Method for preparing liquid fuel through catalytic conversion of biomass platform compound and ABE fermentation product acetoin

A technology for fermentation products and liquid fuels, which is used in the preparation of liquid hydrocarbon mixtures, biological raw materials, and the petroleum industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

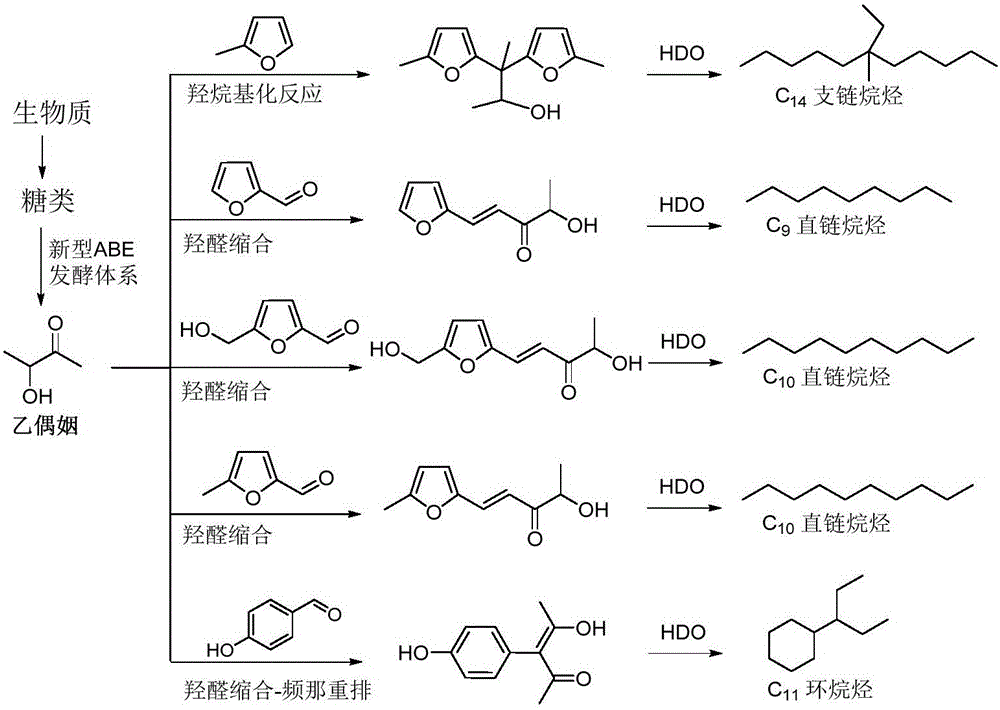

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The experimental device is mainly an eggplant-shaped bottle, which is placed on a magnetic stirrer, and a reflux condenser is placed on it. The raw materials and catalysts are added to the bottle according to a certain molar ratio, the magnetic stirrer is turned on, and the reaction is carried out in a water bath. After the reaction is completed, the reaction Liquid filtration, catalyst washing, drying recovery.

Embodiment 2

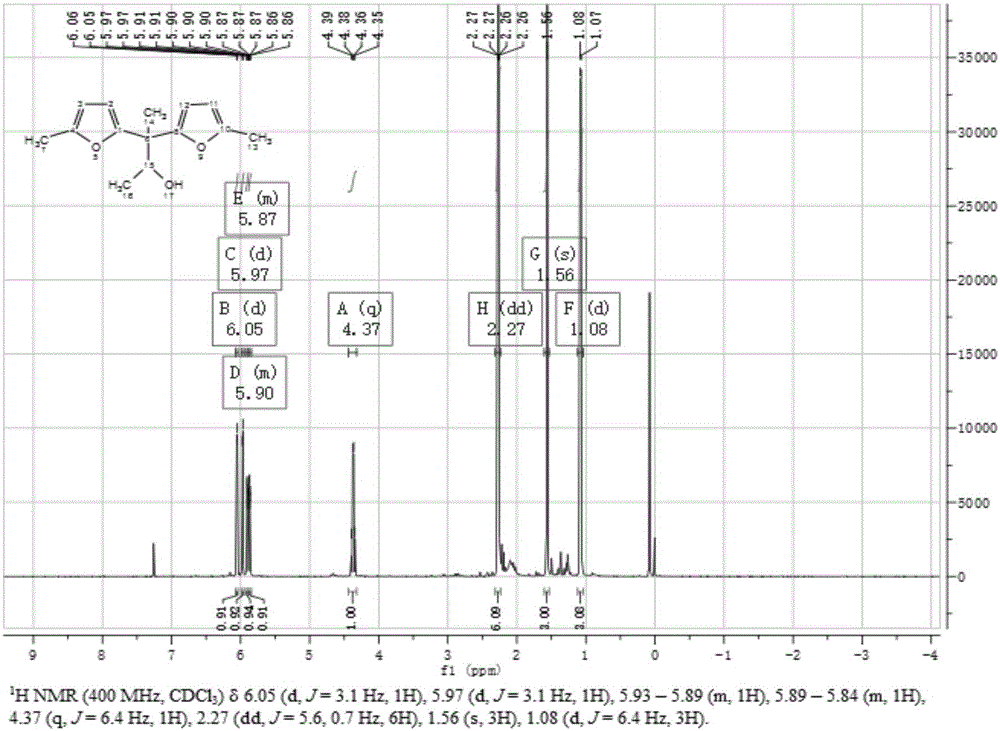

[0044] The experimental device is the same as in Example 1, and accurately weighs 2-methylfuran and acetoin in an eggplant-shaped bottle according to the molar ratio of 2.5:1, and then weighs the trifluoromethanesulfonic acid (TFA- ZrO 2 ) in the raw material solution, the molar ratio of the acid catalyst to acetoin was 0.1:1, and the reaction was performed under magnetic stirring in a water bath at 65° C. for 2 hours without solvent. After the reaction is finished, the reaction solution is filtered, the catalyst is washed, dried and recovered. The reaction conversion rate of this step is 100%, and the selectivity to the target product is 93.45%. Target product NMR see image 3 with Figure 4 .

Embodiment 3-6

[0046] The experimental setup is the same as in Example 1. Accurately weigh 2-methylfuran and acetoin in eggplant-shaped bottles according to the molar ratio of 2.5:1, then weigh the acid catalyst p-toluenesulfonic acid (embodiment 3), Amberlyst- 15 resin (embodiment 4), Nafion-212 lipid film (embodiment 5), sulfonated zirconia (S-ZrO 2 ) (Example 6) In the raw material solution, the molar ratio of the acid catalyst to acetoin was 0.1:1, and the reaction was carried out under magnetic stirring in a water bath at 65° C. for 2.5 hours without solvent. After the reaction, the reaction solution was filtered, the catalyst was washed, dried and recovered (p-toluenesulfonic acid was extracted by adding water and ethyl acetate, and the organic phase was concentrated). Selectivity and conversion are shown in Table 1:

[0047] Selectivity and conversion rate of table 1 embodiment 3-6

[0048] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com