Clean environment-friendly production technique of chromic oxide

A chromium trioxide, clean and environmentally friendly technology, applied in the direction of chromium trioxide, chromium oxide/hydrate, etc., can solve problems such as difficult industrialization, low efficiency, and environmental pollution, and achieve easy industrial scale production, improved production efficiency, and economical benefit-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

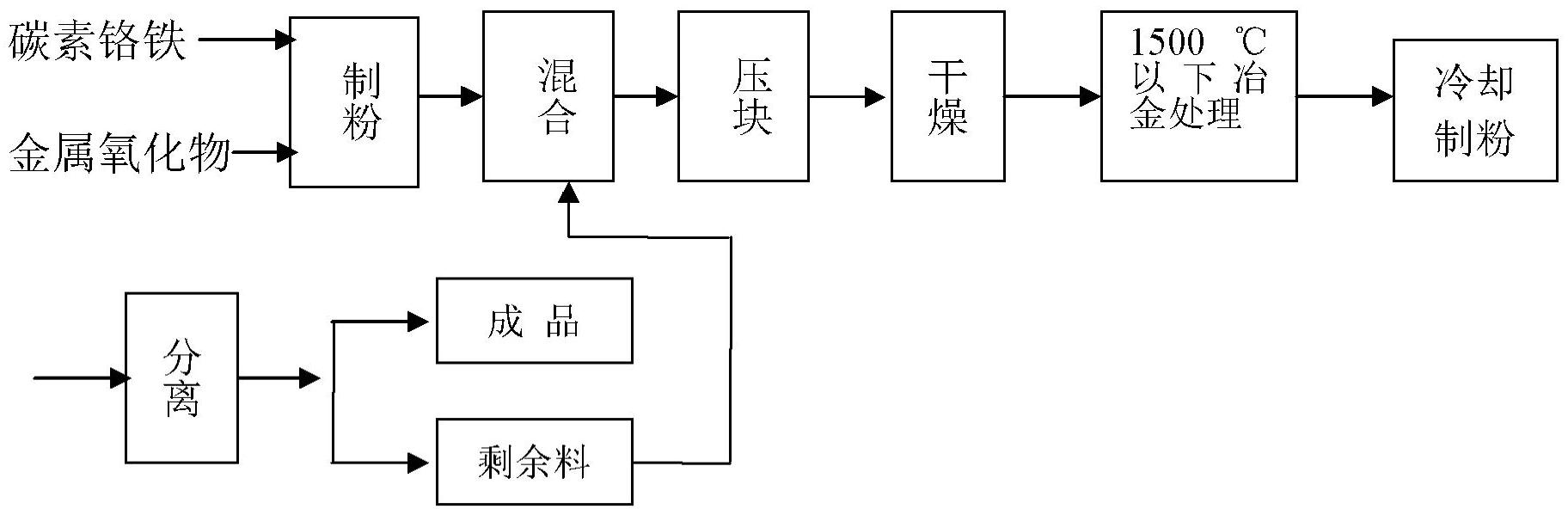

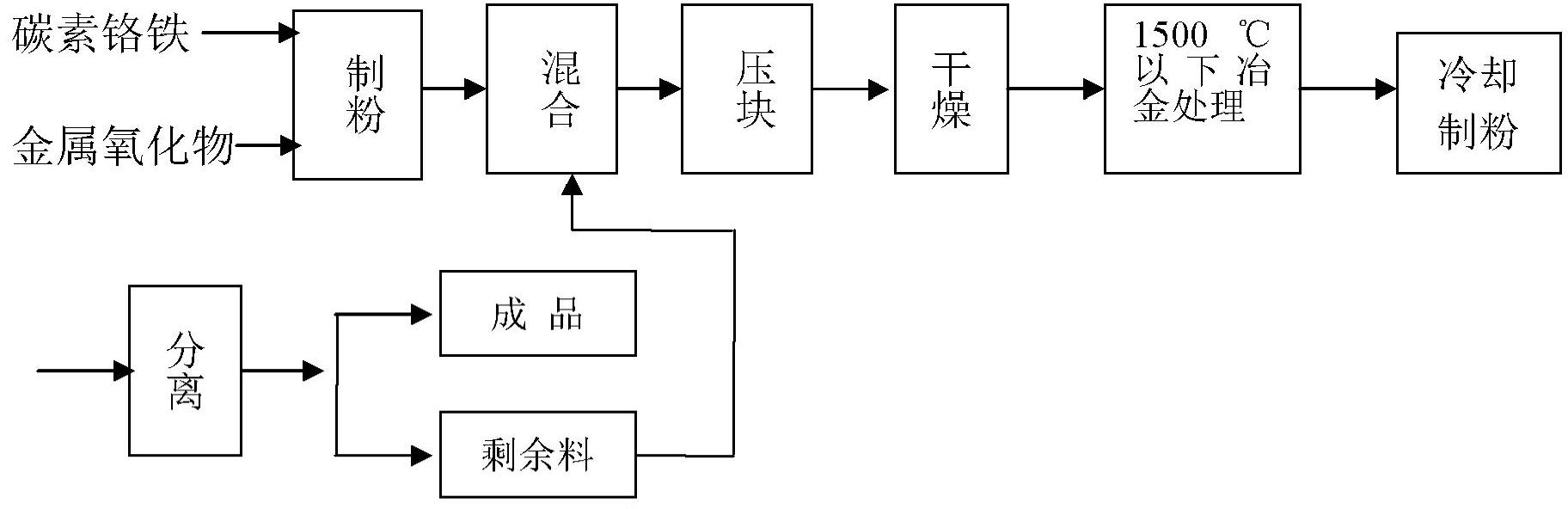

[0012] Embodiment 1, refer to figure 1 , the present invention adopts the principle of high-temperature oxidation-reduction reaction, the thermodynamics and kinetics principle of solid-solid reaction, uses carbon ferrochrome powder as the main raw material, and metal oxide powder as the auxiliary raw material, passes through 500 The high-temperature solid-solid phase metallurgy method at ℃~1500℃ converts the chromium in ferrochromium carbon into dichromium trioxide, and the conversion rate of chromium is 15~95%. After cooling and preparing powder, the water separation method is used Or acid separation to separate chromium trioxide. The weight ratio of the carbon ferrochrome to the metal oxide is 1:0.3-1.2, and the particle size of the carbon ferrochrome and metal oxide powder should be between 1.0 mm and 500 mesh. The chromium content of the carbon ferrochrome is 30-80%, and the quality should meet GB5683-87; the oxide purity of the metal oxide powder is ≥ 60%, preferably usi...

Embodiment 2

[0017] Embodiment 2, the present invention can also add catalyst in the mixed powder of carbon ferrochrome powder and metal oxide, and described catalyst comprises potassium ion type, sodium ion type catalyst, carbon ferrochrome and metal oxide mixed powder The weight ratio of the catalyst to the catalyst is 1:0.005-0.02, and the particle size of the catalyst powder is 80-500 meshes; compaction, drying, and high-temperature metallurgy convert the chromium in the carbon ferrochromium into dichromium trioxide, and prepare it by cooling. After powdering, chromium trioxide is separated by water separation method or acid separation method. Described potassium ion catalyst comprises potassium chloride KCl, potassium fluoride KF, potassium iodide KI or potassium carbonate K 2 CO 3 , sodium ion catalysts include sodium chloride NaCl, sodium fluoride NaF, sodium iodide NaI or sodium carbonate Na 2 CO 3 . refer to figure 1 , all the other are with embodiment 1.

Embodiment 3

[0018] Embodiment 3, the weight ratio of the carbon ferrochrome of the present invention to the metal oxide is 1:0.3-0.5, and the chromium separation rate can reach 15-33%. refer to figure 1 , all the other are with embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com