Flotation separation method of low / extra-low grade copper-molybdenum ore or chat

A separation method and technology for copper-molybdenum ore, applied in flotation, solid separation and other directions, can solve problems such as increased energy consumption, low molybdenum selection yield, violation of flotation column, etc., and achieves flexible adjustment, convenient configuration, and a single unit Small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

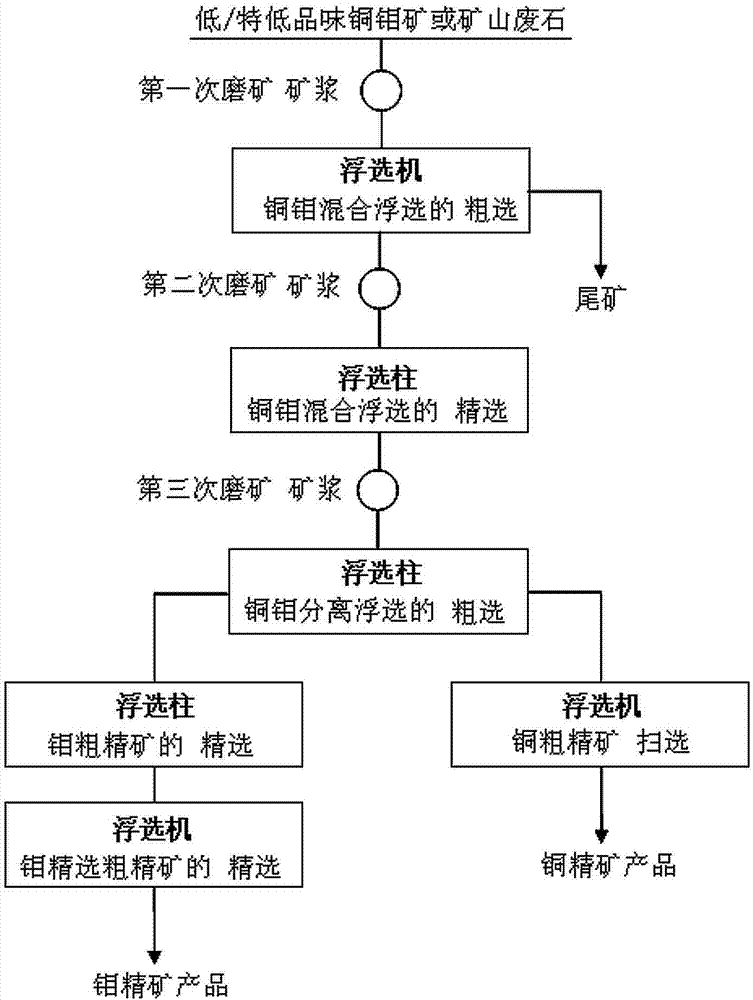

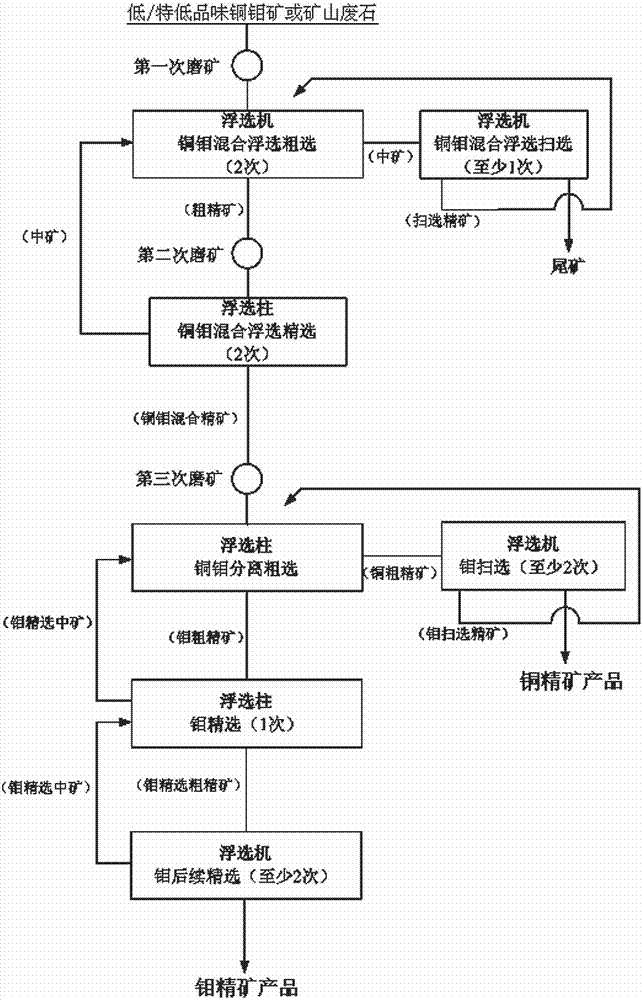

[0037] figure 1 It is the basic process flow of the present invention for the flotation separation method of low / ultra-low grade copper-molybdenum ore or mine waste rock, as described above. On this basis, a preferred comprehensive processing flow such as figure 2 Shown:

[0038] 1': Copper-molybdenum ore containing 0.33% copper and 0.018% molybdenum is used as raw material, crushed and ground to a fineness of -0.074mm with an occupancy rate of 65%, and the raw ore after grinding is prepared into a 35% raw ore slurry.

[0039] The raw ore pulp is adjusted to pH 7~9 with lime in the mixing tank, and according to the content of copper and molybdenum minerals in the raw ore and the amount of mud (the same below), add collector Ⅰ 38g / t, collector Ⅱ 15g / t, collector III 30g / t, foaming agent 50g / t, add ore dressing agent and stir for 4 minutes, use flotation machine to carry out roughing of copper-molybdenum mixed flotation twice to get copper-molybdenum mixed flotation Coarse c...

Embodiment 2

[0047] According to the treatment process of Example 1, the low-grade refractory mine waste rock discarded in the open-pit mining of copper mines with an average copper grade of 0.19% and a molybdenum grade of 0.01% was crushed and ground to a fineness of -0.074 The occupancy rate of mm is 60%, and it is prepared with water to make a raw ore slurry with a weight concentration of 25%~40%, put it in a mixing tank, add lime 1500g / t to adjust the pH value to 8~9, add collector diesel oil 20~60g / t, Ethyl xanthate 5~15g / t and butyl xanthate 5~20g / t, foaming agent terpineol oil 50~100g / t, after stirring, use a flotation machine to carry out 2 times of rough separation of copper and molybdenum mixed flotation , mix the rougher froth of the 1st and 2nd copper-molybdenum mixed flotation to obtain the coarse concentrate and middle ore of copper-molybdenum mixed flotation. The medium mine uses a flotation machine to carry out 2 times of sweeping, and the concentrate obtained from the firs...

Embodiment 3

[0054] According to the processing flow of Example 1, after the self-mining ore containing 0.25% copper and 0.02% molybdenum is crushed, it will be ground to a fineness of -0.074mm with an occupancy rate of 65% through a closed-circuit grinding system formed with a cyclone. After roughing raw materials with copper and molybdenum, add water to prepare a slurry with a weight concentration of 35%, add lime 2000g / t to the mixing tank to adjust the pH value to 8~9, add diesel oil 35g / t, ethylxanthate collector 20g / t, butyl xanthate 10g / t, No. 2 oil 110g / t. After stirring for 5 minutes, it enters the flotation machine, and carries out 2 times of copper-molybdenum mixed roughing and 1 time of sweeping. The concentrates of the second copper-molybdenum mixed roughing are combined into one to obtain copper-molybdenum mixed rough concentrate, and the concentrate obtained by sweeping is returned to the second copper-molybdenum mixed roughing as its raw material, and the copper grade of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com