Chromium-containing wastewater treatment method capable of realizing zero emission of pollutants

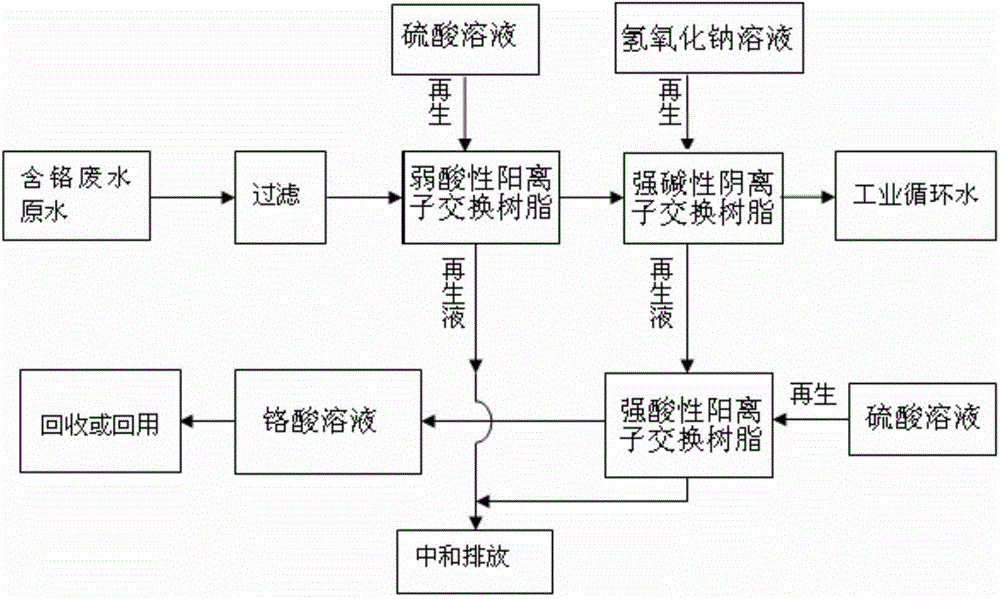

A treatment method and technology for chromium wastewater, applied in the fields of water pollutants, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of waste of chromium resources, unstable treatment effect and high treatment cost, and reduce the operation cost. Cost and investment cost, easy control of operating parameters, simple effect of processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) at 150m 3 In the chromium wastewater collection pool of the cold rolling water station, the chromium-containing wastewater is filtered and then entered into the liquid storage tank, and the pH value is adjusted to 8-11 at room temperature. Put it into the HLMK-CR1 adsorption reactor filled with DK110 weakly acidic cation exchange resin, carry out ion exchange and adsorption of substances other than chromium, and convert the chromium ions in the wastewater into hexavalent chromium;

[0027] When the conductivity of the effluent water from the HLMK-CR1 adsorption reactor is close to the target value (such as <300μs / cm), it will be transferred to the regeneration program, and the residual liquid in the adsorption reactor will be emptied (return to the collection pool), and in the upper part of the adsorption reactor Add compressed air to dry it, first rinse the DK110 weakly acidic cation exchange resin with treated effluent, then add a mass fraction of 5% sulfuric acid ...

Embodiment example 2

[0034] 1) at 150m 3 The waste water is taken from the chromium waste water collection tank and enters the filter. At normal temperature, the filtered chromium-containing waste water is first adjusted to a pH value of 8-11, and then ion-exchanged with a 724-type weakly acidic cation exchange resin to absorb substances other than chromium ( To ensure the purity of chromium in the chromium-containing wastewater), and to convert the chromium ion into hexavalent chromium in the wastewater, the 724 type weakly acidic cation exchange resin is eluted and regenerated with a mass fraction of 7% sulfuric acid solution (2BV adsorbent volume), and the resulting regeneration solution and post-treatment emissions;

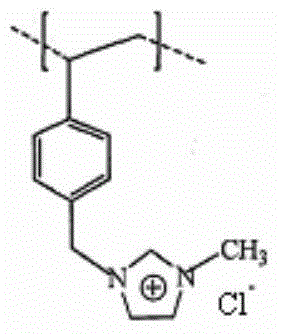

[0035] 2) At normal temperature, adjust the pH value of the chromium-containing wastewater treated with weakly acidic cation exchange resin to 8-11, and then perform ion exchange with polystyrene resin containing imidazole structure to absorb chromium ions in the wastewater. Tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com