Method for quantitatively detecting calcium chromate in vanadium slag calcium roasting clinker

A technology of calcification roasting and calcium chromate, applied in the field of metallurgy and chemical industry, can solve the problems of calcium chromate generation and quantitative analysis of calcium chromate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for quantitative detection of calcium chromate in vanadium slag calcified roasting clinker, comprising the steps of:

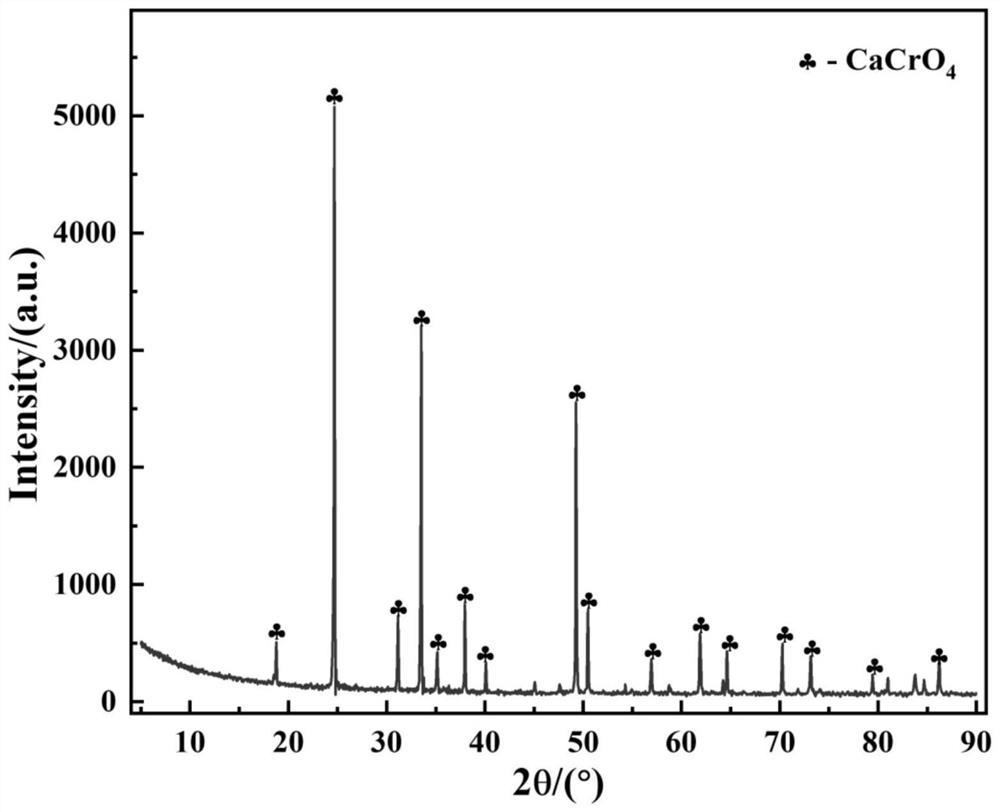

[0034] (1) Calcium chromate standard substance preparation: chemically pure chromium trioxide is mixed with chemically pure calcium oxide, and the mixing ratio is n(CaO) / n(Cr 2 o 3 ) = 2.0, mixed and roasted at 850°C for 25h to obtain pure calcium chromate, calcium chromate was subjected to X-ray diffraction, and the XRD diffraction pattern obtained was as follows figure 1 shown. The calcium chromate has a high degree of coincidence with the standard card of its XRD diffraction pattern, and there are no diffraction peaks of calcium oxide and chromium trioxide. The pure substance of calcium chromate obtained was detected by scanning electron microscopy, and calcium oxide and trioxide were not found in the energy spectrum analysis of the electron microscope. Dichromium pure substance, the obtained calcium chromate pure substance is used as a st...

Embodiment 2

[0041] A method for quantitative detection of calcium chromate in vanadium slag calcified roasting clinker, comprising the steps of:

[0042] (1) Calcium chromate standard substance preparation: the ratio of analytical pure chromium trioxide and analytical pure calcium oxide according to the amount of substance is n(CaO) / n(Cr 2 o 3 ) = 2.0 for mixing, after mixing, roast at a constant temperature of 800°C for 24 hours to obtain a pure substance of calcium chromate. After testing, the calcium chromate has a high degree of coincidence with its standard card, and there are no diffraction peaks of calcium oxide and chromium trioxide; Analysis did not hit calcium oxide and chromium trioxide pure substances.

[0043] (2) Standard medium selection: Take 3g of calcium chromate and add 30ml of sulfuric acid solution with a volume fraction of 7.5% to dissolve and leach for 1h, dissolve and separate the solid and liquid by filtration, collect the leaching solution and add water to dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com