Forging method of large scale conical shell

A conical cylinder, large-scale technology, applied in the direction of metal processing equipment, etc., can solve the problems of large machining allowance and high manufacturing cost of forgings, and achieve the effect of simple steps, convenient and fast performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Each step of the forging method of the large-scale tapered cylinder body of the present invention can refer to Figure 1 to Figure 6 As shown, it includes the following steps:

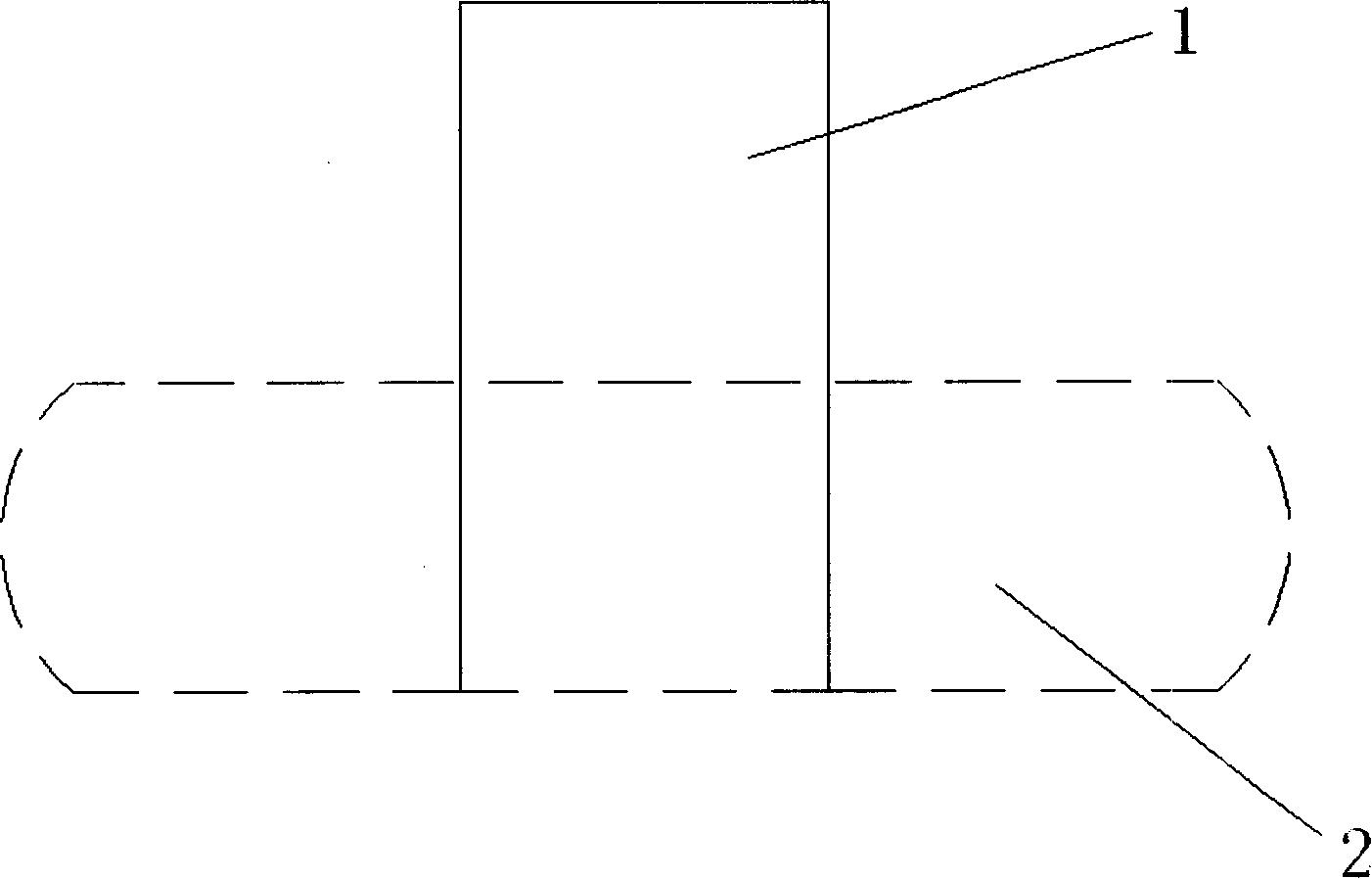

[0016] (1) Upsetting, processing the blank from a columnar shape 1 into a round cake shape 2, such as figure 1 shown;

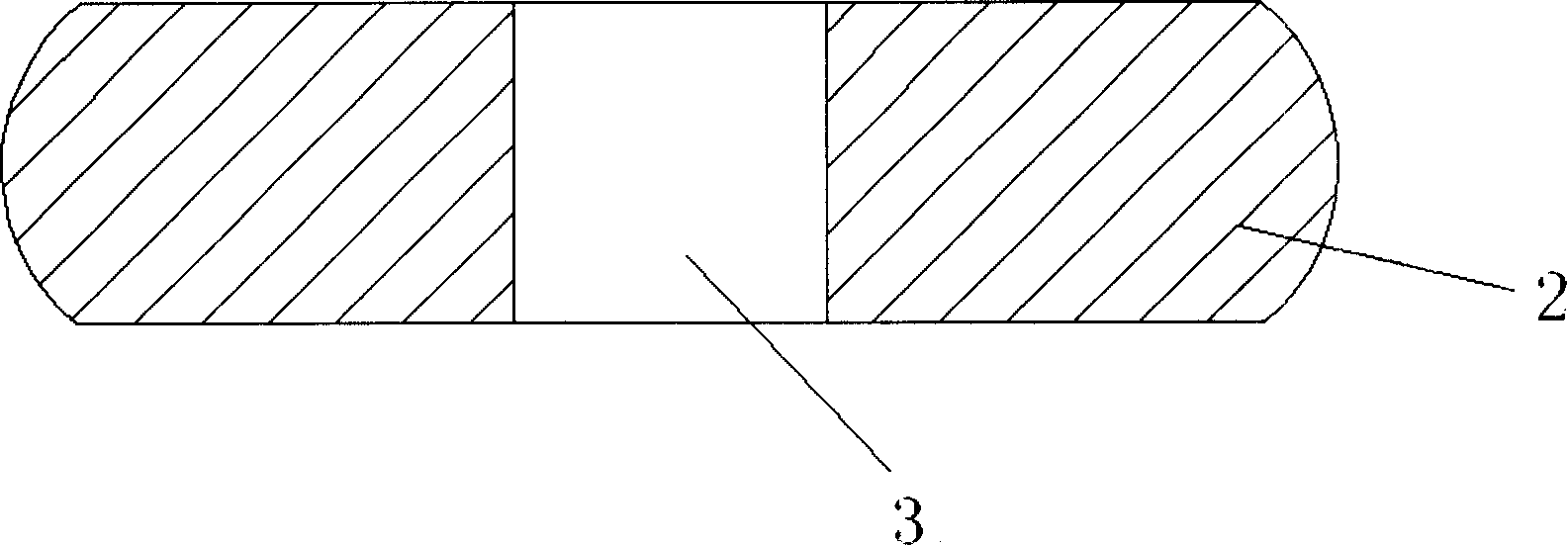

[0017] (2) Punch out a circular hole 3 in the center of the round cake-shaped blank 2, such as figure 2 shown;

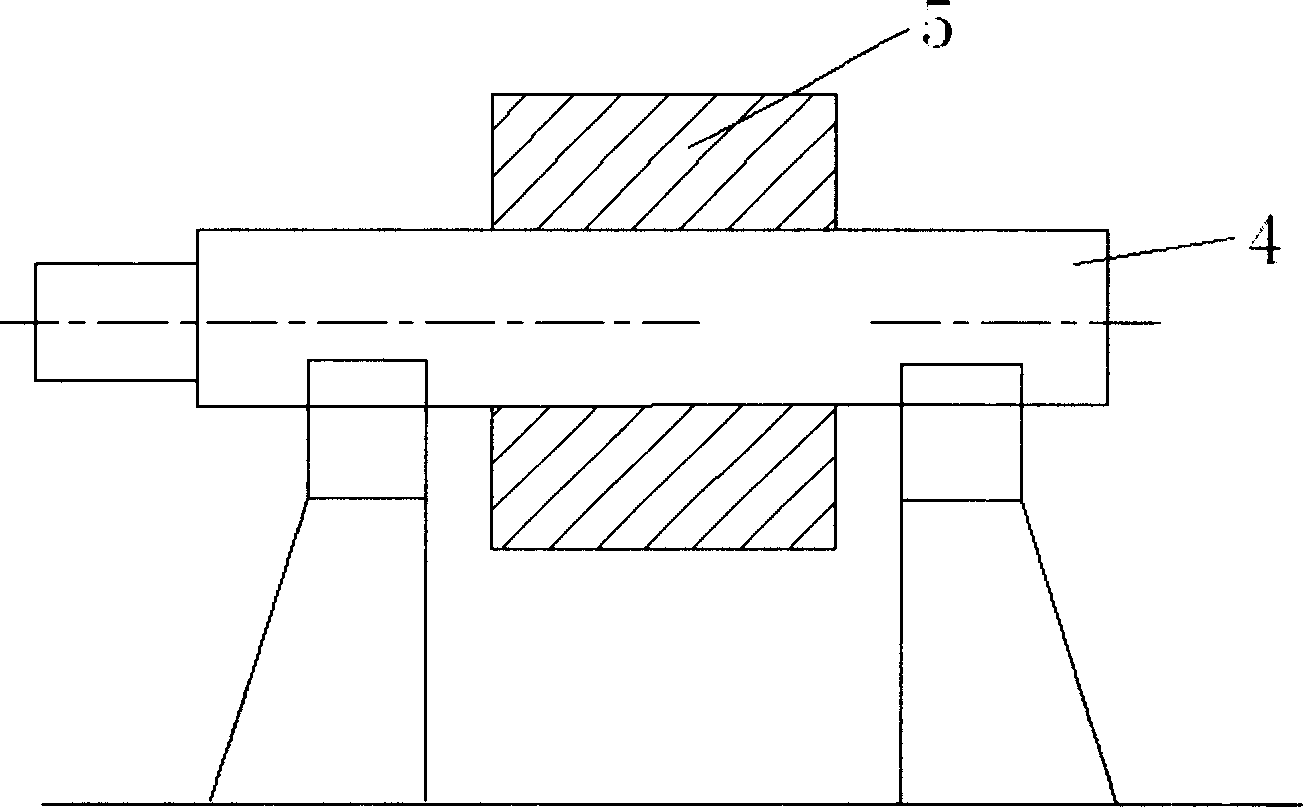

[0018] (3) A rotating shaft 4 is passed through the round hole of the blank, and the rotating shaft drives the blank to rotate, and at the same time, pressure is applied to the blank from the outer side of the blank, and the blank is processed into a cylindrical shape 5, such as image 3 shown;

[0019] (4) The rotating shaft drives the blank to rotate, and at the same time, pressure is applied to the blank from the outside of the blank, and the outside of the cylindrical blank is processed into a stepped blank 6, such as Figure 4 shown;

[0020] (5) The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com