Hydrophobic quartz micro powder as well as integrated production process and application thereof

A technology of quartz micropowder and production process, which is applied in the directions of dyeing organosilicon compound treatment, fibrous filler, dyeing physical treatment, etc. Advanced production process control method, convenient hydrophobicity and dispersibility, rich raw material source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

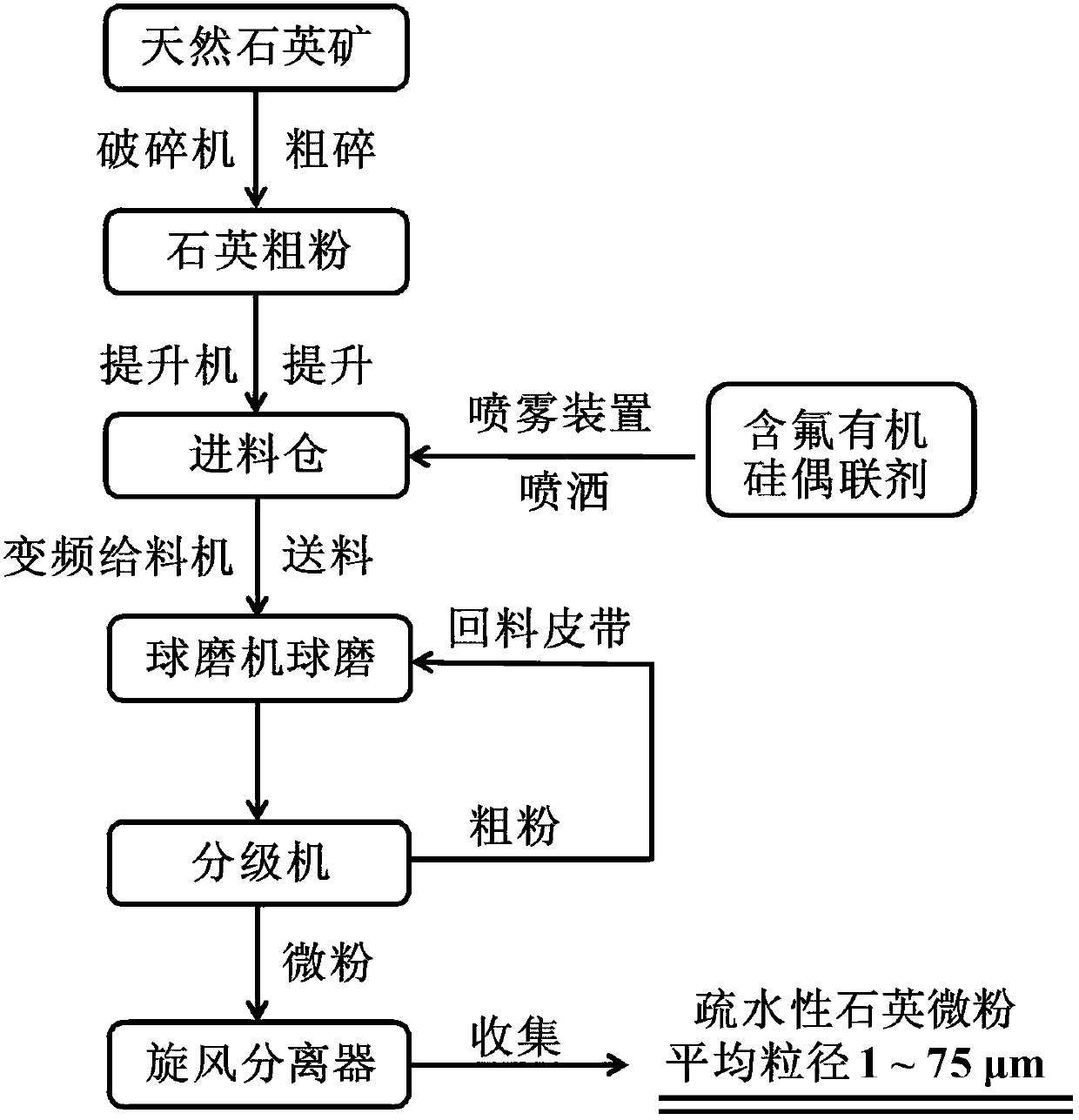

[0044]After the natural quartz ore raw material is roughly crushed by the crusher, the coarse quartz powder with a particle size of 2 to 10 mm is screened out, and it is lifted to the feeding bin by the elevator, and the stirring device of the feeding bin is started, and the organic silicon containing 3 fluorine atoms is mixed. The coupling agent is sprayed on the surface of the quartz powder particles at a speed of 2mL / min by the spray device, and then the coarse quartz powder with the fluorine-containing silicone coupling agent attached to the surface is sent into the ball mill through the frequency conversion feeder, and the quartz powder is in the ball mill. Gradually crushed, and the high temperature generated during the impact process will vaporize the fluorine-containing silicone coupling agent and graft it on the surface of the crushed quartz powder. During the ball milling process, the temperature in the ball mill is controlled at about 80°C by controlling the appropri...

Embodiment 2

[0046] After the natural quartz ore raw material is roughly crushed by the crusher, the coarse quartz powder with a particle size of 2 to 10 mm is screened out, and it is lifted to the feeding bin by the elevator, and the stirring device of the feeding bin is started, and the organic silicon containing 7 fluorine atoms is mixed. The coupling agent is sprayed on the surface of the quartz powder particles at a speed of 4mL / min through the spray device, and then the coarse quartz powder with the fluorine-containing silicone coupling agent attached to the surface is sent into the ball mill through the frequency conversion feeder, and the quartz powder is in the ball mill. Gradually crushed, and the high temperature generated during the impact process will vaporize the fluorine-containing silicone coupling agent and graft it on the surface of the crushed quartz powder. During the ball milling process, the appropriate flow rate of cooling circulating water is controlled by the automa...

Embodiment 3

[0048] After the natural quartz ore raw material is roughly crushed by the crusher, the coarse quartz powder with a particle size of 2-10mm is screened out, and it is lifted to the feeding bin by the elevator, and the stirring device of the feeding bin is started, and the organic silicon containing 17 fluorine atoms is mixed. The coupling agent is sprayed on the surface of the quartz powder particles by the spray device at a speed of 8mL / min, and then the coarse quartz powder with the fluorine-containing silicone coupling agent attached to the surface is sent into the ball mill through the frequency conversion feeder, and the quartz powder is in the ball mill. Gradually crushed, and the high temperature generated during the impact process will vaporize the fluorine-containing silicone coupling agent and graft it on the surface of the crushed quartz powder. During the ball milling process, the appropriate flow rate of cooling circulating water is controlled by the automatic cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com