Patents

Literature

85 results about "2-Methylfuran" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

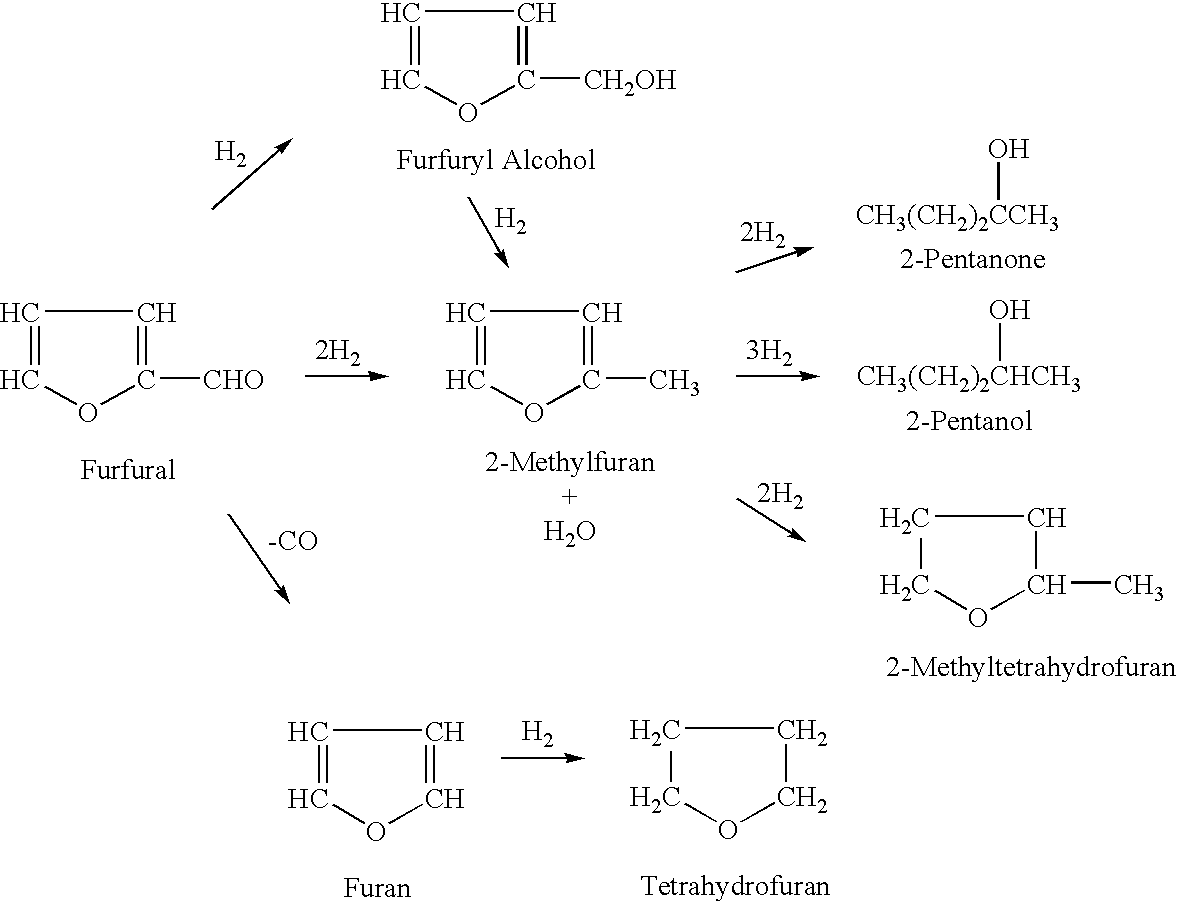

2-Methylfuran is a flammable, water-insoluble liquid with a chocolate odor, found naturally in Myrtle and Dutch Lavender used as a FEMA GRAS flavoring substance, with the potential for use in alternative fuels.

5-(substituted methyl) 2-methylfuran

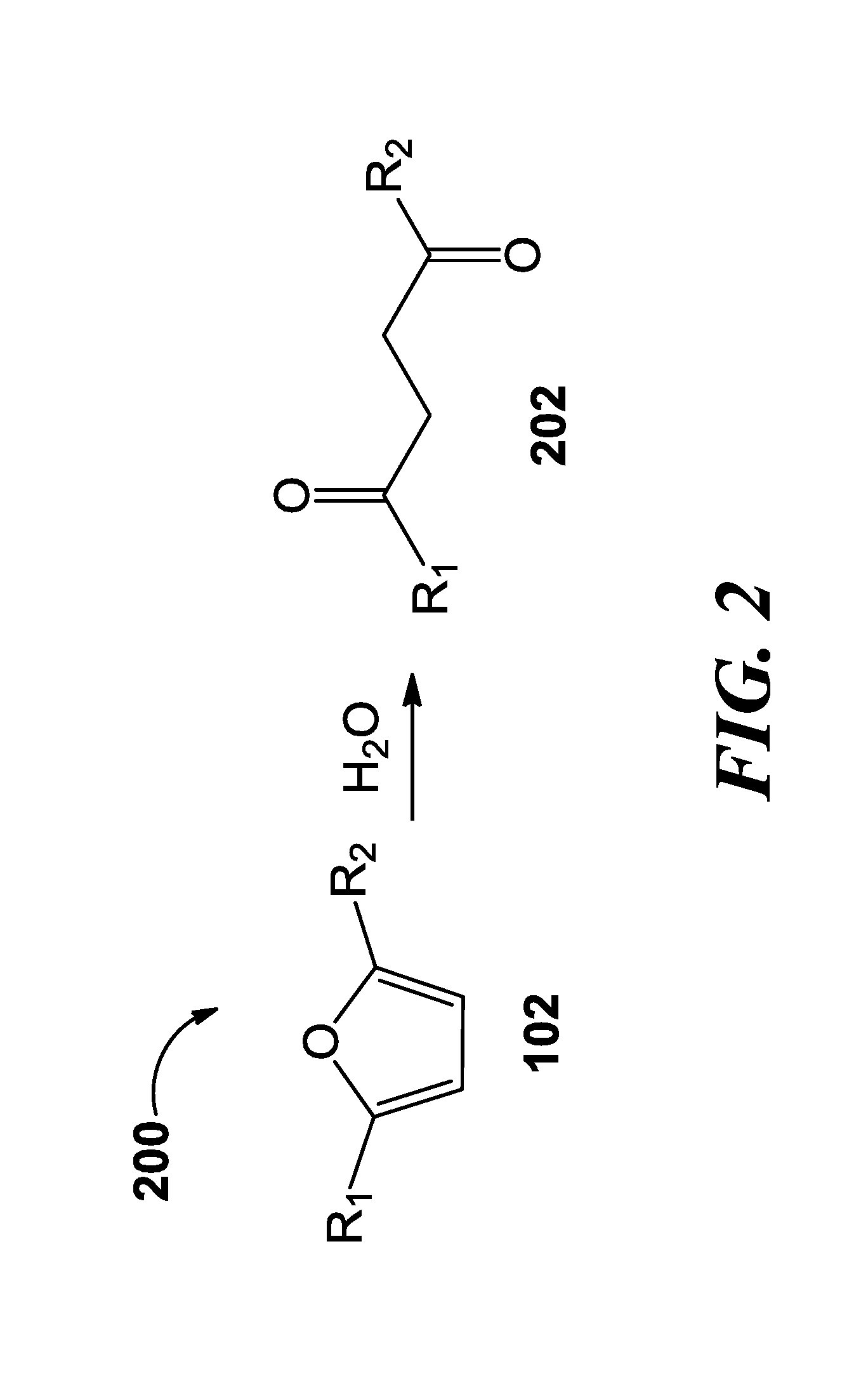

The current invention provides a method for the manufacture of 5-(substituted methyl) 2-methylfuran by reacting 5-(substituted methyl) furfural with hydrogen and a catalyst system, comprising of one or more catalysts. Within the scope of the current invention is the use of 5-(substituted methyl) furfural, and in particular 5-hydroxymethylfurfural and the ethers or esters thereof, which may be obtained from C6 sugars.

Owner:FURANIX TECH BV

Catalyst for preparing 2-methyl furan through gas phase hydrogenation of furfural and preparation method thereof

InactiveCN101961652AHigh activityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranGas phase

The invention discloses a catalyst for preparing 2-methyl furan through gas phase hydrogenation of furfural and a preparation method thereof. The catalyst consists of the following components in percentage by weight: 45 to 60 percent of copper oxide CuO, 30 to 40 percent of chromic oxide CR2O3, 1 to 10 percent of alumina Al2O3 and 1 to 5 percent of silicon oxide SiO2, and is prepared by a coprecipitation method. The catalyst has the characteristics of low activation temperature, long service life, and high selectivity of the 2-methyl furan, and can be used for industrial production of the 2-methyl furan through gas phase hydrogenation of the furfural.

Owner:LAIAN XUNNENG CATALYST

2-methylfuran preparation catalyst by gas-phase hydrogenation of furfural

InactiveCN101422731AHigh activityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsMicrowave methodGas phase

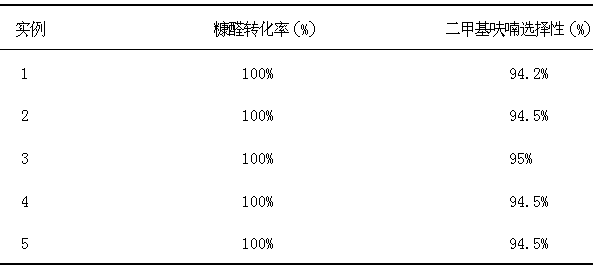

The invention discloses a catalyst that is used for preparing 2-dimethylfuran by furfural gas phase hydrogenation, and is characterized in that the catalyst consists of an active component CuO, a metallic oxide addition agent ZnO and a carrier Al2O3 that are mixed; wherein, the weight percentage of the active component CuO is 18 to 22 percent, the weight percentage of the metallic oxide addition agent ZnO is 3 to 7 percent, and the weight percentage of the carrier Al2O3 is 73 to 77 percent. The preparation method of the catalyst adopts a coprecipitation and microwave method, which comprises the steps of: (1) solution preparation, (2) precipitate generation, (3) precipitate rinsing, (4) precipitate drying, (5) precipitate baking and (6) microwave processing. The invention has the advantages that the catalyst has extremely high activity and selectivity, can achieve the furfural transformation rate of 100 percent and the 2-dimethylfuran selectivity of over 90 percent, and the catalyst does not contain Cr that is harmful to human body and has less environmental pollution.

Owner:CHINA NAT ACAD NANOTECH & ENG

Catalyst for preparing 2-methylfuran by gas-phase hydrogenation of furaldehyde and its preparation method

InactiveCN101143324AHigh activityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalEnvironment effect

The invention provides a catalyst to prepare furfural gas 2-methylfuran and the preparation method. Silica is used as the carrier, copper oxide is used as the main active component and alkali metal or alkaline earth metal is used as the promoter. The preparation method of the catalyst adopts impregnation method. the catalyst has the advantages of high product yield, few by-products, little influence on environment, and long service life, etc, and is widely applicable in production of 2-methylfuran.

Owner:CHINA NAT ACAD NANOTECH & ENG

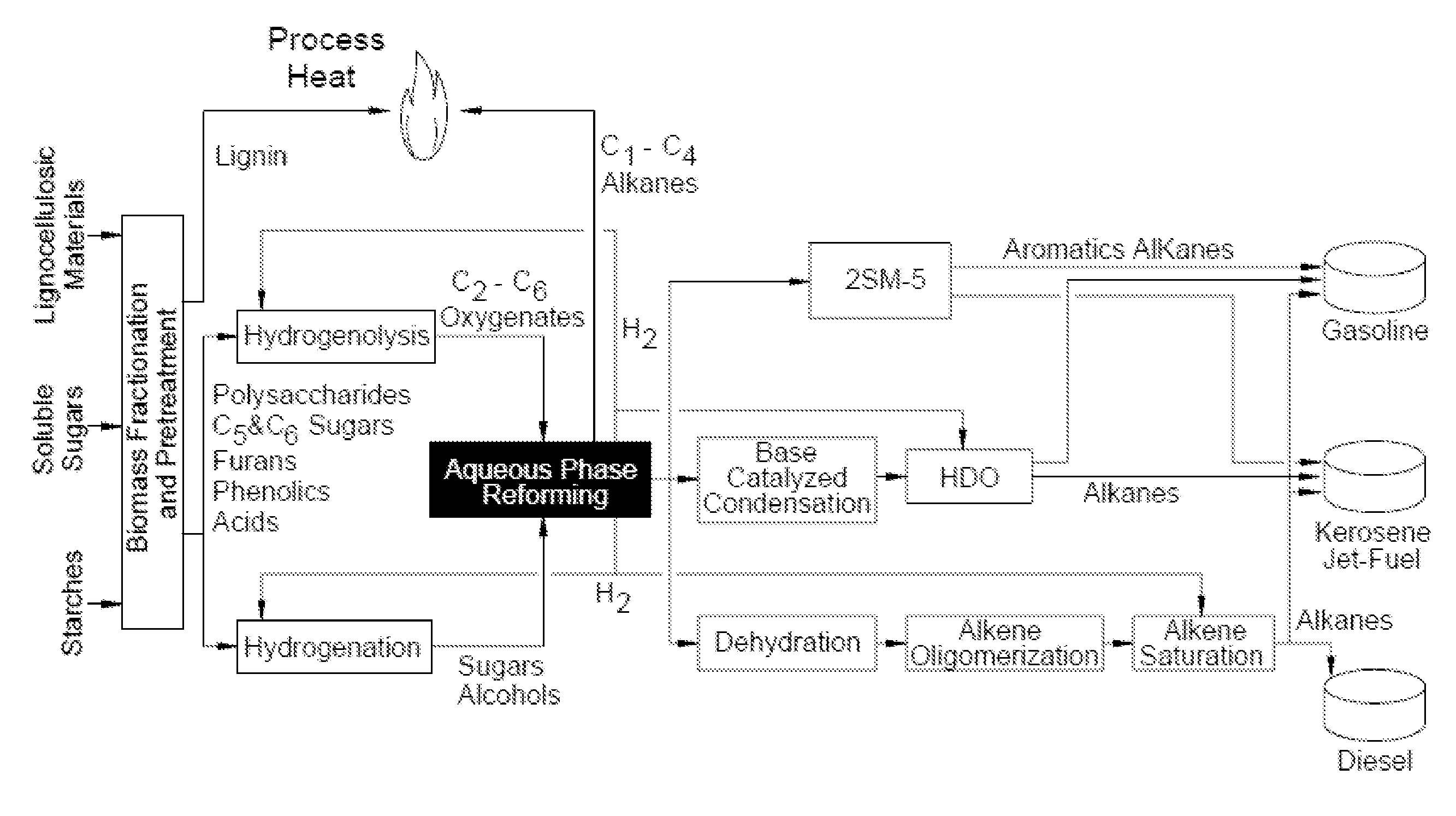

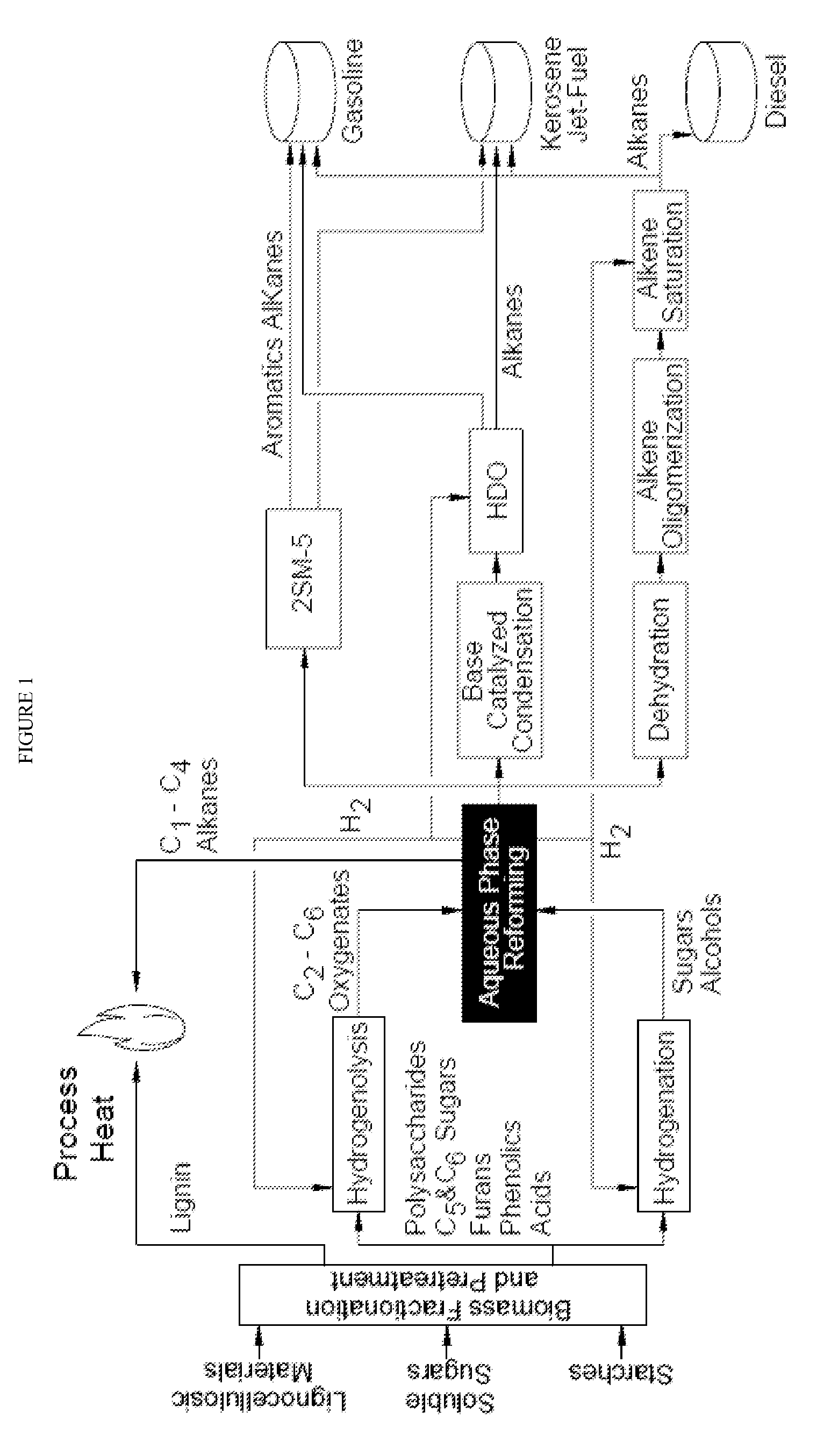

Method for preparing liquid fuel by using biomass

InactiveCN110041953AAvoid damageEmission reductionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHydrodeoxygenation2-Methylfuran

The invention belongs to the field of recycling of solid waste, and provides a method for preparing liquid fuel by using biomass. The method is characterized by comprising the following steps that thereaction phase and the extract phase are mixed to form a two-phase system to serve as a reaction medium; an acid catalyst, a hydrodeoxygenation catalyst, a biomass raw material and the reaction medium are added into a reactor at the specific mass ratio; a hydrogen source is introduced to have the continuous reaction under the specific temperature and stirring conditions, and cellulose and hemicellulose in the biomass are conversed to be 2,5-2-methylfuran and 2-methylfuran respectively; the water phase and the organic phase are separated, the organic phase rich in 2,5-2-methylfuran and 2-methylfuran is obtained to serve as the liquid fuel, and the unreacted rest materials in the water phase are recycled. The method provided by the invention does not need to pre-process the biomass, can lower temperature and hydrogen consumption and loss needed by the reaction, reduces the separation and purification process, and can integrate 2,5-2-methylfuran and methylfuran into the fuel product directly.

Owner:NANKAI UNIV +1

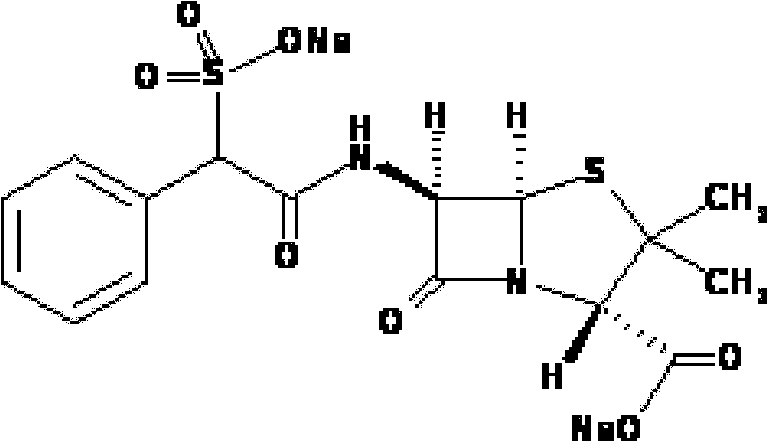

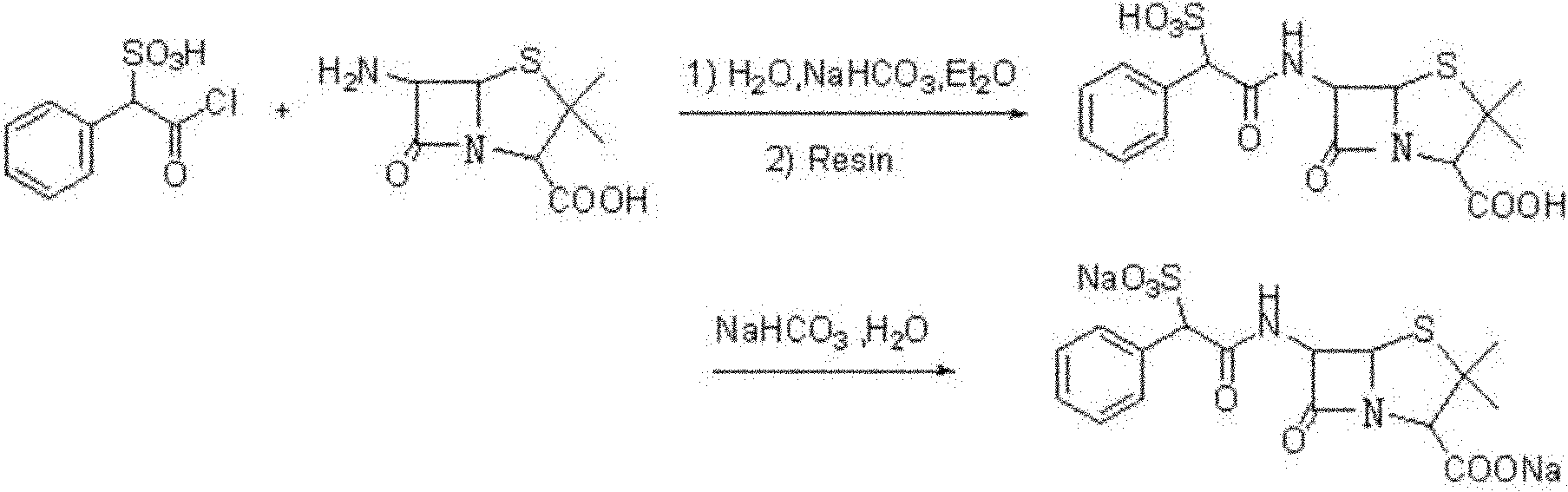

Method for preparing sulbenicillin disodium

The invention provides a method for preparing sulbenicillin disodium. The method comprises the following steps of: preparing alpha-sulfophenylacetyl chloride from alpha-sulfophenylacetic acid; reacting the alpha-sulfophenylacetyl chloride with 6-aminopenicillanic acid (APA) in the mixed solvents of water, ethanol and tetrahydro-2-methylfuran under the condition of the pH value of 5.6 to 7.0 and the temperature of 15 to 25 DEG C for 20 to 40 minutes to obtain crude sulbenicillin disodium; and obtaining the aqueous solution of the sulbenicillin disodium by post treatment and then cooling and drying the aqueous solution of the sulbenicillin disodium to obtain the final product, namely the sulbenicillin disodium. The method has the advantages of reducing energy consumption and saving production cost along with simple process, mild reaction condition and high yield.

Owner:HUNAN SANQING PHARMA +1

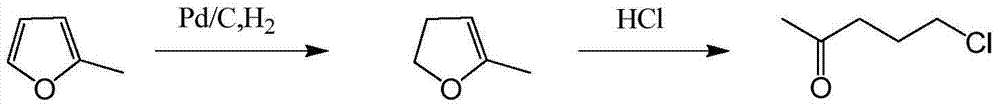

5-chloro-2-pentanone preparation method

ActiveCN103694094AEliminate the effects ofIncrease profitPreparation from heterocyclic compoundsFuranHydrogenation reaction

The present invention provides a 5-chloro-2-pentanone preparation method, which comprises that: 2-methyl furan is subjected to a hydrogenation reaction in the presence of a hydrogenation catalyst and hydrogen gas to prepare 2-methyl-4,5-dihydrofuran, and the 2-methyl-4,5-dihydrofuran and hydrochloric acid are subjected to a ring opening chlorination reaction to obtain the 5-chloro-2-pentanone. According to the present invention, 2-methyl furan is adopted as the raw material, the reaction steps are simple and easy to operate, no wastewater is generated during the production process, and environmental protection requirements are met; the hydrogenation catalyst, the distillate and the hydrochloric acid can be recycled so as to substantially reduce the production cost, and the prepared product has characteristics of high yield and high purity; and compared with the conventional process, the preparation method of the present invention has characteristics of complete elimination of influence of hydrochloric acid on the catalyst, improvement of the catalyst utilization rate, and substantial reduction of the 5-chloro-2-pentanone production cost.

Owner:JIANGSU QINGQUAN CHEM CO LTD

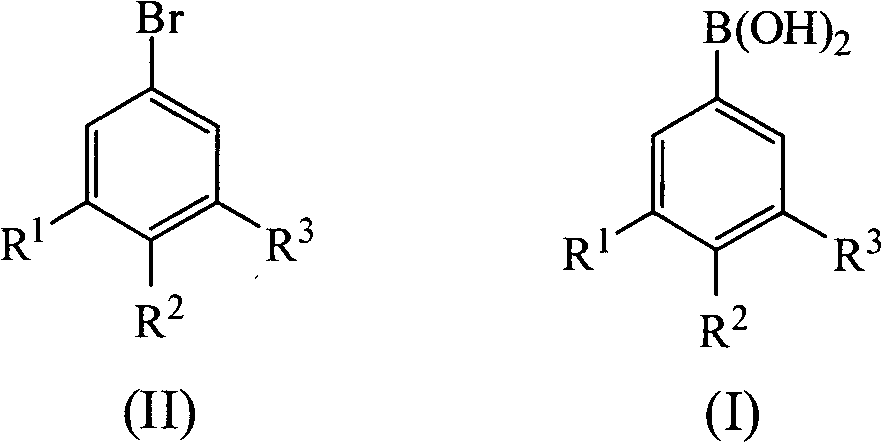

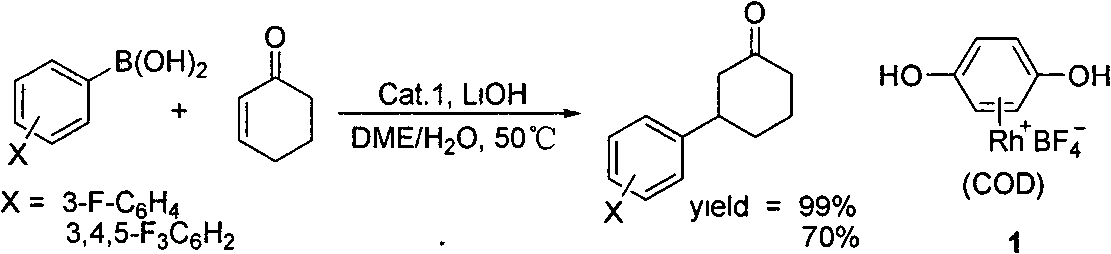

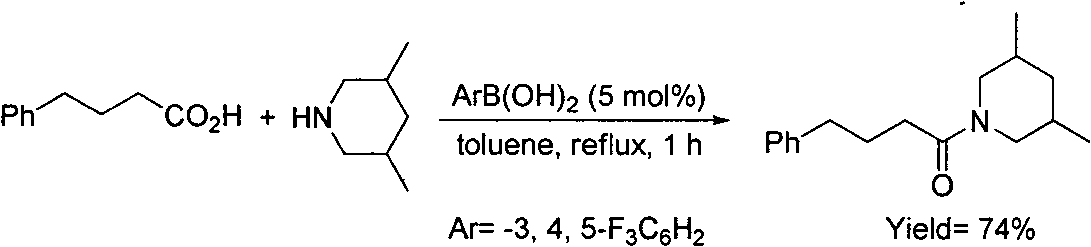

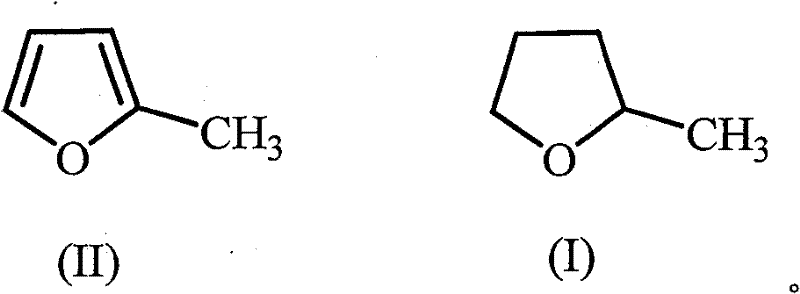

Method for preparing fluoride-bearing phenyloboric acid

InactiveCN101671352ALow water solubilityEasy to recycle and refineGroup 3/13 element organic compoundsOrganic solventGrignard reagent

The invention discloses a method for preparing fluoride-bearing phenyloboric acid with a structure shown in (I). The method is characterized in that by taking tetrahydro-2-methylfuran as solvent, fluoride-bearing bromobenzene shown in (II) and magnesium react for 1-8 hours at the temperature of 10-80 DEG C so as to obtain Grignard reagent; and the Grignard reagent and boric acid ester react in thetetrahydro-2-methylfuran for 0.5-8 hours at the temperature of -45-15 DEG C and then carry out hydrolysis in an acid condition, an organic layer is used for solvent recovery so as to obtain a crude product, and the fluoride-bearing phenyloboric acid is obtained after recrystallization of the crude product. The method utilizes the green organic solvent, i.e. tetrahydro-2-methylfuran, to replace tetrahydrofuran, aether and other conventional organic solvents to synthesize the fluoride-bearing phenyloboric acid, the process is simple and safe, and the obtained product realizes high yield and good purity. As the tetrahydro-2-methylfuran has high recovery rate and can be recycled, the production cost of the fluoride-bearing phenyloboric acid is greatly reduced, and great industrialization prospect can be born.

Owner:ZHEJIANG UNIV OF TECH +1

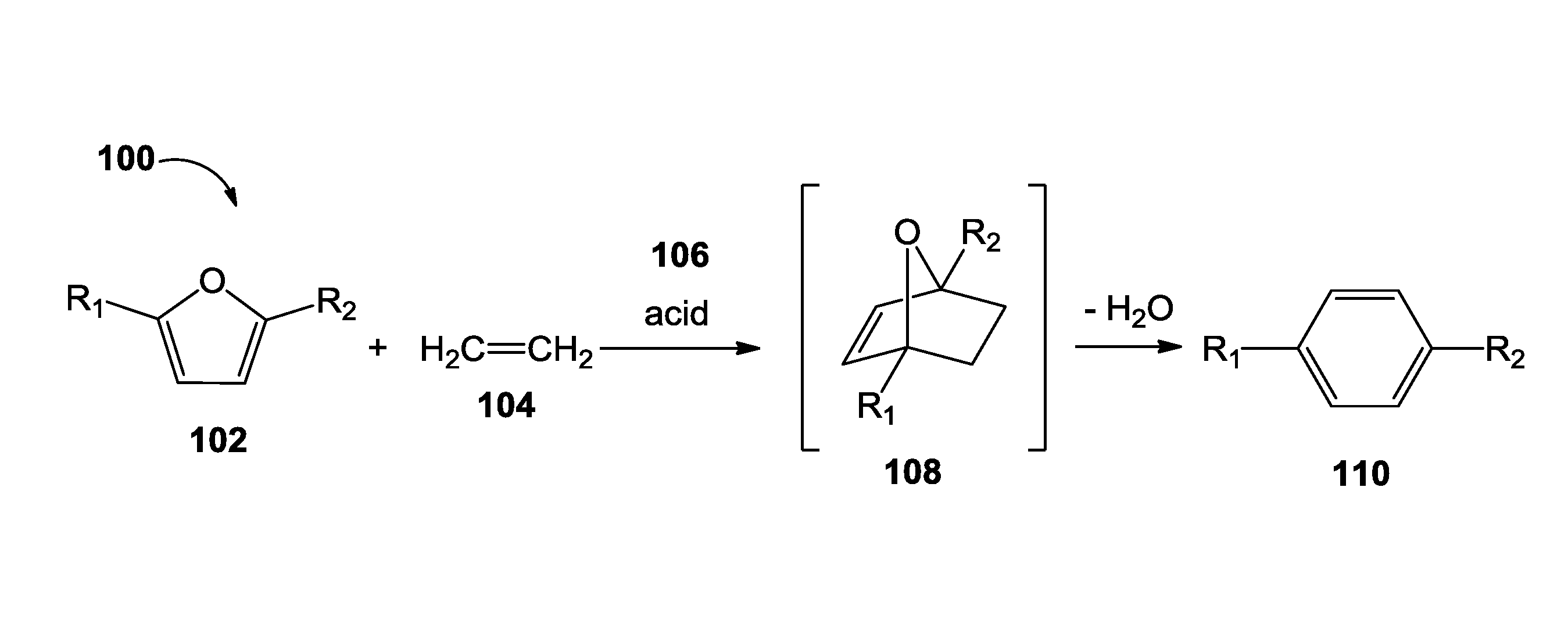

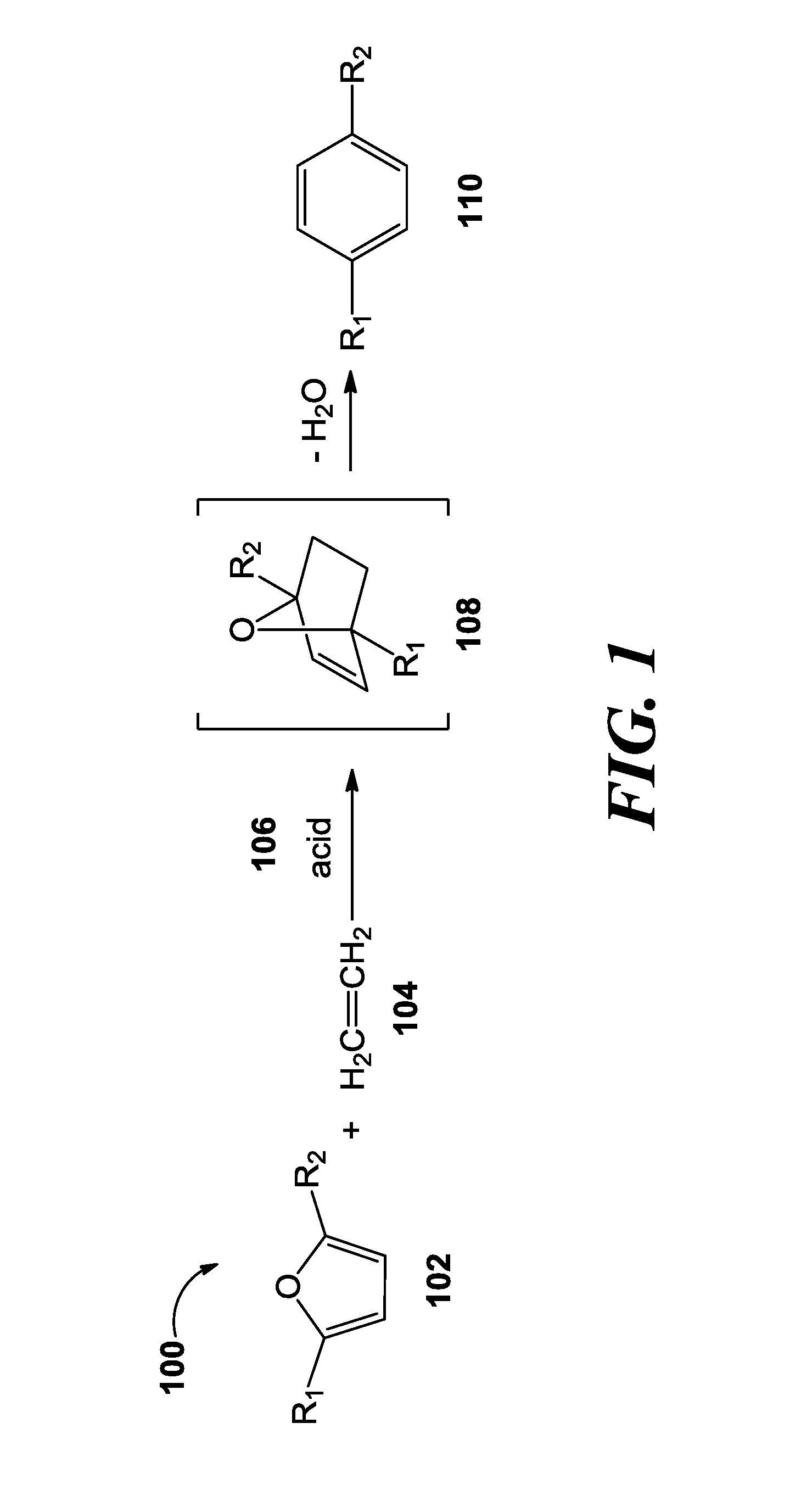

Methods of producing para-xylene and terephthalic acid

ActiveUS9260359B2High yieldMolecular sieve catalystOrganic compound preparation2-MethylfuranRenewable resource

The present disclosure provides methods to produce para-xylene, toluene, and other compounds from renewable sources (e.g., cellulose, hemicellulose) and ethylene in the presence of an acid, such as a Lewis acid. For example, cellulose and / or hemicellulose may be converted into 2,5-dimethylfuran (DMF) and 2-methylfuran, which may be converted into para-xylene and toluene, respectively. In particular, para-xylene can then be oxidized to form terephthalic acid.

Owner:ORIGIN MATERIALS OPERATING INC

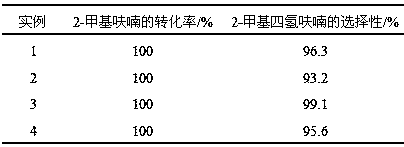

Preparation method of catalyst for preparing 2-methyltetrahydrofuran from 2-methylfuran through gas phase hydrogenation

ActiveCN103977803AEasy to prepareGood repeatabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsGas phaseAmyl alcohol

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

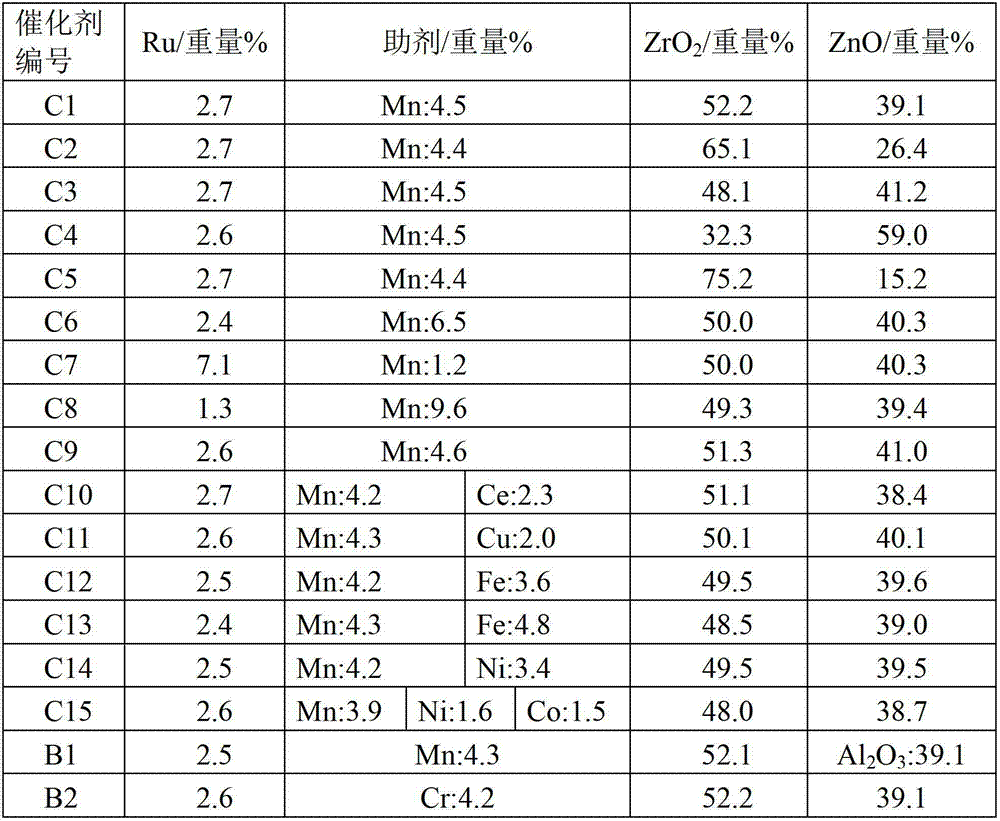

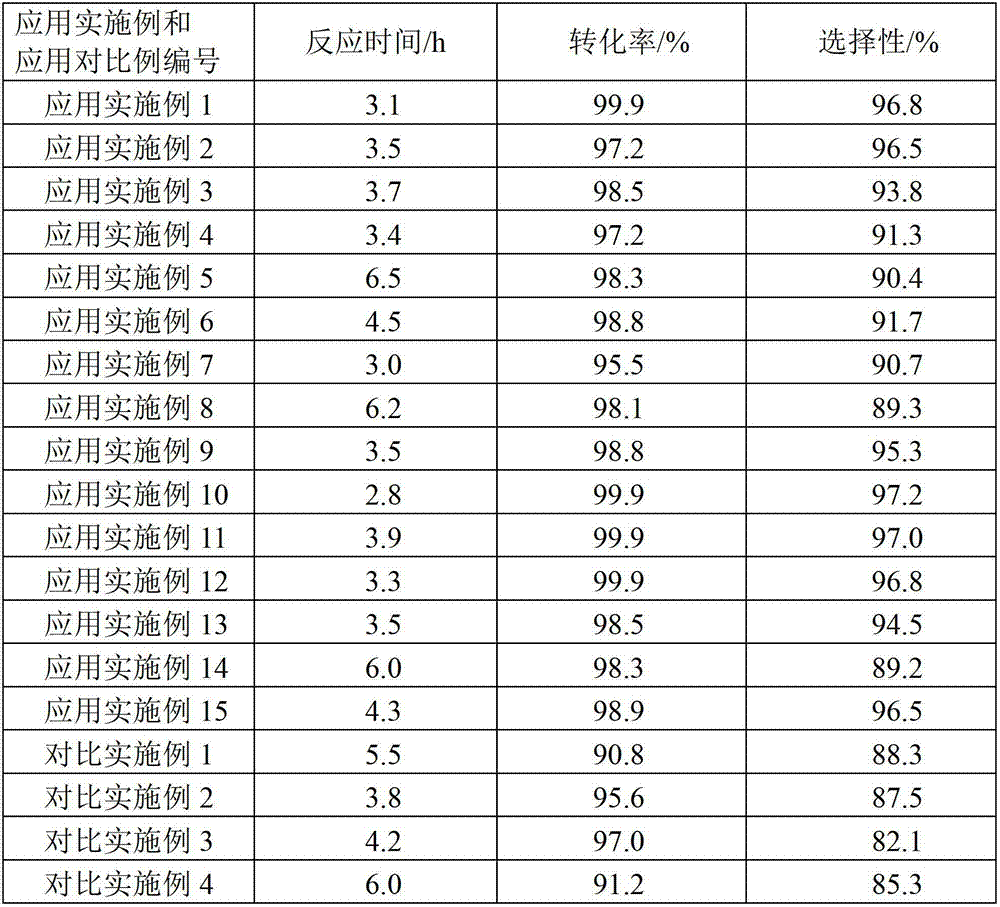

Hydrogenation catalyst, preparation method of hydrogenation catalyst and application of hydrogenation catalyst to 2-methyltetrahydrofuran synthesis

ActiveCN102921415AHigh selectivityHigh catalytic activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranActive component

The invention discloses a hydrogenation catalyst which contains a carrier, an active component and an auxiliary. The active component and the auxiliary are loaded on the carrier, wherein the active component is ruthenium (Ru), the auxiliary is manganese (Mn) or a combination of Mn and at least one of metal components of an IB group, an IIB group, an IIIB group and a VIII group, and the carrier is a composite carrier of ZrO2 and ZnO. The invention further provides a preparation method of the hydrogenation catalyst and an application of the hydrogenation catalyst to 2-methyltetrahydrofuran synthesis. The hydrogenation catalyst has higher catalytic activity and 2-methyltetrahydrofuran selectivity and longer service life in the reaction that raw materials containing 2-methyl furan synthesize the 2-methyltetrahydrofuran through hydrogenation, and the raw materials containing the 2-methyl furan are not required to be rectified so that process is simplified, and energy consumption is reduced.

Owner:JIANGSU QINGQUAN CHEM CO LTD

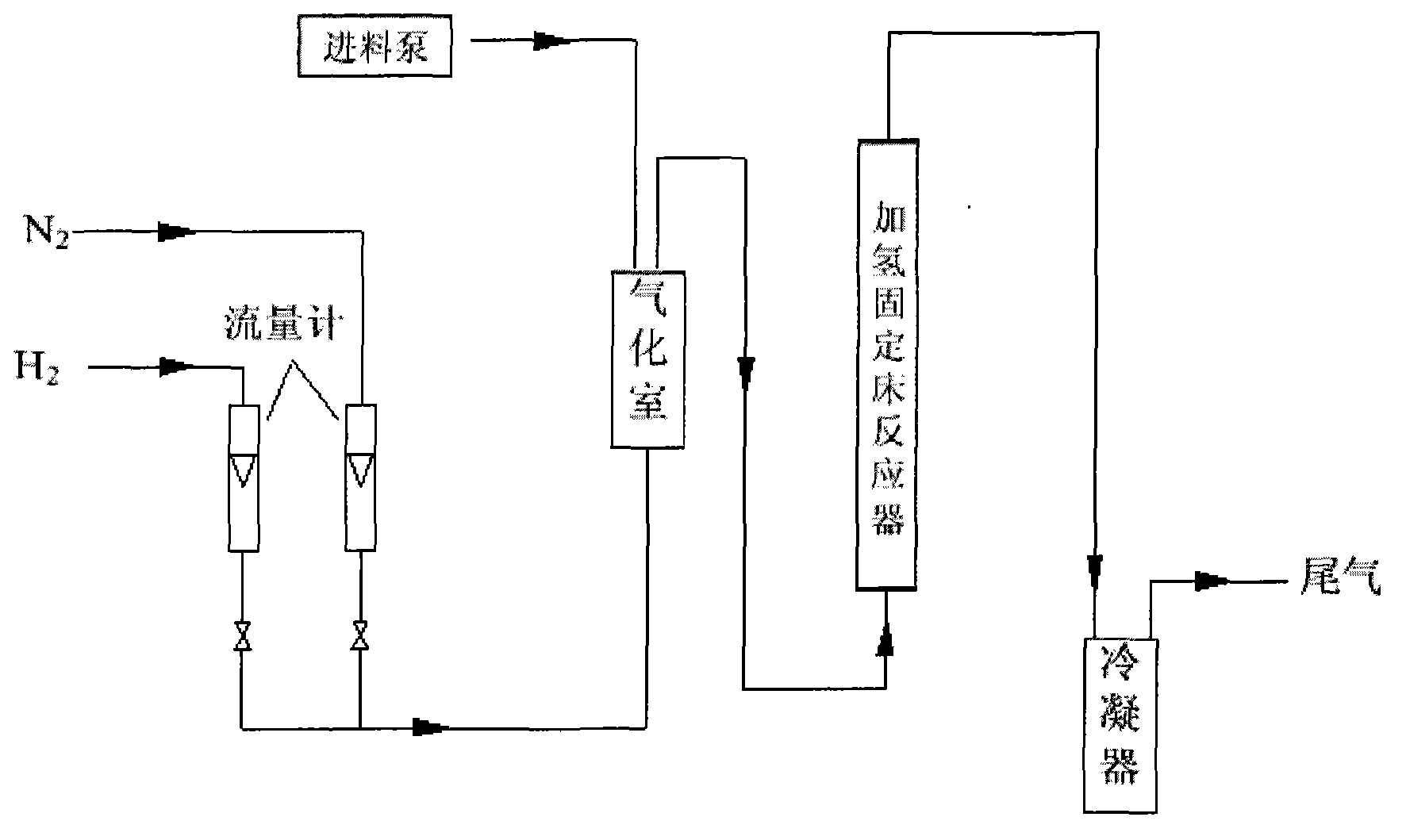

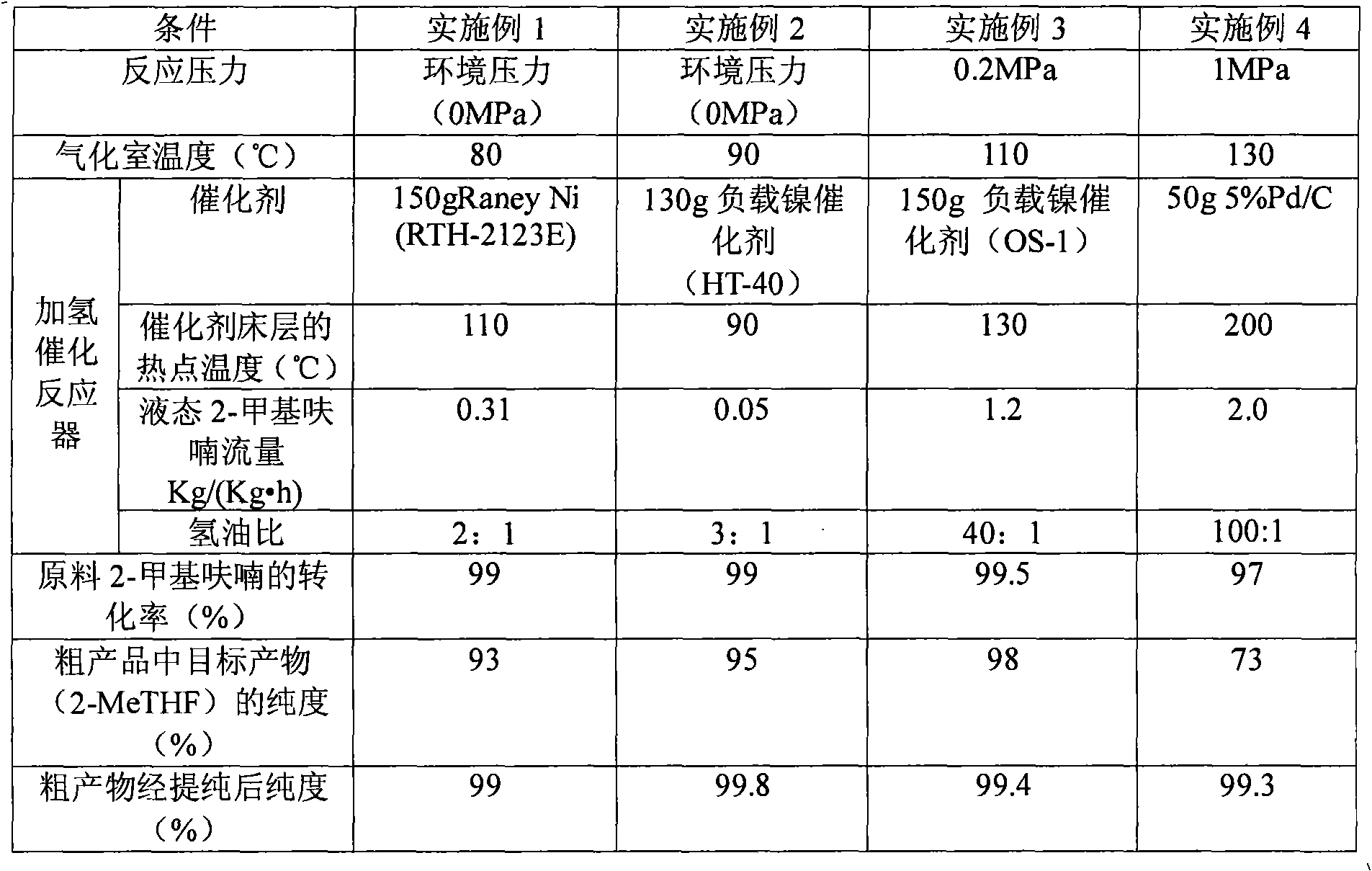

Continuous production method of 2-methyl tetrahydrofuran

The invention discloses a continuous production method of 2-mehtyl tetrahydrofuran. The continuous production method comprises the following steps of: pumping 2-methyl furan to a gasifying chamber for gasifying; mixing the gasified 2-methyl furan with hydrogen gas to obtain a gas mixture; inputting the gas mixture to a hydrogenation fixed-bed reactor for carrying out a catalytic hydrogenation reaction; and inputting the gas output by the hydrogenation fixed-bed reactor to a condensing device for condensing to obtain 2-methyl tetrahydrofuran, wherein the pressure of the gasifying chamber and the hydrogenation fixed-bed reactor is 0-1.0MPa, and catalyst for aromatic saturation hydrogenation is filled in the hydrogenation fixed-bed reactor. The continuous production method of the 2-methyl tetrahydrofuran can be used for changing the high-pressure high-investment and high-risk process for conventionally producing 2-MeTHF and can be used for reducing the use of toxic and noble metal catalyst. Besides, the continuous production method has the advantages of being low in investment, small in risk, large in material throughput within unit time, and high in yield and purity, and is suitable for industrial production.

Owner:ASYMCHEM LAB TIANJIN +4

Method for the preparation of coupling gamma-butyrolactone and silvan

InactiveCN1405163ACan mitigate thermal effectsSave energyOrganic chemistryEnergy inputHydrogenGas phase

The invention relates to a coupling method for preparing gamma-bulyrolactone and 2-methylfuran. It is characterized by making the mixture of the furfural and 1,4-butanediol implement close-coupled reaction on the hydrogenation catalyst under the conditions of gas phase, hydrogenation or no hydrogenation and proper temperature. Said invention possesses hydrogenation and dehydrogenation integration process, so that it can save hydrogen-making equipment, has no need of hydrogenation or recovering hydrogen, and its coupling process is a high-effective one.

Owner:SYNEFUELS CHINA

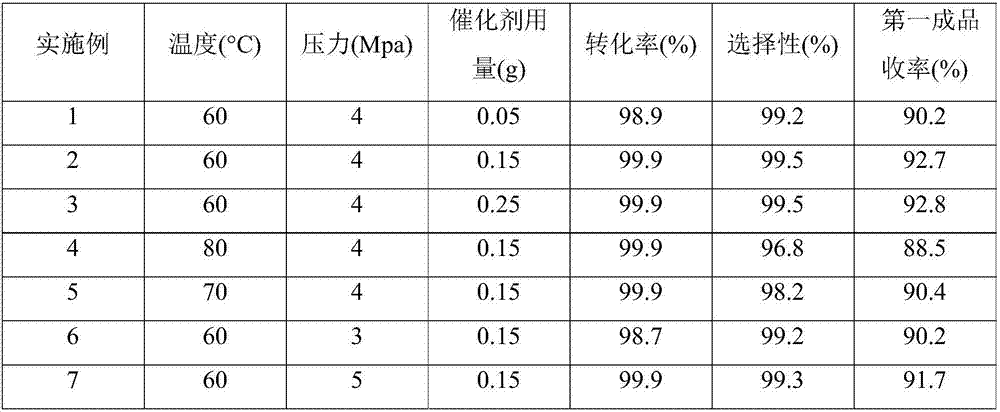

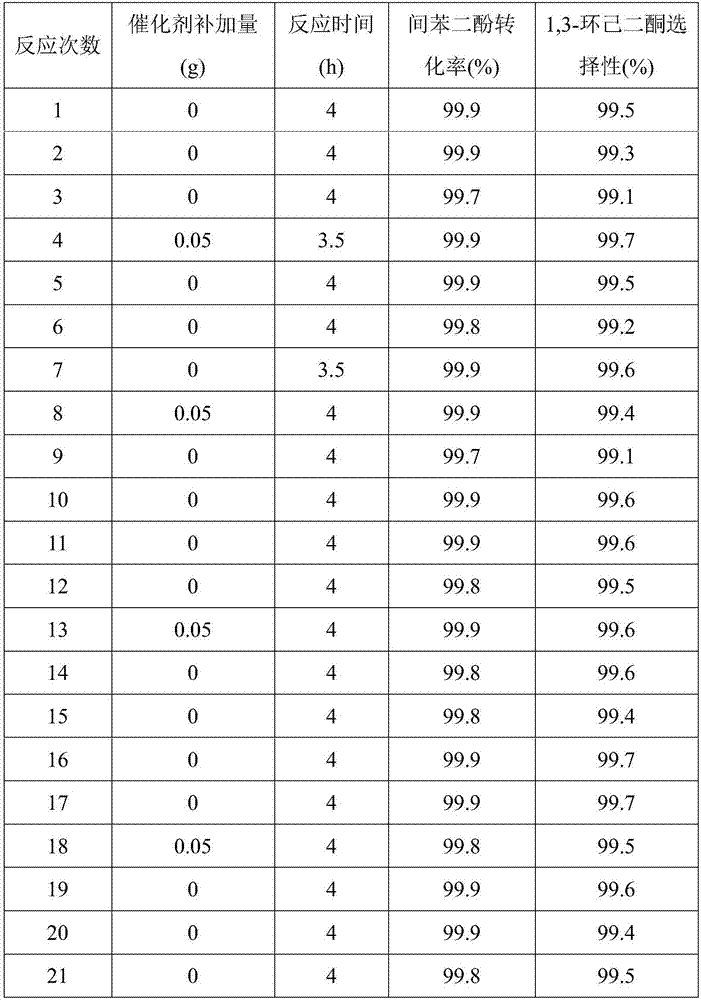

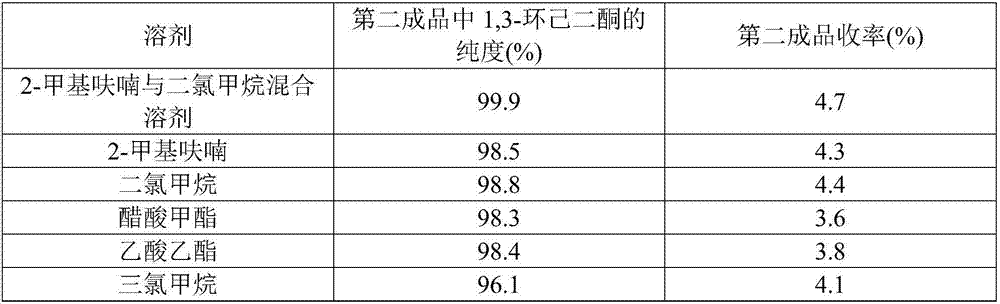

Method for preparing 1,3-cyclohexanedione

ActiveCN107353186AReduce COD contentHigh yieldPreparation by hydroxy compound hydrogenationOrganic compound preparationDistillationReaction temperature

The invention provides a method for preparing 1,3-cyclohexanedione. The method comprises the following steps: carrying out catalytic hydrogenation on resorcinol, an aqueous sodium hydroxide solution and hydrogen at a reaction temperature of 60-100 DEG C under a pressure of 3-5 MPa in the presence of a Co-Pd / C catalyst to obtain a hydrogenation solution, separating and removing the solid catalyst, pickling the hydrogenation solution with hydrochloric acid, cooling and crystallizing the pickled hydrogenation solution, carrying out solid-liquid separation to obtain a solid and a liquid, drying the obtained solid to obtain a first finished product 1,3-cyclohexanedione, extracting the obtained liquid with a 2-methylfuran and dichloromethane mixed solvent, carrying out organic phase distillation to recover the mixed solvent, and drying the obtained substance to obtain a second finished product 1,3-cyclohexanedione. Catalytic hydrogenation using the Co-Pd / C catalyst and recovery of the 1,3-cyclohexanedione from a centrifugal mother liquid through using the 2-methylfuran and dichloromethane mixed solvent are carried out to improve the total yield of the 1,3-cyclohexanedione product and reduce the COD content of reaction process wastewater.

Owner:JIANGSU QINGQUAN CHEM CO LTD

Production of liquid fuels (sylvan-liquid-fuels) from 2-methylfuran

InactiveUS20120316372A1Increase contentHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAlkaneAlkyl transfer

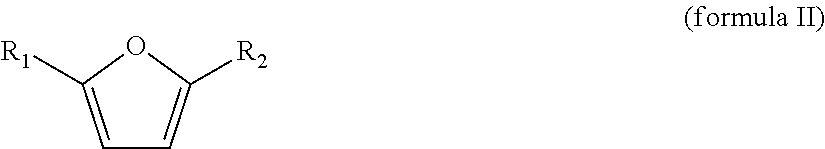

The present invention describes a procedure for the production of liquid fuel having a content high in alkanes and low in oxygenated compounds, comprising as a minimum: —a first step of alkylation of 2-methylfuran (commonly denominated Sylvan) with a furan alcohol 2 having the formula: (2), wherein R1 is H or an aliphatic or aromatic or heteroaromatic moiety, R2 is H or an aliphatic or aromatic or heteroaromatic moiety, and R3 is H, hydroxymethyl or an aliphatic or aromatic or heteroaromatic moiety, in the presence of a catalyst, —a second step of hydrogenation and dehydration of the compound obtained in step 1 in the presence of hydrogen, utilising suitable hydrogenation and dehydration catalysts.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

Green synthesis of 2-methylte-trahydrofuran

ActiveCN101492433BReduce manufacturing costSuitable temperatureOrganic chemistryChemical recyclingReaction temperature2-Methylfuran

Owner:ZHEJIANG UNIV OF TECH +1

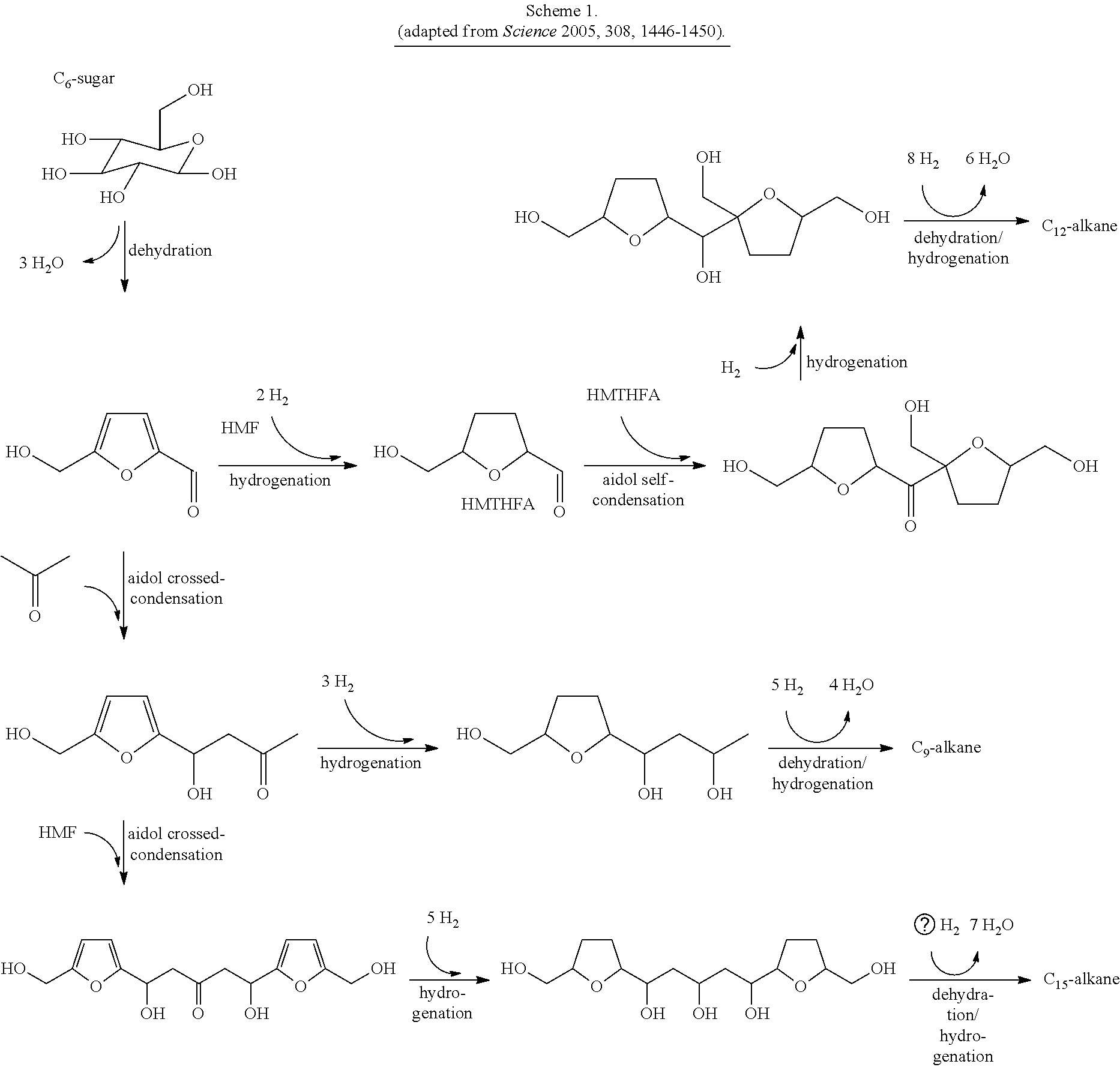

Preparation method of aviation kerosene or diesel oil

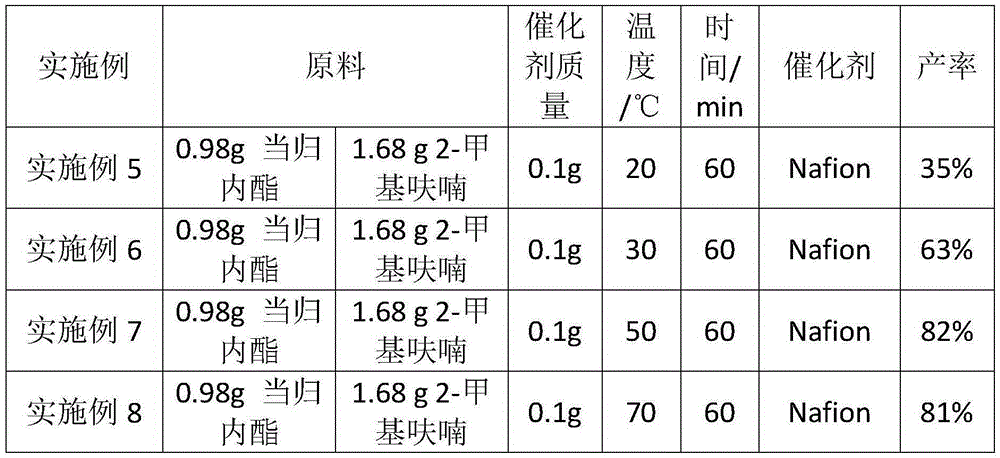

The invention discloses a preparation method of aviation kerosene or diesel oil, and relates to a new path for compounding liquid-state chain hydrocarbon fuel based on a raw material of lignocelluloses platform chemical compound. The preparation method is divided into three parts: (1) preparing 4,4-bis(5-methyl furan-2-furyl) pentanoic acid from a dehydrated product-angelica lactone of levulinic acid in an acid catalyst and 2-methyl furan through an acid catalytic alkylation reaction; (2) hydrogenating the 4,4-bis(5-methyl-2-furyl) pentanoic acid, effectively removing C-C double bonds and C-H double bonds in the 4,4-bis(5-methyl-2-furyl) pentanoic acid, and preparing a saturated organic compound containing oxygen; (3) carrying out hydrodeoxygenation on a hydrogenated alkylate by adopting a metal-carbon catalyst, thus obtaining biomass aviation kerosene or high-quality diesel oil of which the carbon chain length is 8 to 15.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

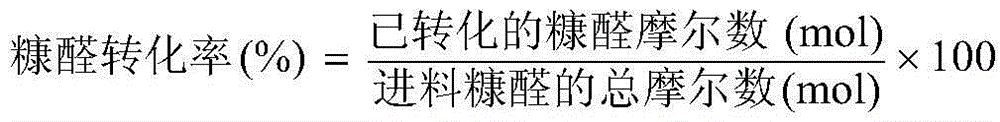

Preparation method of catalyst for effectively converting furfural into 2-methylfuran

InactiveCN109482183AGood dispersionEffective combinationOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAlcoholDistillation

The invention discloses a preparation method of a catalyst for effectively converting furfural into 2-methylfuran, and relates to a preparation method of a catalyst. The catalyst adopts a preparationmethod of solvothermal (water, alcohol and the like) uniform precipitation and distillation treatment to realize high dispersion of an active component Cu and effective synergistic combination with anauxiliary agent. The catalyst mainly comprises the following components in percentage by mass: 10-50% of CuO, 50-90% of silica or alumina, and 0-15% of other auxiliary agents. The catalyst is used for preparing 2-methylfuran through furfural gas phase hydrogenation, the furfural conversion rate is 100%, and the selectivity of the 2-methylfuran reaches more than 94%. According to the method, through effective combination with the Cu and the auxiliary agent, high dispersion of the Cu on the surface of a carrier and effective regulation and control of a Cu structure are realized, so that the catalyst has high activity and stability in furfural hydrogenation synthesis of the 2-methylfuran.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

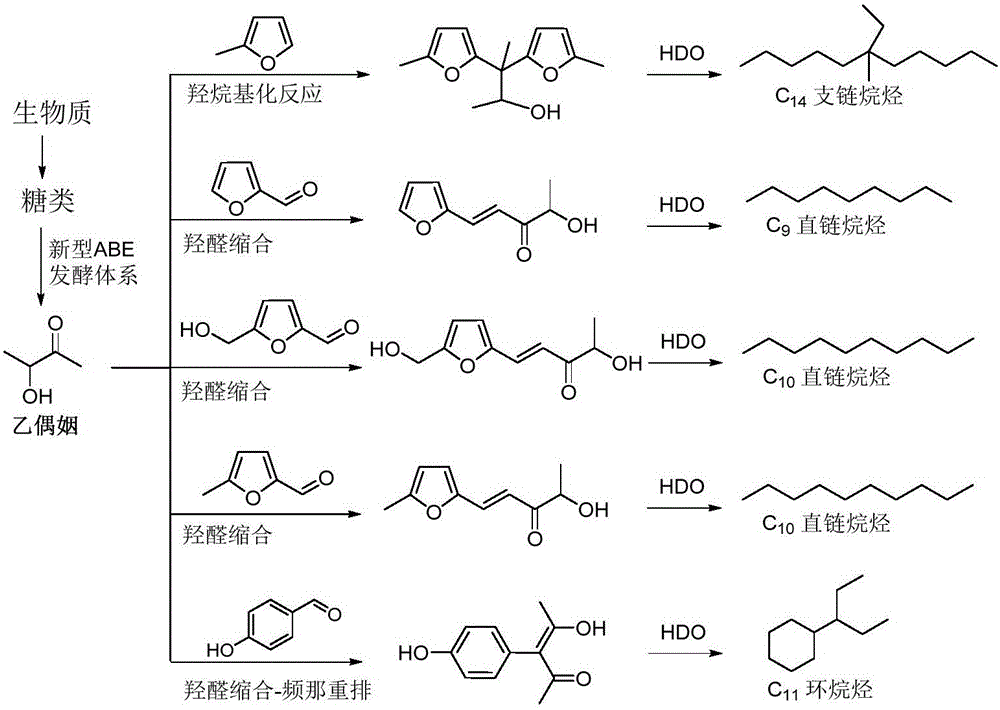

Method for preparing liquid fuel through catalytic conversion of biomass platform compound and ABE fermentation product acetoin

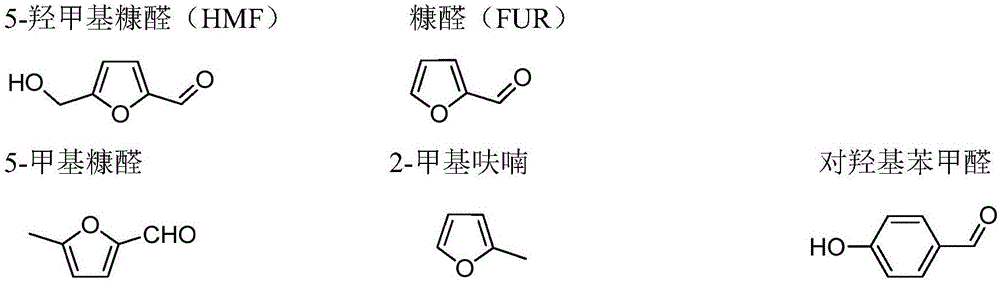

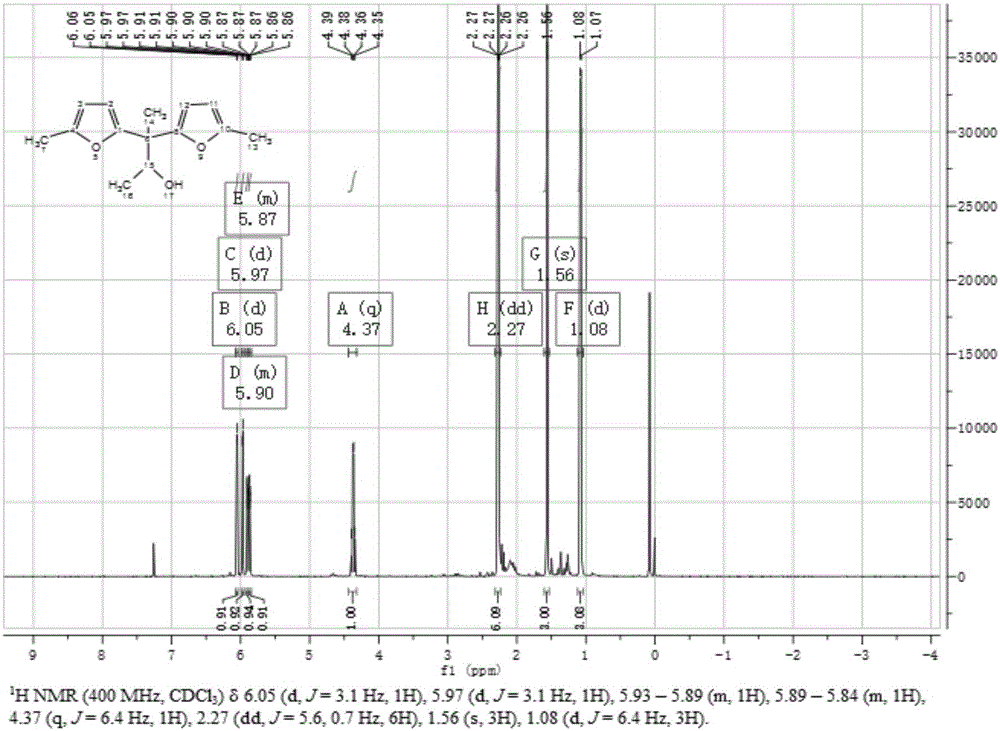

ActiveCN105154129AReduced activityExcellent directional selectivityLiquid hydrocarbon mixture productionBio-feedstockFuranAlkane

The invention discloses a method for preparing liquid fuel through catalytic conversion of a biomass platform compound and ABE fermentation product acetoin. The biomass platform compound and the ABE fermentation product acetoin are added to a reactor, a catalyst is added for a catalytic reaction, a reaction liquid is filtered or extracted after the reaction, concentration is performed, and a C-C bond coupled condensation product is obtained, wherein the biomass platform compound is 2-methyl furan, a furfural compound or an aromatic aldehyde compound. Complete conversion is realized in the reaction and the selectivity is higher than or equal to 90%; a hydrogenation catalyst, solid acid and a solvent are added to the condensation product for a hydrodeoxygenation reaction, complete conversion is realized in the reaction, and the selectivity for alkanes with more than 9 carbon atoms is higher than or equal to 90%; the reaction liquid is filtered and extracted, an organic phase is condensed for removal of the solvent, and a colorless clear liquid, namely, the liquid fuel containing more than 9 carbon atoms, is obtained.

Owner:NANJING UNIV OF TECH

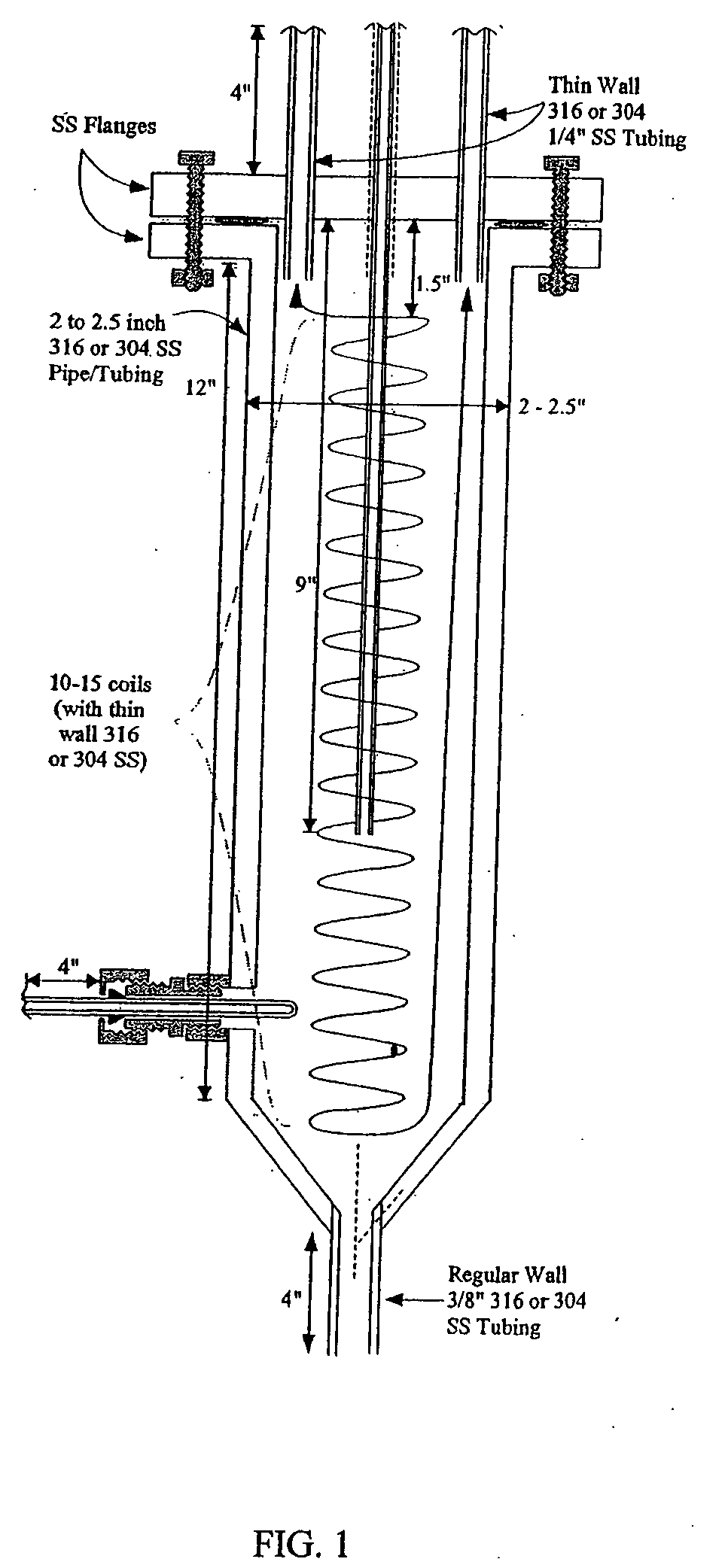

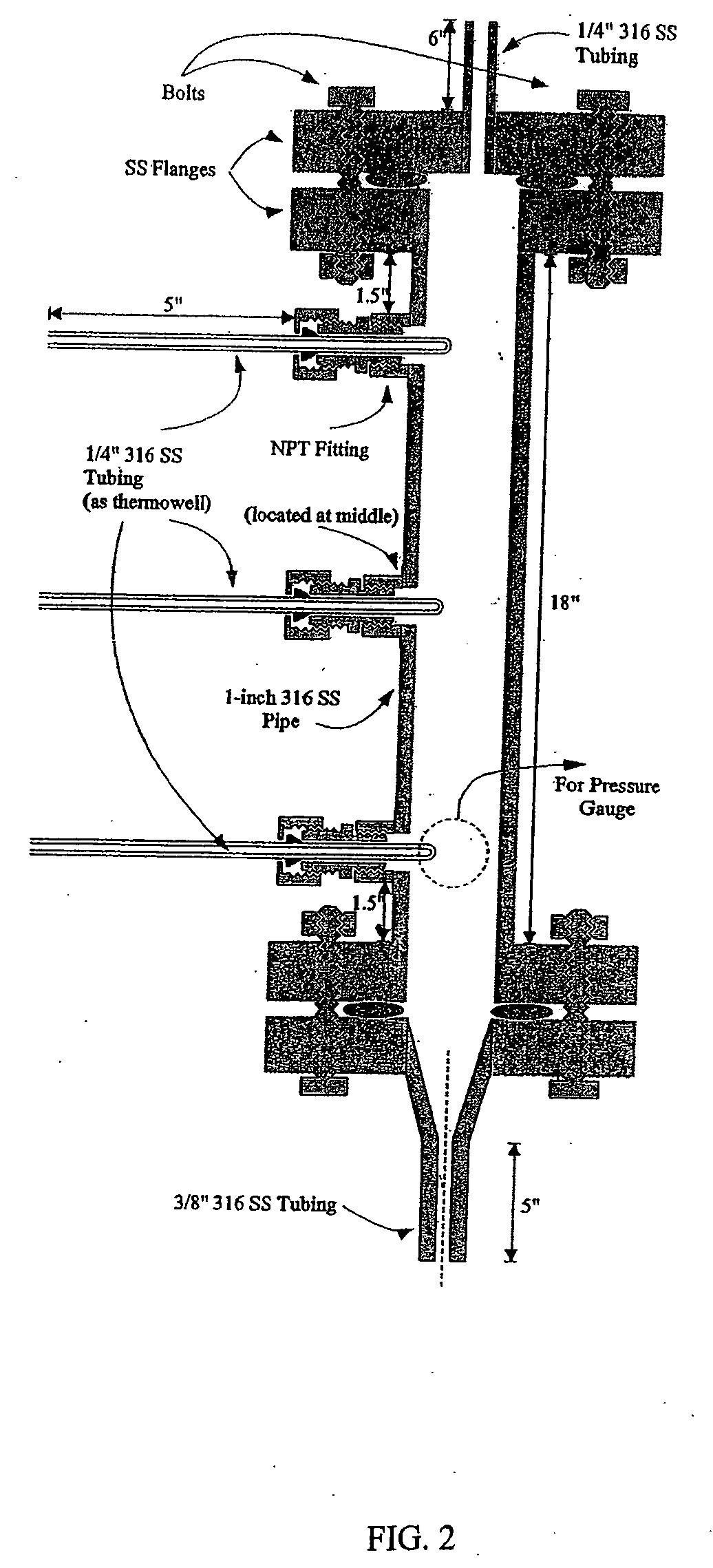

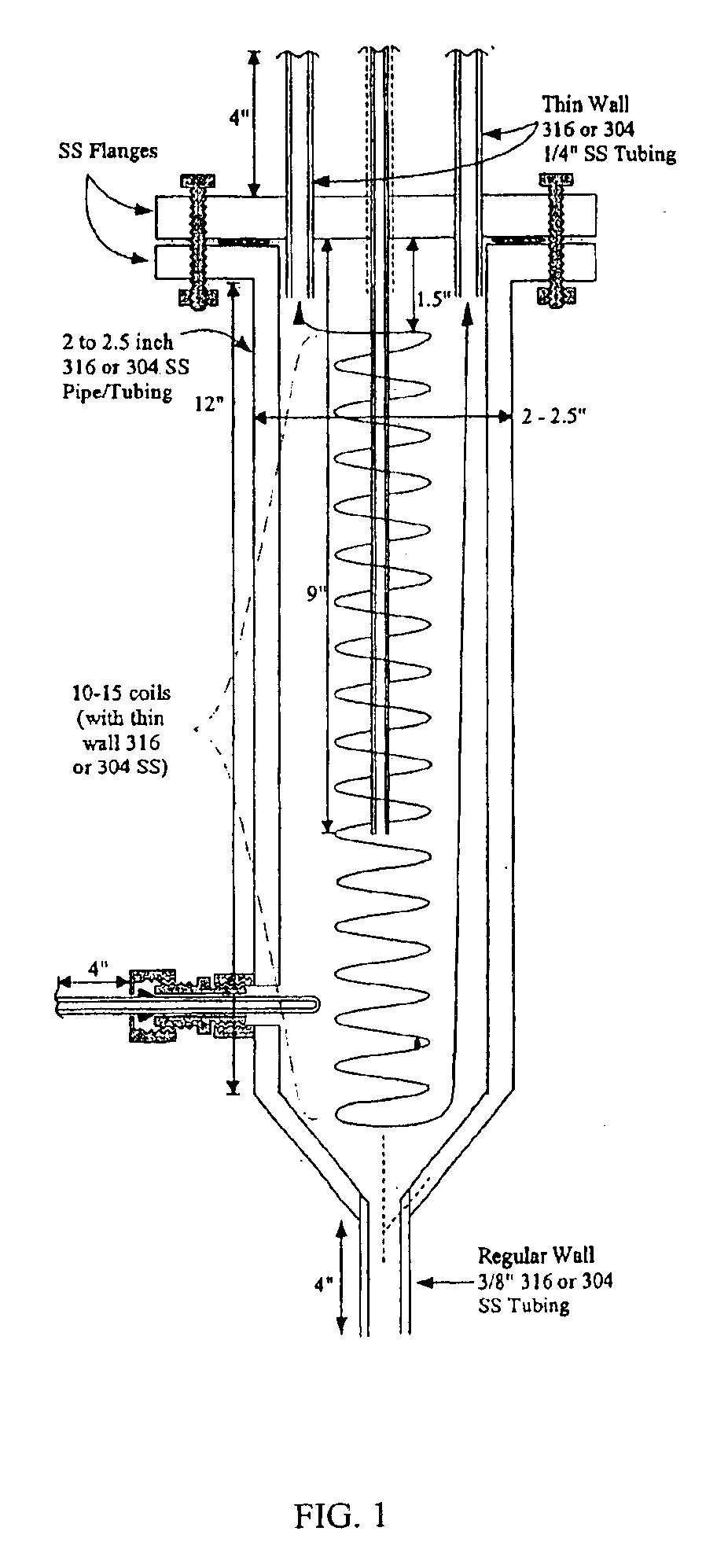

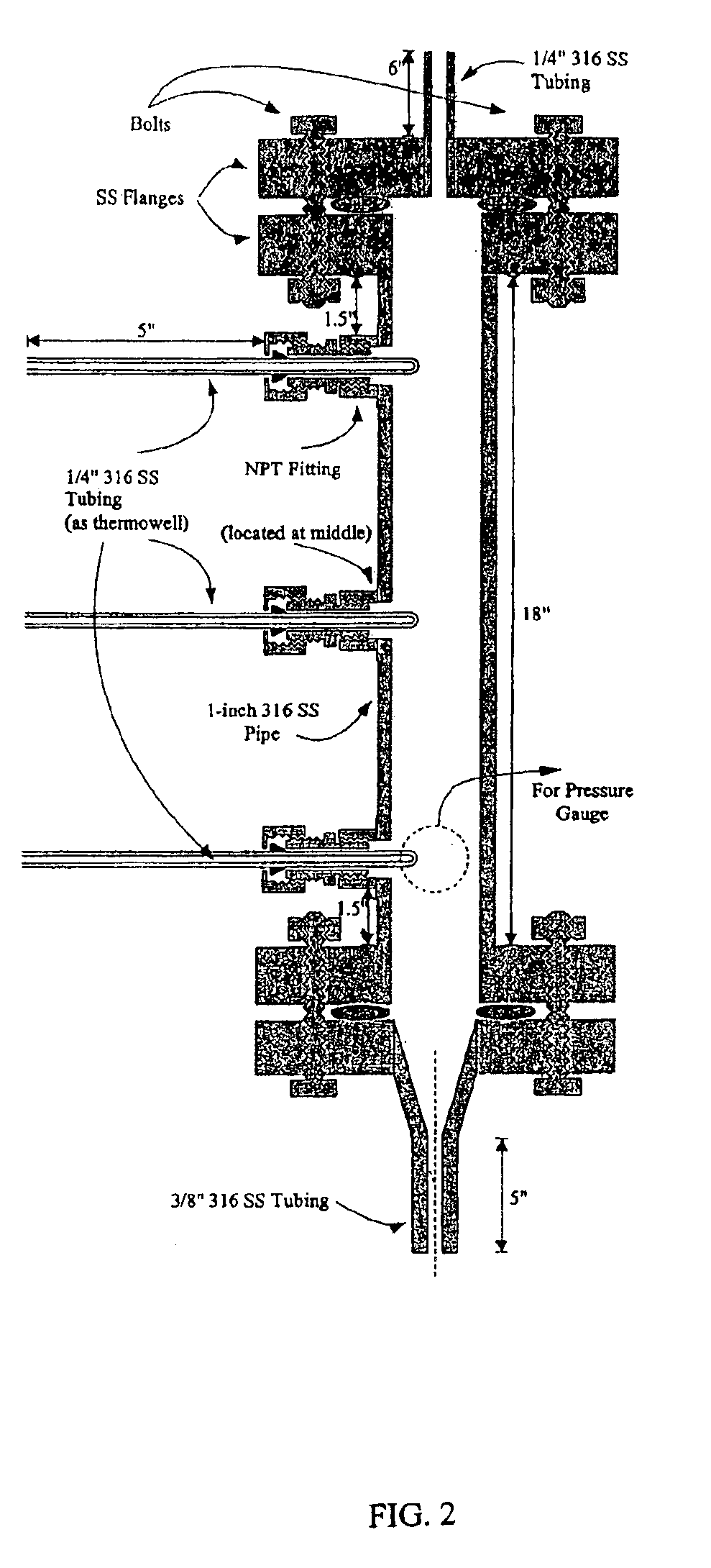

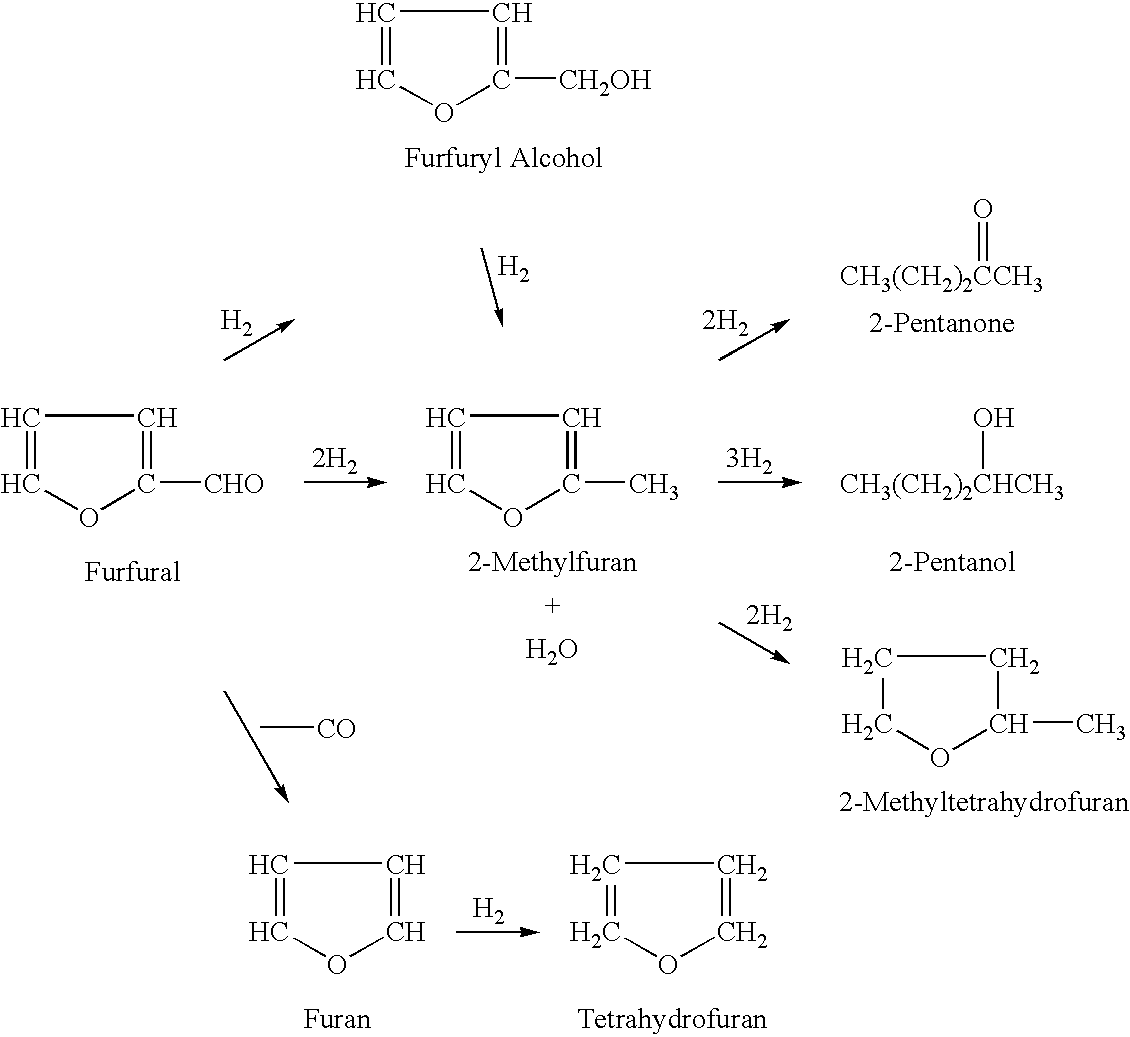

Processes for the preparation of 2-methylfuran and 2-methyltetrahydrofuran

Processes are disclosed for the preparation of 2-methylfuran and 2-methyltetrahydrofuran. The continuous vapor-phase processes are commercially viable and efficient because they permit the preparation of 2-methylfuran and 2-methyltetrahydrofuran using commercially-available catalysts, namely, a reduced copper-based catalyst consisting essentially of cupric oxide, chromium (III) oxide, manganese oxide and barium chromate and a reduced nickel-based catalyst consisting essentially of nickel, nickel (II) oxide, aluminum oxide and silica. An apparatus comprising two inline hydrogenators is used for preparing the 2-methylfuran or 2-methyltetrahydrofuran.

Owner:PURE ENERGY

Methods of producing para-xylene and terephthalic acid

ActiveUS20140350294A1High yieldMolecular sieve catalystOrganic compound preparation2-MethylfuranRenewable resource

The present disclosure provides methods to produce para-xylene, toluene, and other compounds from renewable sources (e.g., cellulose, hemicellulose) and ethylene in the presence of an acid, such as a Lewis acid. For example, cellulose and / or hemicellulose may be converted into 2,5-dimethylfuran (DMF) and 2-methylfuran, which may be converted into para-xylene and toluene, respectively. In particular, para-xylene can then be oxidized to form terephthalic acid.

Owner:ORIGIN MATERIALS OPERATING INC

Coffee Drink Packed In Container And Method Of Producing The Same

InactiveUS20100003389A1Great tasteAdd flavorPackaging protectionFood preparationFlavorAdditive ingredient

The present invention provides a coffee drink packed in container with improved taste and flavor, a coffee drink packed in container in which deterioration of taste and flavor has been suppressed and which is appropriate for long term conservation, and producing methods thereof. In addition the present invention can provide a coffee drink packed in container containing 2-methylfuran, 2-methylbutanal and 3-methylbutanal, which are aroma components, and having improved taste and flavor, a coffee drink packed in container in which diminution of 2-methylfuran, 2-methylbutanal and 3-methylbutanal is prevented, and thus deterioration taste and flavor is suppressed, and producing methods thereof.

Owner:SHOKUHIN SANGYO HIGH SEP

Method for preparing 2-methyltetrahydrofuran catalyst through gas phase hydrogenation of 2-methylfuran

InactiveCN109569611AEasy to prepareEasy to operateOrganic chemistryHeterogenous catalyst chemical elementsMetal nitrateNickel salt

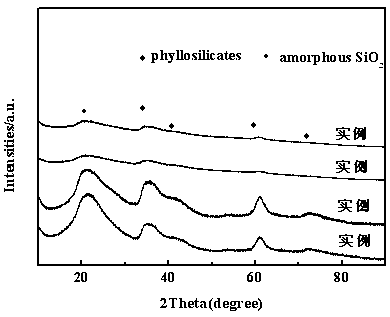

The invention discloses a method for preparing a 2-methyltetrahydrofuran catalyst through gas phase hydrogenation of 2-methylfuran, and relates to a method for preparing the catalyst. The method includes dissolving soluble nickel salt or nickel salt and other metals in water to prepare a metal salt solution with a certain concentration; adding ammonia water into the solution for sealing and stirring; adding silica sol for sealing and stirring again for a certain time after the solution is evenly stirred; evaporating ammonia gas at a certain temperature to regulate the pH value of the obtainedsuspension to reach a certain value; and washing, drying and roasting the precipitate to finally prepare the NiO / SiO2 catalyst, wherein the mass percentage of NiO is 15%-45%, the mass percentage of SiO2 is 55%-85%, and the mass percentage of the metal auxiliary agent is 0.2%-8%; and the soluble metal salts are all metal nitrates. The preparation method of the catalyst is simple and easy to operateand has good repeatability; and the prepared catalyst can form a special layered silicate structure to maintain good activity, selectivity and stability.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Preparation method of catalyst for efficient gas-phase conversion of furfural into 2-methylfuran

InactiveCN110180553AEasy to produceImprove performanceOrganic chemistryHeterogenous catalyst chemical elementsAlkaline earth metalGas phase

The invention relates to a preparation method of a catalyst for efficient gas-phase conversion of furfural into 2-methylfuran, and relates to a catalyst preparation method, which specifically comprises: preparing a solution from a soluble Cu salt, one or two materials selected from Ni salts, Pd salts and Au salts, and one selected from alkaline earth metals or alkali metals such as Mg, Ca, Ba, Na,K and the like; adding a silica sol or orthosilicate or silica gel powder to a concentrated ammonia water solution, adding a certain amount of an aluminum sol, and stirring for 1-5 h; and adding theprepared salt solvent to the ammonia water colloid solution, further stirring for 1-6 h, carrying out heating evaporation, washing, and calcining to synthesize the novel catalyst for hydrogen transfergas-phase conversion of furfural into 2-methylfuran. According to the present invention, the production process is simple, and the prepared catalyst has stable performance and good repeatability; andthe alcohol is used as the hydrogen transfer reagent, such that various dangers caused by the use of hydrogen are overcome.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for preparing 2-methylfuran through furfural hydrogenation

InactiveCN110054602AAvoid pollutionHydrodeoxygenation effect is goodOrganic chemistryPhysical/chemical process catalystsActive componentHydrodeoxygenation

The invention relates to a 2-methylfuran preparation method, in particular to a method for preparing 2-methylfuran through furfural hydrogenation, and aims to solve the problem of low selectivity in existing 2-methylfuran preparation in which Cu-Cr catalysts with Cu as an active component are used for furfural hydrogenation. The method includes catalyzing furfural hydrodeoxygenation by a catalyst,namely cobalt phosphide, to obtain the 2-methylfuran. The method has the advantages that the conversion rate of furfural can reach 100%, and the selectivity of the 2-methylfuran reaches more than 89%; industrial production is easily achieved. The method is mainly applied to preparation of the 2-methylfuran through the furfural hydrodeoxygenation catalyzed by the cobalt phosphide catalyst.

Owner:HEILONGJIANG UNIV

Processes for the preparation of 2-methylfuran and 2-methyltetrahydrofuran

Processes are disclosed for the preparation of 2-methylfuran and 2-methyltetrahydrofuran. The continuous vapor-phase processes are commercially viable and efficient because they permit the preparation of 2-methylfuran and 2-methyltetrahydrofuran using commercially-available catalysts, namely, a reduced copper-based catalyst consisting essentially of cupric oxide, chromium (III) oxide, manganese oxide and barium chromate and a reduced nickel-based catalyst consisting essentially of nickel, nickel (II) oxide, aluminum oxide and silica. An apparatus comprising two inline hydrogenators is used for preparing the 2-methylfuran or 2-methyltetrahydrofuran.

Owner:PURE ENERGY

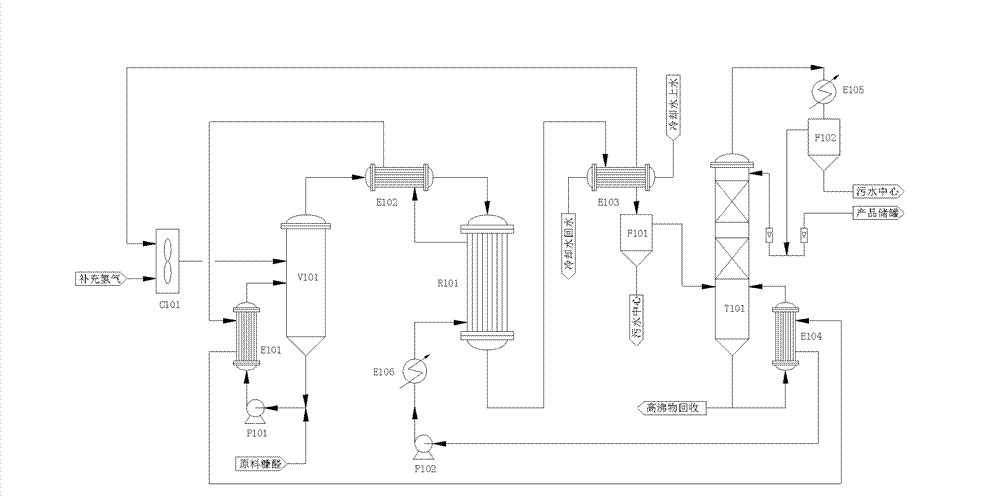

Preparation method of 2-methyl furan

The invention discloses a preparation method of 2-methyl furan, comprising the following steps of: allowing gaseous furfural to contact with hydrogen in a hydrogenation reactor to carry out hydrogenation reaction in the presence of a hydrogenation catalyst under the condition of selective hydrogenation reaction, condensing a reaction product and separating an organic phase from a water phase, and sending the organic phase into a rectifying tower for rectification to obtain 2-methyl furan, wherein at least parts of heat discharged during the hydrogenation reaction process through heat exchange is taken as the heat source of the column bottom of the rectifying tower. According to the method, parts of heat discharged from the hydrogenation reactor is used to provide heat source for a reboiler of the rectifying tower, and preferably parts of heat discharged from the hydrogenation reactor is also used as the heat source for heating and vaporization of the liquid phase furfural raw material and for heating of gaseous furfural and hydrogen, thus making the removed heat form a heat circulatory system. In comparison with traditional external steam or externally introduced heating mode, the preparation method provided by the invention is more energy-saving, and heat recycling is more reasonable.

Owner:JIANGSU QINGQUAN CHEM CO LTD

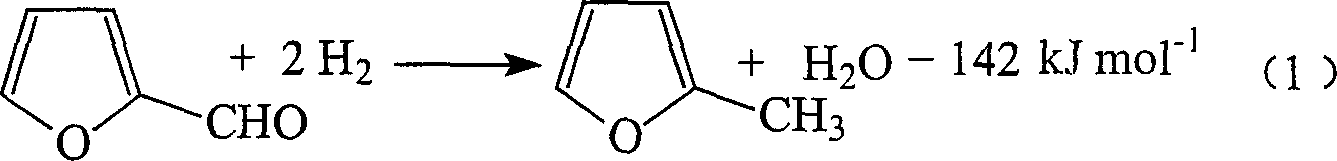

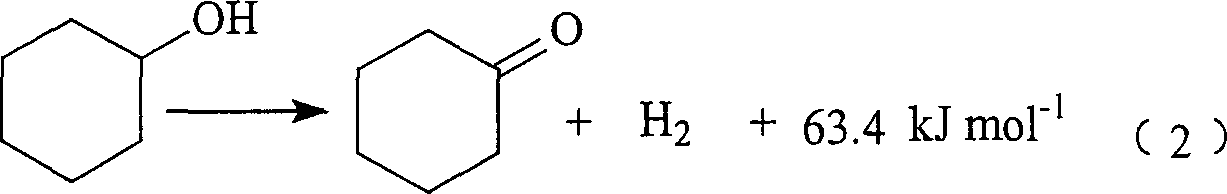

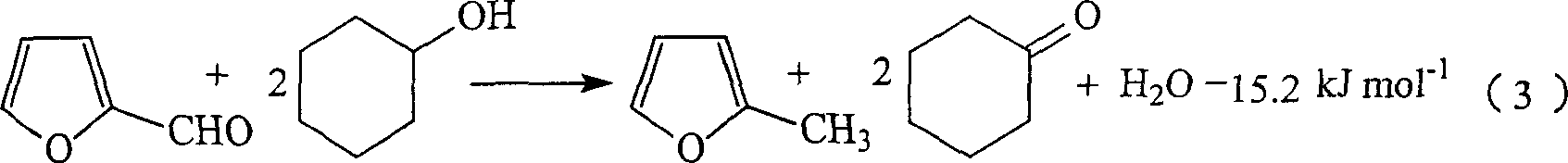

Preparation of 2-methylfuran and cyclohexanone by couple method

InactiveCN1789256ACan mitigate thermal effectsSave energyEnergy inputCarbonyl compound preparation by oxidationCyclohexanoneHydrogen

A coupling method for preparing 2-methylfuran and cyclohexanone, carrying out integral reaction with the mixture of furfuraldehyde and anhydride under the condition of gas phase, existence of additional hydrogen or no additional hydrogen, proper temperature and hydrogen catalyst. The invention is characterized by the low energy consumption, no need for hydrogenation or hydrogen recovery, low producing cost, high selectivity and productivity, simple preparing process and easy-to-operate.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

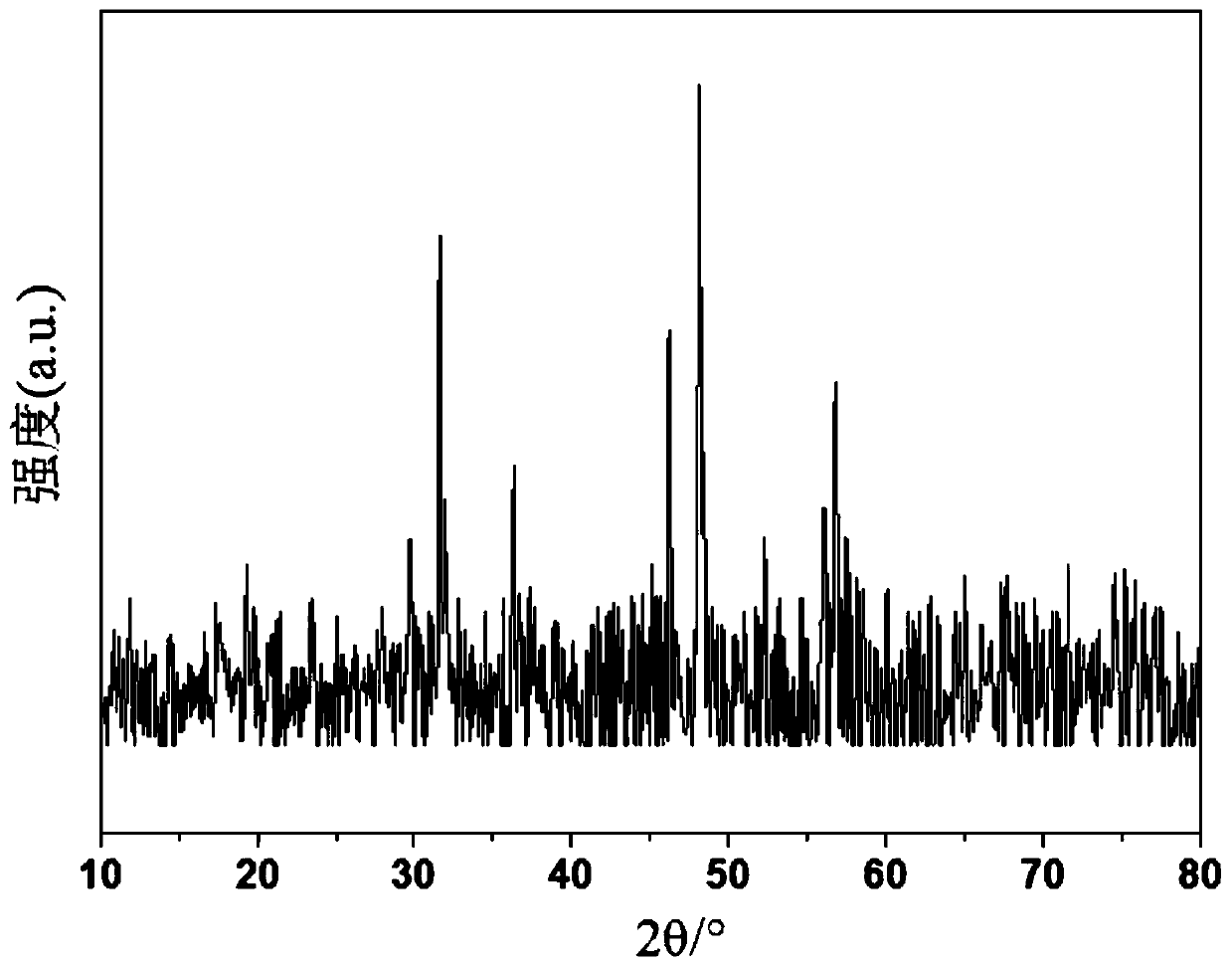

Catalyst for preparing 2-methyl furan through furfural gas phase hydrogenation and preparation method thereof

ActiveCN104368346AHigh low temperature activitySimple componentsOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranGas phase

The invention discloses a catalyst for preparing 2-methyl furan through furfural gas phase hydrogenation and a preparation method thereof. The catalyst contains the following components in percentage by mass: 52-56% of CuO, 40-42% of SiO2 and 3.0-6.0% of CeO2. The preparation method of the catalyst comprises the following steps: (1) respectively preparing a soluble salt solution of copper, a soluble salt solution of cerium and a silica sol, and mixing to obtain a mixed solution; (2) adding an alkaline precipitant into the mixed solution to perform precipitation, and heating to obtain a precipitate; and (3) drying and roasting the precipitate sequentially to obtain the catalyst. Compared with the prior art, the catalyst has the following advantages: (1) the catalyst has single components, namely only has three components, and the raw materials are cheap and readily available; (2) the catalyst, which does not contain extremely poisonous cancerogenic substance Cr, does not have harm to environment and human body; (3) the catalyst has relatively predominant low-temperature activity; and (4) the catalyst has relatively high activity and selectivity.

Owner:中科合成油内蒙古技术研究院有限公司

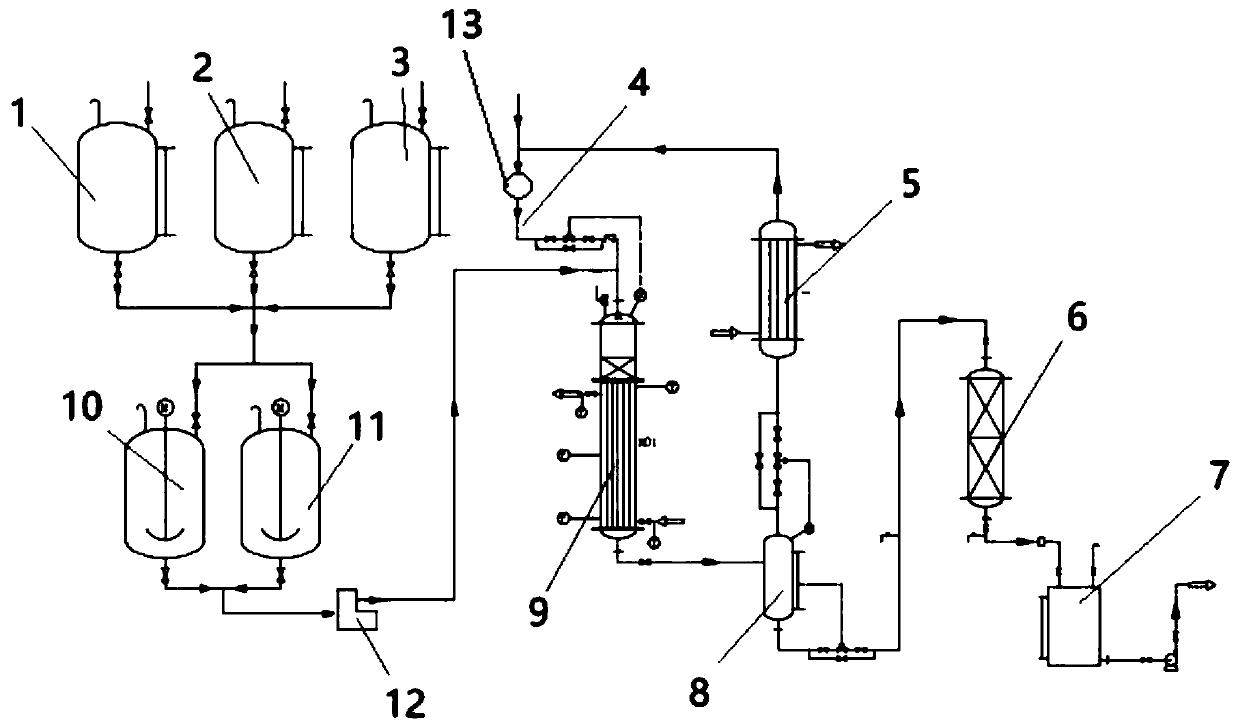

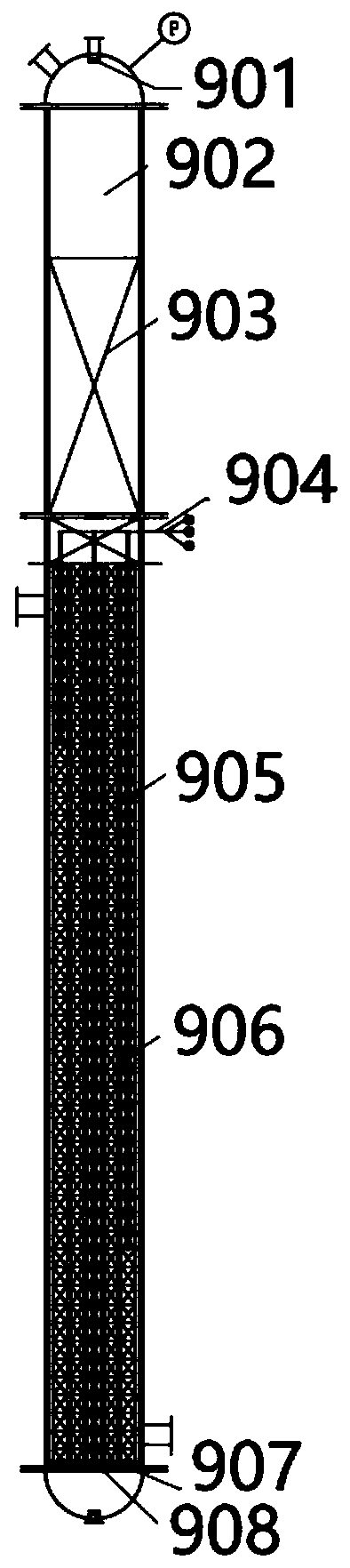

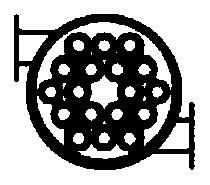

Apparatus and method for producing 3-acetyl-1-propanol by continuous hydrogenation of 2-methylfuran

PendingCN110052049AReduce lossReduce pollutionDistillation separationChemical/physical processesChemical industryHydrogen

The invention relates to the field of chemical industry, in particular to an apparatus and method for producing 3-acetyl-1-propanol by continuous hydrogenation of 2-methylfuran. The method comprises metering a mixture of water, a solvent and 2-methylfuran with a metering pump, feeding the metered mixture and metered hydrogen into a reactor, processing with an atomizer, holding certain temperatureand pressure, carrying out hydrogenation in a fixed bed in the atomized state, discharging the reacted liquid directly into a gas-liquid separator, wherein the discharged liquid is in gas-liquid mixedform, discharging the liquid part from the bottom of the gas-liquid separator after the discharge liquid enters the gas-liquid separator, neutralizing with a secondary reactor, and carrying out subsequent distilling and rectifying; processing hydrogen from the upper portion of the gas-liquid separator through a condenser, further cooling residual liquid in the reacted liquid, reserving in a liquid phase, and feeding non-condensed hydrogen into a hydrogen compressor through a hydrogen return pipe for reuse. The feeding quantity is controlled via the metering pump; the discharging quantity is controlled through a liquid level in the gas-liquid separator; therefore, balance is maintained.

Owner:山东一诺生物质材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com