Nano-fiber-based composite pervaporation membrane and preparation method thereof

A technology of nanofibers and pervaporation, applied in chemical instruments and methods, semi-permeable membrane separation, membranes, etc., can solve problems such as unfavorable polymerization of dense skin, damage to composite membrane structure, and difficulty in uniform deposition, achieving efficient and long-lasting organic solvents Effects of dehydration, enhanced stability, and enhanced separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

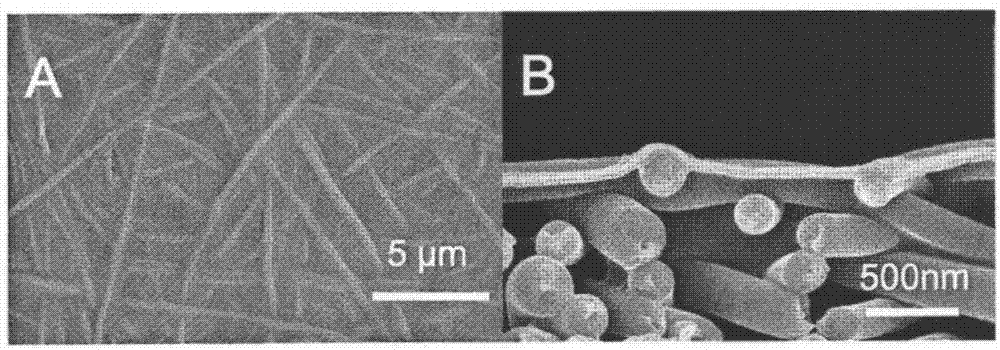

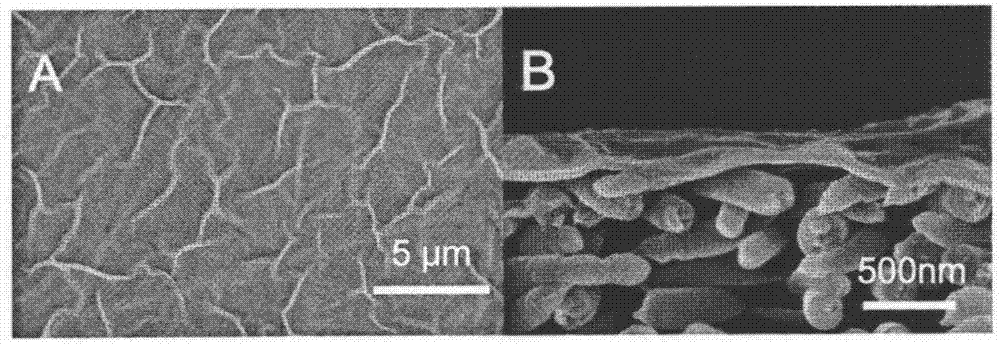

[0033] A nanofiber-based pervaporation composite membrane is composed of a base layer, an intermediate transition layer and a surface layer. The base layer is a nanofiber porous support layer, the intermediate transition layer is a modified graphene oxide layer, and the surface layer is an interface polymerization active separation layer. The thickness of the surface layer is 40nm.

[0034] The preparation method of the above-mentioned nanofiber-based pervaporation composite membrane is as follows:

[0035] (1) Polypropylene (PAN) (M w =120,000g / mol, Jinshan Petrochemical) 8g was dissolved in 92g of N,N-dimethylformamide (DMF) solvent, and stirred at 40°C for 6h to obtain a transparent and uniform electrospinning solution.

[0036] (2) Add the electrospinning solution in step (1) into the syringe, and extrude under the control of a micro-injection pump. The nozzle of the syringe is connected to the high-voltage positive electrode. The electrospinning parameters are controlled...

Embodiment 2

[0043] A nanofiber-based pervaporation composite membrane is composed of a base layer, an intermediate transition layer and a surface layer. The base layer is a nanofiber porous support layer, the intermediate transition layer is a modified graphene oxide layer, and the surface layer is an interface polymerization active separation layer. The thickness of the surface layer is 80nm.

[0044] The preparation method of the above-mentioned nanofiber-based pervaporation composite membrane is as follows:

[0045] (1) polyacrylonitrile (PAN) (M w =120,000g / mol, Jinshan Petrochemical) 8g was dissolved in N,N. dimethylformamide (DMF) solvent 92g, and stirred at 40°C for 6h to obtain a transparent and uniform electrospinning solution.

[0046] (2) Add the electrospinning solution in step (1) into the syringe, and extrude under the control of a micro-injection pump. The nozzle of the syringe is connected to the high-voltage positive electrode. The electrospinning parameters are controll...

Embodiment 3

[0053] A nanofiber-based pervaporation composite membrane is composed of a base layer, an intermediate transition layer and a surface layer. The base layer is a nanofiber porous support layer, the intermediate transition layer is a modified graphene oxide layer, and the surface layer is an interface polymerization active separation layer. The thickness of the surface layer is 60nm.

[0054] The preparation method of the above-mentioned nanofiber-based pervaporation composite membrane is as follows:

[0055] (1) polyacrylonitrile (PAN) (M w =120,000g / mol, Jinshan Petrochemical) 8g was dissolved in 92g of N,N-dimethylformamide (DMF) solvent, and stirred at 40°C for 6h to obtain a transparent and uniform electrospinning solution.

[0056] (2) Add the electrospinning solution in step (1) into the syringe, and extrude under the control of a micro-injection pump. The nozzle of the syringe is connected to the high-voltage positive electrode. The electrospinning parameters are contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com