Method for preparing sodium chromate by mixing chromite and ferrochrome and device for method

A technology of chromite and sodium chromate, applied in the direction of chromate/dichromate, can solve the problems of kiln nodulation, complex treatment process, low slag discharge, etc., to reduce energy consumption and shorten the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

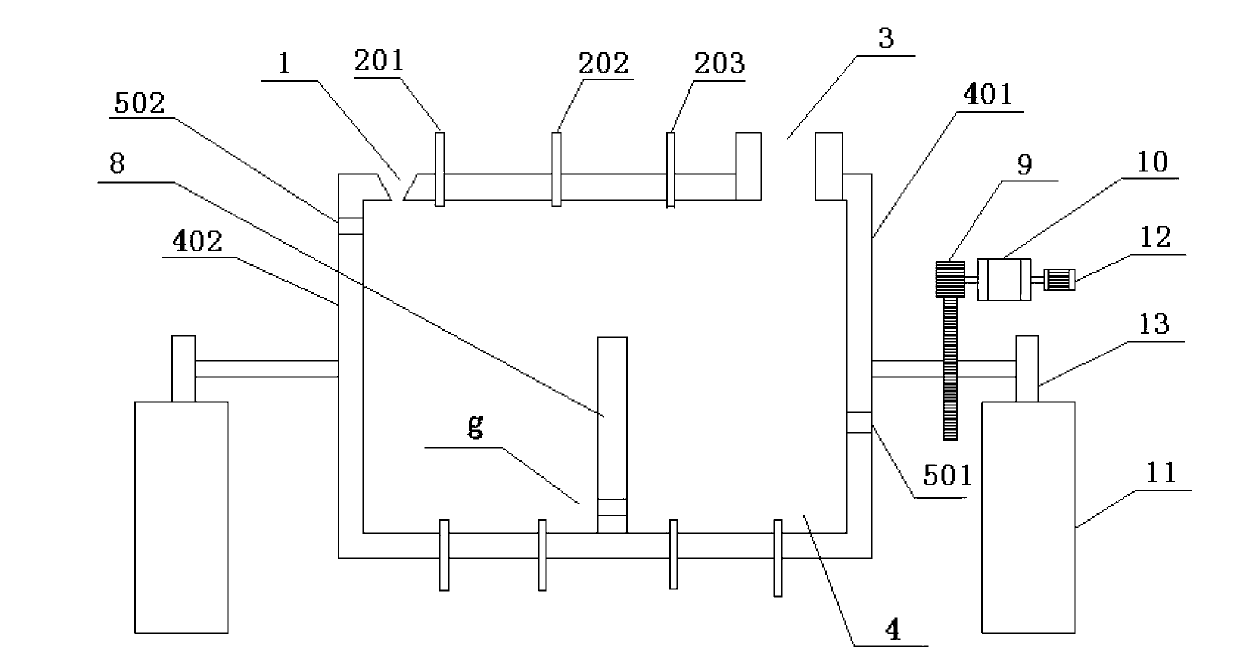

[0102] ① According to the mass ratio, chromite (calculated as dichromium trioxide): ferrochromium (calculated as dichromium trioxide): soda ash: sodium nitrate: sodium peroxide: liquid sodium chromate: clinker after melting and cooling=1: 0.5∶2.0∶0.02∶0.02∶4.5∶0.5, combined into balls to obtain granular raw meal;

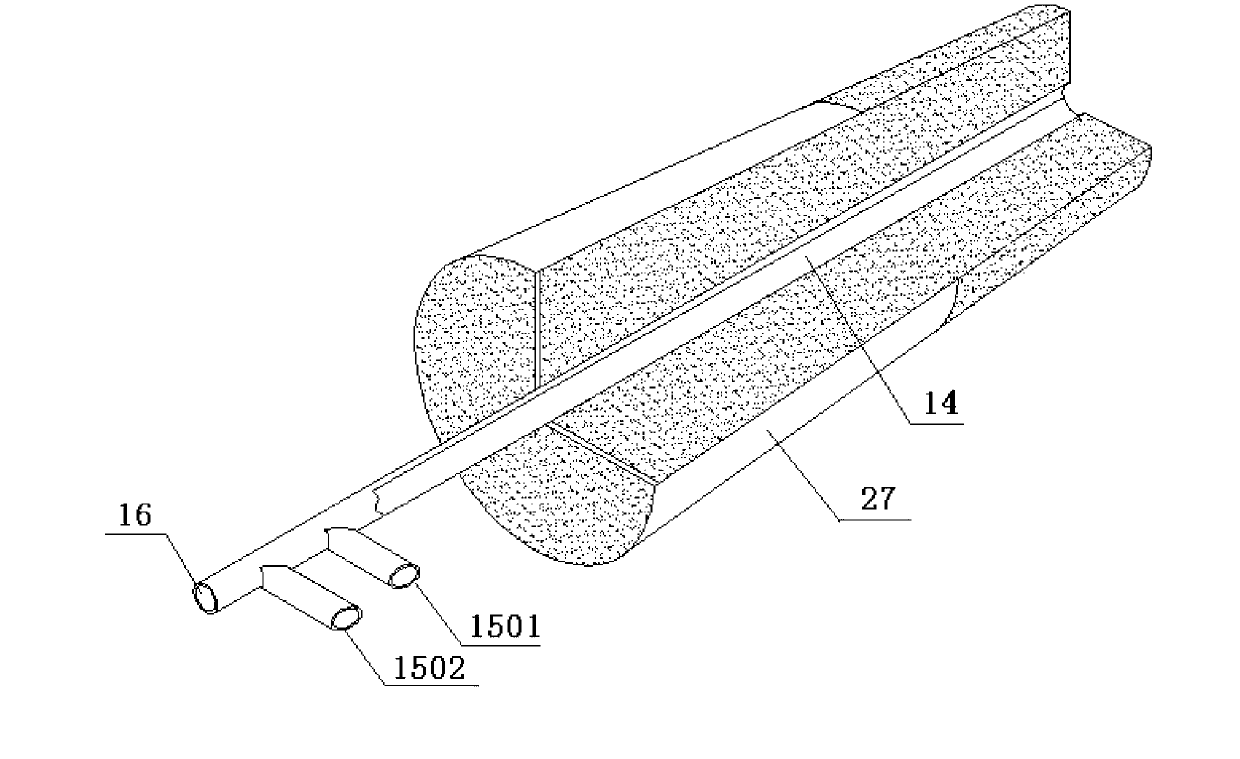

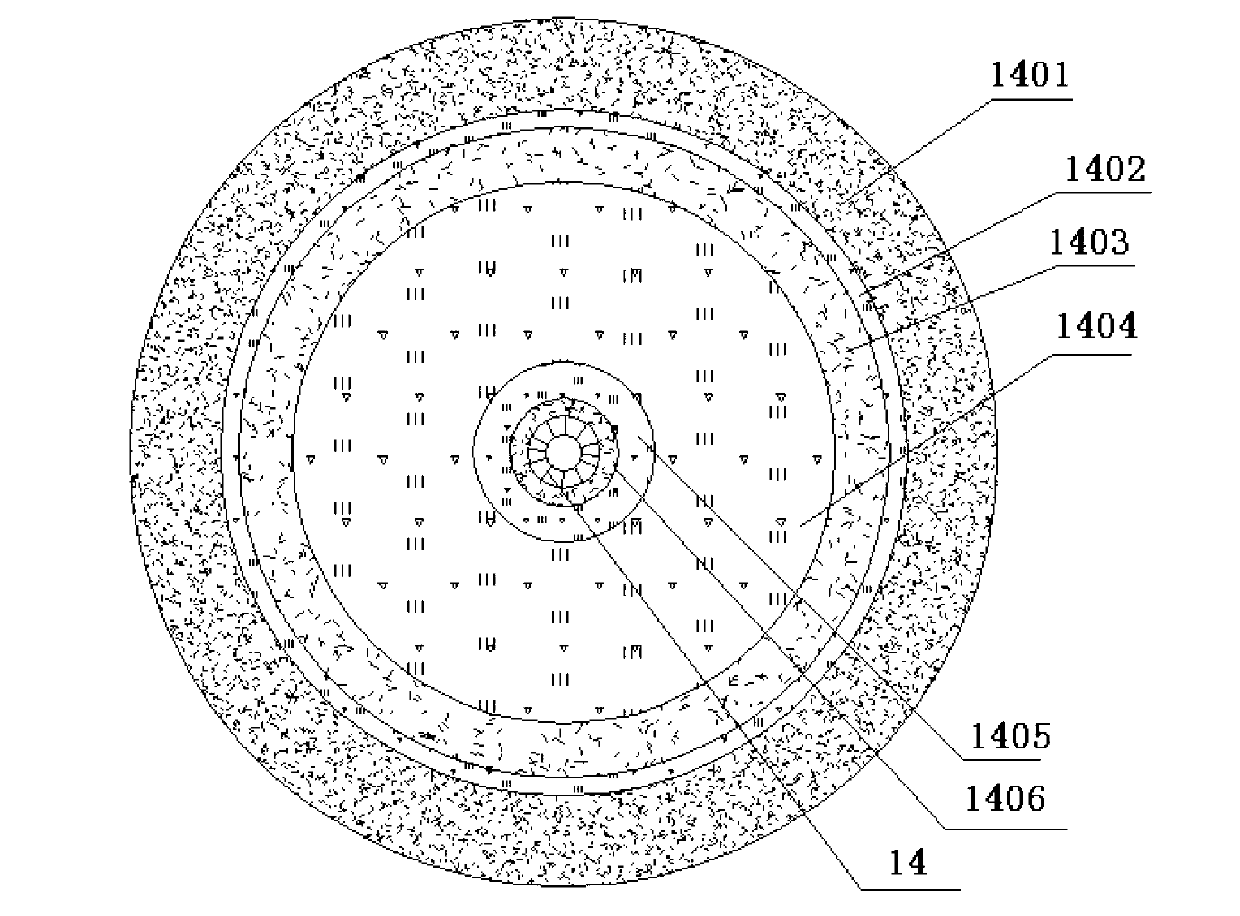

[0103] ②Put the granular raw meal into the horseshoe-shaped horizontal flame kiln through the feeding port a, start the top-blowing oxygen lance b1, b2, control the reaction temperature to 1550°C, and keep it at this temperature for 60 minutes;

[0104] ③Then, continuously spray air into the horizontal flame kiln through the bottom blowing oxygen lances f1, f2, f3, and f4, and react at 1550°C for 5 minutes, during which the reaction mixture is in a molten liquid phase;

[0105] ④The gas produced in the horizontal flame kiln is removed from the flue gas outlet, and the liquid phase clinker is removed through the high-level liquid phase outlet, and is cooled in a roto...

Embodiment 2

[0107] ① According to the mass ratio, chromite (calculated as dichromium trioxide): ferrochromium (calculated as dichromium trioxide): soda ash: sodium nitrate: sodium peroxide: liquid sodium chromate: clinker after melting and cooling=1: 10: 18.50: 0.15: 0.15: 22: 7.0, combined into balls to obtain granular raw meal;

[0108] ②Put the granular raw meal into the horseshoe-shaped horizontal flame kiln through the feeding port a, start the top blowing oxygen lances b1, b2, control the reaction temperature to 1650°C, and keep at this temperature for 40 minutes;

[0109] ③Then, continuously spray air into the horizontal flame kiln through bottom blowing oxygen lances f1, f2, f3, f4, and react at 1650°C for 3 minutes, during which the reaction mixture is in a molten liquid phase;

[0110] ④The gas produced in the horizontal flame kiln is removed from the flue gas outlet, and the liquid phase clinker is removed through the high-level liquid phase outlet, and is cooled in a rotor cup...

Embodiment 3

[0112] ① According to the mass ratio, chromite (calculated as dichromium trioxide): ferrochromium (calculated as dichromium trioxide): soda ash: sodium nitrate: sodium peroxide: liquid sodium chromate: clinker after melting and cooling=1: 50:100:1:1:100:35, combined into balls to obtain granular raw meal;

[0113] ②Put the granular raw meal into the horseshoe-shaped horizontal flame kiln through the feeding port a, start the top blowing oxygen lance b1, b2, control the reaction temperature to 1850 °C, and keep it at this temperature for 40 minutes;

[0114] ③ Then, continuously spray air into the horizontal flame kiln through bottom blowing oxygen lances f1, f2, f3, f4, and react at 1850°C for 2 minutes, during which the reaction mixture is in a molten liquid phase;

[0115] ④The gas produced in the horizontal flame kiln is removed from the flue gas outlet, and the liquid phase clinker is removed through the high-level liquid phase outlet, and is cooled in a rotor cup made of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com