Medicinal patch forming process

A molding process, a technology of drug stickers, which is applied in the direction of making drugs into special physical or taking forms of devices, other household appliances, household components, etc., and can solve problems such as labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

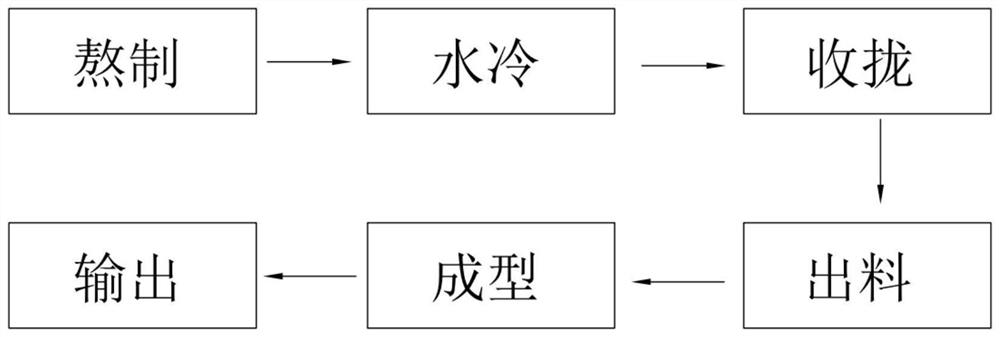

[0101] Such as figure 1 Shown, a kind of plaster molding process, it comprises the following steps:

[0102] Step 1, the boiling process, the traditional Chinese medicine is placed in the boiling equipment 2 to boil the plaster;

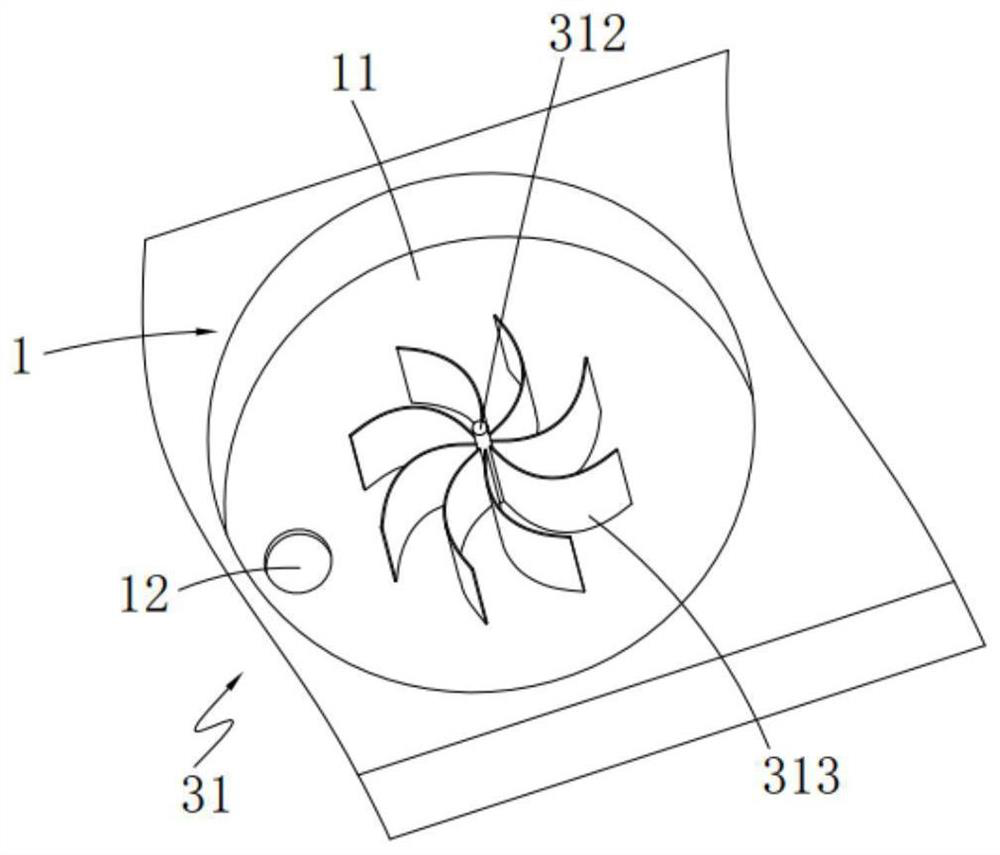

[0103]Step 2, water-cooling process, pour the plaster boiled in the brewing equipment 2 into the water-cooling tank 11, and the plaster is detoxified in the cold water in the water-cooling tank 11, and at the same time, the plaster is in the form of a plaster slurry in the water after cooling; Step 3, the folding process, the second driving member 314 drives the first rotating shaft 312 to rotate, and the agitating blade 313 stirs the plaster slurry, so that the plaster slurry continues to move in the water cooling tank 11, and at the same time, the second bracket 321 and the first rotating shaft The rotation direction of 312 is opposite, and the plaster slurry enters into the two gathering plates 3233, and the rotation of the second rotating shaft ...

Embodiment 2

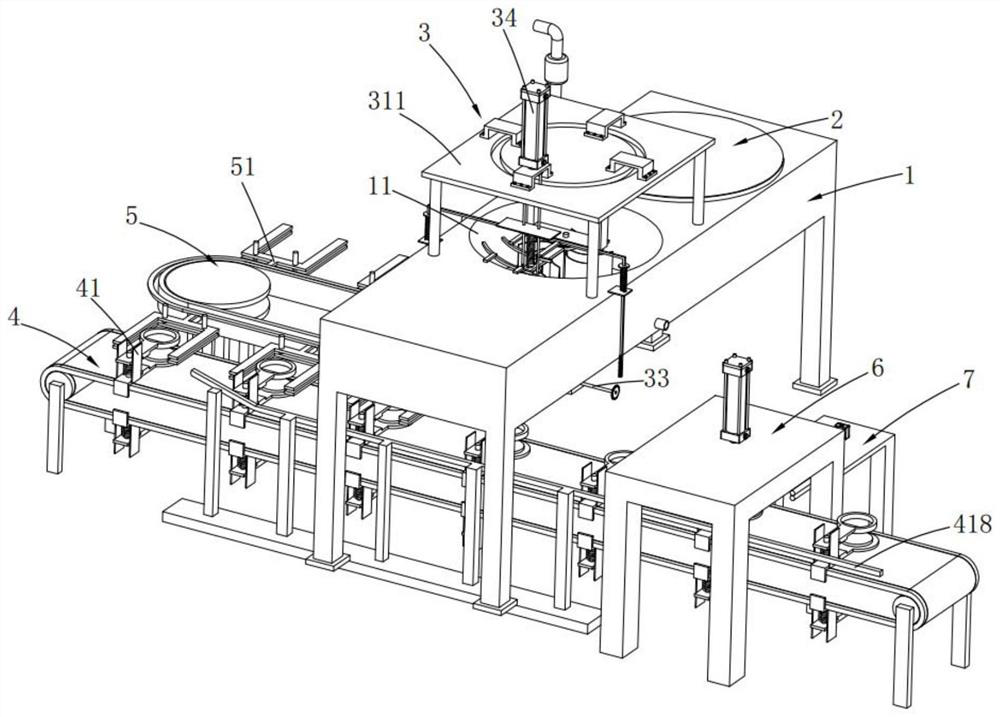

[0119] Such as figure 2 with 5 Shown, a kind of plaster molding process, it comprises;

[0120] A first base 1, the first base 1 is provided with a boiling equipment 2, the boiling equipment 2 boils the plaster slurry, and the first base 1 is provided with a water cooling tank 11;

[0121] Forming mechanism 3, the forming mechanism 3 includes a stirring assembly 31, a gathering assembly 32, a discharge assembly 33 and a first driving member 34, the stirring assembly 31 is rotatably arranged in the water cooling tank 11; the gathering assembly 32 and The direction of rotation of the agitating assembly 31 is opposite, and the gathering assembly 32 rotates to gather the plaster slurry; the discharging assembly 33 is arranged on the first base 1, and the position of the discharging assembly 33 corresponding to the gathering assembly 32 is the discharging station; the first driver 34 is located above the discharge station, and it drives the discharge assembly 33 to move;

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com