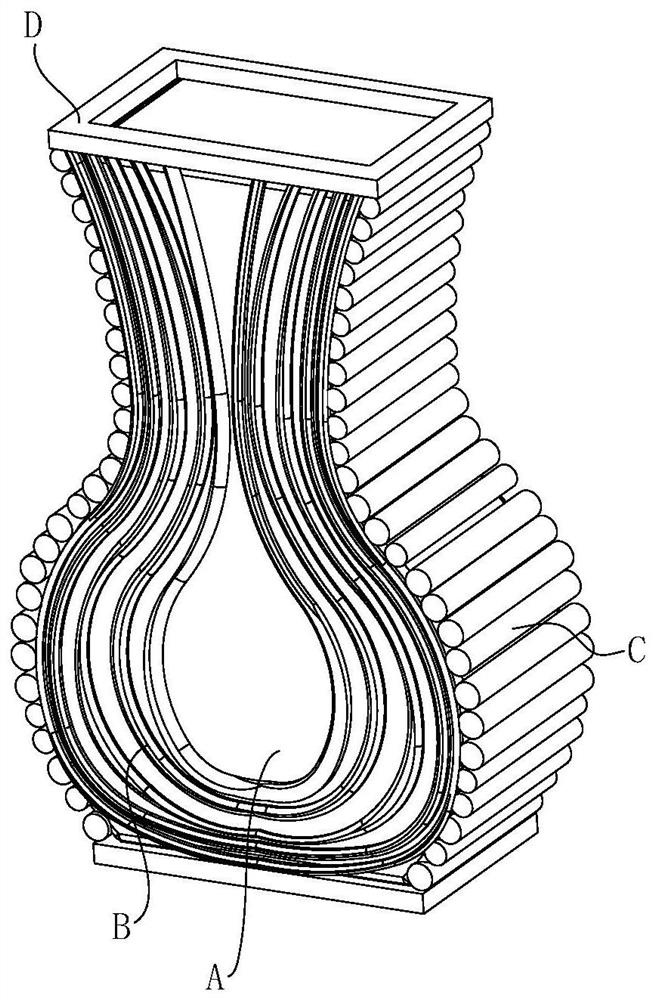

Porcelain Blank Forming System

ActiveCN110126066BRealize automatic moldingImprove molding qualityDischarging arrangementMouldsStructural engineeringMachining

The invention belongs to the technical field of ceramic production and machining and particularly relates to a ceramic blank forming system. The ceramic blank forming system comprises a die, a die conveying device, a padding device, a pressurizing device and a die releasing device, wherein the padding device, the pressurizing device and the die releasing device are arranged in sequence in the conveying direction of the die conveying device. The die comprises a ring-shaped die sleeve made of an elastic material, a top plate and a bottom plate, wherein the top plate and the bottom plate are located at the upper end and the lower end of the ring-shaped die sleeve correspondingly. The ring-shaped die sleeve is provided with a waist-shaped structure, a die sleeve ring face corresponding to thewaist-shaped structure is equally divided into at least two independent arc faces in the circumferential direction, every two adjacent arc faces are integrally connected through a rib plate, the rib plates are of hinge-shaped structures, two hinge faces of each rib plate are integrally connected with the adjacent edges of the adjacent two arc faces, and the hinges protrude on the outer ring face of the ring-shaped die sleeve. By means of the ceramic blank forming system, due to the padding device, the pressurizing device and the die releasing device, automatic forming of ceramic blank bodies is achieved, the production and machining efficiency is greatly improved, and the labor cost is saved.

Owner:安徽智汇和科技服务有限公司

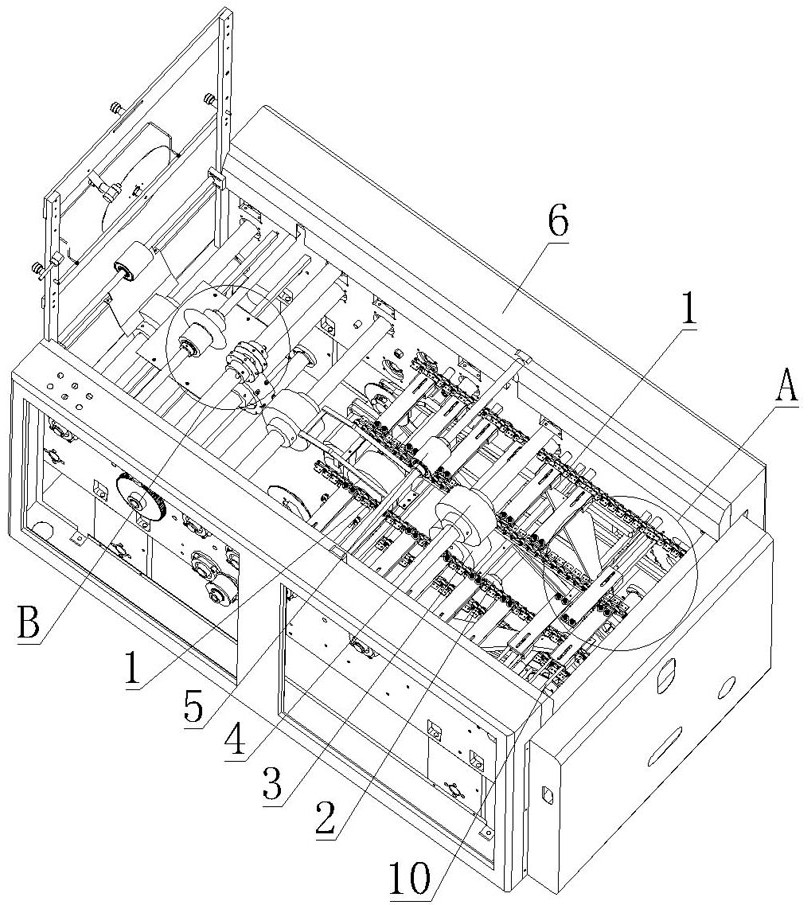

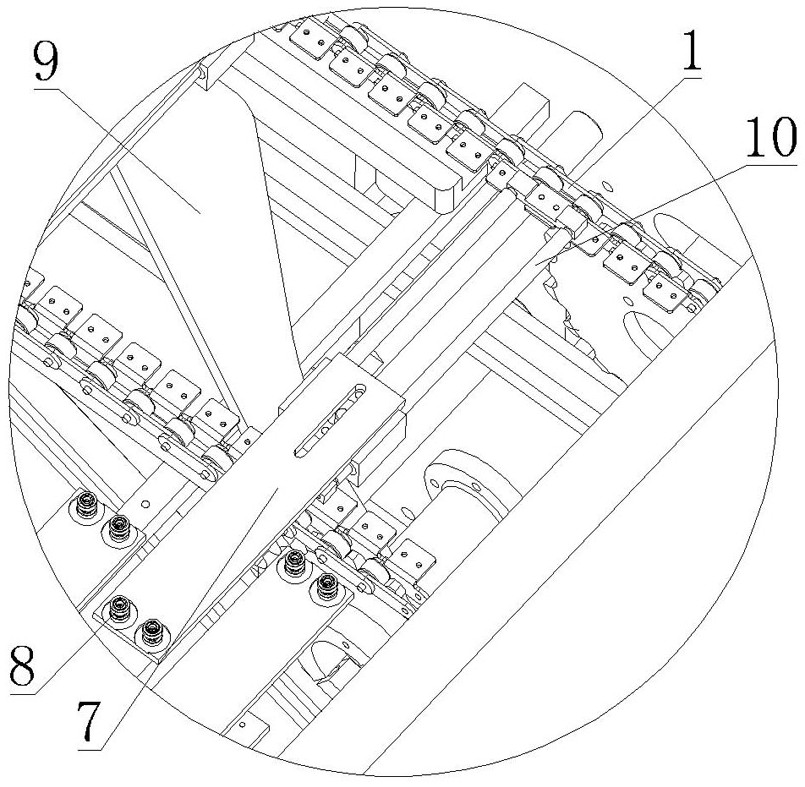

Forming mechanism for round rope bag handle of packaging bag

PendingCN111605250ARealize automatic moldingSimple structurePaper/cardboard articlesTransmission beltStructural engineering

The invention discloses a forming mechanism for a round rope bag handle of a packaging bag. The forming mechanism is characterized in that the mechanism comprises a machine frame (6), a gluing assembly, an upper unwinding roller set (5), a lower unwinding roller set (2) and a round rope bag handle unwinding set; the two sides of the machine frame are provided with transmission belts (1), and the two transmission belts are provided with installation rods (10) in a staggered mode; the installation rods (10) are movably provided with moving seats (7); the moving seats (7) are connected with guideassemblies and provided with round rope winding parts; and a pressing assembly is arranged between the left transmission belt (1) and the right transmission belt (1). The forming mechanism is simplein structure, reasonable in design and capable of conveniently forming of the round rope bag handle and pasting the round rope bag handle onto bag handle paper so that the round rope bag handle and the bag handle paper can be integrally connected to the packaging bag.

Owner:WENZHOU RUIZHI PACKING MACHINERY

Medicine patch forming device

ActiveCN112237547ARealize automatic moldingReduce manual laborPharmaceutical product form changeDomestic articlesPharmacy medicinePoultice

The invention relates to the technical field of traditional Chinese medicine production, in particular to a medicine patch forming device. The medicine patch forming device comprises a first base, a forming mechanism, a first conveying mechanism, a second conveying mechanism, a press-forming mechanism and a film conveying mechanism, wherein the first base is provided with decocting equipment; theforming mechanism includes a stirring assembly, a gathering assembly, a discharging assembly and a first driving part; the first conveying mechanism conveys clamping assemblies at intervals; the second conveying mechanism is arranged below the first base; the press-forming mechanism is used for performing press forming on a medicine patch, and the position, corresponding to the first conveying mechanism, of the press-forming mechanism is a press-forming station; and the film conveying mechanism is used for conveying a thin film to the press-forming station. According to the medicine patch forming device, plaster slurry in the decocting equipment is poured into a water cooling tank; after being gathered with the cooperation of the gathering assembly and the stirring assembly, the plaster slurry is cut into small parts through a cutter acting at intervals and the small parts are conveyed to the clamping assemblies on the second conveying mechanism; the thin film is conveyed to the press-forming station through the film conveying mechanism; and press forming is performed on base cloth, the plaster slurry and the thin film by the press-forming mechanism, so that automatic forming of the traditional Chinese medicine patch is realized, and the manual labor is reduced.

Owner:安徽美邸康药业有限公司

Automatic forming method of rubber hair ring

InactiveCN108162419BRealize automatic moldingIncrease productivityDomestic articlesRubber ringEngineering

The invention discloses an automatic rubber hair ring forming method. The automatic rubber hair ring forming method comprises the following steps that a rubber wire is wound around a forming shaft, and the rubber wire is spirally arranged on the forming shaft; in the winding process, the rubber wire is wound around the forming shaft through rotation of the forming shaft; the rubber wire wound intoa spiral shape is cut in the axial direction of the forming shaft; the cut rubber wire is staggered at the breaking position of each circle, the staggered rubber wire is in linkage in an end-to-end manner, and a plurality of rubber rings are formed; and dispensing operation is conducted at the connector positions of the rubber rings, and head-tail fixed connection of the rubber rings is achieved.By means of the automatic rubber hair ring forming method, automatic rubber hair ring forming can be achieved, the production efficiency is high, and the product quality and consistency are improved.

Owner:CHINA JILIANG UNIV

Handicraft automatic forming system

ActiveCN112519471BRealize automatic moldingImprove molding efficiencyWood compressionSpecial ornamental structuresElastomerEngineering

The invention relates to an automatic molding system for handicrafts, which includes elastic body feeding equipment, the outlet of the elastic body feeding equipment is connected with the inlet of the elastic body molding equipment, the outlet of the elastic body molding equipment is connected with the inlet of the green body positioning equipment The material mouth is connected, and the elastic body forming equipment is used to export the connected elastic body to the positions on both sides of the green body in the green body positioning equipment and fix it. The cap feeding equipment is used to export the end caps to the two ends of the green body and fix them with both ends of the green body and the elastic body. When implementing automatic processing of this kind of handicraft, the forming system can effectively improve the molding of this type of handicraft. efficiency.

Owner:合肥迈亚家具有限公司

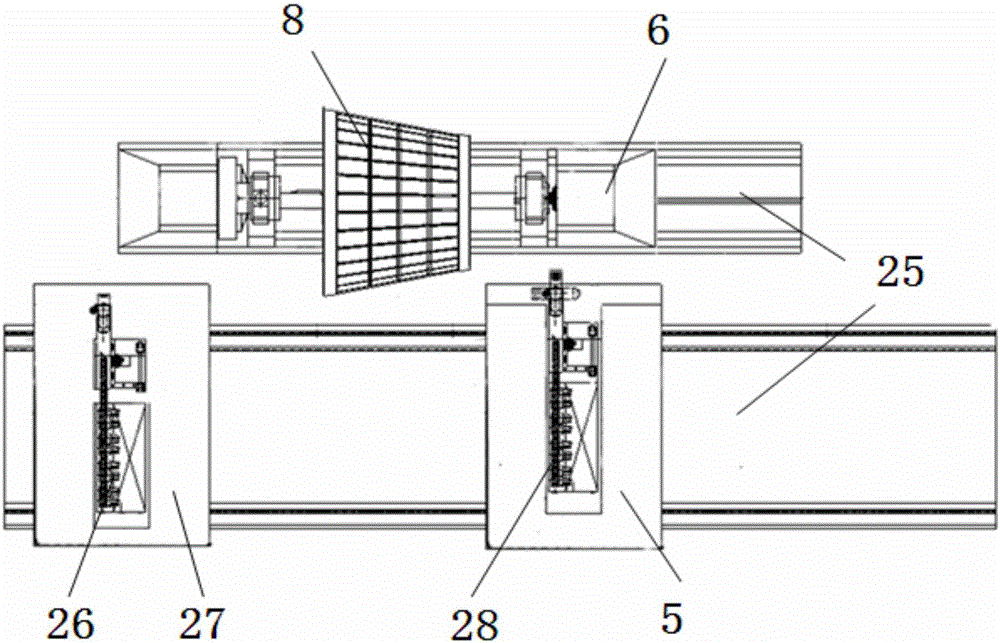

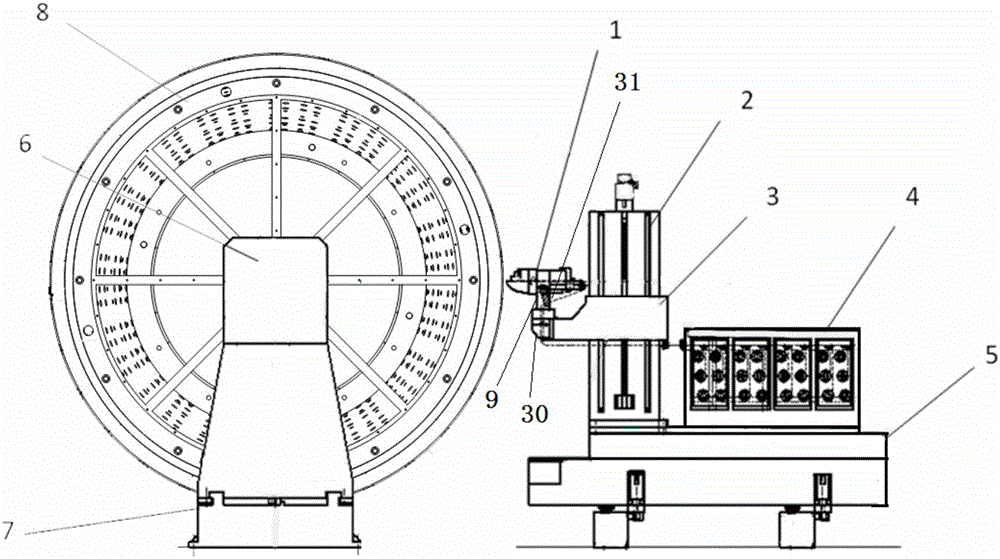

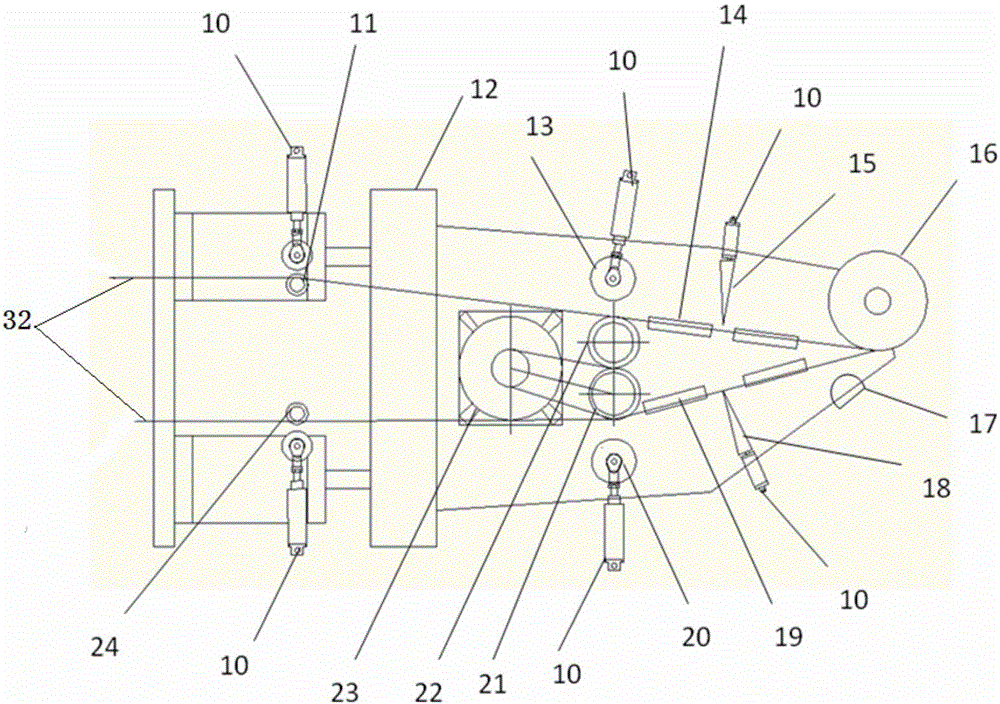

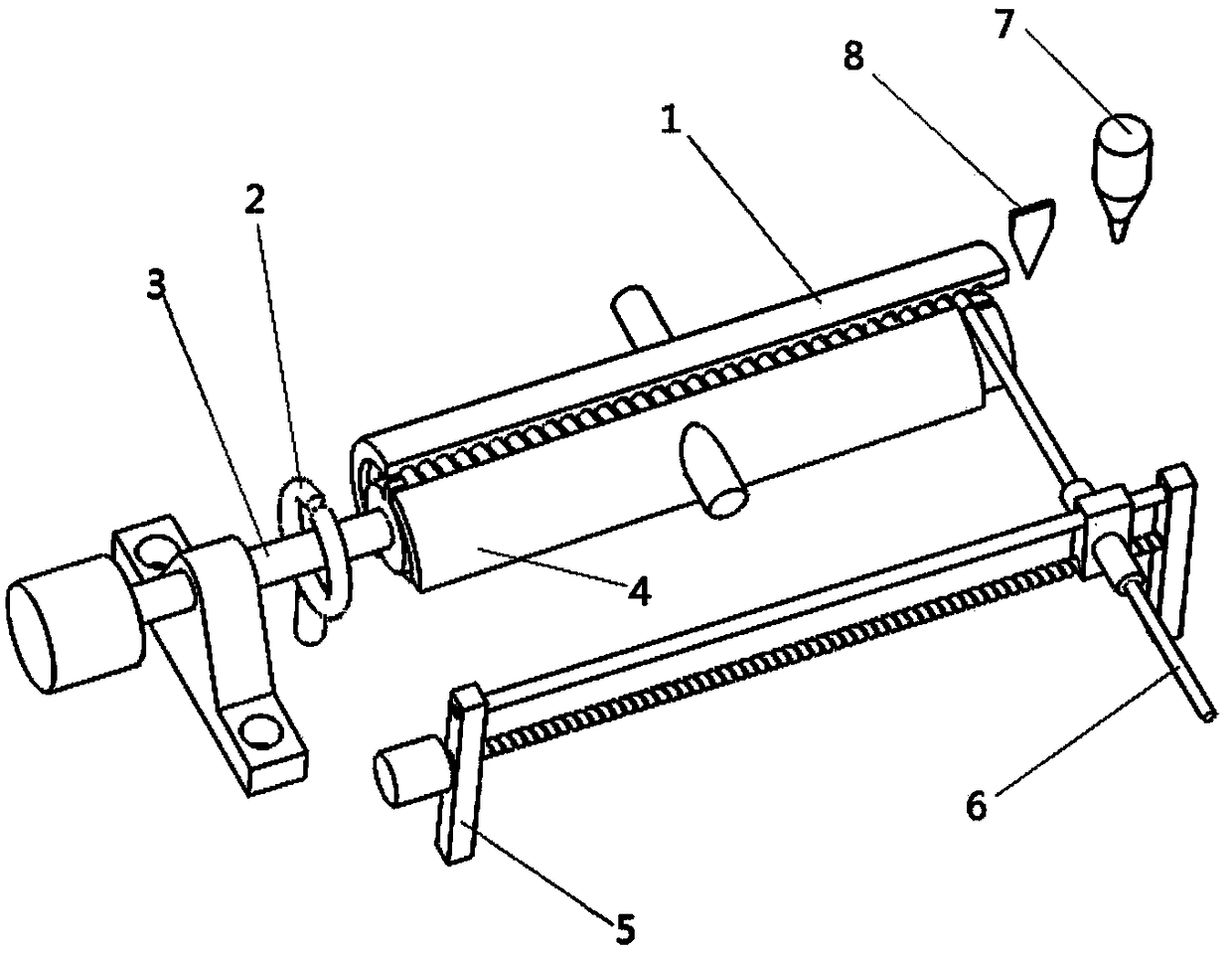

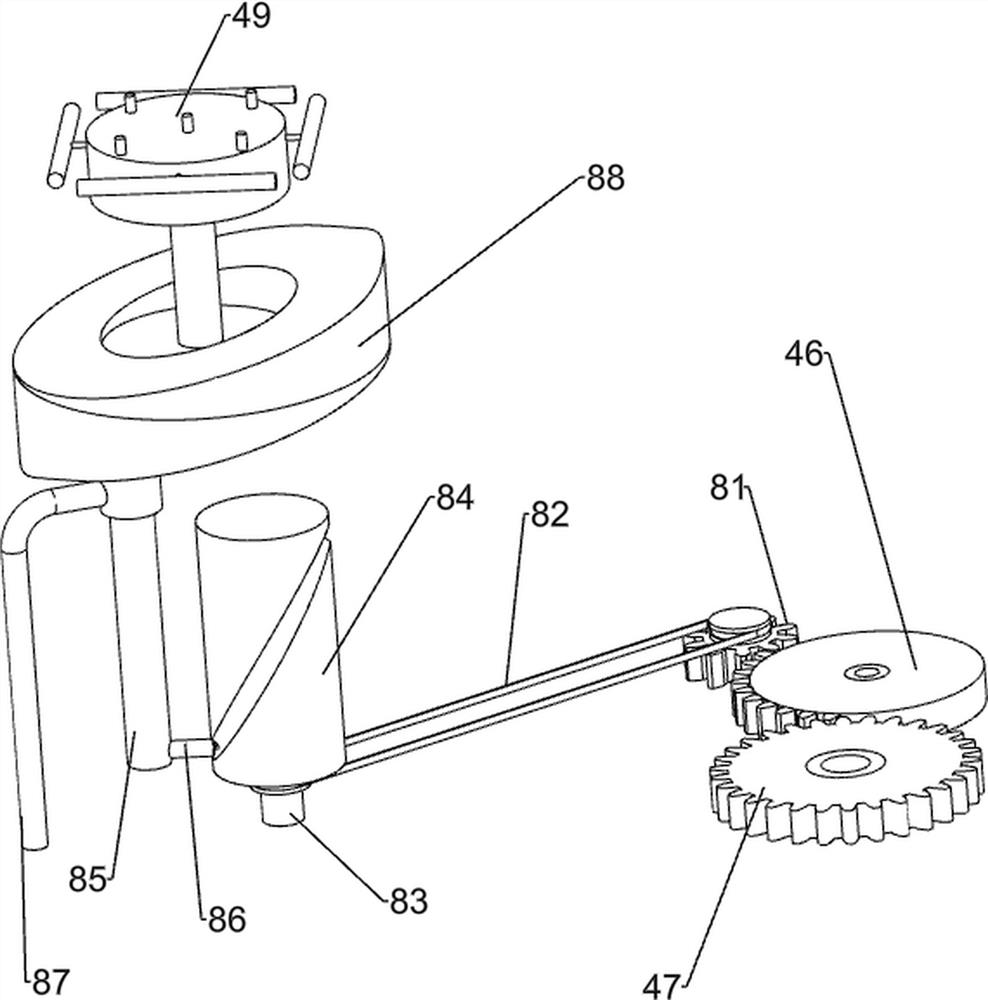

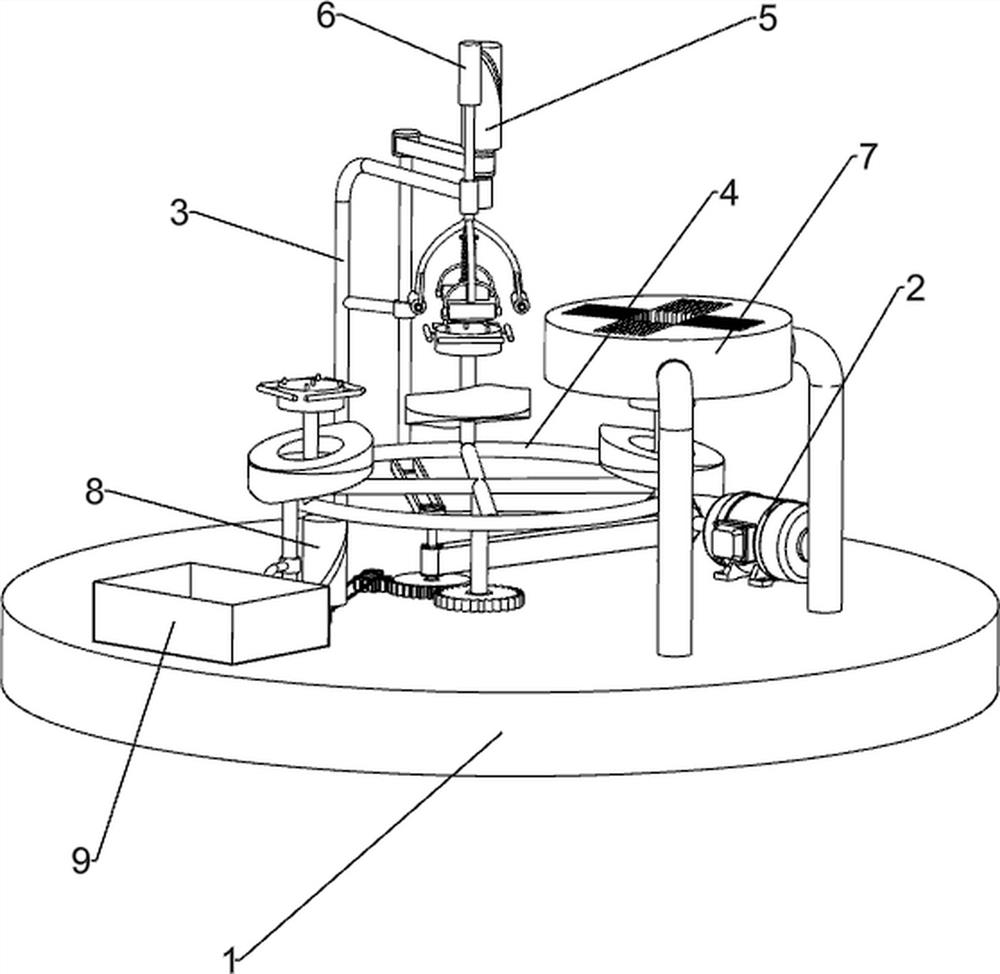

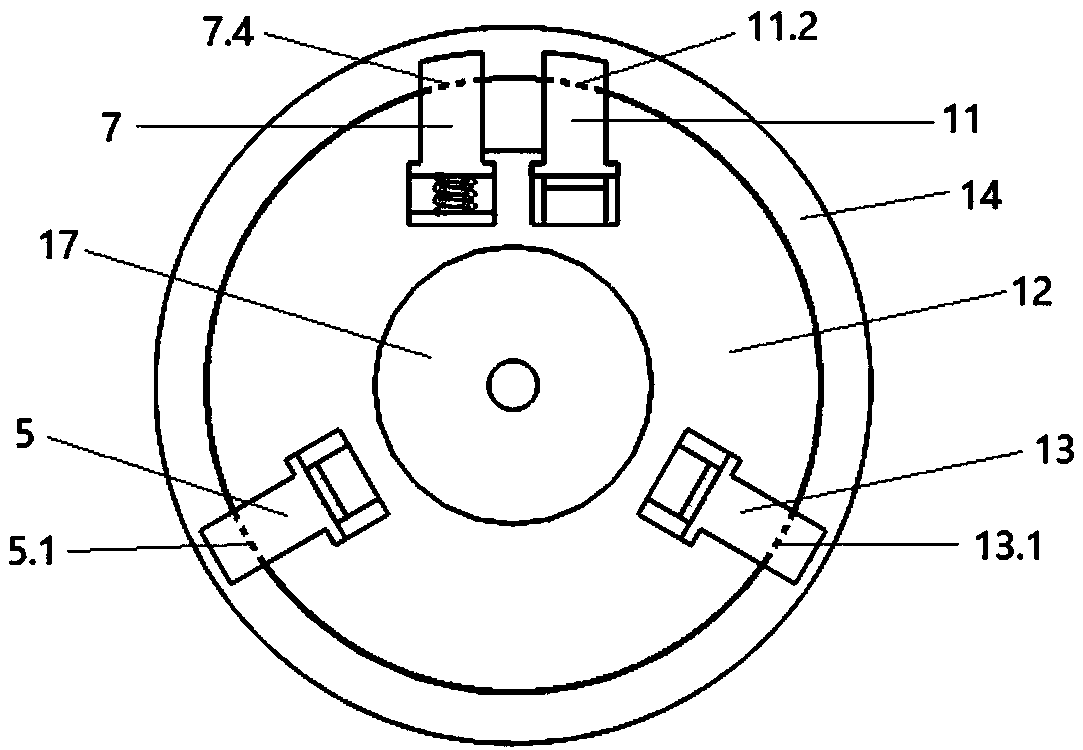

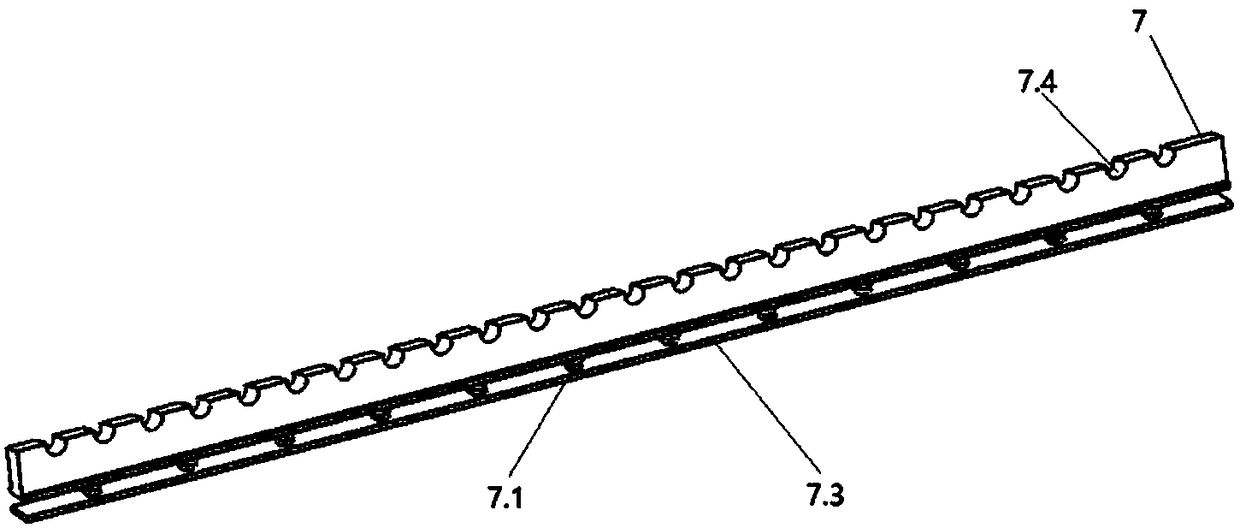

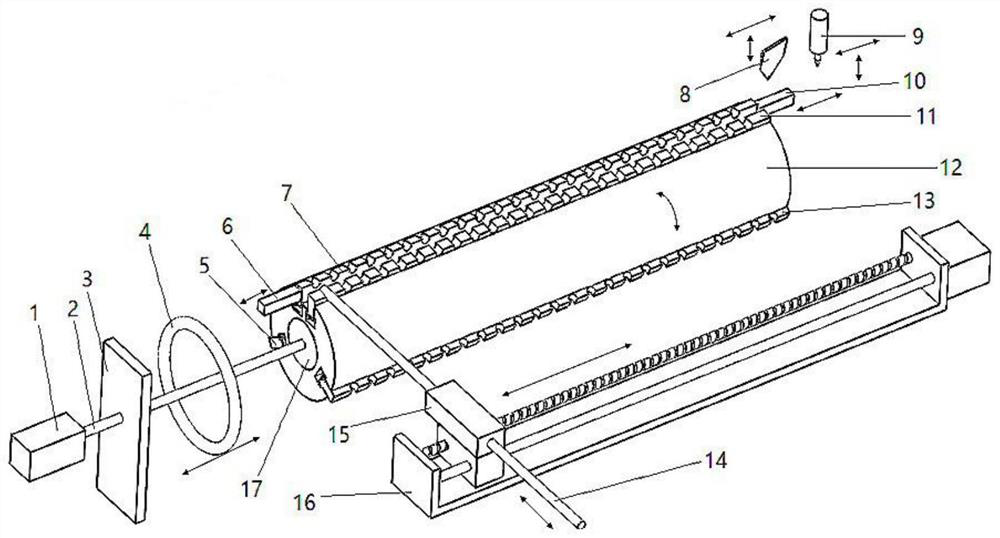

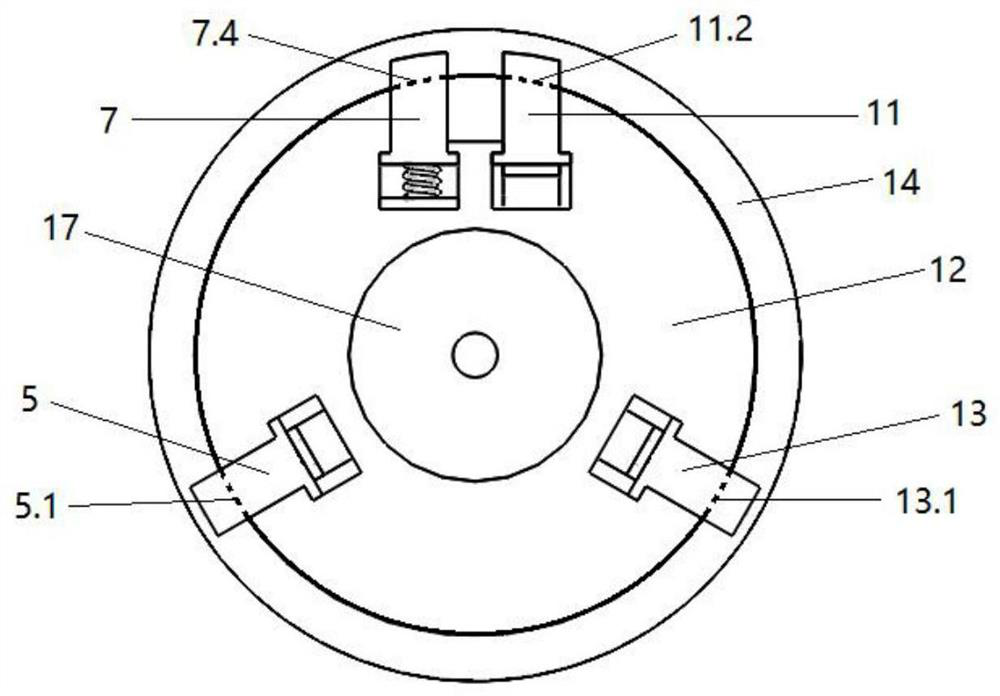

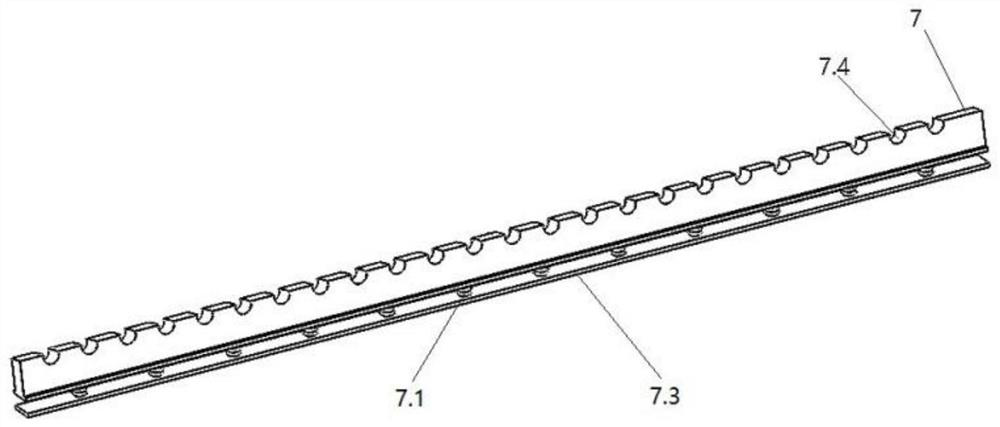

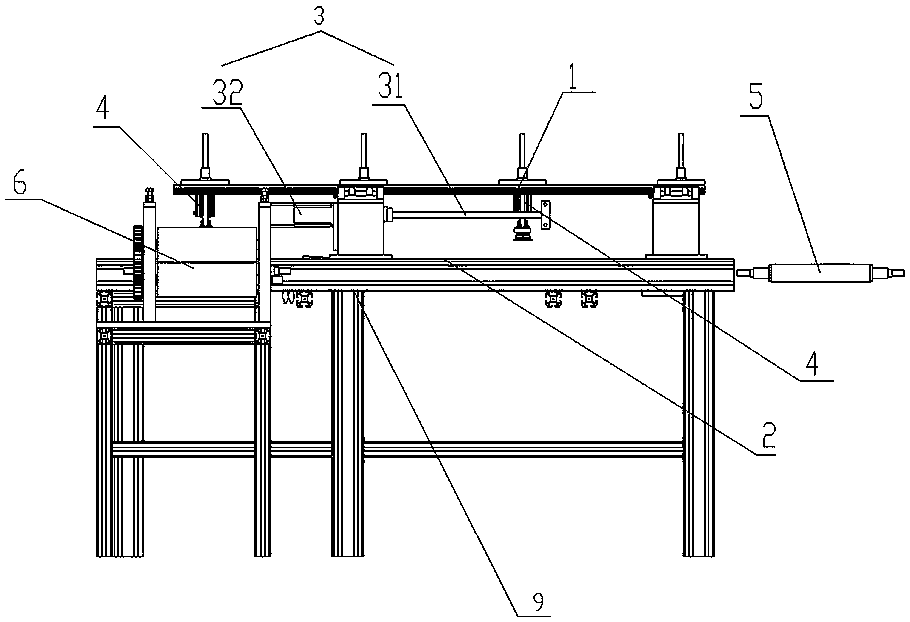

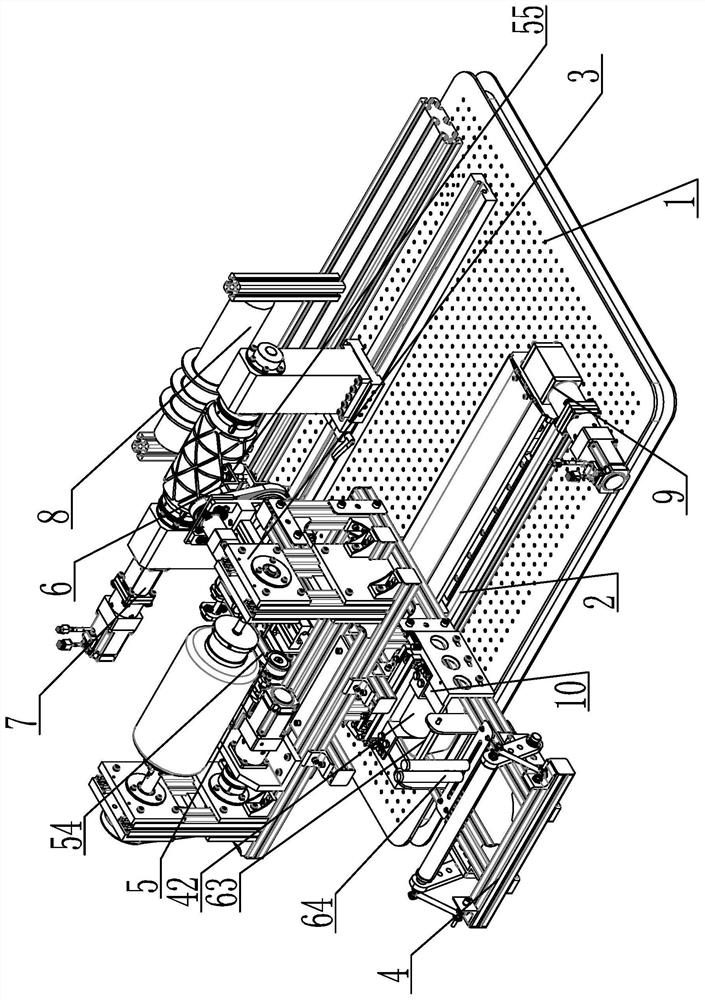

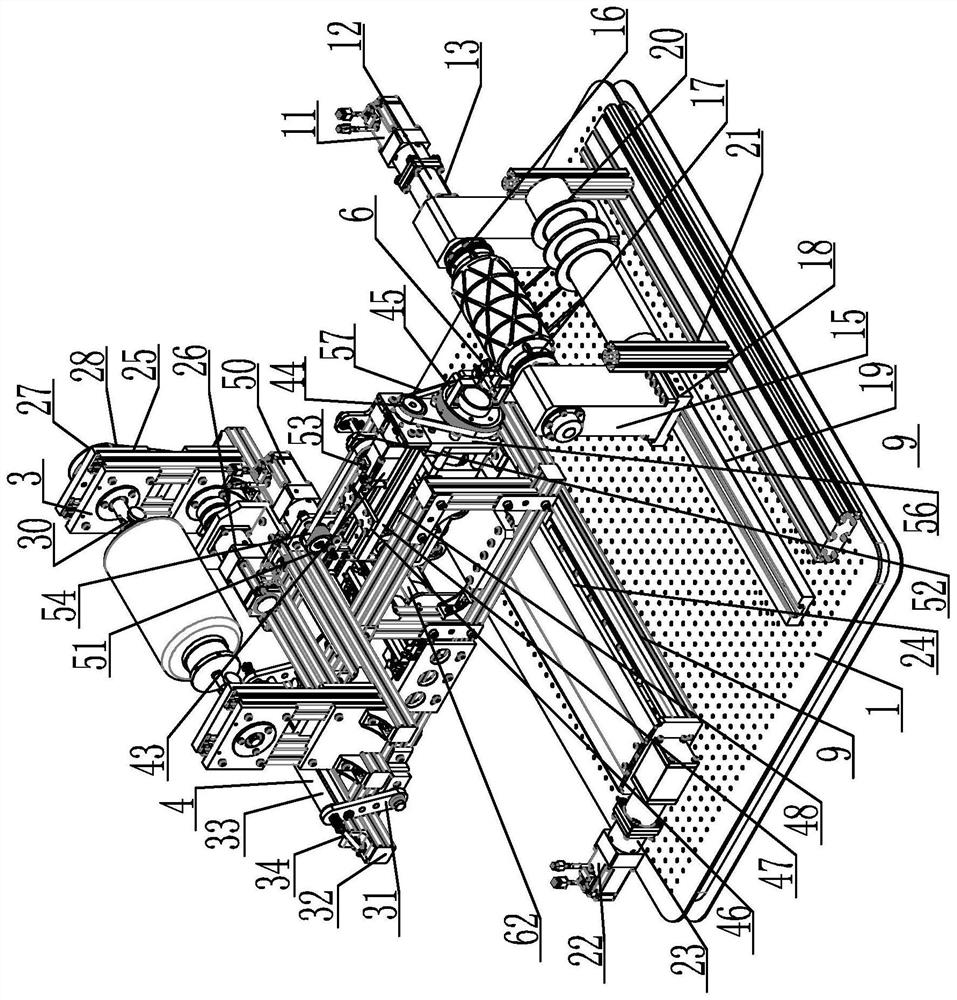

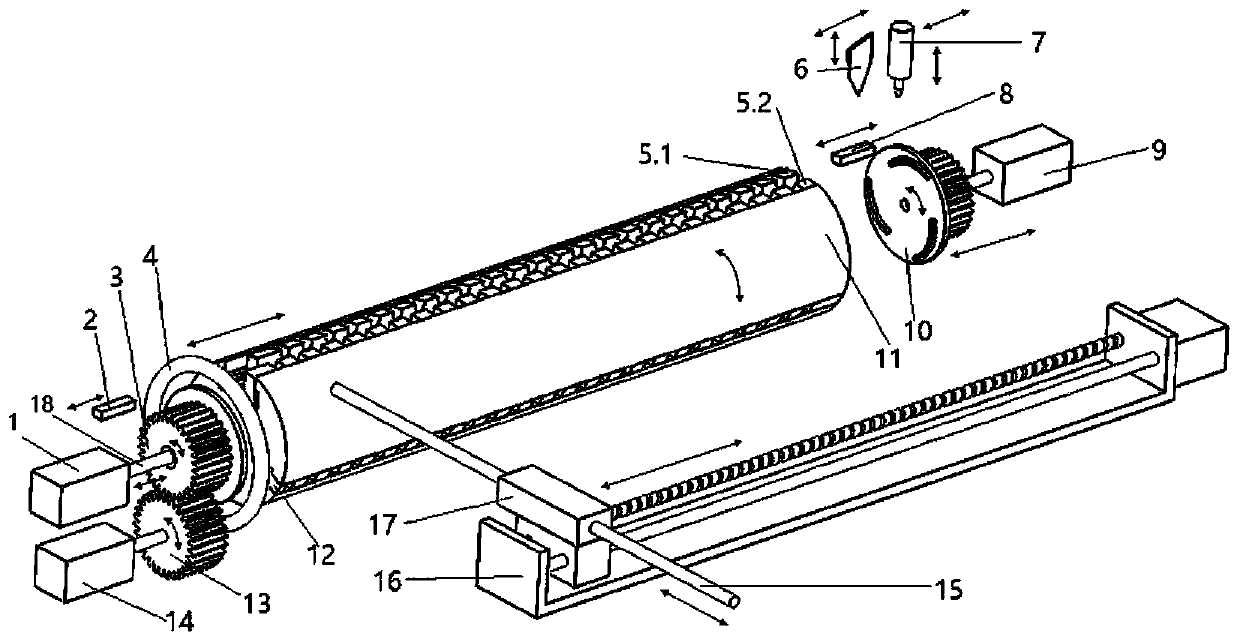

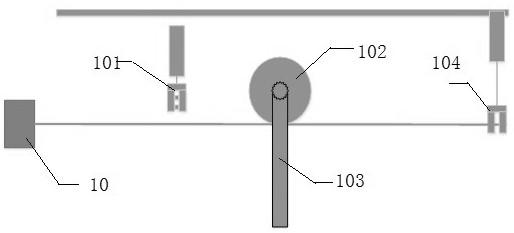

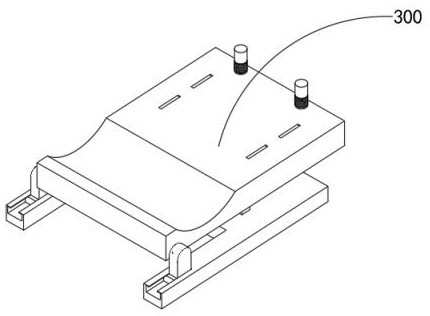

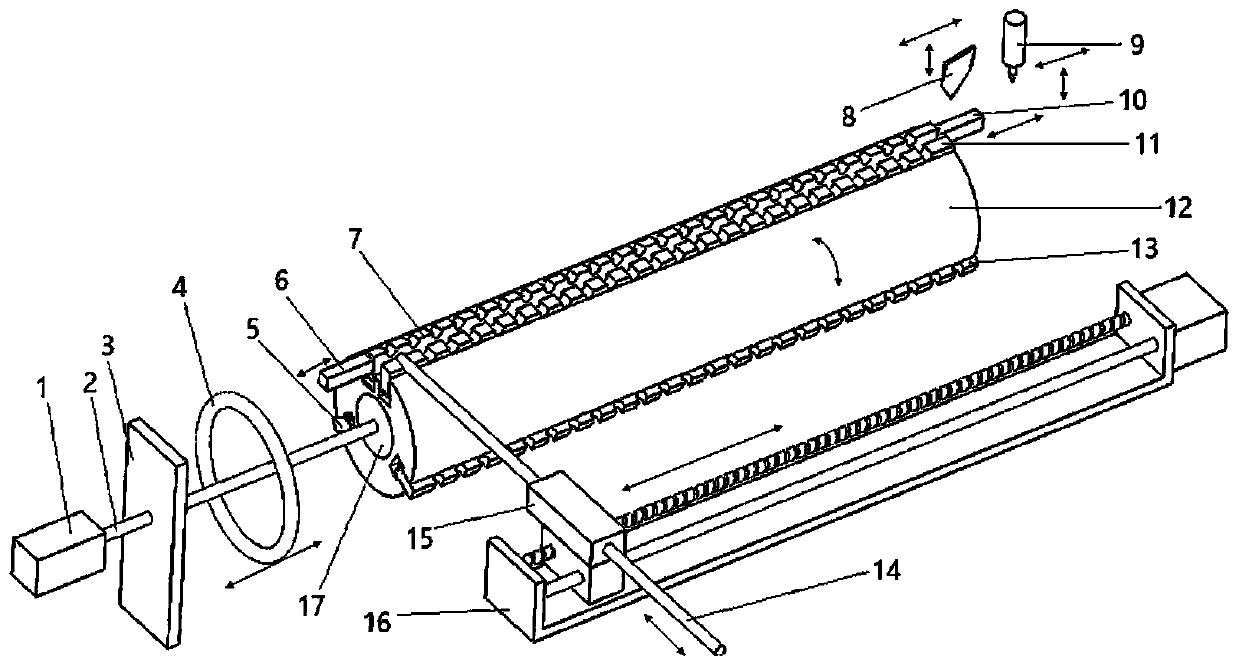

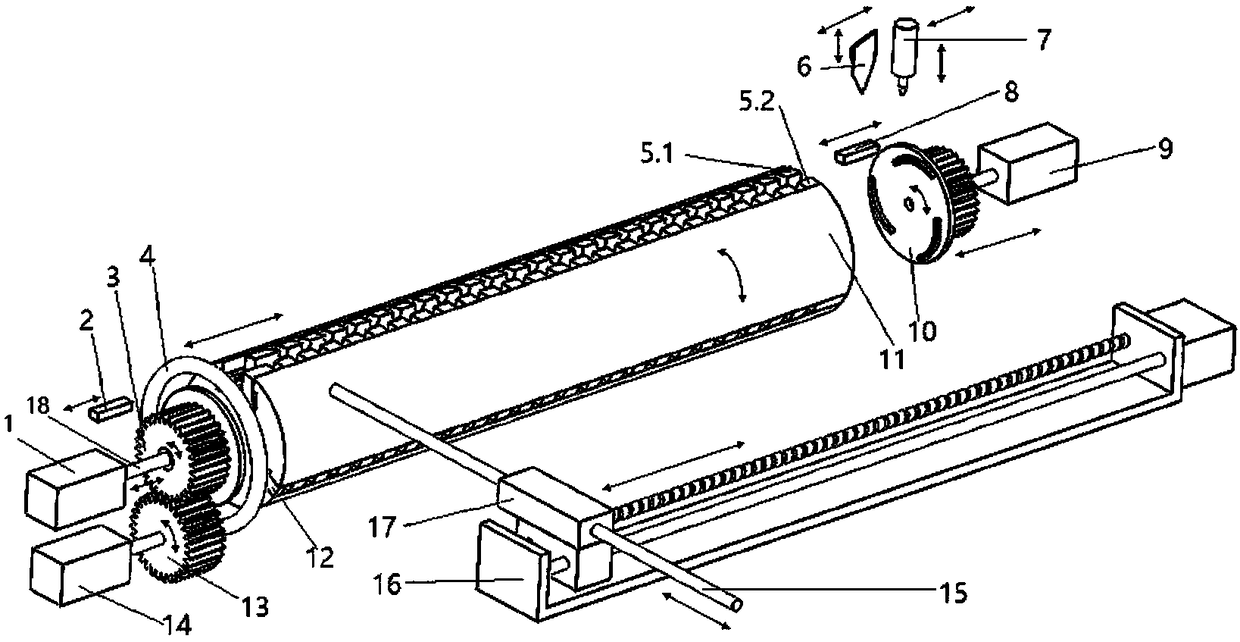

A desktop four-axis linkage fiber winding machine for grid structure forming

The invention provides a desktop type four-axis linkage fiber winding machine for molding a grid structure and relates to one fiber winding machine, aiming at solving the problems that an existing winding machine cannot meet winding of the grid structure and winding molding of a mini-type spacecraft component. The desktop type four-axis linkage fiber winding machine comprises a machine tool platform, a movable frame body, a frame body movement driving mechanism, a fiber rewinding mechanism, a yarn picking mechanism, a glue immersing mechanism, a retractable arm assembly, a silk nozzle assembly, a main shaft rotary part and an annular rib winding assembly; the frame body movement driving mechanism, the main shaft rotary part and the annular rib winding assembly are mounted on the machine tool platform; the main shaft rotary part is located between the frame body movement driving mechanism and the annular rib winding assembly; the movable frame body is mounted on the frame body movementdriving mechanism; the fiber rewinding mechanism, the yarn picking mechanism, the glue immersing mechanism, the retractable arm assembly and the silk nozzle assembly are mounted on the movable frame body. The desktop type four-axis linkage fiber winding machine belongs to the field of molding of composite materials.

Owner:HARBIN INST OF TECH

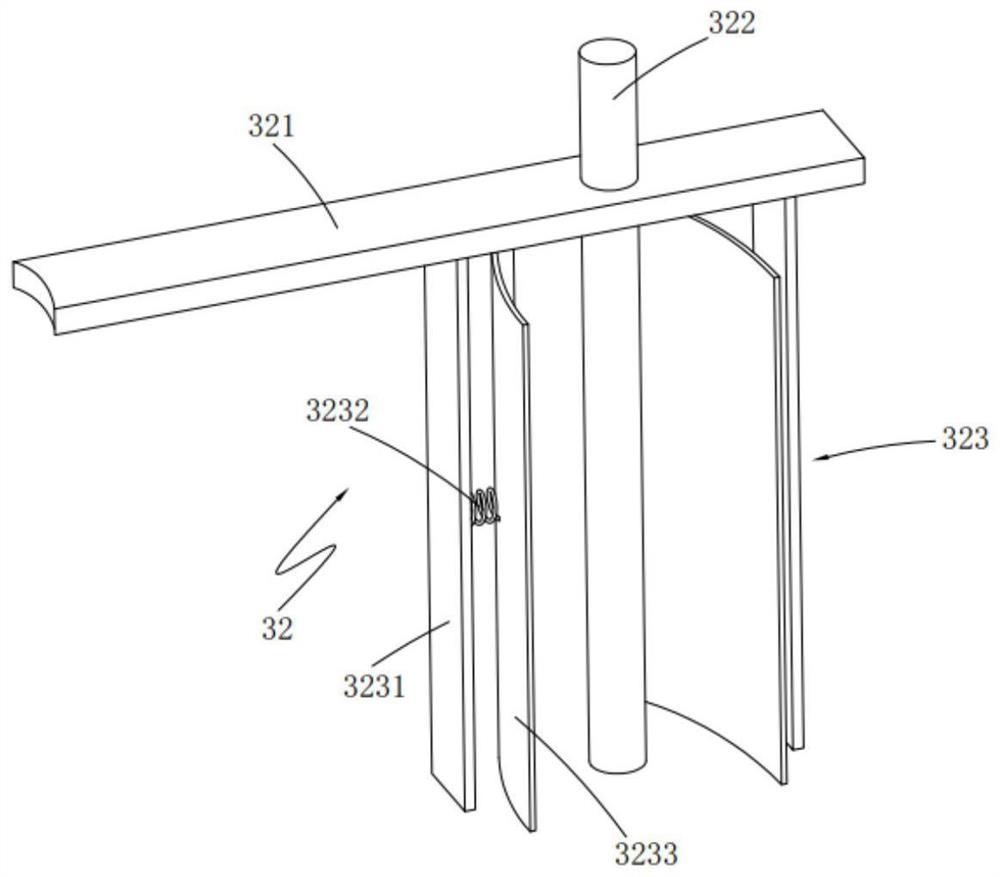

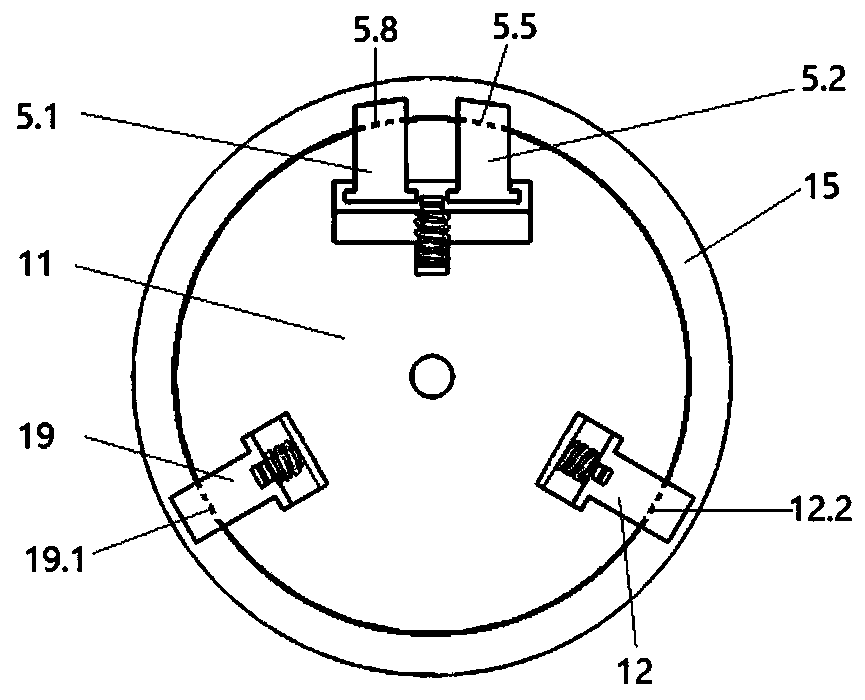

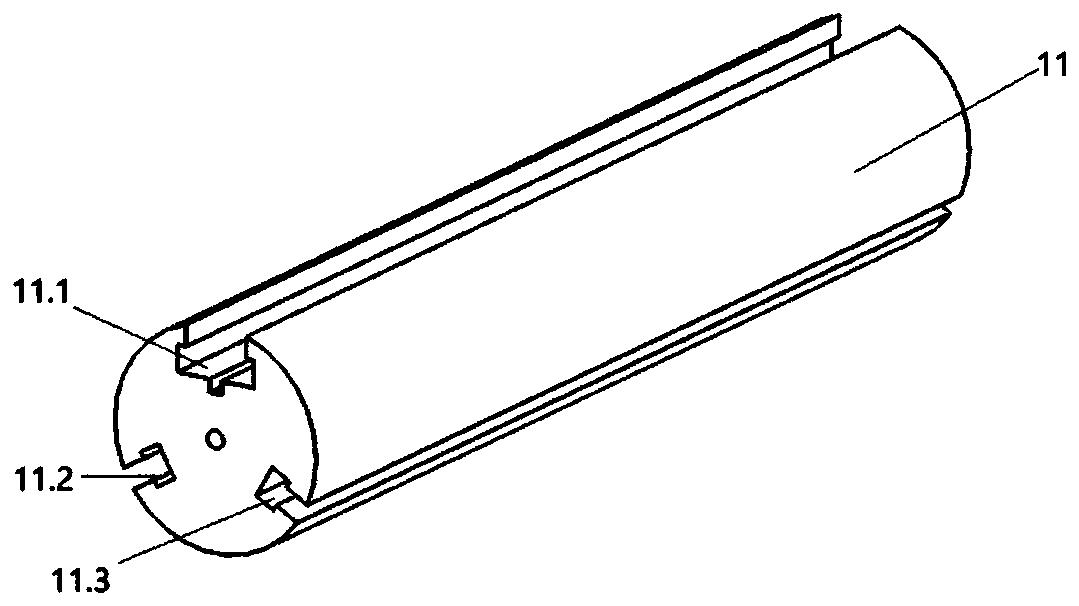

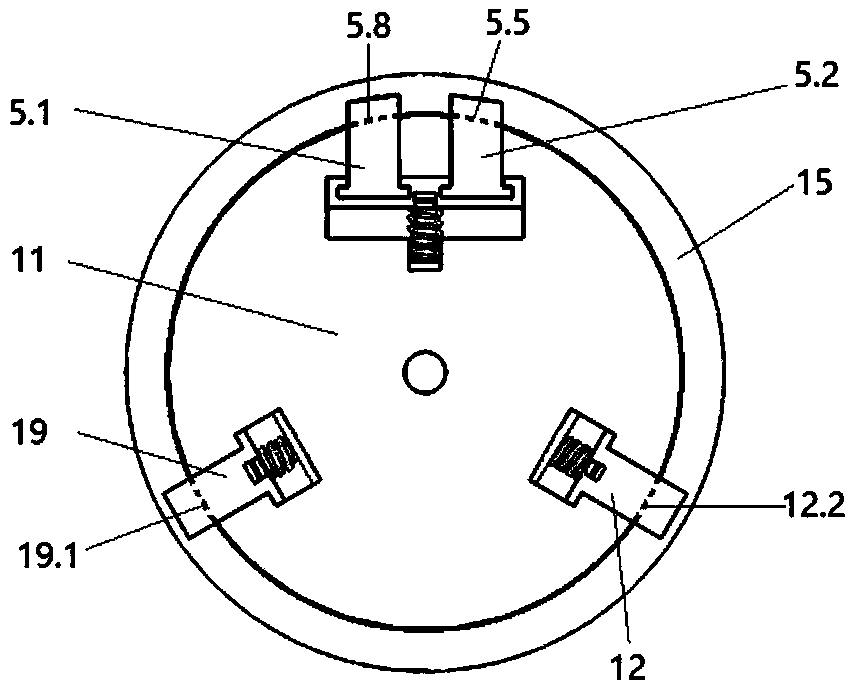

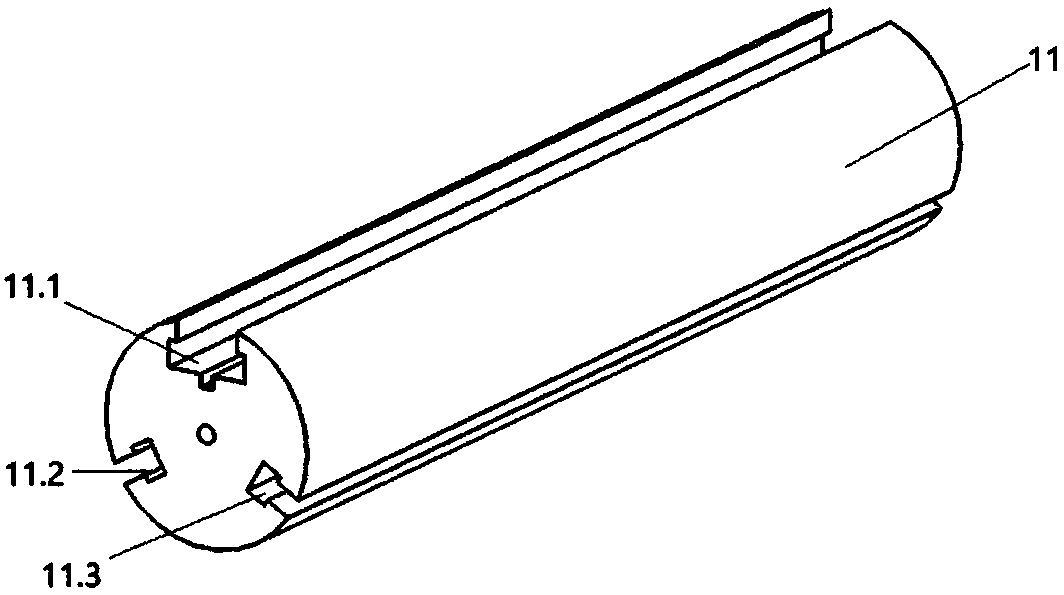

Automatic dislocation forming method for rubber hair ring

InactiveCN108145984BRealize automatic moldingIncrease productivityCurling devicesRubber ringDislocation

The invention discloses an automatic dislocation forming method of a rubber hair ring. A left molding strip (19), a right molding strip (12) and a combination molding strip are installed in a moldingcylinder. A plurality of notches being involved by a rubber line are arranged on the each molding strip, and a state switch mechanism drives the left molding strip, the right molding strip and the combination molding strip to extend and retract from a corresponding mounting groove. After the line is winded, a cutting mechanism cuts the rubber line, and at that time, the combination molding strip is misplaced so that the cut rubber line is misplaced at the disconnecting position of each circle. After misplacing, the rubber line is connected from the beginning to the end to form multiple rubberrings. A dispensing mechanism performs dispensing operations at the interface of the rubber ring. The automatic forming of rubber hair ring is realized, the production efficiency is high, and the product quality and the consistency are improved.

Owner:CHINA JILIANG UNIV

Inner cylinder wall forming machine

ActiveCN111001725BRealize automatic moldingSolve defects that are not suitable for transportationMetal-working feeding devicesOther manufacturing equipments/toolsMolding machineMechanical engineering

The invention belongs to the technical field of assembly and manufacturing, and specifically relates to an inner cylinder wall forming machine, which includes a hemming mechanism, a flipping mechanism, a buckle seam mechanism and a shaping mechanism, and the hemming mechanism is used to bend the two ends of a plane sheet into The V-shaped bayonet and the flat sheet are delivered to the turning mechanism, and the turning mechanism is used to turn the two ends of the flat sheet 180° respectively and make the two ends dock at the buckle mechanism, and the buckle mechanism is used for The two ends of the planar sheet are crimped and fixed so that the sheet is connected into an annular tube, and the shaping mechanism is used to roll the annular tube into a cylindrical shape. The invention integrates the rolling and seaming mechanism of cylindrical parts, and adjusts the processing sequence, that is, first seams and then shaping, which solves the defect that thin-walled parts are not suitable for transportation after rolling, and realizes thin-walled cylindrical parts. The automatic molding of parts simplifies the processing process and improves production efficiency.

Owner:长丰吾道智能光电科技有限公司

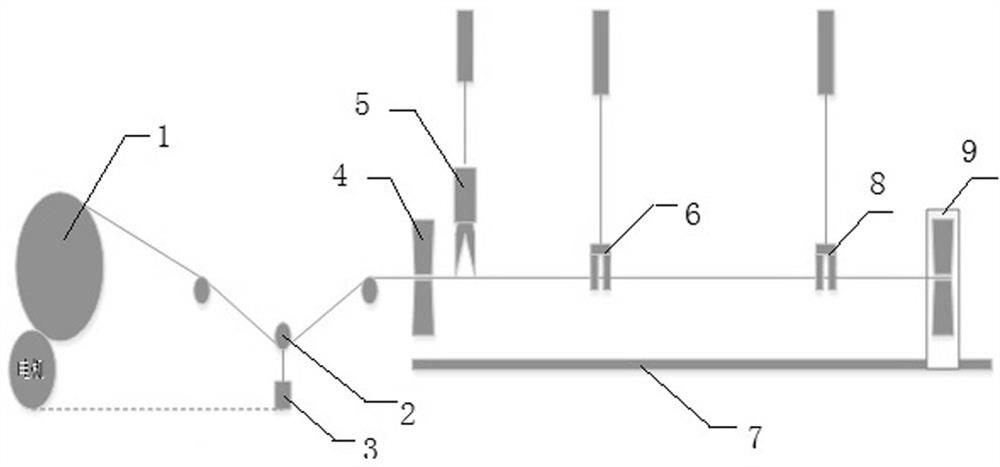

A bench type transformer lead wire intelligent production system and its working method

ActiveCN111370213BRealize automatic pay-offQuantitativeLine/current collector detailsInductances/transformers/magnets manufactureTransformerWire cutting

The invention proposes a bench type transformer lead wire intelligent production system and its working method, including an automatic wire cutting mechanism, a cable shaping mechanism, a pneumatic stripping machine and a pneumatic crimping machine, and the automatic wire cutting mechanism cuts the cables according to specifications After completion, it is sent to the cable shaping mechanism for bending and shaping processing. The cable after bending and shaping in the cable shaping mechanism is sent to the pneumatic stripping machine for peeling treatment. The automatic wire cutting mechanism is connected with the control cabinet, and the control cabinet is connected with the upper computer. connect. The present invention as a whole adopts quantitative and fixed-length cutting of cables and automatic rapid shaping of cables, so that the production efficiency of the whole set of cables is high, labor intensity is reduced, and an intelligent assembly line operation mode is realized as a whole.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +1

Automated production and processing methods for handicrafts

ActiveCN112455142BRealize automatic moldingImprove molding efficiencySpecial ornamental structuresWood working apparatusElastomerPositioning equipment

Owner:合肥迈亚家具有限公司

Shielding mechanism and its assembly for rainproof and low wind resistance of electric vehicle

ActiveCN113212611BAvoid the problem of inconvenient removalRealize automatic moldingWeather guardsGear wheelEngineering

The invention discloses a shielding mechanism for rainproof and low wind resistance of an electric vehicle and its assembly, including a protection assembly, a limit drive assembly, a fixing assembly, a restraint mechanism, an extension assembly and a joint mechanism. The protection assembly includes a sealed shell and is installed on the The guide piece in the outer notch of the sealed casing, the limit drive assembly includes a screw rod that is movably installed in the outer straight cylinder of the sealed casing, and the fixed assembly includes a base. By setting the inner shaft, and fixing two backing plates at both ends of the inner shaft, and setting gears on the outside of the backing plate, and using the backing plate to connect multiple sets of buckles and deflectors connected by cross bars, when rainy weather occurs At the same time, the user controls the servo motor to drive the chain, and drives the rotation of the screw rod to control the buckle and the backing plate to extend in a semicircle to the outside, so that the awning can be unfolded quickly, and the installation of the existing electric vehicle is avoided. The problem of inconvenient removal behind the awning.

Owner:徐州乐生车业有限公司

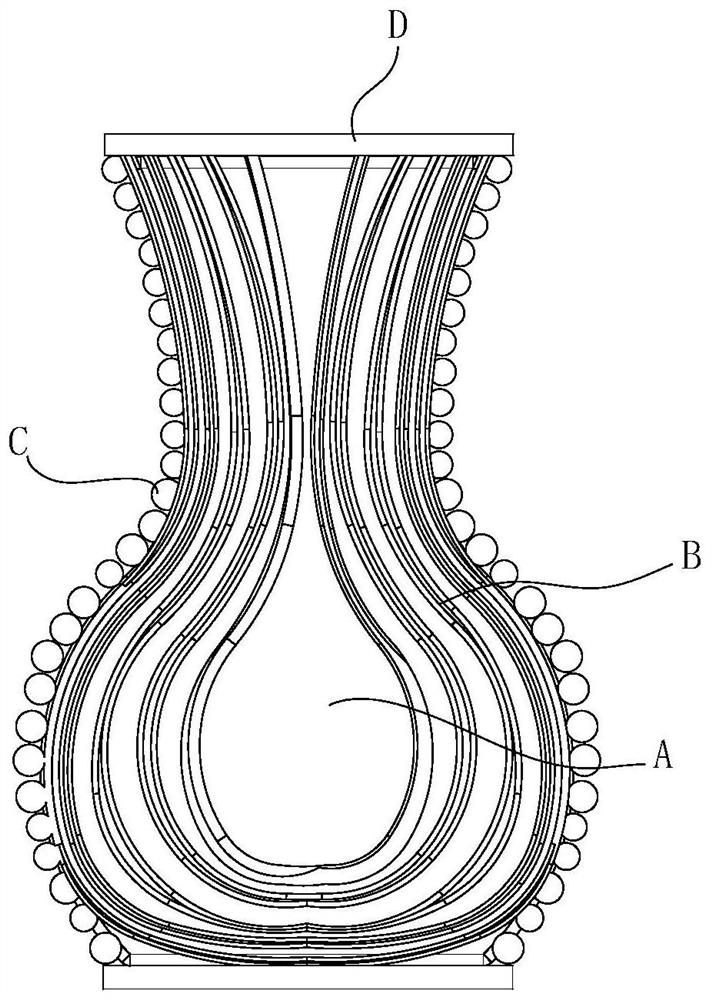

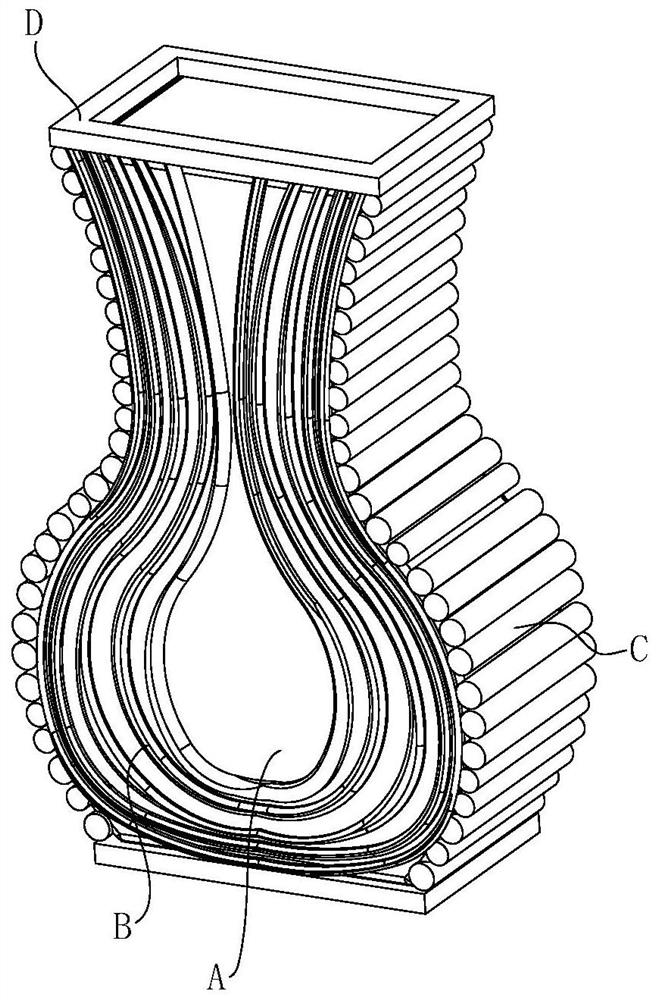

Negative curvature composite material grid structural member and forming method thereof

PendingCN114311728ASolve the problem of automatic moldingBreak the cycleDomestic articlesStructural engineeringRocket

The invention discloses a forming method of a negative-curvature composite material grid structural member, which comprises the following steps of: laying prepreg filaments for forming negative-curvature grid ribs in a grid mold, breaking the prepreg filaments in a node area when the prepreg filaments are laid, scattering the tail ends of the prepreg filaments, laying the prepreg filaments to an adjacent area of a negative-curvature grid, and alternately laying the prepreg filaments and prepreg for forming an end frame, so as to form the negative-curvature composite material grid structural member. The application range of the grid structure is expanded from a simple rotation structure to a rotation-like complex surface, the limitation of bridging and periodicity of an existing forming process is broken through, and automatic forming of the negative curvature grid structure with negative curvature and non-periodicity can be achieved. The invention further discloses the negative-curvature composite material grid structural part obtained through the forming method based on the negative-curvature composite material grid structural part. The negative-curvature composite material grid structural part can be applied to research and production of spaceflight rocket body grid cabin sections, aircraft fuselages, wings and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Handicraft automatic production and processing system

ActiveCN112549839BRealize automatic moldingImprove molding efficiencyOrnamental structuresSpecial ornamental structuresElastomerMachining system

The invention relates to an automatic production and processing system for handicrafts, comprising elastomer feeding equipment, the outlet of the elastomer feeding equipment is connected with the inlet of the elastomer molding equipment, and the outlet of the elastomer molding equipment is connected to the blank The feed port of the body positioning equipment is connected. The elastic body forming equipment is used to export the connected elastic body to the position on both sides of the green body in the green body positioning device and fix it. The side of the green body positioning device is also The end cap feeding equipment is provided, and the end cap feeding equipment is used to export the end caps to the positions at both ends of the green body and implement fixation with both ends of the green body and the elastic body. This molding system can effectively improve the quality of this type of handicraft. Molding efficiency.

Owner:合肥迈亚家具有限公司

A kind of barrel forming method

ActiveCN110947838BSolve defects that are not suitable for transportationRealize automatic moldingMetal-working feeding devicesOther manufacturing equipments/toolsMetal stripsPlane sheet

Owner:长丰吾道智能光电科技有限公司

Automatic artware forming method

ActiveCN112477496ARealize automatic moldingImprove molding efficiencySpecial ornamental structuresCane mechanical workingElastomerStructural engineering

The invention relates to an automatic artware forming method. The method comprises the following steps of leading out a green body feeding belt to a position above a positioning plate of green body positioning equipment, enabling a single green body to be close to a forming plate of elastic body forming equipment, and implementing straightening operation on elastic bodies on an arrangement rollerby utilizing a straightening mechanism arranged on the arrangement roller; guiding the elastic bodies guided out from an outlet of an arrangement plate to the position between the forming plate and aforming pressing plate of the elastic body forming equipment; enabling the outer contours of the bent elastic bodies to be matched with the outer contours of the two sides of a bottled blank above a positioning plate of blank positioning equipment; enabling fixing gun nail heads of fixing equipment to move at intervals in the circumferential direction of the outer contour of one side of the blankbody, guiding out the fixing gun nail heads and ejecting the fixing gun nail heads to one side of the elastic body and the blank body; and guiding the green bodies on the positioning plate of the green body positioning equipment to the feeding belt of end cover feeding equipment, and starting an end cover guiding-out head and an end cover fixing head of the end cover feeding equipment to fix the end cover and the two ends of the green body so as to finish the production of the whole artware.

Owner:合肥迈亚家具有限公司

Electromagnetic rubber hair ring automatic forming device

InactiveCN108127930BRealize automatic moldingIncrease productivityDomestic articlesRubber ringMechanical engineering

The invention discloses an electromagnetic rubber hair band automatic forming device. The device comprises a thread outlet mechanism, a forming drum, a status switching mechanism, a cutting mechanismand a glue dispensing mechanism. A left side forming strip, a right side forming strip and a combined forming strip are mounted in the forming drum. An electromagnet is arranged in the forming drum. Aplurality of notches allowing rubber threads to be wound therein are formed in each forming strip. The electromagnet drives the left side forming strip, the right side forming strip and the combinedforming strip to stretch out of and retract from corresponding mounting grooves. After thread winding is completed, the cutting mechanism cuts the rubber threads, at this time, the combined forming strip is staggered, the broken position of each ring of the cut rubber threads is staggered, the staggered rubber threads are connected end to end, and a plurality of rubber bands are formed; and the glue dispensing mechanism is used for performing glue dispensing work at joints of the rubber bands. According to the electromagnetic rubber hair band automatic forming device, the rubber hair bands canbe automatically formed, the production efficiency is high, and the product quality and consistency are improved.

Owner:CHINA JILIANG UNIV

A kind of plaster molding process

ActiveCN112137887BRealize automatic moldingReduce manual laborPharmaceutical product form changeDomestic articlesPharmaceutical drugProcess engineering

The invention relates to the technical field of production of traditional Chinese medicines, in particular to a molding process of medicinal plasters, which includes step 1, a boiling process; Material process, the push rod pushes out the plaster slurry on the second rotating shaft; step five, forming process, the first cylinder drives the pressing part to press the base cloth, plaster slurry and film into shape; step six, output process, manually or mechanically Take out the traditional Chinese medicine paste from the top of the ring hoop; the present invention pours the plaster slurry in the brewing equipment into the water-cooled tank, and after the plaster slurry is gathered by the cooperation of the gathering component and the stirring component, the plaster slurry is squeezed by the cutting knife that moves at intervals. Cut into small parts and put them on the clamping assembly on the second conveying mechanism, convey the film to the molding station through the film feeding mechanism, and press and form the base cloth, plaster slurry and film by the molding mechanism, realizing the traditional Chinese medicine The automatic molding of stickers reduces the labor force.

Owner:安徽美邸康药业有限公司

Automatic dislocation forming method of rubber hair ring

InactiveCN108145984ARealize automatic moldingIncrease productivityCurling devicesRubber ringEngineering

The invention discloses an automatic dislocation forming method of a rubber hair ring. A left molding strip (19), a right molding strip (12) and a combination molding strip are installed in a moldingcylinder. A plurality of notches being involved by a rubber line are arranged on the each molding strip, and a state switch mechanism drives the left molding strip, the right molding strip and the combination molding strip to extend and retract from a corresponding mounting groove. After the line is winded, a cutting mechanism cuts the rubber line, and at that time, the combination molding strip is misplaced so that the cut rubber line is misplaced at the disconnecting position of each circle. After misplacing, the rubber line is connected from the beginning to the end to form multiple rubberrings. A dispensing mechanism performs dispensing operations at the interface of the rubber ring. The automatic forming of rubber hair ring is realized, the production efficiency is high, and the product quality and the consistency are improved.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com