Acidic water repellent associated matter fracturing fluid

A technology of hydrophobic associates and fracturing fluids, which is applied in the direction of drilling compositions, chemical instruments and methods, etc. It can solve the problems of poor temperature resistance, salt resistance, shear resistance, poor shear stability, and temperature resistance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

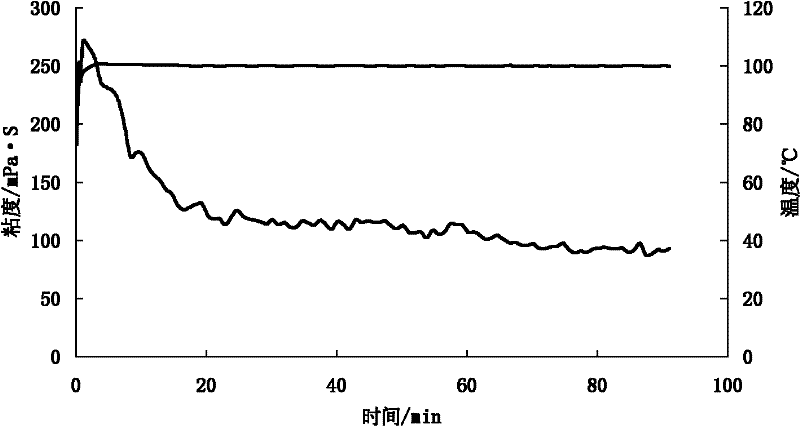

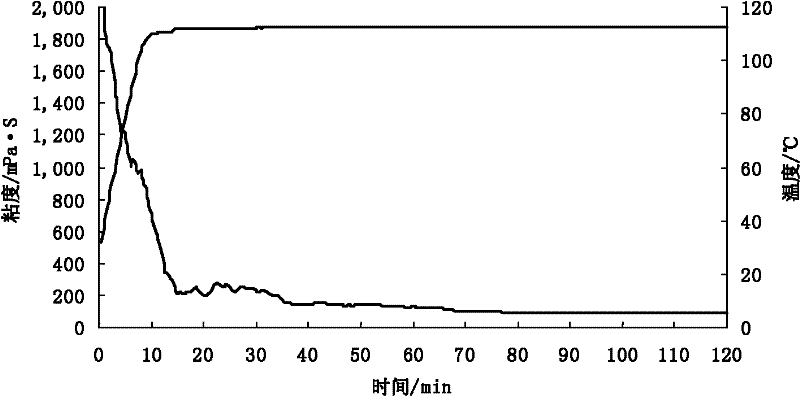

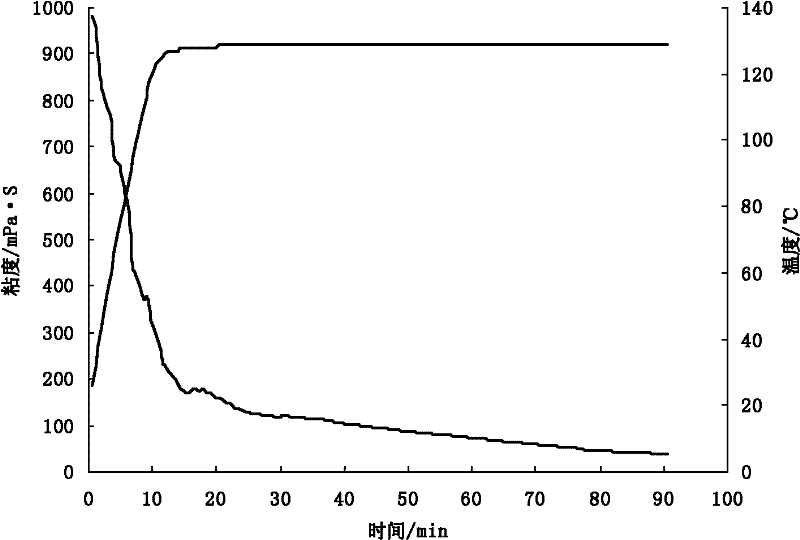

[0039] Evaluation of Sand Carrying Ability of Acidic Hydrophobic Associated Fracturing Fluid

[0040]Sand grains are the main proppant in the fractured space, and its function is to prevent the closure of fractures and maintain a good conductivity after the fracturing construction is completed. If the sand-suspending performance of the fracturing fluid is not good, sand jams or sand plugs may occur in the wellbore or fractures during construction, resulting in increased pump pressure and even interruption of construction, causing serious adverse effects on construction. Therefore, in the process of acid fracturing, the fracturing fluid should have better sand-carrying ability. The sand-carrying capacity of the fracturing fluid is mainly determined by the resistance (internal friction) encountered by the sand particles when moving in the fracturing fluid medium. The test method for the sand-carrying capacity: suspend 20-40 mesh ceramsite in the polymer fracturing The suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com