Method for extracting fragrant sunflower seed oil

A technology of sunflower seed oil and extraction method, which is applied in the direction of edible oil/fat, fat oil/fat production, fat oil/fat refining, etc., can solve the late, since 1994 Wang Zhang, Professor Xu Shiying and other problems in China for the first time, to achieve the equipment The effect of simplicity, wide application, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0054] Experimental example 1 Screening experiment of optimal parameters of hot-frying process conditions

[0055] 1 Materials and methods

[0056] 1.1 Materials and reagents

[0057]

[0058] 1.3 Experimental method

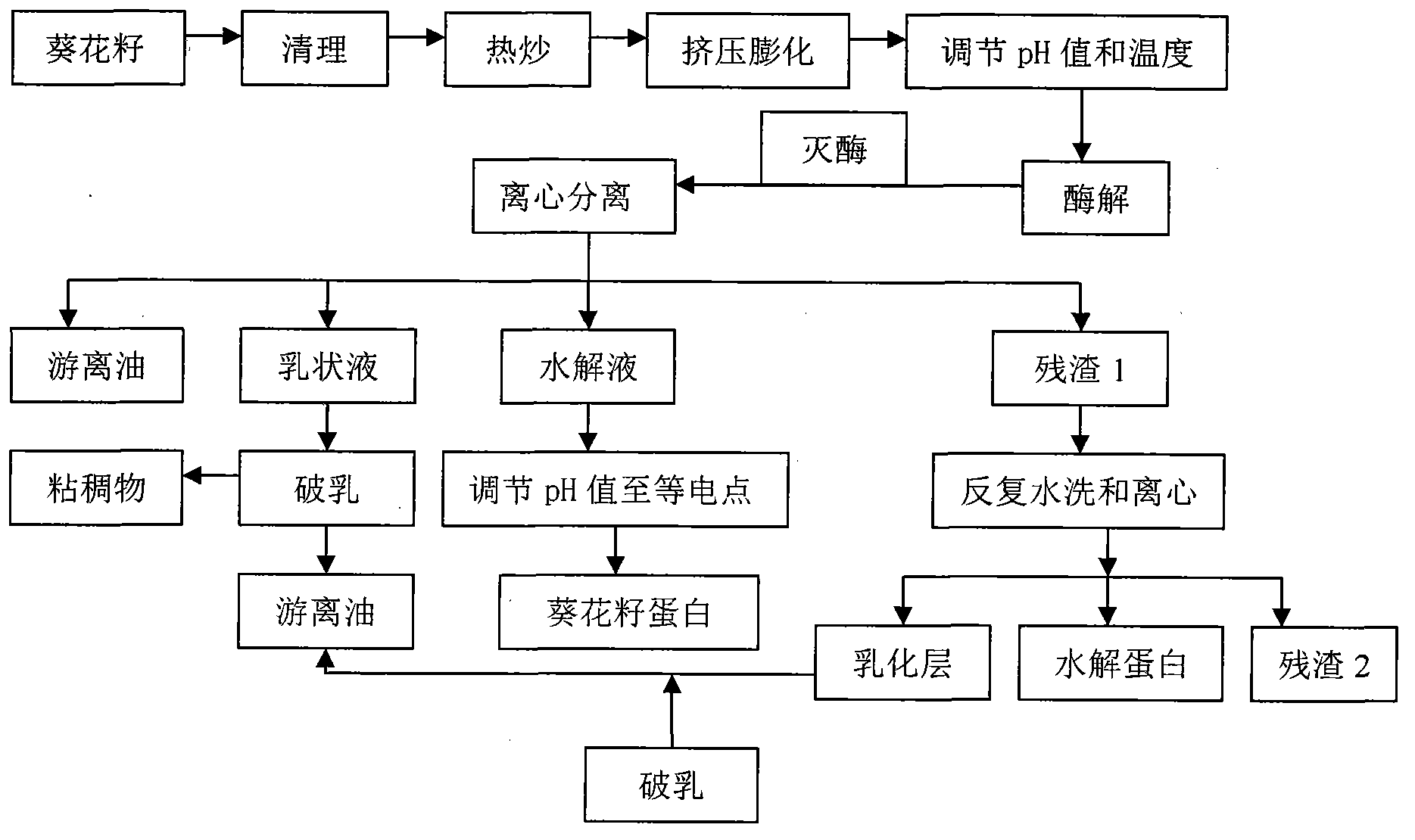

[0059] 1.3.1 Process flow

[0060] Sunflower seeds→cleaning→stir-frying→moisture adjustment→extrusion (die diameter 15mm, sleeve temperature 100°C, material moisture content 9.25%, screw speed 41r / min)→crushing→adjust pH value and temperature→enzymolysis→ Enzyme inactivation→centrifugation→sunflower oil

[0061] 1.3.2 Calculation formula

[0062] Total oil extraction rate (%)=(grams used for raw material sunflower seeds*mass fraction of oil in sunflower seeds-residual oil in residue after enzymolysis) / grams used for raw materials sunflower seeds*mass fraction of oil in sunflower seeds

[0063] 2 Results and Discussion

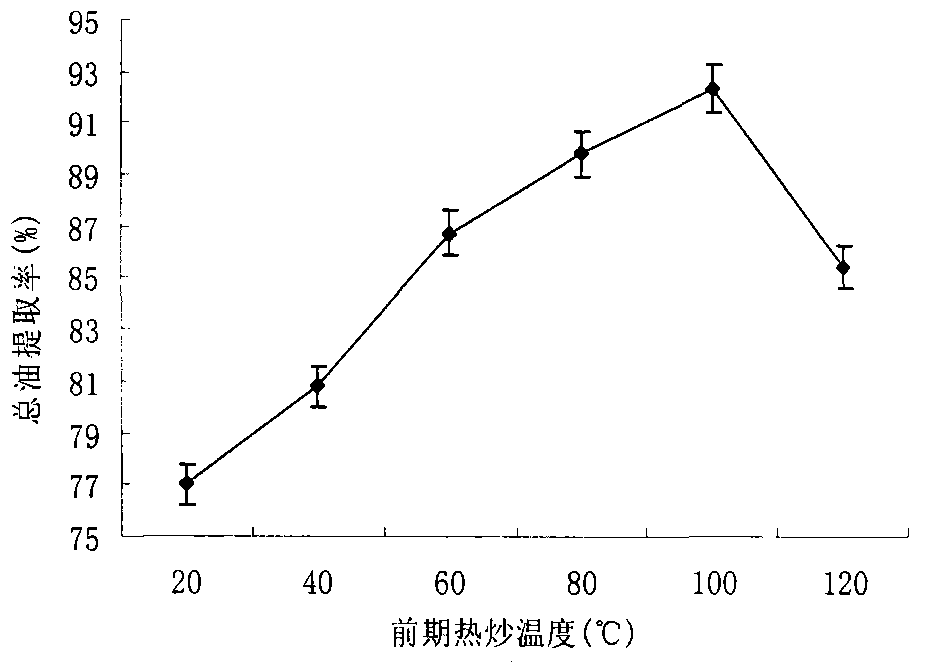

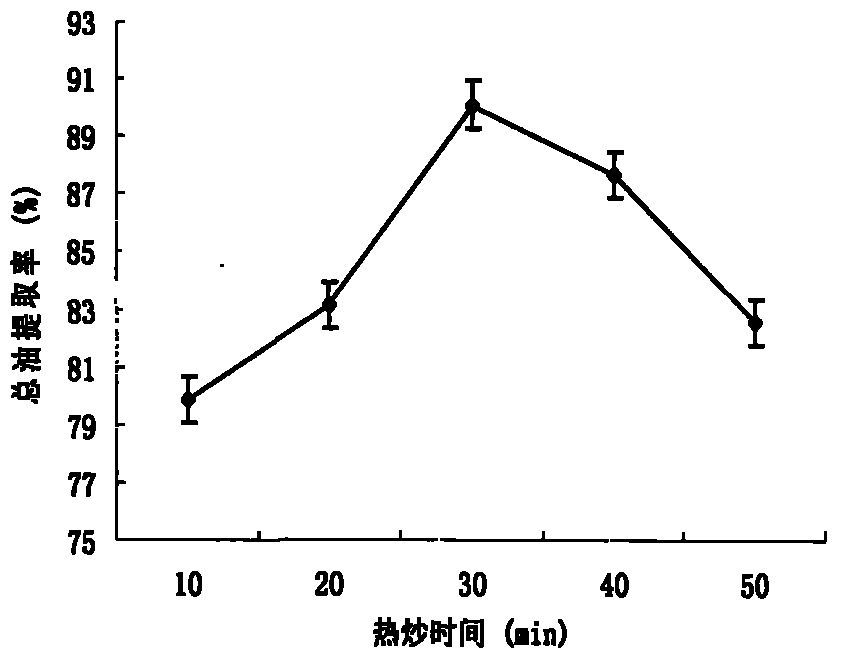

[0064] 2.1 Effect of the single factor condition of hot-frying process on the extraction rate of total oil

[0065] 2.1.1 Effect of fr...

experiment example 2

[0095] Experimental example 2 Screening experiment of optimal parameters of sunflower seed enzymatic hydrolysis process conditions

[0096] 1 Materials and methods

[0097] 1.1 Materials and reagents

[0098]

[0099]

[0100] 1.3 Experimental method

[0101] 1.3.1 Composition determination of sunflower seeds

[0102]Moisture determination: GB5497-85 for determination; protein determination: GB5511-85 for determination; fat determination: GB5512-85 for determination; total sugar determination: phenol-sulfuric acid method; ash content determination: GB5505-85 for determination; crude fiber determination: GB5505-85 / T6434-94 for determination.

[0103] 1.3.2 Process flow

[0104] Sunflower seeds→cleaning→crushing→moisture adjustment→extrusion (die hole diameter 15mm, sleeve temperature 100°C, material moisture content 9.25%, screw speed 41r / min)→crushing→adjust pH value and temperature→enzymolysis→extinguish Enzyme→centrifugation→sunflower oil

[0105] 1.3.3 Calculat...

experiment example 3

[0145] Experimental Example 3 Optimum Experiment of Process Parameters of Crushing, Extruding and Expanding Pretreatment Process of Raw Materials Before Enzymolysis

[0146] Based on the process of extracting sunflower seed oil and protein by the best water enzymatic method determined in Experimental Example 2, carry out single factor extrusion test, determine each extrusion expansion system parameter (sleeve temperature, die hole aperture, screw speed, material moisture content ) range. Taking the total oil extraction rate as the investigation index, a response surface design experiment with 4 factors and 5 levels was carried out

[0147] 1 Materials and methods

[0148]1.1 Materials and reagents

[0149]

[0150] 2.2

[0151] 1.3 Experimental method

[0152] 1.3.1 Process flow

[0153] Sunflower seeds→cleaning→stir-frying→moisture adjustment→extrusion puffing→crushing→adjusting pH value and temperature→enzymolysis (compound cellulase, the process conditions are: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com