Method for extracting chromium and vanadium from vanadium slag at low temperature and normal pressure

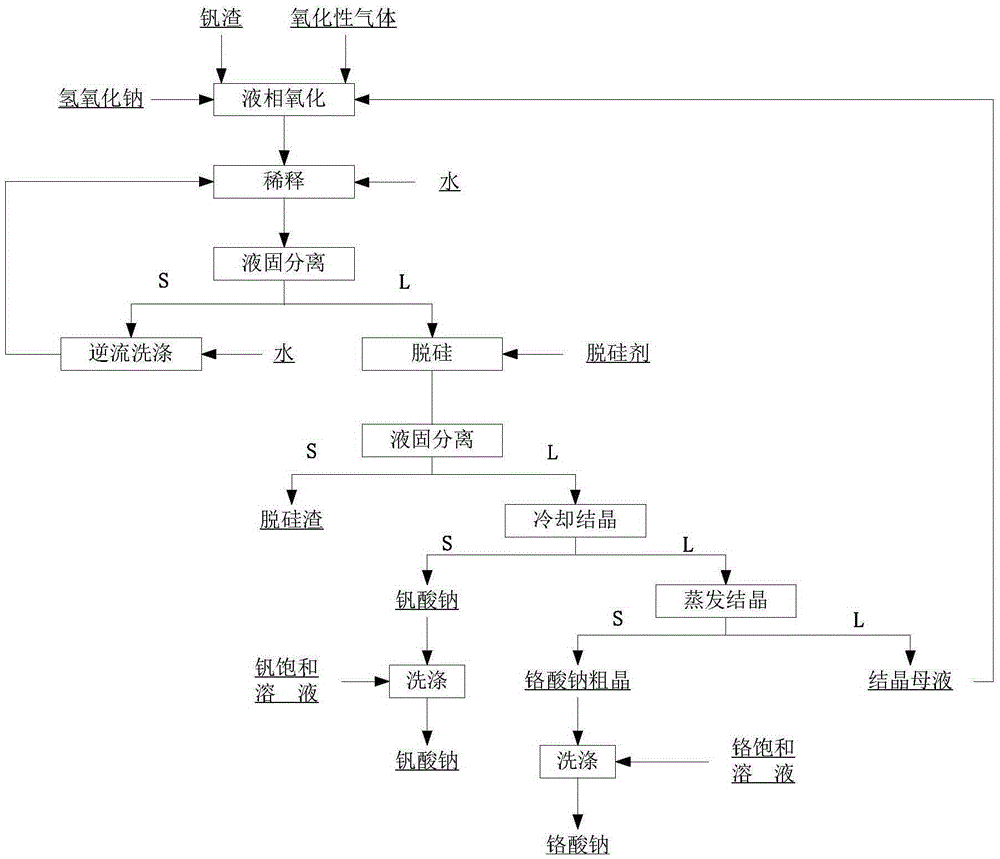

A low temperature and normal pressure vanadium slag technology, applied in the field of extracting vanadium and chromium from vanadium slag at low temperature and normal pressure, can solve the problems of low oxygen solubility, lower temperature and energy consumption, and ineffective alkaline solution aeration method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Ingredients: In a 15L reactor, add 2kg of vanadium slag and 40wt% NaOH solution, wherein the vanadium slag contains V 2 o 5 8.3wt%, Cr 2 O33.41%, the mass ratio of alkali ore is 2:1;

[0069] (2) Reaction: Stir and heat the slurry prepared in step (1) to 120°C, put a microporous aeration head at the bottom of the normal pressure reactor, connect the aeration head to a pressure-resistant metal hose, Air was blown into the kettle. The aerator head is a rod-shaped structure with a diameter of 20mm and a length of 100mm, which is fired from titanium alloy powder and has an average pore diameter of 20μm. The gas distribution pressure of the micropores is 0.3MPa, the gas flow rate is 0.4L / min, the gas temperature is 80°C, and it is heated by a hot blast stove. Insulation reaction for 4 hours, so that the vanadium slag can fully react with oxygen, and finally get NaOH, Na 3 VO 4 、Na 2 CrO 4 、Na 2 SiO 4 The conversion rates of vanadium and chromium in solutions su...

Embodiment 2

[0076] (1) Ingredients: In a 15L reactor, add 2kg of vanadium slag and 50wt% NaOH solution, wherein the vanadium slag contains V 2 o 5 8.3wt%, Cr 2 O33.41%, the mass ratio of alkali ore is 2.5:1;

[0077] (2) Reaction: Stir and heat the slurry prepared in step (1) to 130°C, put a microporous aeration head at the bottom of the normal pressure reactor, connect the aeration head to a pressure-resistant metal hose, Air was blown into the kettle. The aerator head is a hemispherical structure with a diameter of 100mm and a micropore diameter of 30μm, which is fired from nickel alloy powder. Micropore air distribution pressure is 0.8MPa, gas flow rate is 0.6L / min, gas temperature is 120°C, and is heated by a hot blast stove. Insulation reaction for 5 hours, so that the vanadium slag can fully react with oxygen, and finally get NaOH, Na 3 VO 4 、Na 2 CrO 4 、Na 2 SiO 4 The conversion rates of vanadium and chromium in solutions such as iron-rich tailings and vanadium slag are 9...

Embodiment 3

[0085] (1) Ingredients: In a 15L reactor, add 2kg of vanadium slag and 60wt% NaOH solution, wherein the vanadium slag contains V 2 o 5 8.3wt%, Cr 2 O33.41%, the mass ratio of alkali ore is 2.5:1;

[0086] (2) Reaction: Stir and heat the slurry prepared in step (1) to 125°C, put a microporous aeration head at the bottom of the normal pressure reactor, connect the aeration head with a pressure-resistant metal hose, Oxygen-enriched air (oxygen content is 40%) is blown into the kettle. The aerator head is a box-shaped structure with length, width and height of 50mm, 25mm and 15mm respectively, and is made of nickel alloy powder. The gas distribution pressure of the micropores is 0.8MPa, the gas flow rate is 0.3L / min, the gas temperature is 145°C, and it is heated by a hot blast stove. Keeping the temperature for 3 hours, so that the vanadium slag can fully react with oxygen, and finally get NaOH, Na 3 VO 4 、Na 2 CrO 4 、Na 2 SiO 4 The conversion rates of vanadium and chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com