Chemical conditioning method for improving dehydration property of surplus sludge

A technology for excess sludge and dewatering performance, applied in the field of resources and environment, can solve the problems of insufficient carbon source in sewage plants and unsatisfactory sludge dewatering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

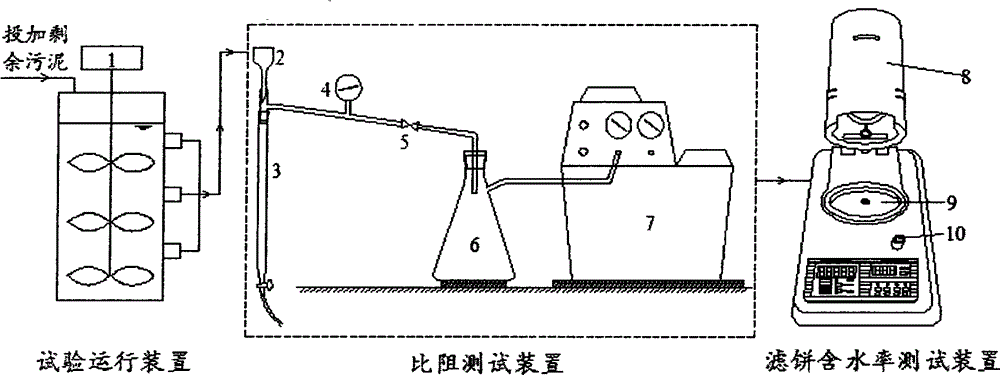

[0017] Take the excess sludge from a sewage treatment plant (using the multi-point water inflow A / O process) and return it to the sludge pump room, put it in the excess sludge hydrolysis acidification device, and control the stirring speed within the range of 70-90r / min (this When the remaining sludge can be stirred evenly but will not generate vortex), use 30% HCl and 20% NaOH solution to adjust the pH value, adjust once every 2h in the initial stage, and adjust once every 12h after stabilization. The sludge was adjusted to be acidic (pH=3.0) in the first 8 days, and the sludge was adjusted to be alkaline (pH=10.0) after sampling on the 8th day, and the reaction was carried out at room temperature for a total of 16 days. Take samples from the upper, middle and lower ports of the reactor, mix them evenly and measure the relevant indicators until the end of the reaction period. The specific resistance coefficient b is measured by the Buchner funnel method, and it is brought int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com