Hexavalent chromium-containing waste water treatment method

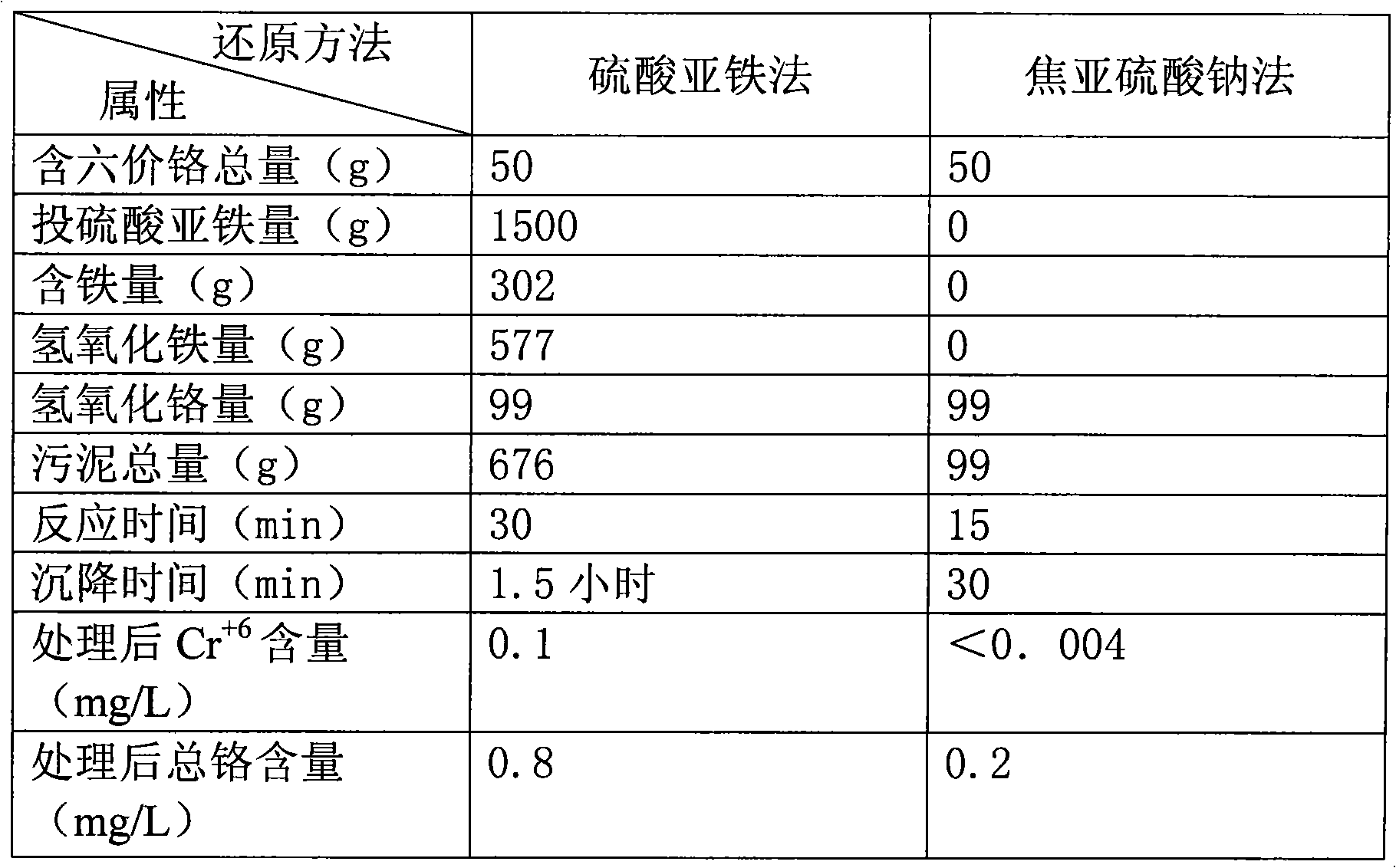

A technology for wastewater treatment and hexavalent chromium, which is applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, reduced water/sewage treatment, etc. The problem of large dosage of solid ferrous sulfate, etc., achieves the effect of less slag and convenient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

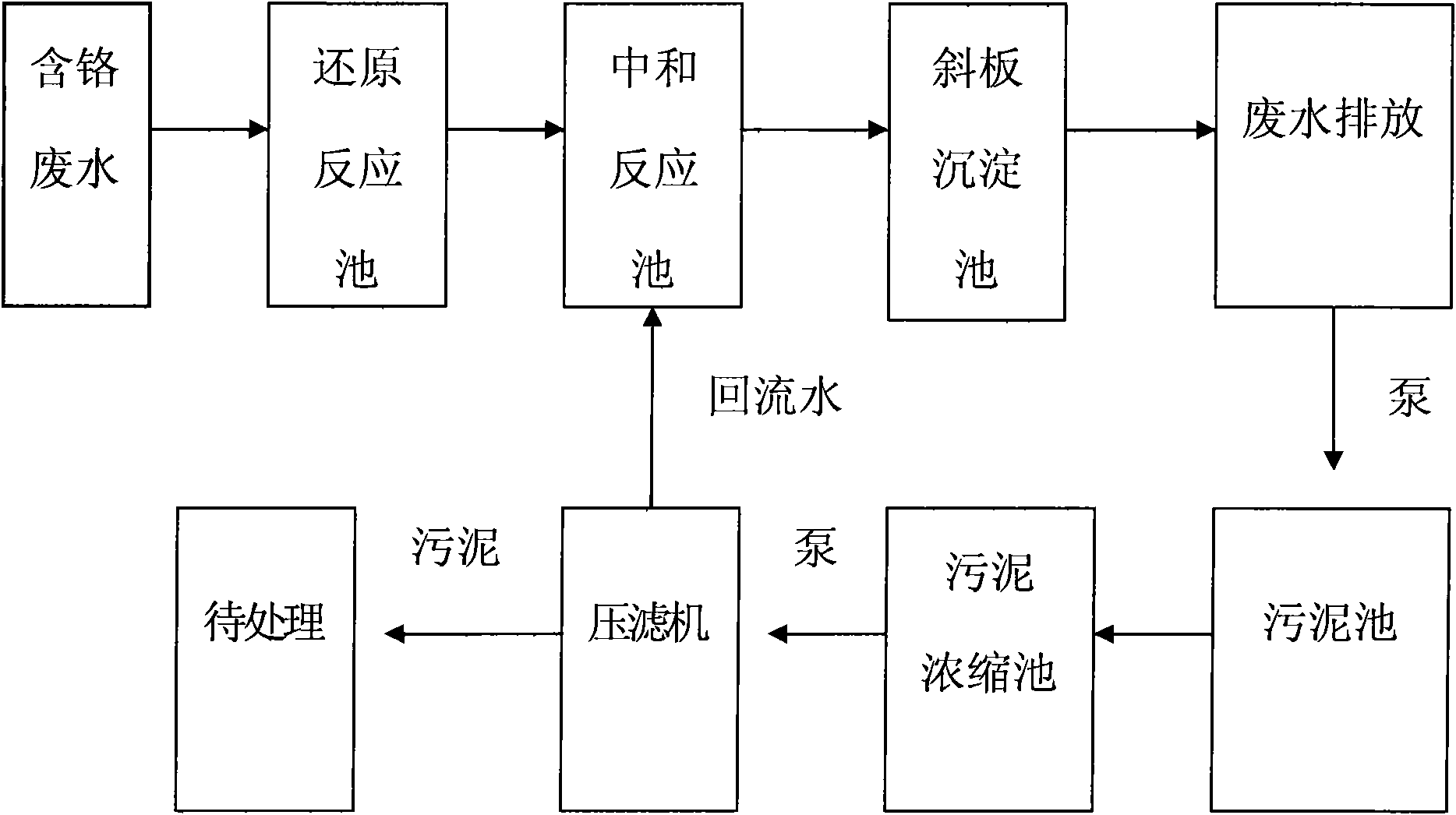

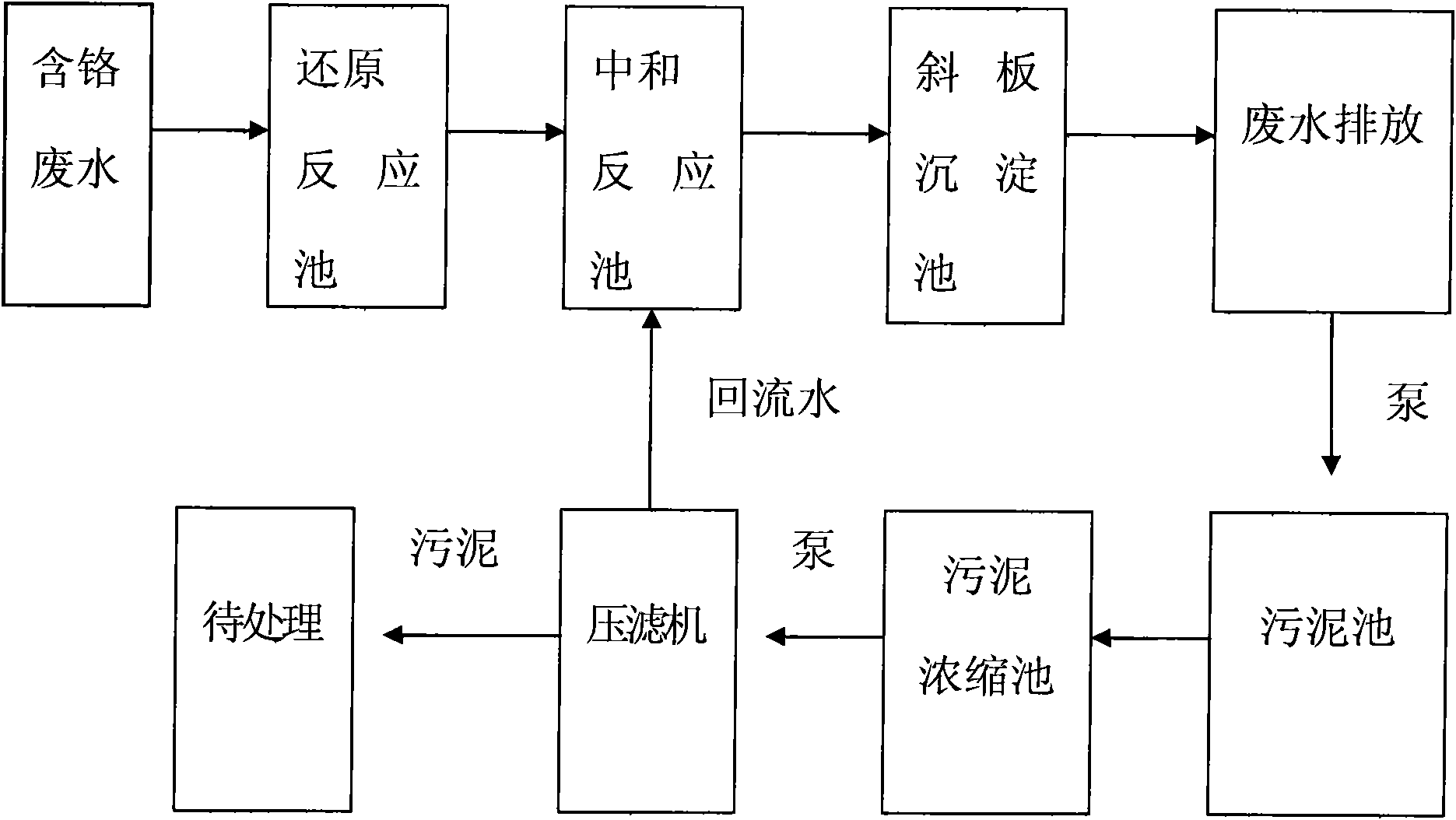

Image

Examples

Embodiment 1

[0036] Embodiment 1: Chromium-containing wastewater treatment method is:

[0037] ①Add industrial sulfuric acid with ρ=1.84mg / mL in the reaction tank, according to the calculation formula G 1 =D×Q Calculate the acid dose and add it carefully and slowly;

[0038] where: G 1 : Acid dose, kg

[0039] D: per m 3 The amount of acid required for wastewater is 0.3 ~ 0.4kg / m 3

[0040] Q: Total volume of wastewater

[0041] 2. Add sodium metabisulfite in the reaction tank, and add it according to the weight ratio of sodium metabisulfite to hexavalent chromium ion at a dosage ratio of 3.5:1, so that the hexavalent chromium in the chromium-containing wastewater is reduced to trivalent chromium;

[0042] ③ Add sodium hydroxide to the neutralization tank to make the trivalent chromium completely form chromium hydroxide precipitation, and add sodium hydroxide according to the following formula:

[0043] G2=T×Q

[0044] In the formula: G2: the mass of caustic soda to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com