High-temperature wear-resistant repairing coating and preparation method thereof

A high-temperature wear-resistant and coating technology, applied in the field of refractory materials, can solve the problems of low flexural strength, consumption of manpower and financial resources, and short service life, and achieve the effect of saving manpower and material resources, improving production efficiency, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, high temperature wear-resistant repair paint, is made up of the first material of 70 parts of weight and the second material of 30 parts of weight, wherein:

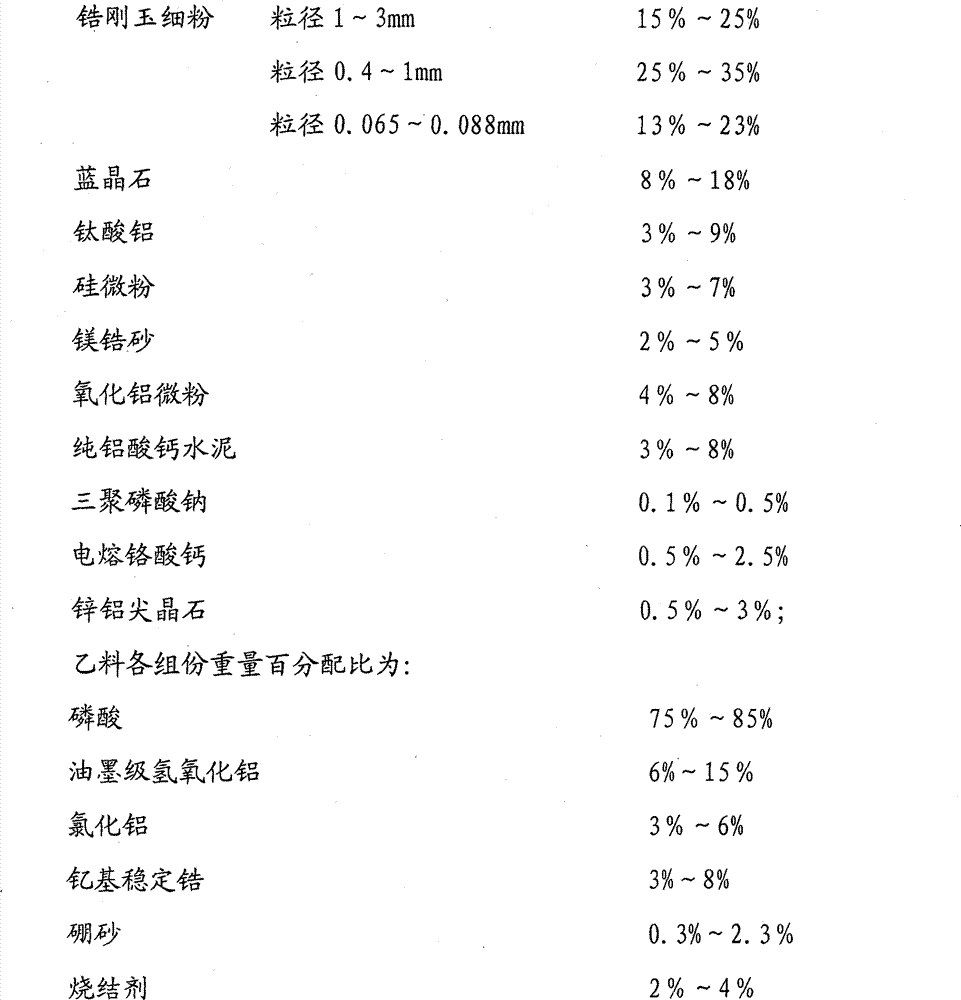

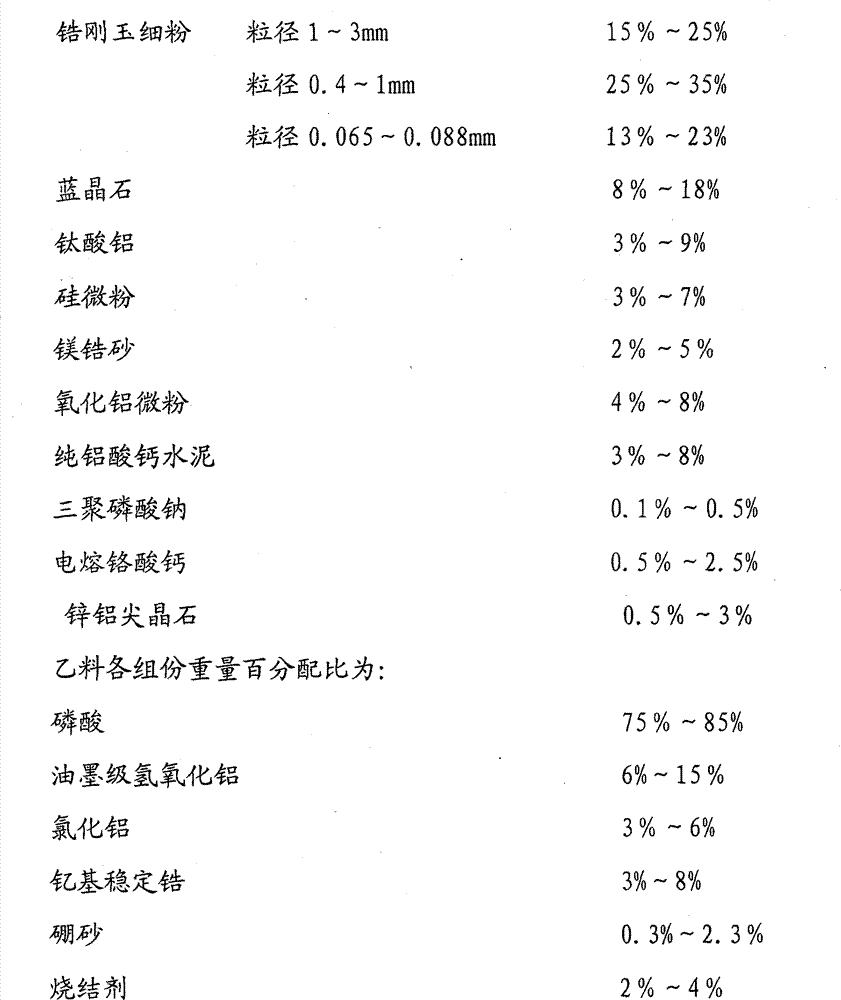

[0017] The weight percentage of each component of material A is:

[0018]

[0019]

[0020] Among them: the fineness of kyanite is 180 mesh to 220 mesh (sieved); the silicon powder is Elkem silicon powder with silicon content Si≥98%, the content of magnesium oxide (MgO) in magnesia-zirconium sand is 90%, titanic acid Titanium dioxide (TiO 2 ) content is 40%.

[0021] The weight percent of each component of second material is:

[0022]

[0023] Among them: the concentration of phosphoric acid is 85%; the fineness of aluminum chloride is 0.008-0.05mm, and the middle temperature sintering agent is silicate.

[0024] During manufacture, the components of material A are uniformly mixed according to the proportion and packed in bags, and the components of material B are uniformly mixed accordin...

Embodiment 2

[0025] Embodiment 2, high temperature wear-resistant repair paint, is made up of the first material of 80 parts by weight and the second material of 20 parts by weight, wherein:

[0026] The weight percentage of each component of material A is:

[0027]

[0028] Among them: the fineness of kyanite is 180 mesh to 220 mesh (sieved); the silicon powder is Elkem silicon powder with silicon content Si≥98%, the content of magnesium oxide (MgO) in magnesia-zirconium sand is 90%, titanic acid Titanium dioxide (TiO 2 ) content is 40%.

[0029] The weight percent of each component of second material is:

[0030]

[0031] Among them: the concentration of phosphoric acid is 85% phosphoric acid; the fineness of aluminum chloride is 0.008-0.05mm, and the middle temperature sintering agent is boric acid.

[0032] During manufacture, the components of material A are uniformly mixed according to the proportion and packed in bags, and the components of material B are uniformly mixed ac...

Embodiment 3

[0033] Embodiment 3, high temperature wear-resistant repair paint, is made up of the first material of 85 parts of weight and the second material of 15 parts of weight, wherein:

[0034] The weight percentage of each component of material A is:

[0035]

[0036] Among them: the fineness of kyanite is 180 mesh to 220 mesh (sieved); the silicon powder is Elkem silicon powder with silicon content Si≥98%, the content of magnesium oxide (MgO) in magnesia-zirconium sand is 90%, titanic acid Titanium dioxide (TiO 2 ) content is 40%.

[0037] The weight percent of each component of second material is:

[0038]

[0039]

[0040] Among them: phosphoric acid with a concentration of 85% phosphoric acid; the fineness of aluminum chloride is 0.008-0.05mm, and the medium temperature sintering agent is nickel oxide.

[0041] During manufacture, the components of material A are uniformly mixed according to the proportion and packed in bags; the components of material B are uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com