Ultra-temperature organic zirconium crosslinker suitable for polymer crosslinking and prepared fracturing solutions of ultra-temperature organic zirconium crosslinker

A technology of zirconium cross-linking agent and polymer, which is applied in the field of oil exploitation, can solve the problems of large formation damage and high residue content of gel-breaking fluid, and achieve the effects of low damage, good sand-carrying performance and elasticity, and low residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides an ultra-high temperature organic zirconium crosslinking agent suitable for polymer crosslinking and a fracturing fluid prepared therefrom.

[0031] The organic zirconium crosslinking agent provided in this example comprises the following raw materials: 300 g of water, 200 g of ethylene glycol, 70 g of zirconium oxychloride, 20 g of lactic acid, and 320 g of diethanolamine.

[0032] The organic zirconium crosslinking agent provided in this embodiment is prepared according to the following steps:

[0033] Add ethylene glycol into water at room temperature, stir and mix evenly with a stirrer, then heat up to 50°C;

[0034] Zirconium oxychloride was added under stirring conditions, and then reacted under stirring at 50°C for 3.5 hours;

[0035] Then add lactic acid and diethanolamine, and react under stirring at 50°C for 3 hours to prepare the ultra-high temperature organic zirconium crosslinking agent suitable for polymer crosslinking.

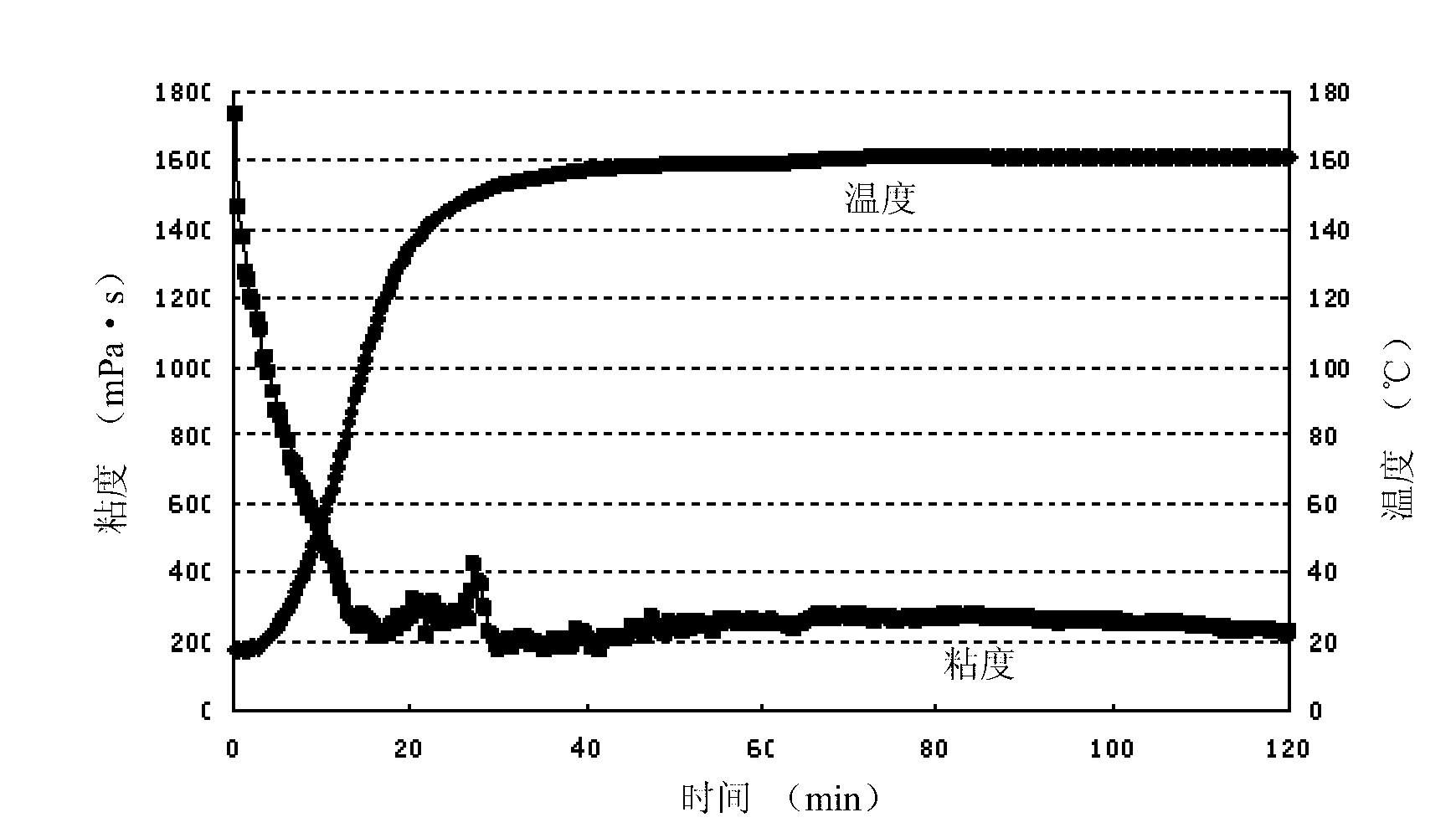

[0036] Thi...

Embodiment 2

[0043] This example provides an ultra-high temperature organic zirconium crosslinking agent suitable for polymer crosslinking and a fracturing fluid prepared therefrom.

[0044] The organic zirconium crosslinking agent provided in this example comprises the following raw materials: 300 g of water, 240 g of glycerol, 60 g of zirconium chloride, 30 g of lactic acid, and 300 g of isopropanolamine.

[0045] The organic zirconium crosslinking agent provided in this embodiment is prepared according to the following steps:

[0046] Add glycerol to water at room temperature, stir and mix evenly with a stirrer, then heat up to 55°C;

[0047] Zirconium chloride was added under stirring conditions, and then reacted under stirring at 55°C for 3.5 hours;

[0048] Then add lactic acid and isopropanolamine, react at 55° C. for 3 hours under stirring, and prepare the ultra-high temperature organic zirconium crosslinking agent suitable for polymer crosslinking.

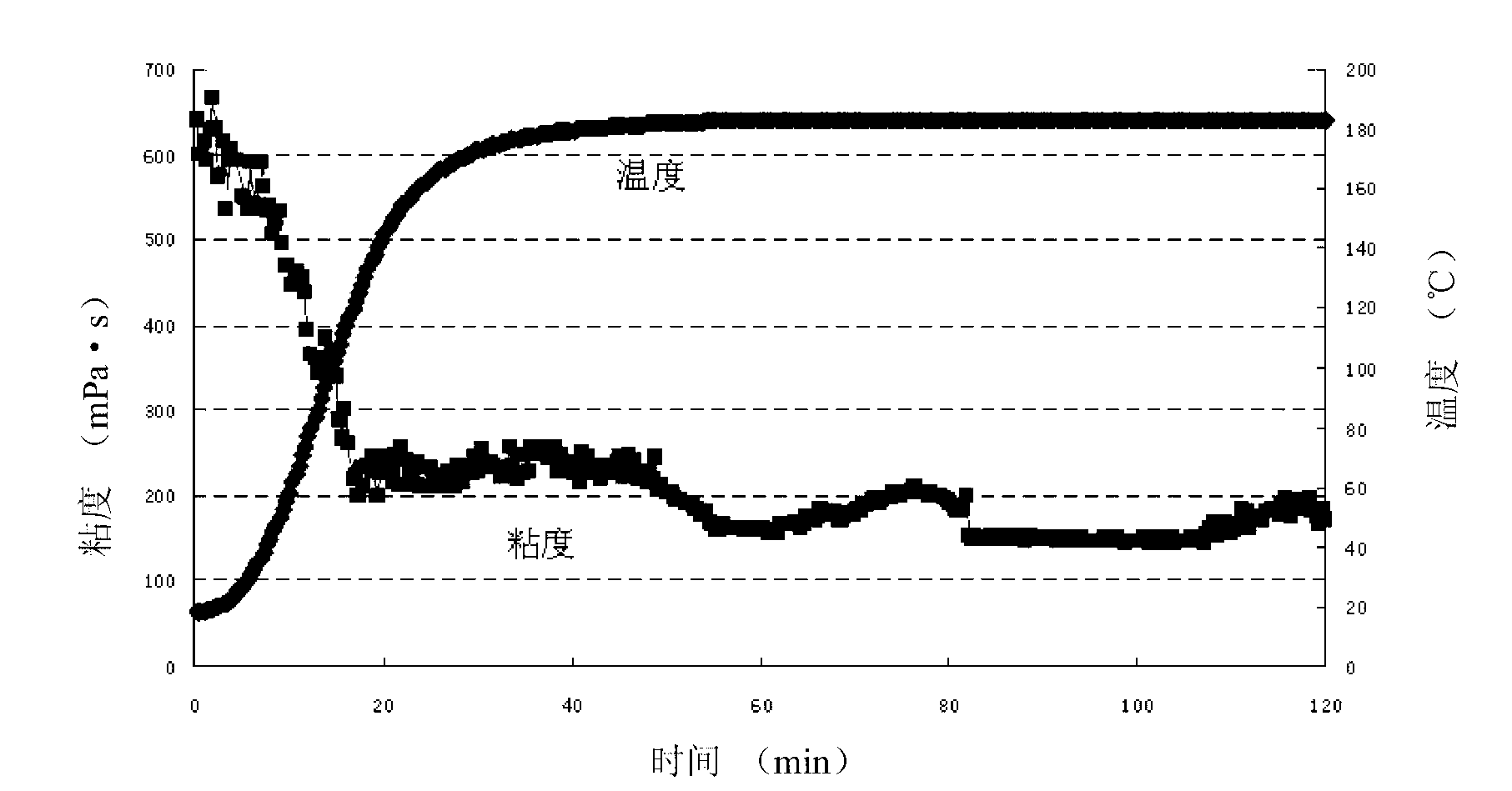

[0049] This embodiment also ...

Embodiment 3

[0057] This example provides an ultra-high temperature organic zirconium crosslinking agent suitable for polymer crosslinking and a fracturing fluid prepared therefrom.

[0058] The organic zirconium crosslinking agent provided in this example comprises the following raw materials: 300 g of water, 260 g of n-butanol, 90 g of zirconium chloride, 20 g of acetic acid, and 320 g of triethanolamine.

[0059] The organic zirconium crosslinking agent provided in this embodiment is prepared according to the following steps:

[0060] Add n-butanol to water at room temperature, stir and mix evenly with a stirrer, then heat up to 60°C; add zirconium chloride under stirring conditions, and then react at 60°C for 4 hours; then add acetic acid and triethanolamine, at 60°C ℃ for 3 hours under stirring to prepare the ultra-high temperature organic zirconium crosslinking agent suitable for polymer crosslinking.

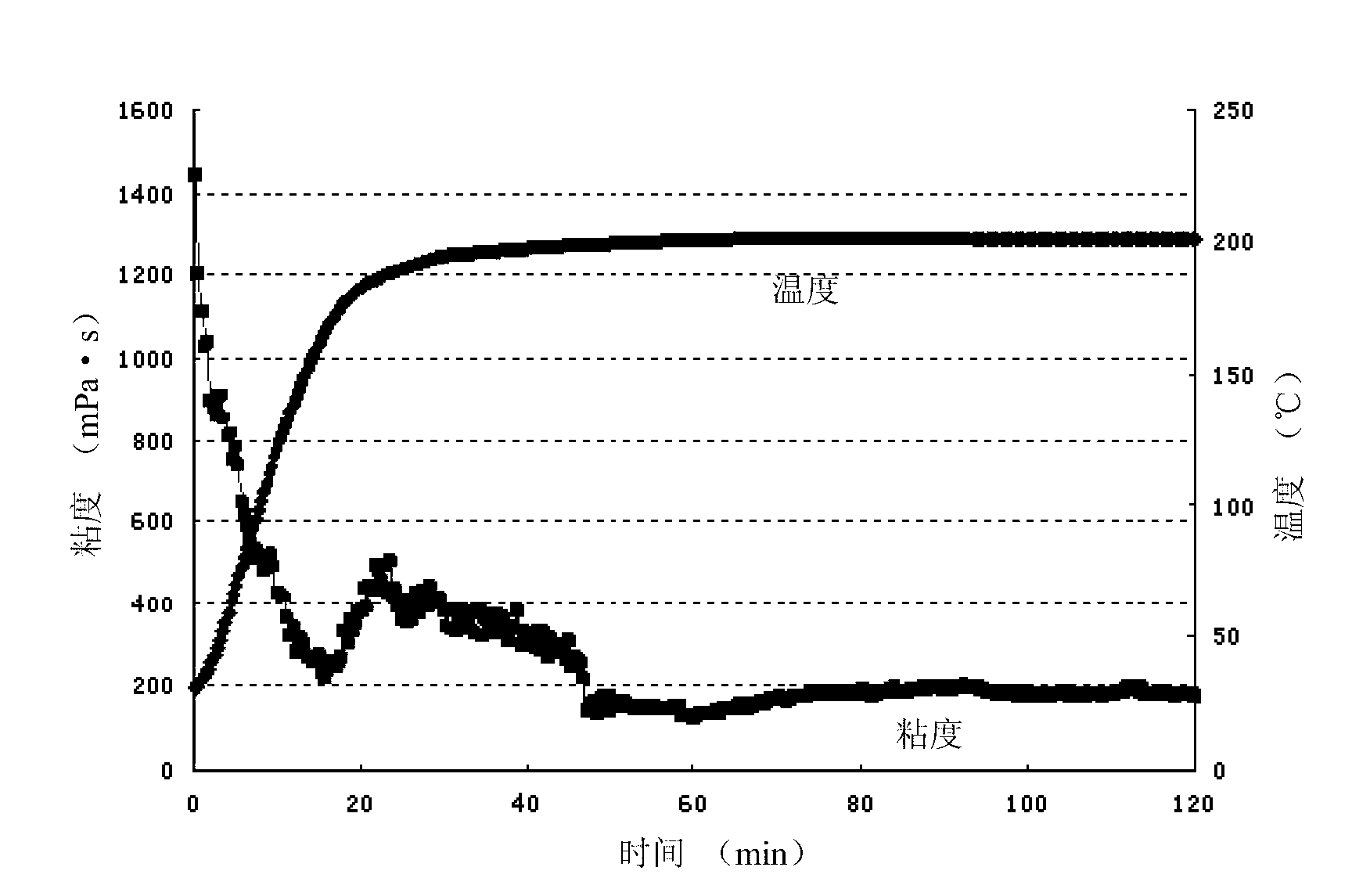

[0061] This embodiment also provides a polymer fracturing fluid, which includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com