Preparation method of 1-2-micron samarium oxide

A technology of samarium oxide and samarium chloride, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of time-consuming, cumbersome steps, high impurity content, etc., achieve short precipitation time, Good repeatability and uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

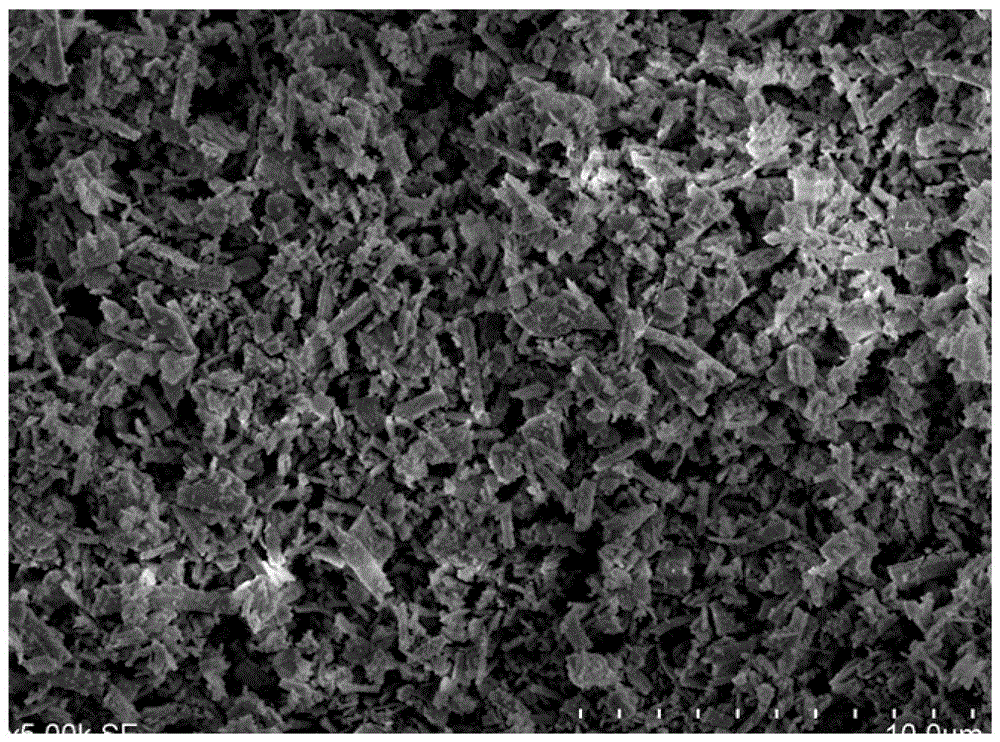

[0016] The samarium chloride solution has a concentration of 1.7 mol / L and a volume of 350 ml, and the pH is adjusted to be 2 with ammonia water with a concentration of 28% by mass. The concentration of oxalic acid was 1 mol / L, 5.3 g of polyethylene glycol was added, and the pH was adjusted to 4 with 28% aqueous ammonia. Control the molar ratio of oxalic acid to samarium chloride solution to be 1.8:1. Keep the temperature at 50°C, and add the previously treated samarium chloride solution into the oxalic acid solution for 10 minutes. Filter and wash. Incubate at 900°C for 2 hours, detect D 50 =1.26μm. Fe 2 o 3 (μg / g)=4.06ppm, SiO 2 (μg / g) - (μg / g) = 300ppm. The total amount of rare earth oxides is 99.05%. Scanning electron microscope picture as figure 1 .

Embodiment 2

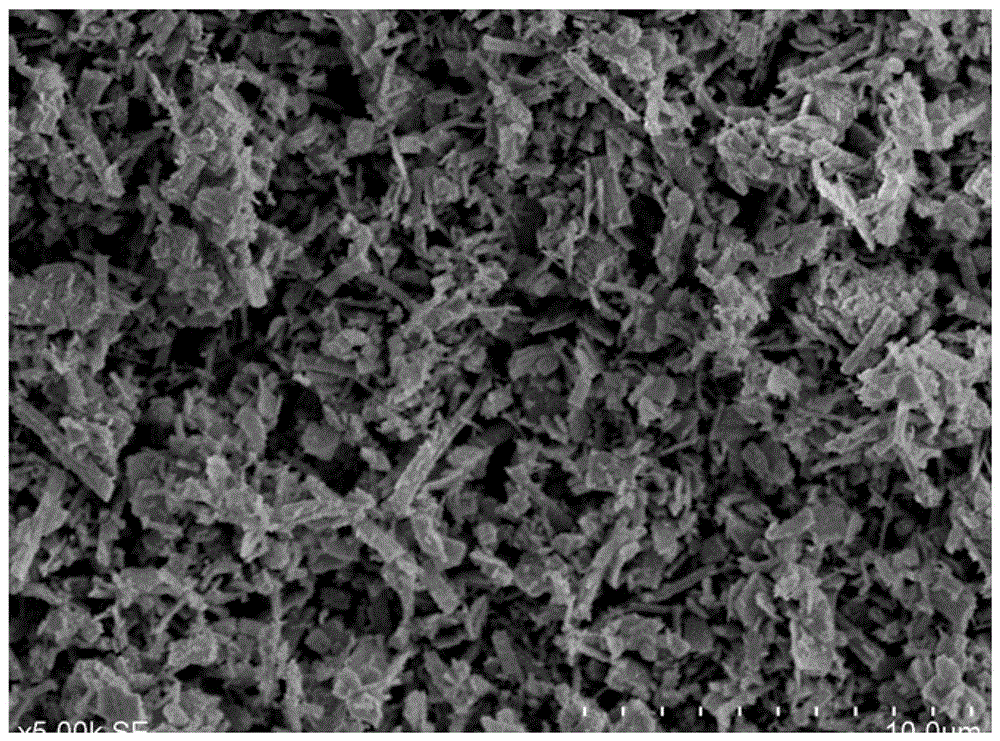

[0018] The samarium chloride solution has a concentration of 1.3 mol / L and a volume of 100 ml, and the pH is adjusted to be 2 with ammonia water with a mass percent concentration of 28%. The concentration of oxalic acid was 1.5 mol / L, 1.8 g of polyethylene glycol was added, and the pH was adjusted to 5 with 28% aqueous ammonia. Control the molar ratio of oxalic acid to samarium chloride solution to be 1.8:1. Keep the temperature at 40°C, and add the previously treated samarium chloride solution into the oxalic acid solution for 5 minutes. Filter and wash. Incubate at 1000°C for 2 hours, detect D 50 =1.19 μm. Fe 2 o 3 (μg / g)=6.4ppm, SiO 2 (μg / g) - (μg / g) = 180ppm. The total amount of rare earth oxides is 99.5%. Scanning electron microscope picture as figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com