Sewage treatment agent as well as preparation method and application thereof

A sewage treatment agent and flocculant technology, which is applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of large flocculation particles, short sedimentation time and thorough sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

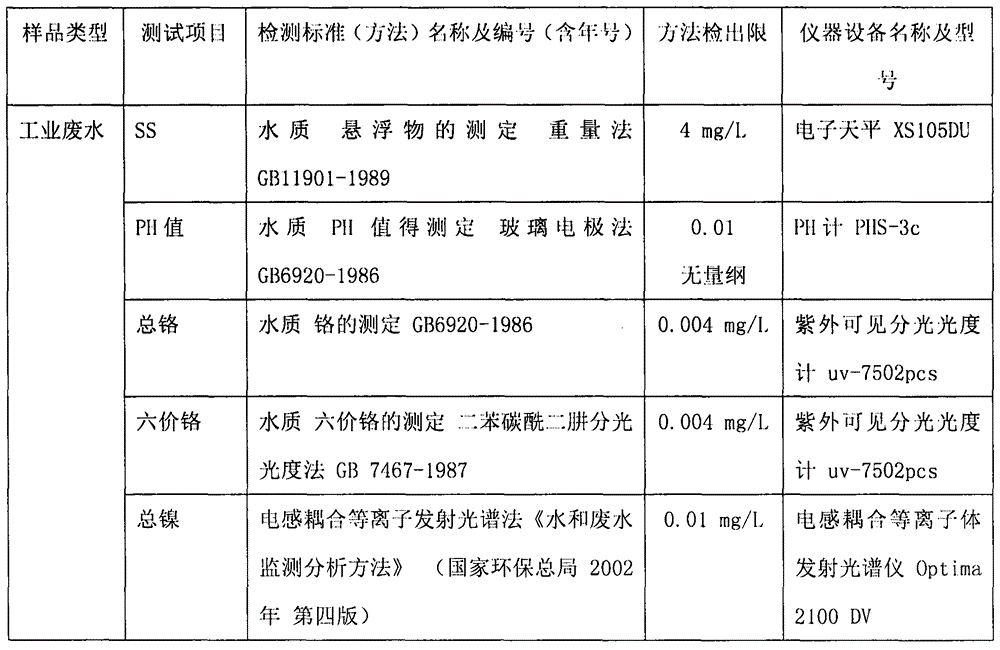

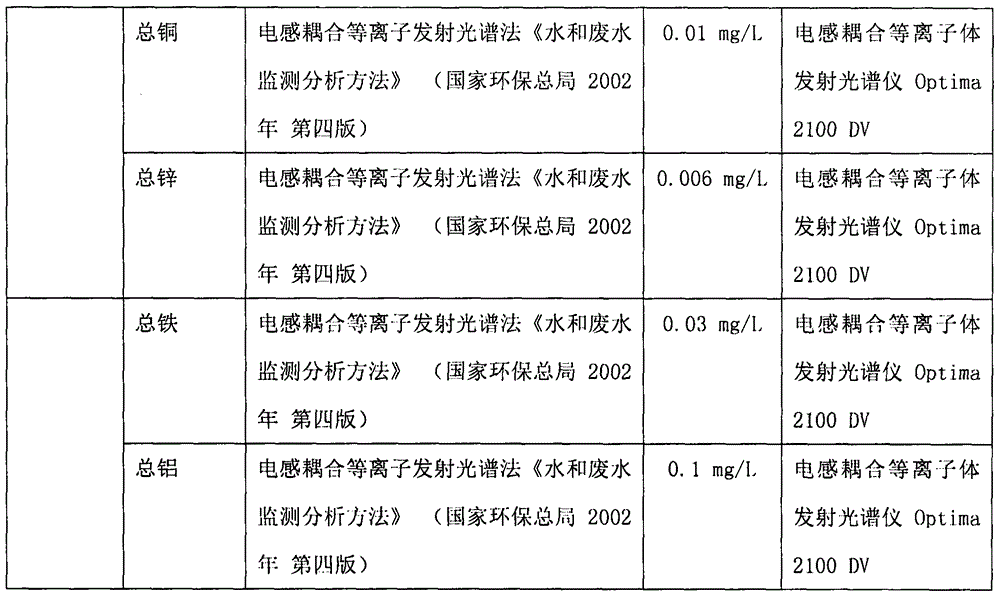

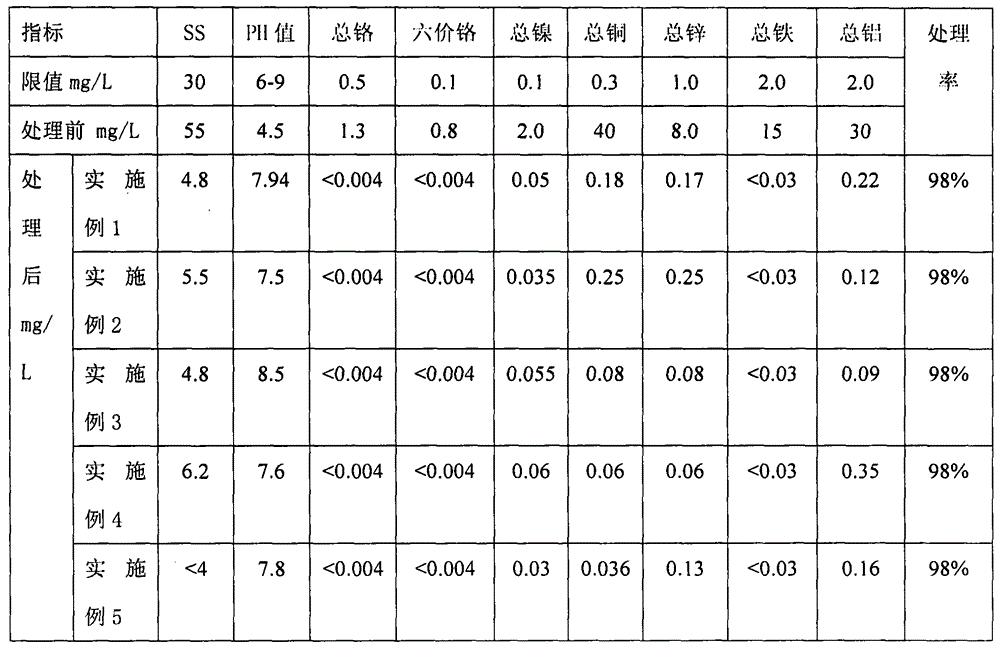

[0020] A kind of sewage treatment agent, the weight percentage of its raw material components is shown in Table 1.

[0021] In the above-mentioned sewage treatment agent, the raw material sulfate is aluminum sulfate, the alkalizing agent is sodium hydroxide, and the polymer flocculant is anionic polyacrylamide.

[0022] The method for preparing the above-mentioned sewage treatment agent is as follows: the magnesium oxide and the macromolecular flocculant in the raw materials shown in Table 1 are simultaneously added to the mixer for 10 minutes through the feeding machine; then, the remaining raw material zeolite is passed through the feeding machine. , sulfate and alkalinizing agent are added into the same mixer, and the stirring is continued for 10 minutes; then the products obtained by stirring are separately packaged through a blanking packaging machine.

[0023] In the preparation method of the above-mentioned sewage treatment agent, magnesia, zeolite, sulfate, alkalizing ...

Embodiment 2

[0025] A kind of sewage treatment agent, the weight percentage of its raw material components is shown in Table 1.

[0026] In the above-mentioned sewage treatment agent, the raw material sulfate is ferric sulfate, the alkalizing agent is slaked lime, and the polymer flocculant is positive ion polyacrylamide.

[0027] The method for preparing the above-mentioned sewage treatment agent is as follows: the magnesium oxide and ferric sulfate in the raw materials shown in Table 1 are simultaneously added to the mixer for 15 minutes by the feeder and stirred for 15 minutes; Molecular flocculant and slaked lime were added to the same mixer, and the mixing was continued for 18 minutes; then the products obtained by mixing were separately packaged through a blanking packaging machine.

[0028] In the preparation method of the above-mentioned sewage treatment agent, magnesia, zeolite, sulfate, alkalizing agent and polymer flocculant need to be pulverized before stirring, and passed thro...

Embodiment 3

[0030] A kind of sewage treatment agent, the weight percentage of its raw material components is shown in Table 1.

[0031] In the above-mentioned sewage treatment agent, the raw material sulfate is nickel sulfate, and the alkalizing agent is sodium peroxide;

[0032] The method for preparing the above-mentioned sewage treatment agent is as follows: the magnesium oxide and sodium peroxide in the raw materials shown in Table 1 are simultaneously added to the mixer for 10 minutes by the feeding machine; then, the remaining raw materials zeolite, The polymer flocculant and nickel sulfate are added into the same mixer, and the mixing is continued for 20 minutes; then the products obtained by mixing are separately packaged through a blanking packaging machine.

[0033] In the preparation method of the above-mentioned sewage treatment agent, magnesia, zeolite, sulfate, alkalizing agent and polymer flocculant need to be pulverized before stirring, and passed through a 200-mesh sieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com