Silicon-carbon negative electrode material and preparation method thereof

A negative electrode material, silicon carbon technology, applied in the field of silicon carbon negative electrode material and its preparation, can solve the problems of potential safety hazards, complicated preparation process, harmful environment, etc., achieve good conductivity, no potential safety hazards, and improve electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

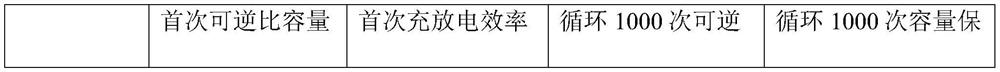

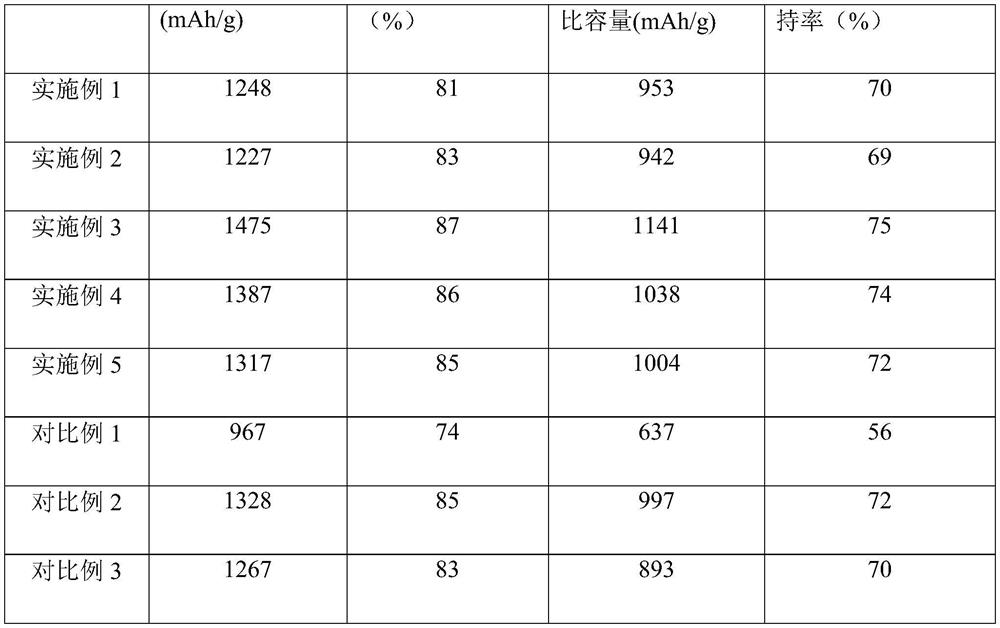

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing a silicon-carbon negative electrode material, comprising the following steps:

[0027] Nano-silicon, calcium chromate aqueous solution (mass concentration is 20g / L), carboxymethyl cellulose are joined in the microwave hydrothermal reaction kettle, (the mass ratio of nano-silicon, carboxymethyl cellulose and calcium chromate is 7: 1:70) continuously stirred for 5 hours, then microwave heated to 40°C, filtered to obtain a filter cake, and dried the filter cake in a blast drying oven at 120°C for 3 hours to obtain the first intermediate product;

[0028] Mix dopamine and the first intermediate product in a beaker and stir for 3 hours (the mass ratio of the first intermediate product to dopamine is 3:7), then put it into a tube furnace, and calcinate it for 12 hours under an argon atmosphere to obtain the second intermediate product. product;

[0029] Add the second intermediate product and dilute sulfuric acid solution (conc...

Embodiment 2

[0031] This embodiment provides a method for preparing a silicon-carbon negative electrode material, comprising the following steps:

[0032] Nano-silicon, calcium chromate aqueous solution (mass concentration is 30g / L), sodium hexametaphosphate are added in the microwave hydrothermal reaction kettle, (the mass ratio of nano-silicon, sodium hexametaphosphate and calcium chromate is 5:1: 80) Stir continuously for 2 hours, then microwave heating to 60°C, filter to obtain a filter cake, and place the filter cake in a blast drying oven at 80°C for 5 hours to obtain the first intermediate product;

[0033] Mix dopamine and the first intermediate product in a beaker and stir for 1 hour (the mass ratio of the first intermediate product and dopamine is 3:8), then put it into a tube furnace, and calcinate it for 9 hours under a neon gas environment to obtain the second intermediate product. product;

[0034] Add the second intermediate product and dilute sulfuric acid solution (the co...

Embodiment 3

[0036] This embodiment provides a method for preparing a silicon-carbon negative electrode material, comprising the following steps:

[0037] Add nano-silicon, calcium chromate aqueous solution (mass concentration of 25g / L), and sodium pyrophosphate into the microwave hydrothermal reaction kettle, (the mass ratio of nano-silicon, sodium pyrophosphate and calcium chromate is 6:1:75) Stir continuously for 3 hours, then microwave heating to 50°C, filter to obtain a filter cake, and place the filter cake in a blast drying oven at 100°C for 4 hours to obtain the first intermediate product;

[0038] Mix dopamine and the first intermediate product in a beaker and stir for 2 hours (the mass ratio of the first intermediate product to dopamine is 3:8), then put it into a tube furnace, and calcinate it under an argon atmosphere for 11 hours to obtain the second intermediate product. product;

[0039] Add the second intermediate product and dilute sulfuric acid solution (the concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com