Method for transferring graphene by using micro-molecule paraffin

A graphene and small molecule technology, applied in the field of small molecule paraffin transfer graphene, can solve the problems that affect the performance of graphene devices and cannot completely remove the polymer layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

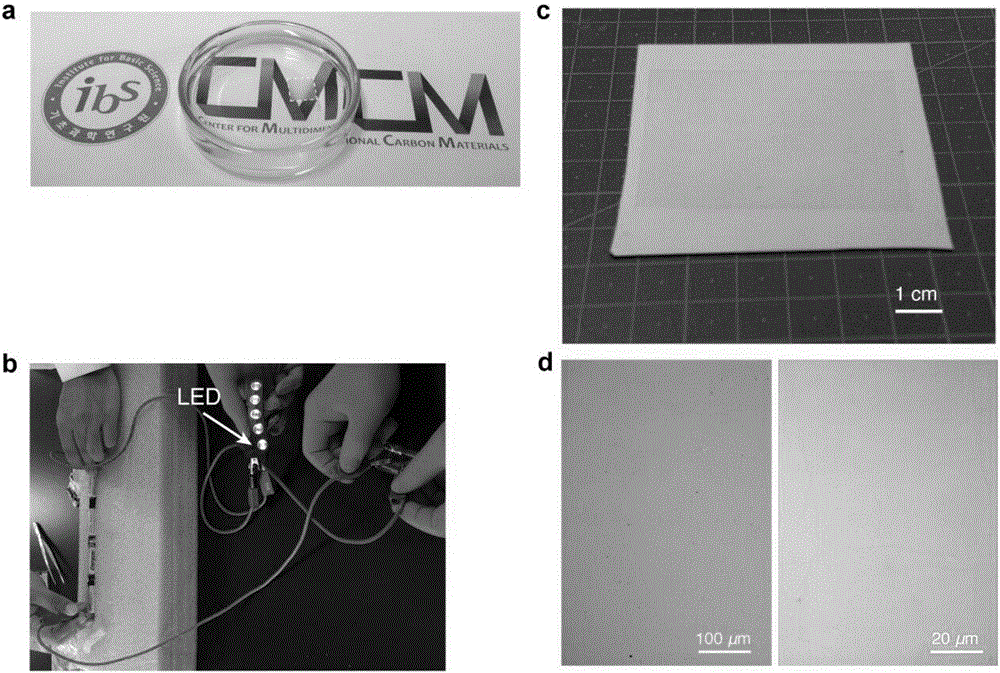

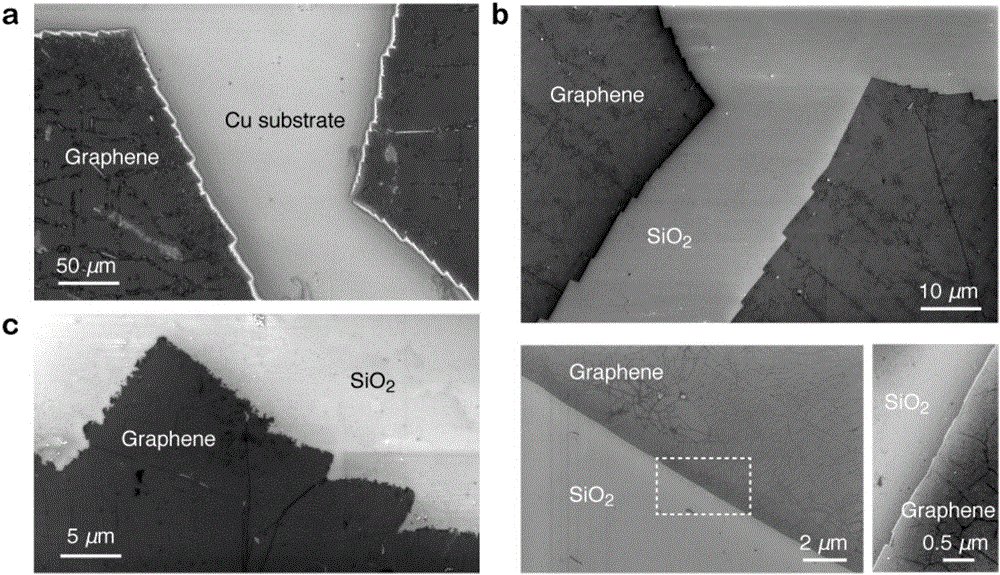

Embodiment 1

[0033] Graphene was grown by CVD to obtain a graphene film grown on copper foil, one side of the above-mentioned graphene film material was etched in oxygen plasma for 10 min, and the other side was to be transferred. Heat solid paraffin (melting point: 58-62°C) to 70°C to become liquid, spin-coat the above-mentioned paraffin onto the copper sheet with graphene at 500rpm to form a paraffin / graphene / copper sheet sandwich-like composite layer, and combine the above The layer was cooled to room temperature and washed with (NH 4 ) 2 S 2 o 8 The solution etches away the copper sheet, resulting in a paraffin / graphene film, which is washed multiple times with deionized water and transferred to the target substrate. Put the above-mentioned paraffin / graphene / substrate in the surrounding environment for 1 hour, so that the layers of the paraffin / graphene / substrate can be in better contact with each other. The above-mentioned composite layer was annealed to remove the paraffin layer....

Embodiment 2

[0035] Graphene was grown by CVD to obtain a graphene film grown on copper foil, one side of the above-mentioned graphene film material was etched in oxygen plasma for 15 minutes, and the other side was to be transferred. Heat solid paraffin (melting point: 58-62°C) to 75°C to become liquid, spin-coat the above-mentioned paraffin on the copper sheet with graphene at 1000rpm to form a paraffin / graphene / copper sheet sandwich-like composite layer, and combine the above The layer was cooled to room temperature and washed with (NH 4 ) 2 S 2 o 8 The solution etches away the copper sheet, resulting in a paraffin / graphene film, which is washed multiple times with deionized water and transferred to the target substrate. Put the above-mentioned paraffin / graphene / substrate in the surrounding environment for 1 hour, so that the layers of the paraffin / graphene / substrate can be in better contact with each other. The above composite layer was annealed to remove the paraffin layer. The an...

Embodiment 3

[0037] Graphene was grown by CVD to obtain a graphene film grown on copper foil, one side of the above-mentioned graphene film material was etched in oxygen plasma for 30 min, and the other side was to be transferred. Heat solid paraffin (melting point: 58-62°C) to 80°C to become liquid, spin-coat the above-mentioned paraffin on the copper sheet with graphene at 3000rpm to form a paraffin / graphene / copper sheet sandwich-like composite layer, and combine the above The layer was cooled to room temperature and washed with (NH 4 ) 2 S 2 o 8 The solution etches away the copper sheet, resulting in a paraffin / graphene film, which is washed multiple times with deionized water and transferred to the target substrate. Put the above-mentioned paraffin / graphene / substrate in the surrounding environment for 1 hour, so that the layers of the paraffin / graphene / substrate can be in better contact with each other. The above composite layer was annealed to remove the paraffin layer. The anneal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com