Main iron trough castable for small blast furnace

A technology of castables and main iron channels, applied in the field of metallurgical refractory materials, can solve the problems of stable and safe production of blast furnaces, high viscosity of binders, thermal spalling structures, etc., and achieve enhanced high temperature strength and various properties, thermal shock stability Good performance, increase the effect of wetting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

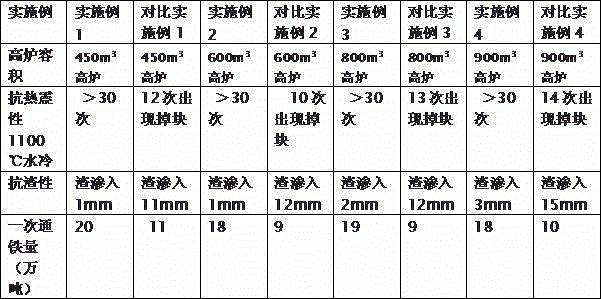

Examples

Embodiment 1

[0020] Use formula 1 to prepare the main iron channel of blast furnace: mix the ingredients according to formula 1 and stir in the mixer, then add 3-8% of the above-mentioned total amount of clean water, stir evenly, and pour it into the mold installed in the main iron channel where the molten iron flows. Add castables, and natural curing for 1 hour to demould the blast furnace main iron trough.

Embodiment 2

[0022] Prepare the main iron channel of blast furnace with formula 2: mix the ingredients according to formula 2 and stir in the mixer, then add 3-8% of the above-mentioned total amount of clean water, stir evenly, and pour it into the mold installed in the main iron channel where the molten iron flows. Add castables, and natural curing for 1 hour to demould the blast furnace main iron trough.

Embodiment 3

[0024] Prepare the main iron channel of blast furnace with formula 3: mix the ingredients according to formula 3 and stir in the mixer, then add 3-8% of the above-mentioned total amount of clean water, stir evenly, and pour it into the mold installed in the main iron channel where the molten iron flows. Add castables, and natural curing for 1 hour to demould the blast furnace main iron trough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com