Novel multifunctional sludge treatment method with sterilization and dewatering functions

A technology of sludge treatment and a new method, which is applied in the directions of dehydration/drying/concentrated sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., which can solve the problems of complex operation equipment of sterilization technology, long preparation period of conditioning agent, Problems such as cumbersome operation steps, to achieve the effects of automatic processing, high virus removal effect, and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

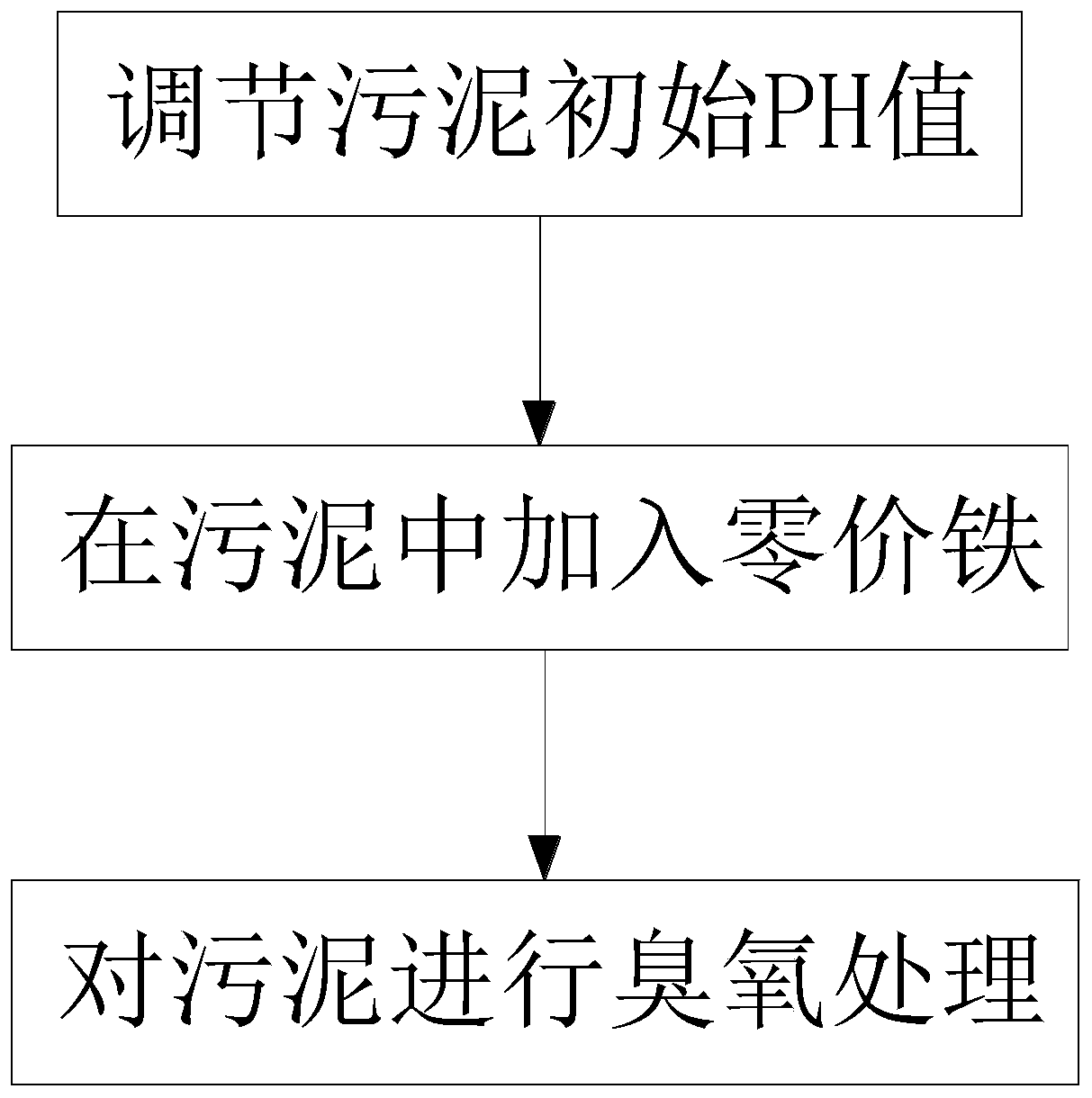

Method used

Image

Examples

Embodiment 1

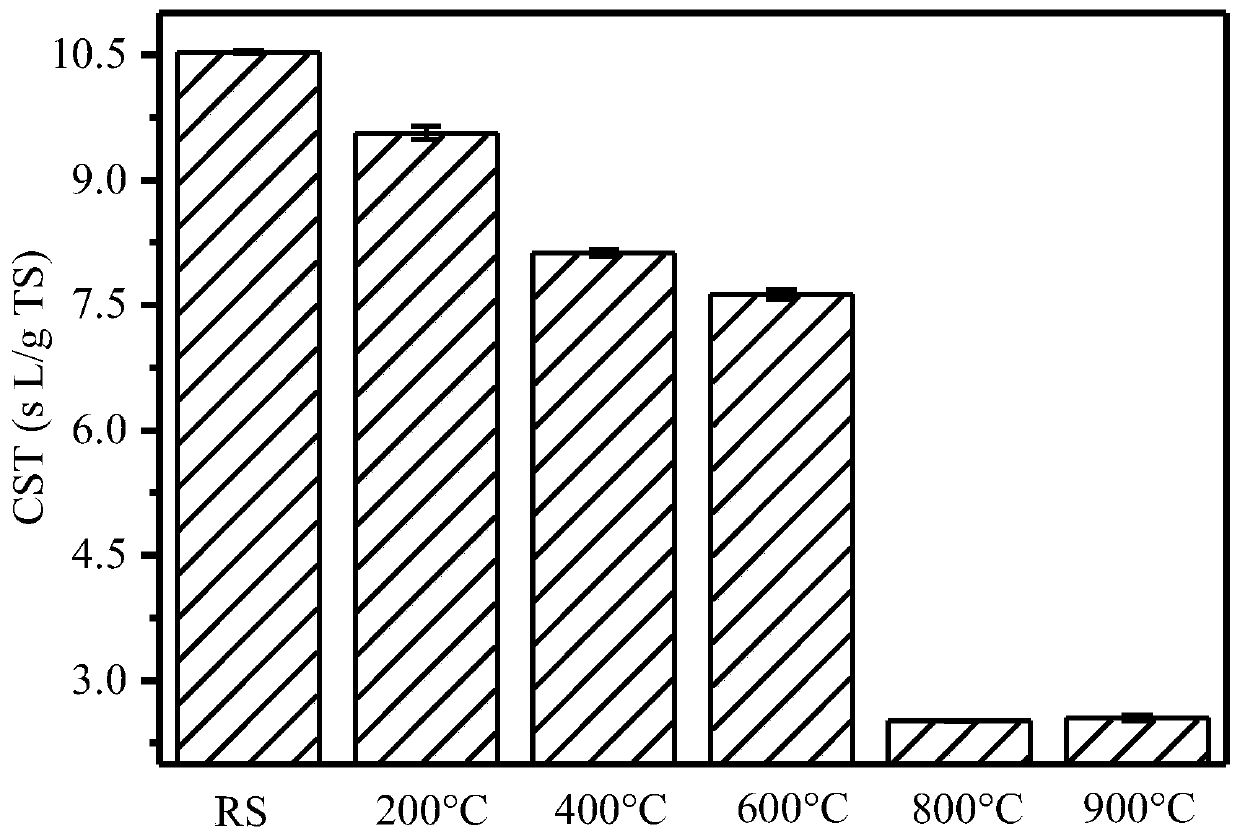

[0049] (1) Fenton agent (Fe 2+ of 110mg / g VS and H 2 o 2 of 88mg / g VS) and CaO (110mg / gVS) conditioned municipal sludge press-filtered, and the prepared dewatered cake was dried in an oven at 105°C and then crushed for later use.

[0050] (2) Take about 20g of crushed mud cake powder in a porcelain boat, push it into the heating area of the tube furnace, pass argon gas into the tube furnace, and discharge the remaining air in the tube to create an oxygen-free pyrolysis atmosphere. After reaching the set temperature (200-900°C), pyrolyze at a constant temperature for 60 minutes; after the pyrolysis is completed, cool to room temperature in an argon atmosphere, take it out, grind it with a mortar, and pass through a 100-mesh sieve to obtain the original mud, and store the raw mud in a brown wide-mouth reagent bottle for later use.

[0051] (3) Take 250mL of raw mud and put it into the reaction device, adjust the initial pH to 2, then add the iron-based catalyst prepared in ...

Embodiment 2

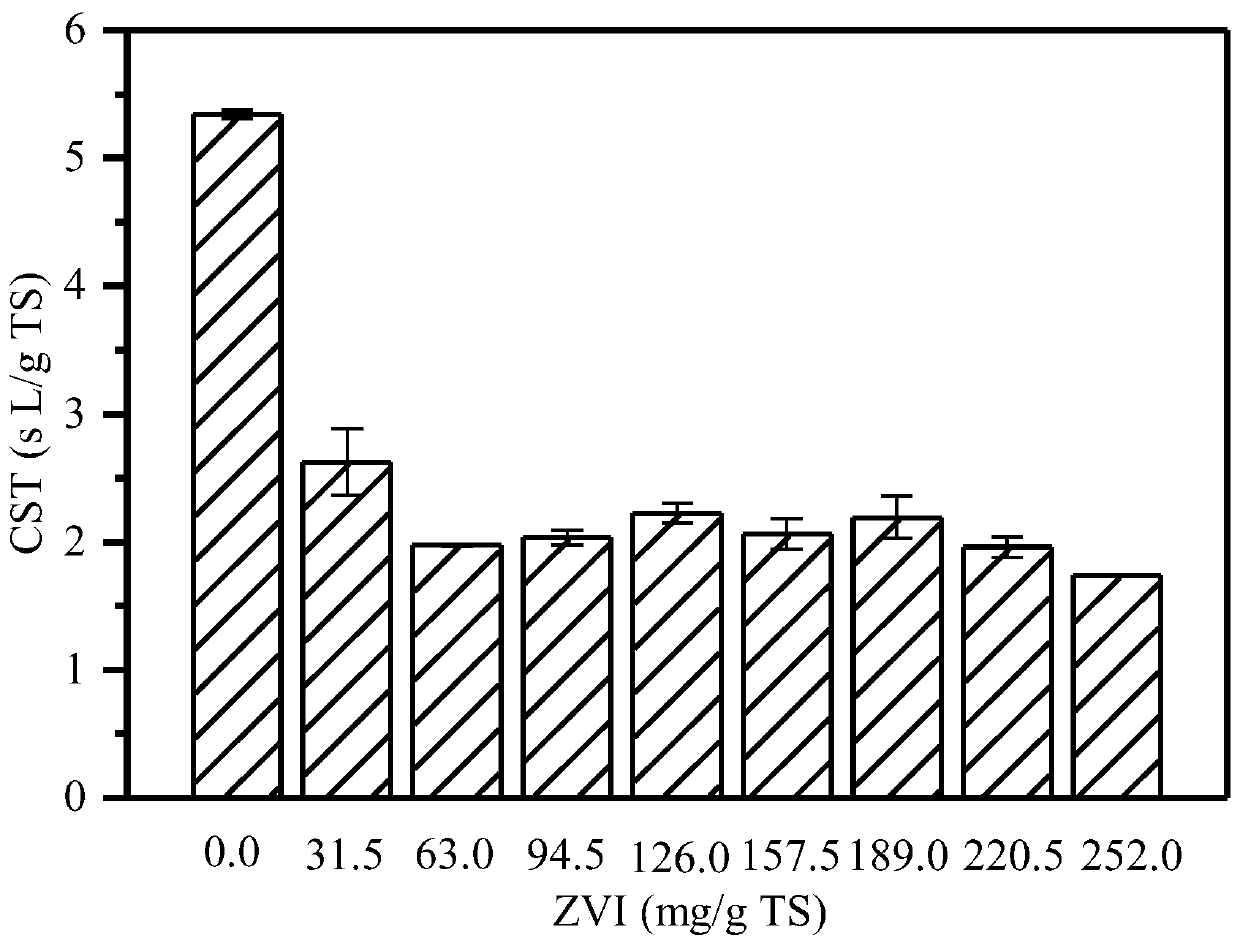

[0054] (1) Take 250mL raw mud and put it into the reaction device, adjust the initial pH to 2, then add 31.5-252mg / g TS zero-valent iron, stir and mix evenly with a glass rod, and finally pass 30mg O 3 / g TS ozone, the dosage of ozone is controlled by the reaction time, and the sum of stirring time and ozone ventilation time is controlled to be 20min.

[0055] From image 3 It can be seen from the figure that under acidification conditions, when no zero-valent iron is added, the CST value of the ozone-conditioned sludge is 5.34s L / g TS. When the dosage of zero-valent iron is 31.5mg / g TS, The CST of the sludge decreased to 2.62s L / g TS. As the dosage of zero-valent iron continued to increase, the CST of the sludge continued to decrease. When the dosage of zero-valent iron increased to 63mg / g TS , the CST of the sludge decreased to 1.97s L / g TS, and continued to increase the dosage of zero-valent iron, the CST of the sludge basically tended to be stable; it can be seen that aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com