Method for measuring sulfur in graphite

A graphite and re-adding technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of affecting the test results, easy gas leakage, and complicated use of equipment, etc., to achieve the effect of simple operation method, accurate sulfur content, and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

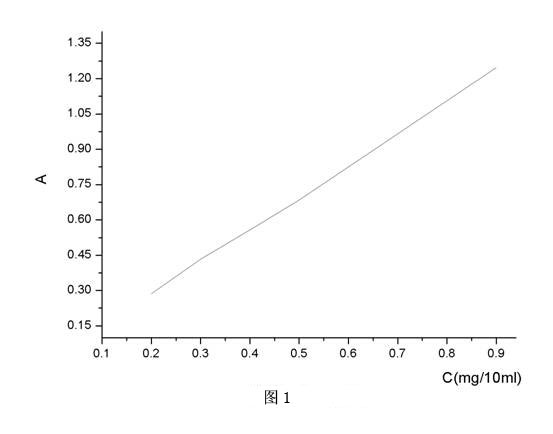

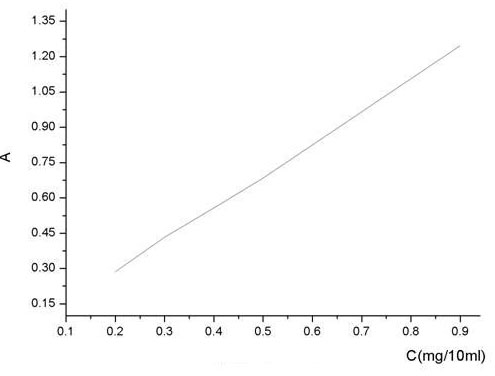

Image

Examples

Embodiment Construction

[0018] A method for measuring sulfur in graphite according to the present invention, comprises the following steps:

[0019] ① Take 1.5g of graphite with a particle size of less than 0.15mm and put it into a porcelain crucible containing 2g of aldrin, stir well to obtain a mixture, then add 1g of aldrin to cover the mixture evenly, and finally obtain a sample;

[0020] ② Put the sample in step ① into a high-temperature furnace, so that the temperature of the high-temperature furnace is raised to 1000°C within 1-1.5 hours, and kept for 1.5-2 hours;

[0021] ③ Take the sample out of the high temperature furnace, and after cooling to room temperature, move the sample to the beaker, rinse the inner wall of the crucible with pure water at 40-60°C, pour the washing liquid in the crucible into the beaker, and then add 30ml- 40ml of pure water at 40℃-60℃, put it into the ultrasonic instrument for 3 minutes, take it out, filter it, and make up to 250ml;

[0022] ④ Take 10ml of the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com