Scraper device

A scraper device and scraper technology, applied in the scraper field, can solve the problems of long welding seam length, poor welding stability, deformation, etc., and achieve the effects of solving the deformation while processing, reducing the manufacturing cost and reasonable process structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

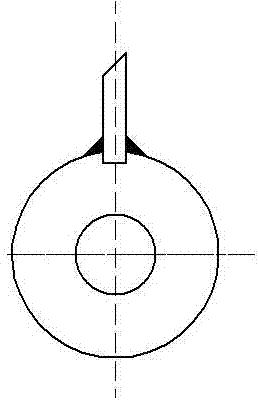

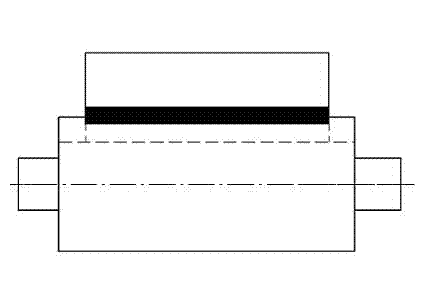

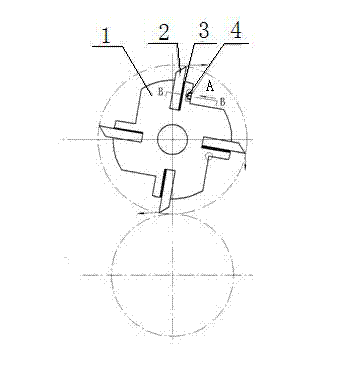

[0018] Such as image 3 , Figure 4 and Figure 5 As shown, the scraper device includes a roller 1, a scraper blade 2 and a distance adjusting component 3. The roller 1 is uniformly and symmetrically provided with at least two knife grooves along the circumferential surface, and the scraper blade 2 is installed in the knife grooves. When the roller When there are two knife grooves on the roller, the two knife grooves are symmetrically distributed at 180° on the circumferential surface of the roller, and the scraper blade 2 is also symmetrically distributed at 180° on the circumferential surface of the roller. When grooving, the three knife grooves are distributed symmetrically at 120° on the peripheral surface of the roller, that is, the scraper blades 2 are also distributed symmetrically at 120° on the peripheral surface of the roller. Similarly, the roller is provided with 4, 5, 6 equal numbers of sipes, the distribution of which on the circumferential surface of the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com