System and process for producing carbon mud by anaerobic cracking of sludge

A mud system and pyrolysis carbon technology, applied in sludge treatment, petroleum industry, pyrolysis treatment of sludge, etc., can solve the problems of easy over-excavation or missed excavation, low resource utilization efficiency, dam damage, etc. The effect of improving energy utilization efficiency, avoiding dioxin production, and wide market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

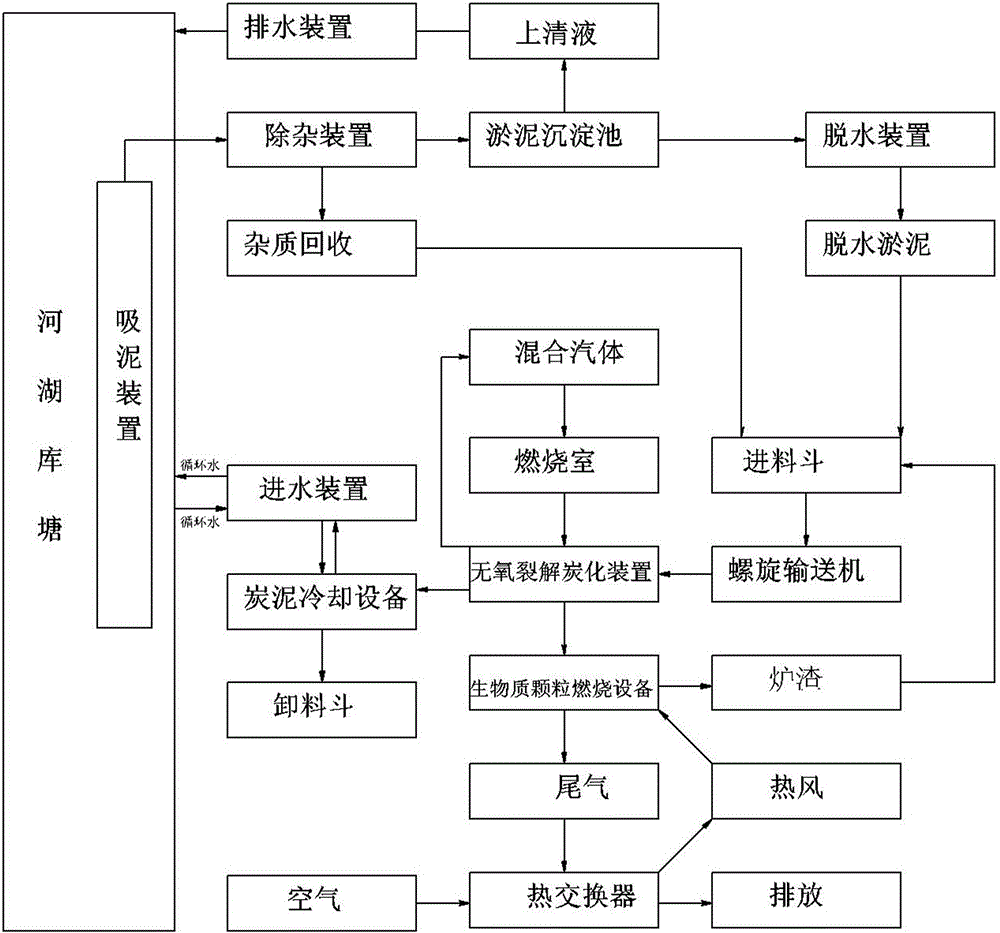

[0036] The first object of the present invention is to provide a system for producing carbon mud by anaerobic pyrolysis of sludge. The system is arranged adjacent to the sludge source. The sludge source includes but not limited to rivers or lakes or ponds or reservoirs. The system includes a sludge suction device and an impurity removal device. , Dehydration device, material conveying device, anaerobic cracking and carbonization device, water inlet device, drainage device.

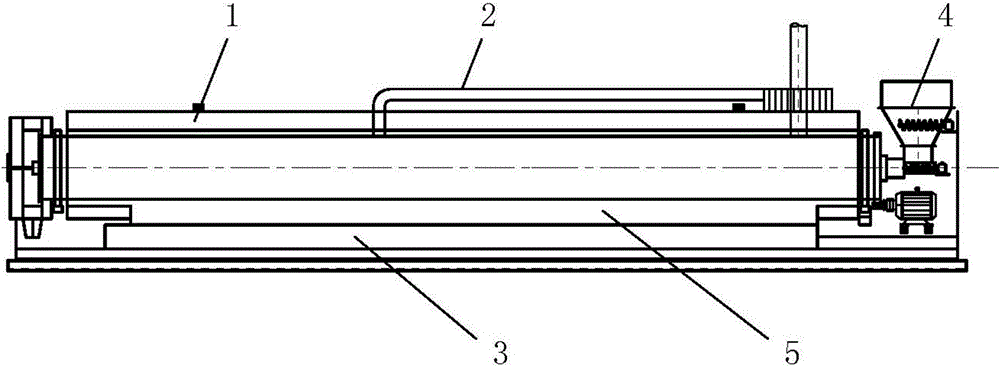

[0037] Anaerobic pyrolysis carbonization device, which includes a converter body 1, sludge feeding equipment composed of a feed hopper and a screw conveyor 4, mixed gas treatment equipment for processing mixed gas generated by anaerobic pyrolysis carbonization 2, and biomass particle processing equipment Exhaust gas treatment equipment for combustion exhaust gas, biomass pellet combustion equipment 3, and carbon mud cooling equipment.

[0038] The impurity removal device includes a vibrating grate for sepa...

Embodiment 2

[0048] In conjunction with embodiment 1, a kind of sludge anaerobic cracking carbon mud process, process steps are as follows:

[0049] The second object of the present invention is to provide a kind of silt anaerobic cracking carbon mud process, process steps are as follows:

[0050] The first step, suction mud: extract silt from river course or lake or pond or reservoir by suction device;

[0051] The second step, impurity removal: the impurities in the sludge are separated by the vibrating grid of the impurity removal device; the impurities include plastic bags, branches, stones or other large particles, and the impurities are crushed and then enter the anaerobic cracking and carbonization device for treatment; the sludge passes through the pipe transported to the dehydration unit;

[0052] The 3rd step, sludge dehydration: the sludge water content after dehydration is less than 70%;

[0053]The fourth step is anaerobic pyrolysis to make carbon mud: the product obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com