Method for separating and recovering vanadium and chromium from vanadium-chromium slag

A technology for separation and recovery of vanadium chromium slag, applied in the field of separation and recovery, can solve the problems of large equipment investment, difficult precise operation, complicated process, etc., and achieve the effect of less equipment investment, simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

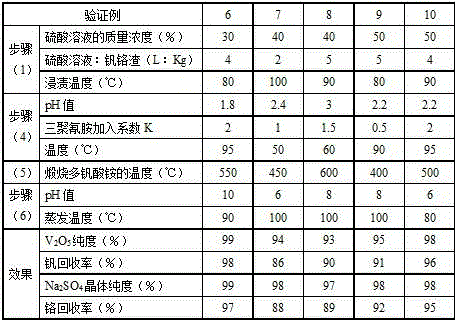

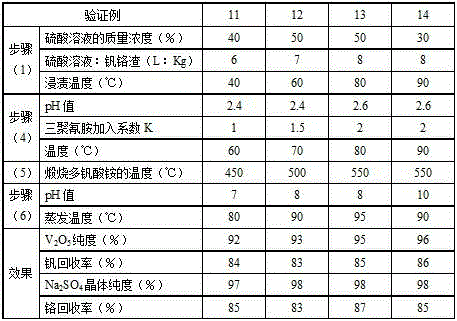

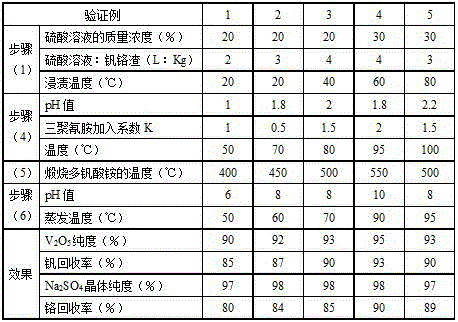

Examples

Embodiment Construction

[0014] A method for separating and recovering vanadium and chromium from vanadium-chromium slag, characterized in that the method comprises the following steps:

[0015] (1) Add vanadium chromium slag to sulfuric acid (H 2 SO 4 ) solution, then stand still, impregnate, and filter to obtain the filtrate dissolved in vanadium ions and chromium ions; among them, the mass of vanadium and chromium contained in vanadium-chromium slag accounts for 3.1% and the mass of chromium accounts for 18.8% as the calculation basis , under the situation that the mass concentration of sulfuric acid solution is 20~50%, sulfuric acid solution: vanadium-chromium slag=2~8L: 1Kg; Immersion temperature is 20~100 ℃, and the immersion time no longer has new vanadium ion, chromium ion Dipping out to a certain degree (usually 0.5 ~ 2h).

[0016] The function of this step is to separate the vanadium ions and chromium ions mixed in the vanadium-chromium slag from the vanadium-chromium slag.

[0017] (2) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com