Treatment process method of chrome slag

A treatment process and a technology for chrome slag, applied in the field of chrome slag treatment technology, can solve the problems of slow reproduction speed of functional bacteria, reduced ability to reduce chromium, low bacterial survival rate, etc., and achieve low implementation cost, improved environmental protection, and simple implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

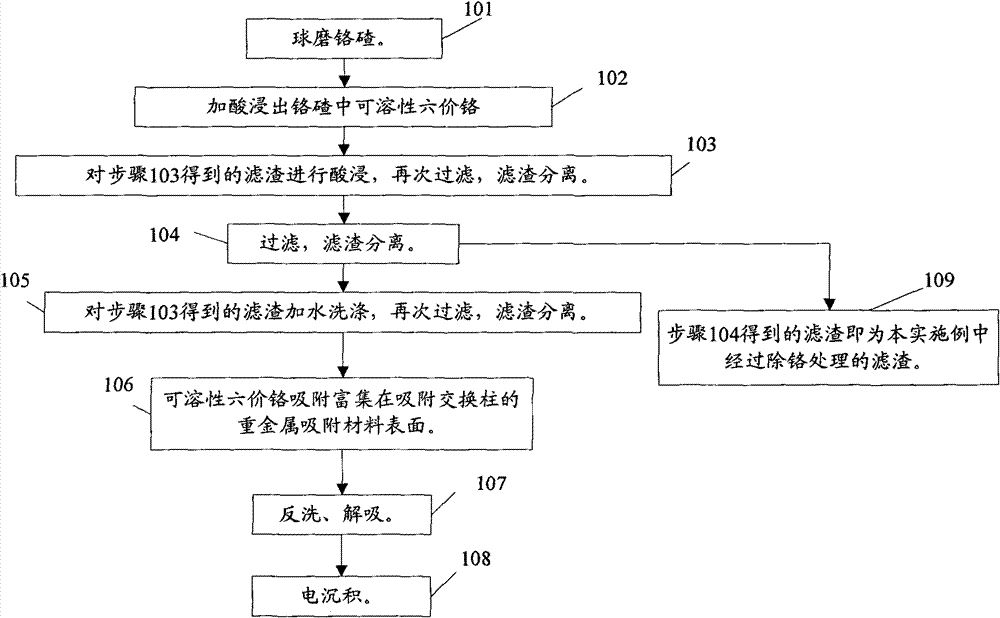

[0074] figure 1 A schematic flow chart of a processing method for chrome slag provided in this embodiment, referring to the illustration, the process mainly includes:

[0075] Step 101: Ball mill the chrome ballast.

[0076] In this embodiment, the original chromium slag can be ball milled to reduce its particle size and improve the effect of chromium treatment. For example but not limited to the following implementation techniques:

[0077] The loader loads the chromium slag into the belt conveyor funnel. In order to prevent dust pollution, it can also be equipped with a spray device to spray the chromium slag to reduce the dust flying rate and reduce air pollution. After the chromium slag enters the ball mill from the belt conveyor funnel through the belt conveyor, it is wet-milled with water. At this time, the circulating water of the system is used as the supplementary water of the ball mill.

[0078]After the chromium slag is ground by the ball mill, the chromium slag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com