Low-rank pulverized coal pyrolysis and semicoke gasification composite process system

A composite process and semi-coke technology, applied in the field of coal chemical industry, can solve the problems of complexity and low efficiency, and achieve the effects of high economic value, reasonable process structure and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

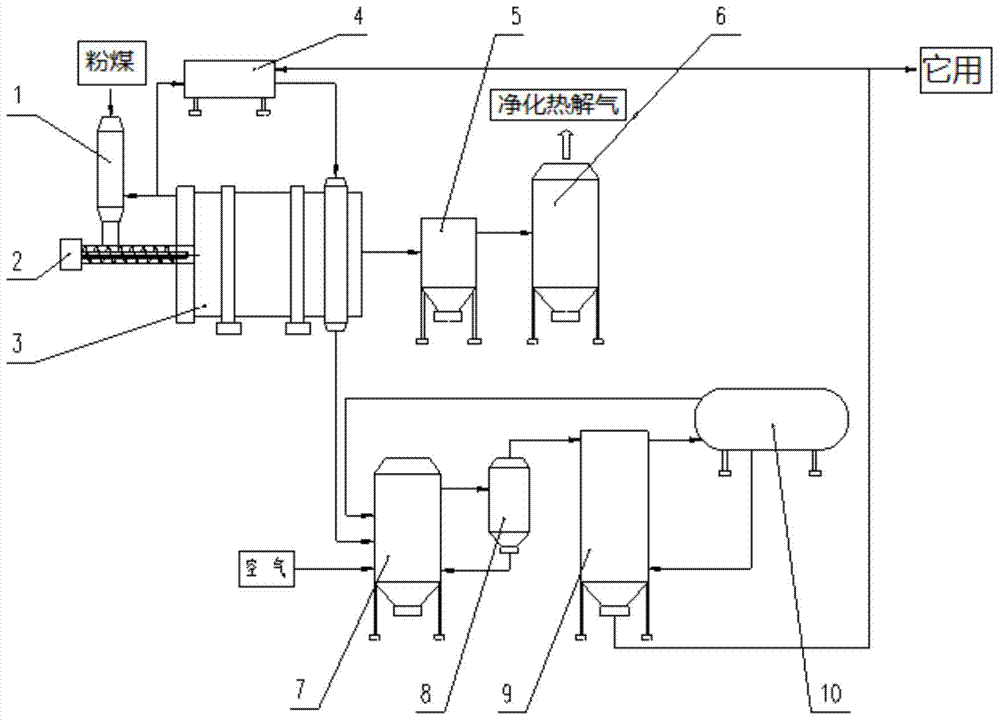

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] A low-order pulverized coal pyrolysis and semi-coke gasification composite process system, including a vertical preheater 1, a feeding screw 2, a pyrolysis kiln 3, a hot air heating furnace 4, a settling box 5, a high-temperature filter device 6, Semi-coke gasifier 7, cyclone separator 8, waste heat boiler 9 and steam drum 10;

[0022] The discharge port of the vertical preheater 1 is connected to the inlet of the feeding screw 2, and the outlet of the feeding screw 2 is connected to the multi-tube heating rotary pyrolysis kiln 3. The air outlet of the pyrolysis kiln 3 is divided into two routes, one is connected with the air inlet of the preheater 1, and the other is connected with the air inlet of the hot air heating furnace 4, and the air outlet of the hot air heating furnace 4 is connected with the air outlet of the pyrolysis kiln 3 The air inlet of the pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com