Water-contained material pressing and dehydrating method and device

A dehydration device, press dehydration technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of long operation cycle, poor fluidity, low efficiency, etc., and achieve the effect of low-cost dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

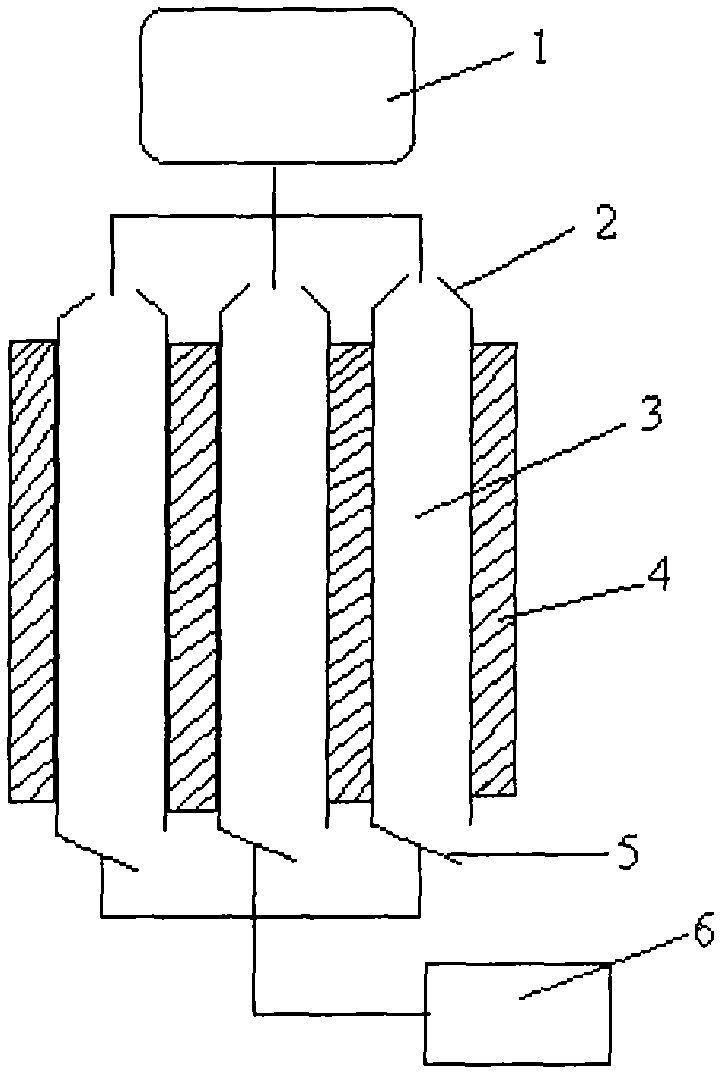

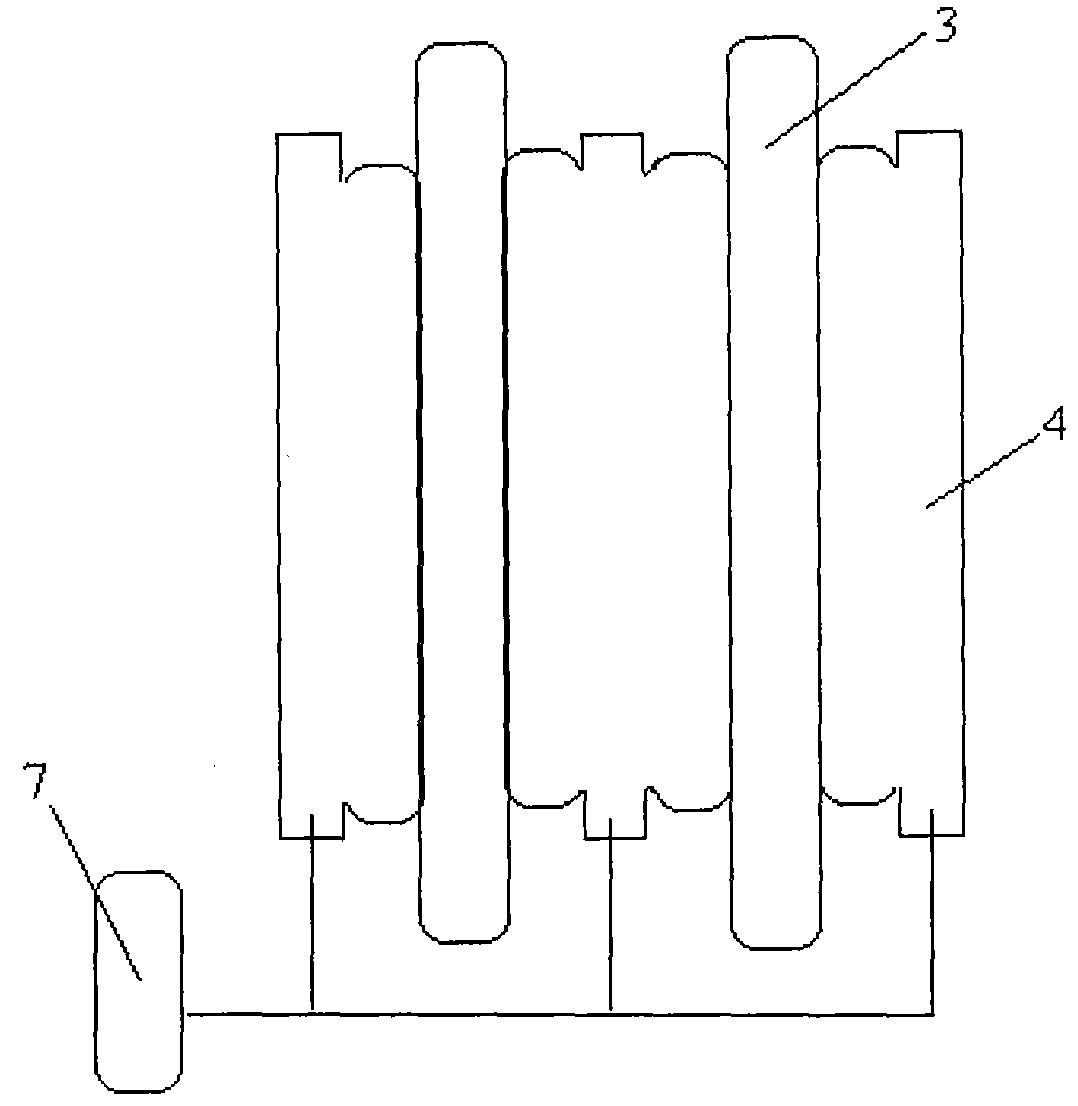

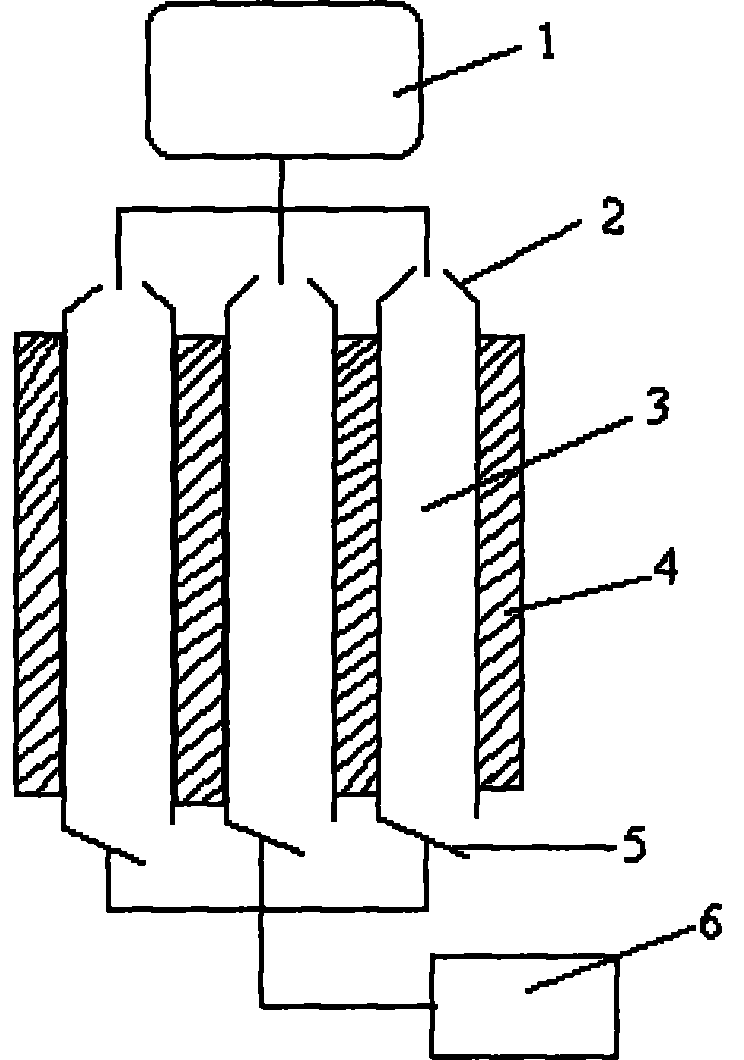

Embodiment 1

[0026] In this example, the sludge dehydrated by the belt dehydrator of the sewage treatment plant is squeezed and dehydrated. The moisture content of the initial sludge is 82%. After the sludge is tempered, the sludge is transported to all filter bags at the same time through a single screw pump and a multi-feeding device. The feeding process uses vibration to prevent material bridging. Before the sludge is conveyed, the opening and closing control device of the upper and lower openings of the filter bag will close the lower opening of the filter bag and open the upper opening. The sludge feeding time is controlled at 10 minutes. After the sludge is transported to the specified amount, the upper port of the filter bag is closed, and at the same time, the air compressor is turned on to pressurize the air bag in the filter bag pressurization mechanism, and the pressure is kept at 0.8MPa. Carry out press dehydration, and the dehydration time is controlled at 60 minutes. After t...

Embodiment 2

[0028] This example is the press dehydration of tapioca starch residue produced in the process of cassava starch processing. The initial moisture content of the cassava residue is 85%. The cassava residue is transported to all filter bags at the same time through the slurry pump and the multi-feed inlet device. The feeding process adopts a pressurized method to prevent the material from bridging. The feeding time is controlled at 5 minutes, the pressurizing mechanism of the filter bag adopts a water bag, the pressure is maintained at 1.0 MPa, the dehydration time is controlled at 90 minutes, and other operating procedures are the same as in Example 1.

Embodiment 3

[0030] This example is the press dehydration of distiller's grains and food residues. The initial moisture content of the distiller's grain residue is 80%, and the distiller's grain residue is conveyed to all filter bags at the same time through the feeding device. The feeding process adopts a combination of pressure and vibration to prevent material bridging. The feed time is controlled at 15min, the pressurizing mechanism adopts an air bag, the pressure is controlled at 0.6MPa, the dehydration time is controlled at 75min, and other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com