Perovskite type conductive ceramic membrane and preparation method and application thereof

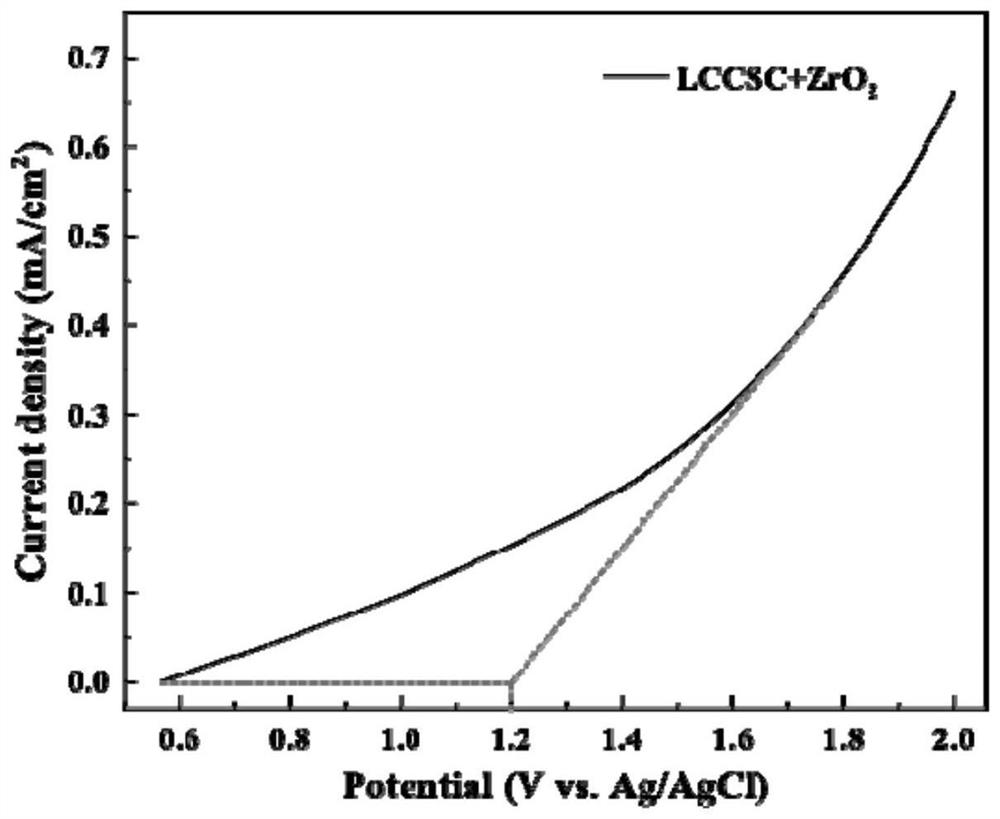

A conductive ceramic and perovskite-type technology, which is applied in the field of water treatment conductive ceramic membrane preparation, can solve the problems of low mechanical strength, long service life, and unstable electrochemical performance of the conductive layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A perovskite-type conductive ceramic film, the preparation method comprising the following steps:

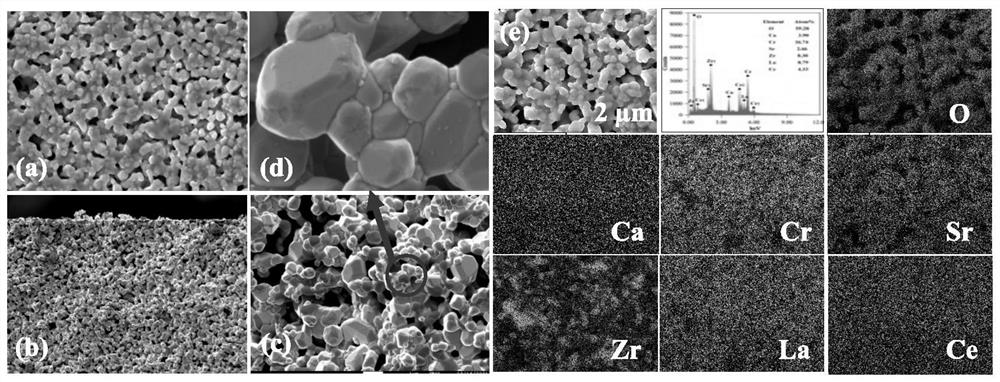

[0034] (1) Preparation of perovskite-type conductive precursor powder: First, the nitrate solutions of chromium, lanthanum, cerium, strontium, and calcium are mixed in a molar ratio of 1:0.4:0.2:0.2:0.2 to prepare homogeneous nitrates solution, then put into the citric acid crosslinking agent with a molar ratio of 1.2:1.0 to the metal cation to form a homogeneous transparent solution, and then put into the ethylenediaminetetraacetic acid (EDTA) chelating agent with a molar ratio of 1.1:1.0 to the metal cation, and then The pH of the obtained precursor solution was adjusted to 7.0 with a volatile alkali (ammonia), mixed evenly, and heated and dehydrated in a water bath at 80°C. Finally, pulverize the dry gel and place it on a flat-panel electric furnace at 350 °C to burn and remove carbon to obtain a brown solid powder. Finally, grind the obtained brown powder to below 200...

Embodiment 2

[0039] The ratio of chromium, lanthanum, cerium, strontium, and calcium in the preparation of the perovskite-type conductive precursor powder in step (1) of Example 1 is adjusted to 1:0.4:0.1:0.3:0.2, and other conditions remain unchanged.

Embodiment 3

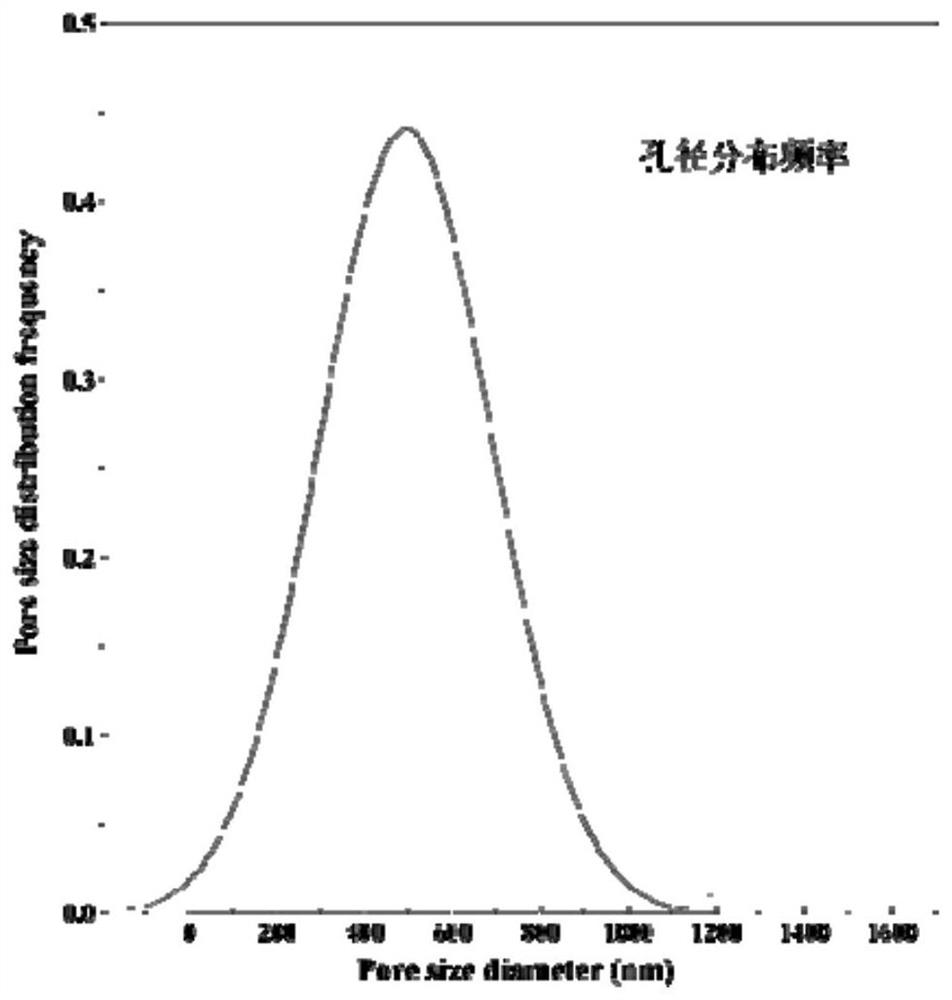

[0041] In the preparation of conductive ceramic powder in step (2) of Example 1, the mass ratio of conductive precursor to zirconia ceramic powder, binder and pore-forming agent was adjusted to 75wt%, 20wt%, 2wt% and 3wt%, and other Conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com