Rare earth doped barium titanate particles and preparation method thereof

A rare earth doping and barium titanate technology, which is applied in the field of barium titanate particles and its preparation, can solve the problems of product performance brittleness, application limitations, and easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

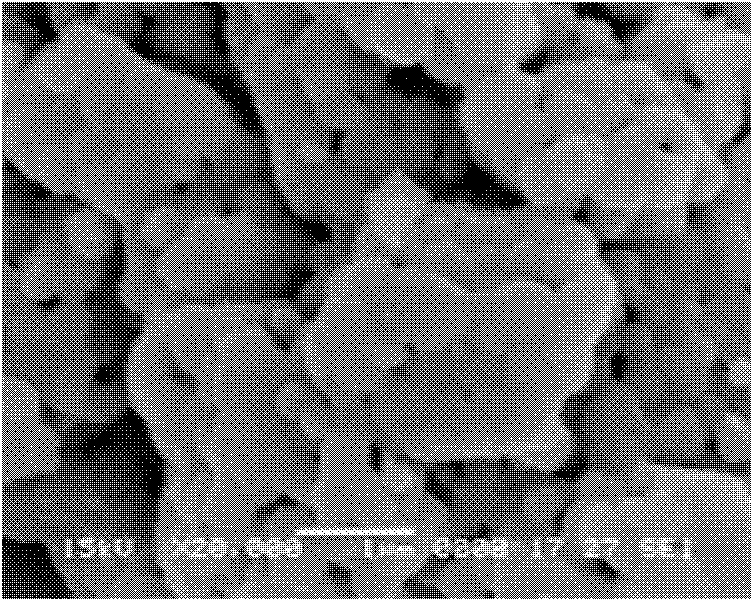

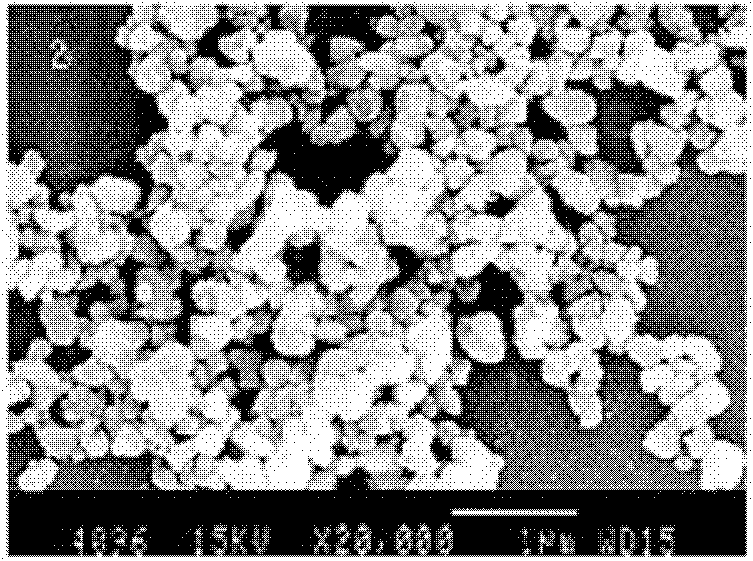

Image

Examples

Embodiment 1

[0026] Add 51 moles of BaCO to the vertical ball mill 3 , then add 50 moles of titanium dioxide, and finally add deionized water for ball milling. The material after ball milling is directly pumped to the vacuum dryer by vacuum pump for drying. Wherein said ball mill is the QMJ200 vertical ball mill of Shanghai Hua Rock Instrument Equipment Co., Ltd. The mass ratio of barium carbonate to deionized water is 1:5, and the ball milling time of the mixed material is 120 minutes. The vacuum drying time is 45-70 minutes, and the vacuum degree is ≤-0.065Mpa.

[0027] The dried material is left for 24 hours and put into a fully automatic pusher kiln for firing. The heat treatment atmosphere is air. Push plate speed 8.5mm / min. The firing kiln used is a 20M fully automatic pusher kiln. Divided into 11 temperature zones. The fired material is crushed, pulverized and classified. Washing with deionized water and firing twice can get pure barium titanate. Grinding conditions: feed f...

Embodiment 2

[0031] Dissolve the oxides of lanthanum, praseodymium, rubidium, samarium, erbium, and gadolinium in concentrated nitric acid respectively, then heat until the oxides are decomposed, adjust the concentration with formamide reagents after cooling, and prepare a solution with a molar concentration of 0.02.

[0032] Add 51 moles of BaCO to the vertical ball mill 3 , and then respectively add lanthanum, praseodymium, rubidium, samarium, erbium, gadolinium oxide-concentrated nitric acid solution, then add 50 moles of titanium dioxide, and finally add deionized water for ball milling. The molar ratio of the rare earth ions in the oxide-concentrated nitric acid solution to the barium ions in the barium carbonate is 0.001-0.005. The material after ball milling is operated according to the conditions and steps of implementation 1.

Embodiment 3

[0034]Dissolve oxides of lanthanum, praseodymium, rubidium, samarium, erbium, and gadolinium in concentrated nitric acid respectively, then heat until the oxides are decomposed, adjust the concentration with formamide reagents after cooling, and prepare a solution with a molar concentration of 0.02.

[0035] Add 51 moles of BaCO to the vertical ball mill 3 , and then add the above-mentioned lanthanum, praseodymium, rubidium, samarium, erbium, gadolinium oxide-concentrated nitric acid solution, then add 50 moles of titanium dioxide, and finally add absolute ethanol for ball milling. The material after ball milling is directly pumped to the vacuum dryer by vacuum pump for drying. Wherein said ball mill is the QMJ200 vertical ball mill of Shanghai Hua Rock Instrument Equipment Co., Ltd. The mass ratio of barium carbonate to deionized water is 1:3, and the ball milling time of the mixed material is 120 minutes. The vacuum drying time is 45-70 minutes, and the vacuum degree is ≤-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com