A kind of barrel forming method

A forming method and the technology of the annular cylinder, applied in the direction of the feeding device, positioning device, storage device, etc., can solve the problems of inability to accurately locate and realize automatic transfer, and achieve the effect of simplifying the processing process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

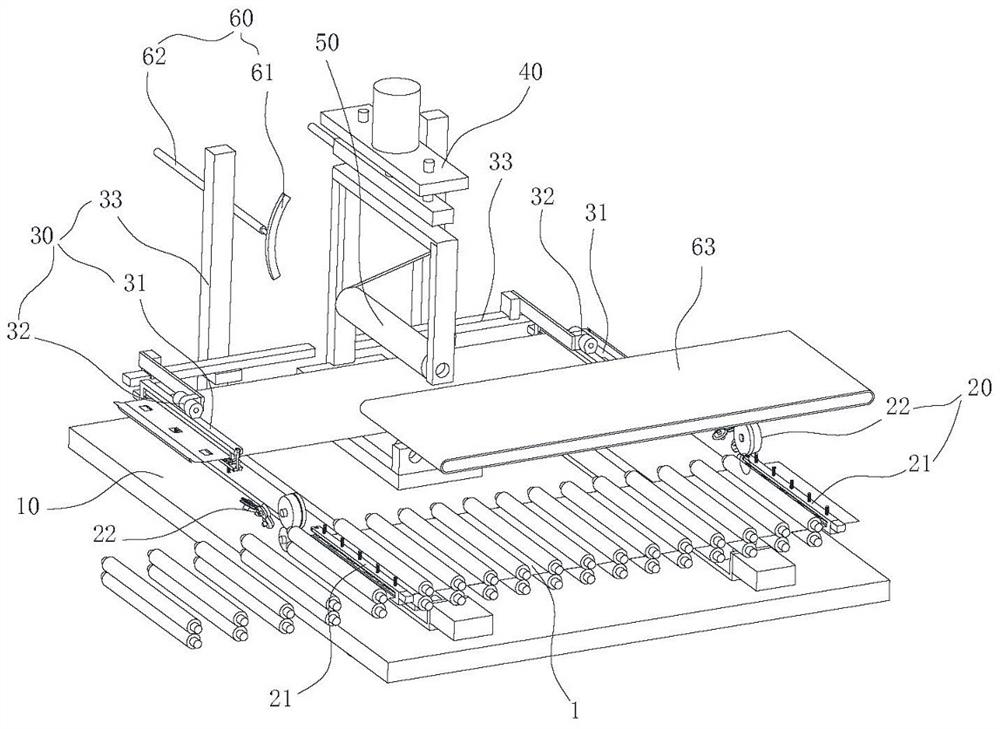

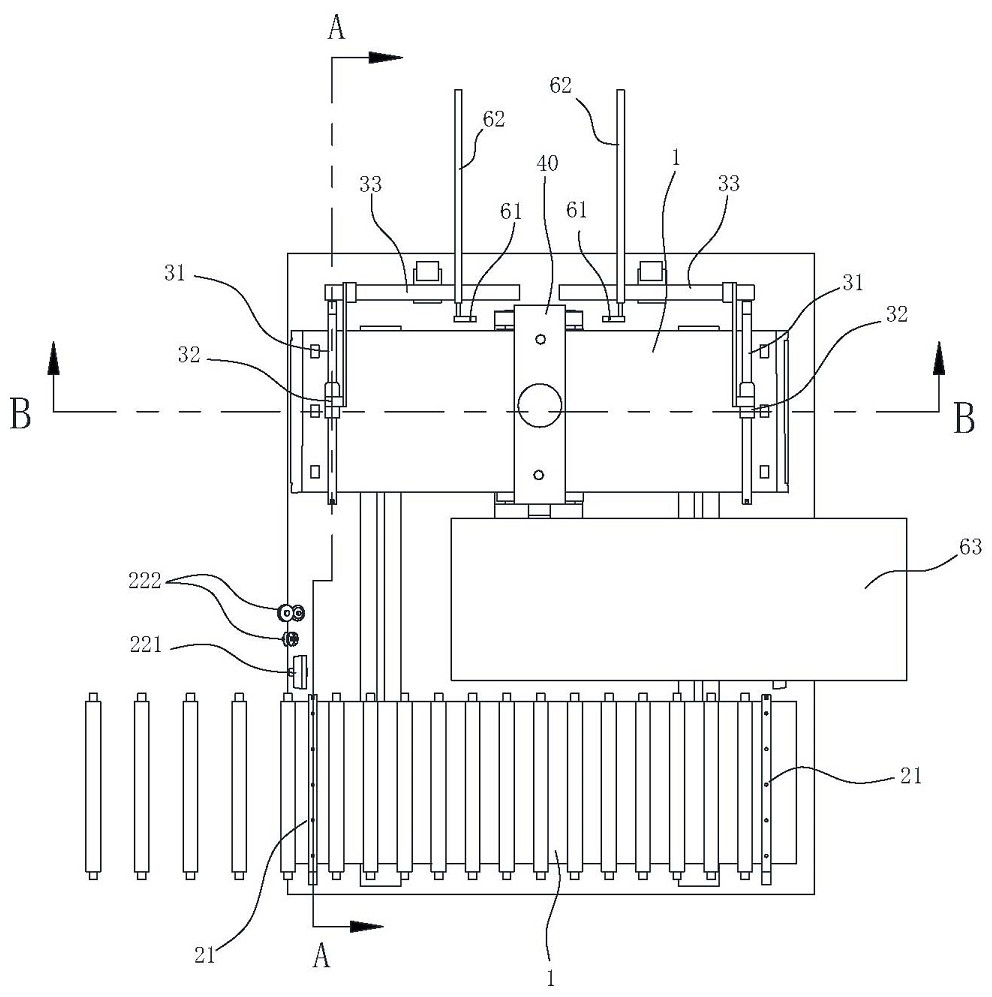

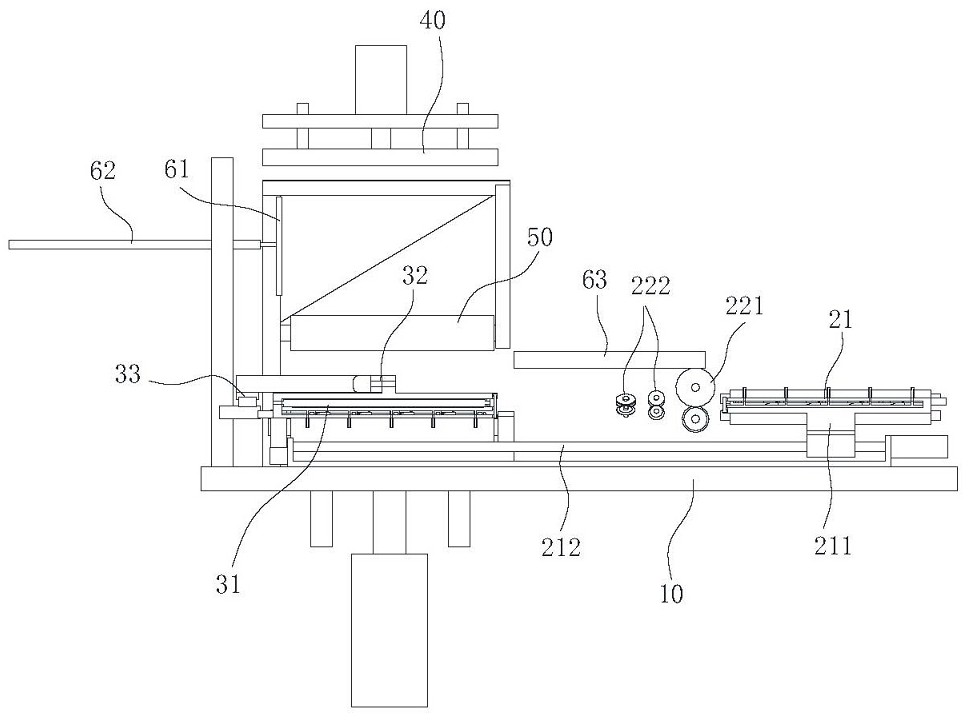

[0035]Such asfigure 1 ,2As shown, a laundry machine inner cylinder wall molding machine, including a folding mechanism 20, a flip mechanism 30, a buckle mechanism 40, and a shaping mechanism 50, which is used to bend two ends of the plane sheet 1 The V-shaped card opening and conveys the planar sheet 1 to the flip mechanism 30, the inverting mechanism 30 for flipping the both ends of the planar sheet 1 by 180 °, respectively, and at the seam sewing mechanism 40. The snug seam mechanism 40 is configured to secure the sheet 1 on both ends of the plane to a ring cylinder 2, the shaping mechanism 50 for pressing the annular cylindrical material 2 to cylindrical shape. The present invention integrates the roller press and buckle mechanism 40 of the cylindrical member, and adjusts the processing order, that is, after the seam is shaped, it is solved the deficiencies that the thin-walled parts roller pressure is not allowed to achieve thin wall cylinders. The automation of the part of the ...

Embodiment 2

[0047]A cartridge forming method for applying the above-described molding machine, including the steps of:

[0048]Step 1: Upset, cut the metal strip into a rectangular planar sheet 1;

[0049]Step 2: Criminalize, the uneven structure and mounting holes are stamped on the planar sheet 1 according to the design requirements;

[0050]Step 3: Fold, transport the planar sheet 1 to the folding mechanism 20, and use the flanged mechanism 20 to bend the V-shaped bay at both ends of the plane sheet 1;

[0051]Step 4: Turning, conveying the plane of the folded plane to the flip mechanism 30, using the flip mechanism 30 to flush 180 ° on both ends of the plane sheet 1, and transfer the V-shaped bay port of the end to the snug seam mechanism 40 Attack;

[0052]Step 5: Sewing, using the snug seam mechanism 40 to riveting the fastener area of the V-shaped bay, so that the plane sheet 1 is fixed to form a ring cylinder 2;

[0053]Step 6: Shape, release the flip mechanism 30, while clamping the ring cylinder 2 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com