Method for preparing chromate from oyster shells and tanning sludge

A technology of tanning sludge and oyster shells, applied in the environmental field, to achieve the effects of cost reduction, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A resource recovery method for preparing chromate from oyster shells and tannery sludge, which specifically includes the following steps:

[0037] (1) Precipitate the waste water produced in the chrome tanning process of the tanning industry with alkali. The concentration of chromium in the waste water is 4637mg / L. Sodium hydroxide is used for precipitation, and about 2.7g of sodium hydroxide is added to 1L of waste water. The precipitated chromium-containing sludge is dried in an oven at 60°C, crushed with a crusher, passed through a 100-mesh screen, and set aside for use.

[0038] (2) Crush the washed and air-dried oyster shells to a size of 3-5 cm, try not to damage the overall structure, and set aside.

[0039] (3) Put 100-mesh chromium-containing precipitate and 3-5cm oyster shells in a crucible at a mass ratio of 1:6, infiltrate with deionized water, and mix well.

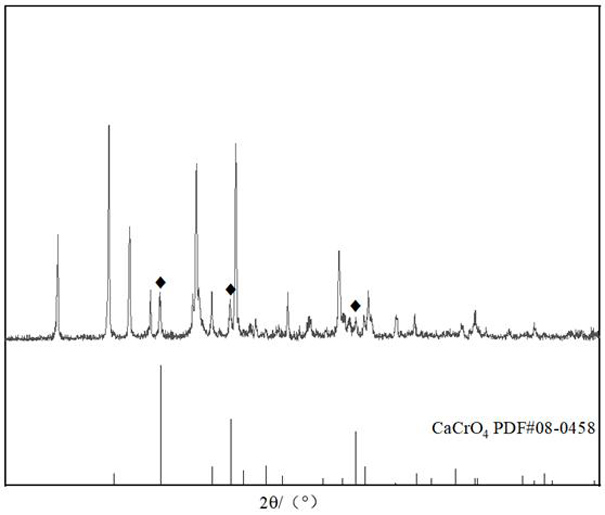

[0040] (4) Put the homogeneously mixed chromium-containing sludge and oyster shells in a tubular m...

Embodiment 2

[0044] A resource recovery method for preparing chromate from oyster shells and tannery sludge, which specifically includes the following steps:

[0045] (1) Precipitate the waste water produced by the chrome tanning process in the tanning industry with alkali. The concentration of chromium in the waste water is 4637mg / L. Precipitate with sodium hydroxide, and add about 2.7g of sodium hydroxide to 1L of waste water. The precipitated chromium-containing sludge is dried in an oven at 60°C, crushed with a crusher, and passed through a 100-mesh screen for use.

[0046] (2) Crush the washed and air-dried oyster shells with a crusher, pass through a 100-mesh sieve, and set aside.

[0047] (3) Put 100 meshes of chromium-containing precipitate and oyster shell powder in a crucible at a mass ratio of 1:2, infiltrate with deionized water and mix evenly.

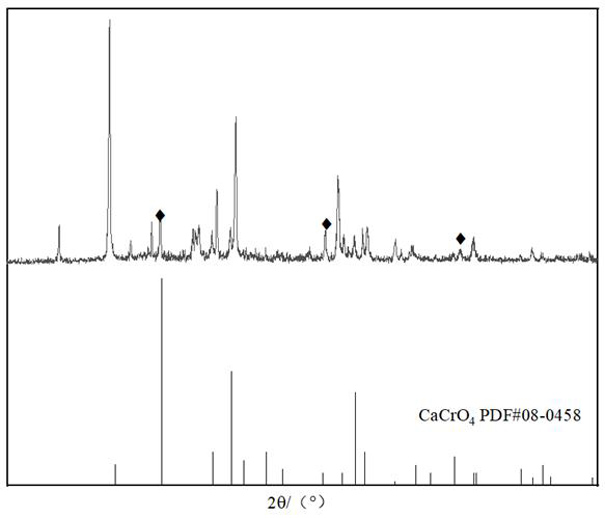

[0048] (4) Put the homogeneously mixed chromium-containing sludge and oyster shell powder in a tubular muffle furnace, react at 800°...

Embodiment 3

[0052] A resource recovery method for preparing chromate from oyster shells and tannery sludge, which specifically includes the following steps:

[0053] (1) Precipitate the waste water produced by the chrome tanning process in the tanning industry with alkali. The concentration of chromium in the waste water is 4637mg / L. Precipitate with sodium hydroxide, and add about 2.7g of sodium hydroxide to 1L of waste water. The precipitated chromium-containing sludge is dried in an oven at 60°C, crushed with a crusher, and passed through a 100-mesh screen for use.

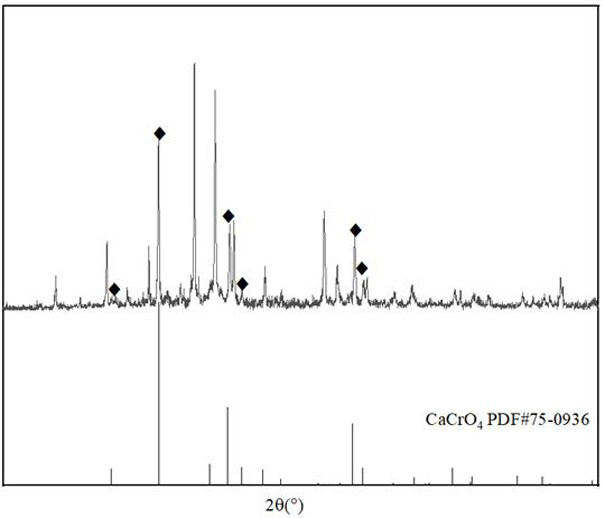

[0054] (2) Crush the washed and air-dried oyster shells with a crusher, and place them in a tubular muffle furnace at 800 °C for 2 h at a heating rate of 10 °C / min to modify the oyster shells. The oyster shell biomass powder is passed through a 100-mesh sieve and set aside.

[0055] (3) Put 100 meshes of chromium-containing precipitate and oyster shell biomass powder in a mass ratio of 1:1 in a crucible, infiltrate with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com