Biomass waste residue squeezer

A squeeze dryer and biomass technology, applied in the field of biomass waste residue squeeze dryer, can solve the problems of low usable value and low water content, and achieve the effect of compact shape, unique structure, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

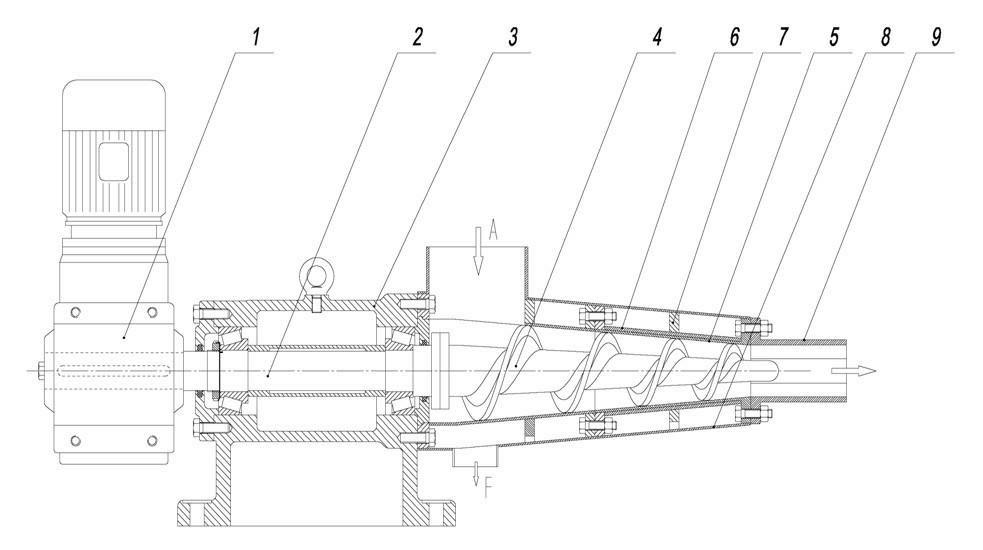

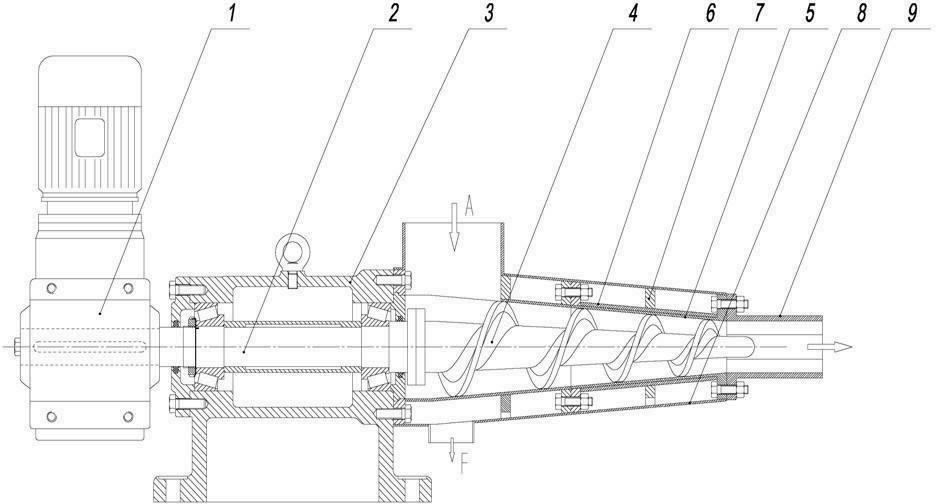

[0027] Attached below figure 1 And specific examples further illustrate the content of the present invention.

[0028] Such as figure 1 As shown, the biomass waste residue squeezer of the present invention has a power box 1, a transmission shaft 2, a bearing seat 3, a conical screw shaft 4, a filter screen cylinder 5, a lining cylinder 6, a rib frame 7, a casing 8 and Anti-slip cylinder 9 and other components, in which the filter cylinder, liner cylinder, ribbed frame and casing form a multi-layer combined conical casing, the inner layer of which is the filter cylinder, and the smaller filter holes are distributed in an orderly manner. The inner layer is a lining cylinder with larger filter holes, the second outer layer is a ribbed frame, and the outermost layer is a casing with a drain hole and no filter holes. The inner layer filter screen cylinder of the multi-layer combined conical casing and the second inner layer lining mesh cylinder are closely attached to each other,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com