Method for preparing poly aluminum ferric silicate composite flocculating agent by using red mud and ferrous sulfate

A polyaluminum-iron silicate and composite flocculant technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of short floc settling time, simple process and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

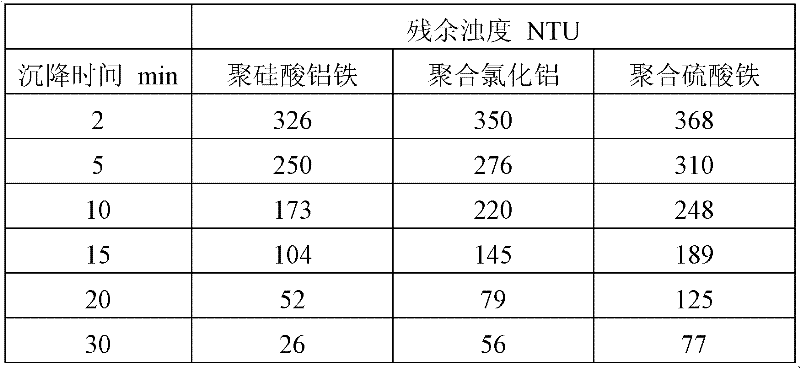

Examples

Embodiment 1

[0033] First crush the red mud to a particle size of 100 mesh, then weigh 1Kg of red mud, 1Kg of ferrous sulfate and 0.5Kg of soda ash and mix thoroughly, roast the above mixture at 900°C for 1 hour, cool naturally to room temperature, and then The roasted product is acid-leached with 25Kg of industrial hydrochloric acid with a volume ratio of 1:1 at 90°C for 2 hours with stirring, and finally the acid-leached product is centrifuged, and the filtrate is aged at room temperature for 1 hour to obtain polyaluminum iron silicate Composite flocculant, the product is stored for 3 months without gel.

Embodiment 2

[0035] First crush the red mud to a particle size of 200 mesh, then weigh 1.5Kg of red mud, 1.95Kg of ferrous sulfate and 1.2Kg of soda ash and mix them thoroughly, roast the above mixture at 800°C for 2 hours, and cool it down to room temperature naturally. Then the roasted product is acid-leached with 70Kg of industrial hydrochloric acid with a volume ratio of 1:1 at 60°C for 4 hours with stirring, and finally the acid-leached product is centrifuged, and the filtrate is aged at room temperature for 2 hours to obtain polysilicic acid. Aluminum-iron composite flocculant, the product has not gelled for 3 months.

Embodiment 3

[0037] First, crush the red mud to a particle size of 80 meshes, then weigh 2Kg of red mud, 2.4Kg of ferrous sulfate and 1.4Kg of soda ash and mix them thoroughly, roast the above mixture at 700°C for 2.5 hours, cool naturally to room temperature, and then The roasted product was acid-leached with 100Kg of industrial hydrochloric acid with a volume ratio of 1:1 at 80°C for 5 hours with stirring, and finally the acid-leached product was centrifuged, and the filtrate was aged at room temperature for 1 hour to obtain polyaluminum silicate Iron composite flocculant, the product has not gelled for 3 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com