Using method of sour crude oil emulsion breaker

A technology of demulsifier and compound demulsifier, which is applied in the direction of dehydration/demulsification by chemical methods, which can solve the problems of not being able to achieve the ideal demulsification effect and the large amount of demulsifier used, so as to achieve improved dehydration effect, low cost and high degree of dehydration high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

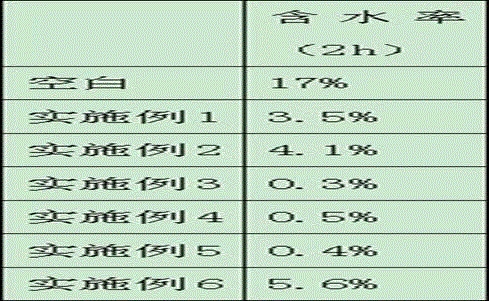

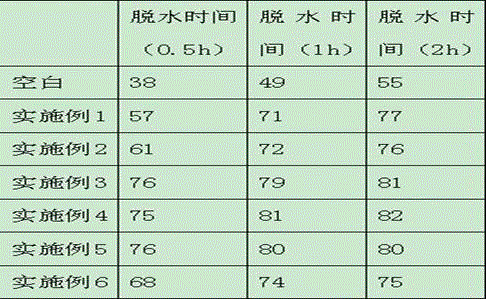

Embodiment 1

[0022] A method for using an acidic crude oil demulsifier, comprising:

[0023] Step 1, prepare crude oil composite demulsifier, the crude oil composite demulsifier includes 48-52wt% polyoxyethylene polyoxypropylene block polyether, 0.8-1.2wt% sodium cetyl sulfonate, 5-8wt% D-terpene, 10-15% by weight of C2-C6 carboxylic acid, and the rest is water.

[0024] The concrete preparation steps of described crude oil composite demulsifier are:

[0025] Step 1.1, adding C2-C6 carboxylic acid to water, and then adding sodium cetylsulfonate under stirring conditions to obtain a mixed solution;

[0026] Step 1.2, heating the mixed solution to 30-50°C, adding polyoxyethylene polyoxypropylene block polyether to the mixed solution during the heating process;

[0027] In step 1.3, after mixing evenly and when the temperature reaches 30-50°C, add D-terpene and mix evenly to make a demulsifier.

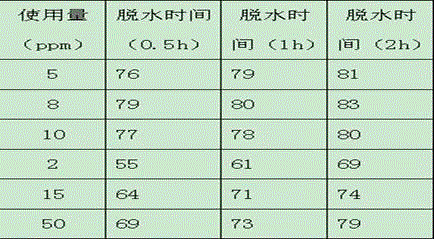

[0028] Step 2, adding the crude oil composite demulsifier into the crude oil in an amount of 5...

Embodiment 2

[0031] The difference between this example and Example 1 is that the C2-C6 carboxylic acid in this example is citric acid.

Embodiment 3

[0033] The difference between this example and Example 1 is that the C2-C6 carboxylic acid in this example is glutaric acid and citric acid with a weight ratio of 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com