Hydrogenation catalyst, preparation method of hydrogenation catalyst and application of hydrogenation catalyst to 2-methyltetrahydrofuran synthesis

A technology for hydrogenation catalysts and compounds, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of unsatisfactory 2-methyltetrahydrofuran yield, The difficulty of in-situ regeneration of the copper catalyst is increased, and the production is difficult to proceed smoothly, so as to achieve the effects of reducing energy consumption, simple preparation method, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

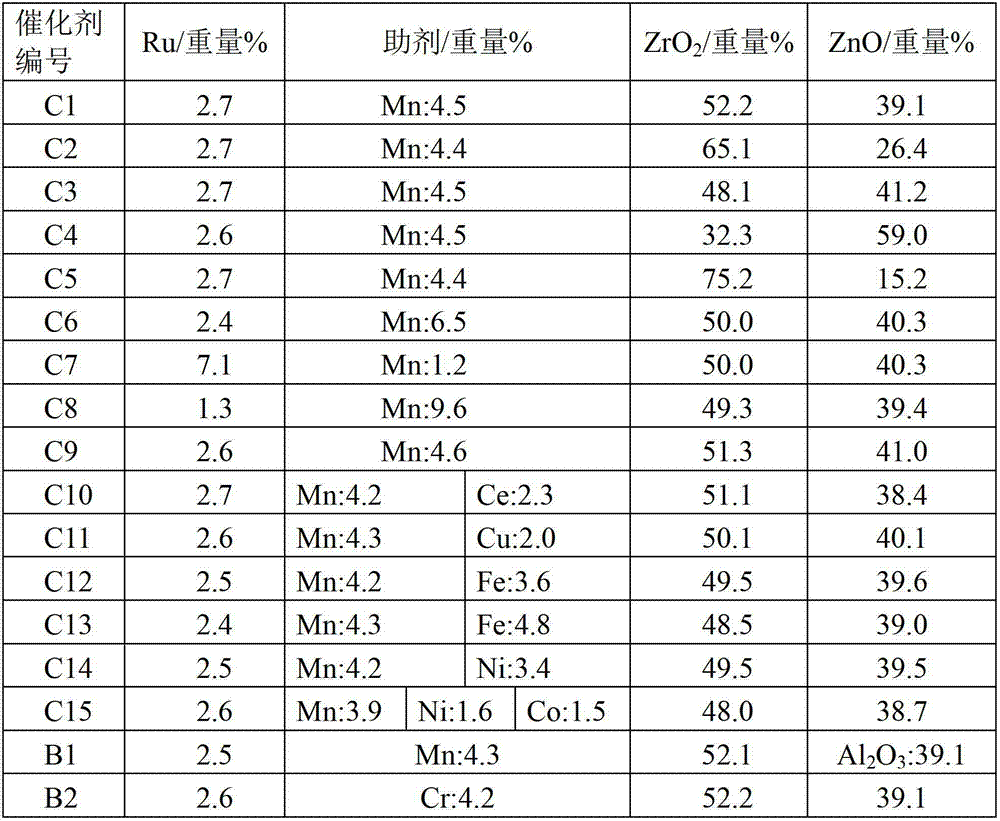

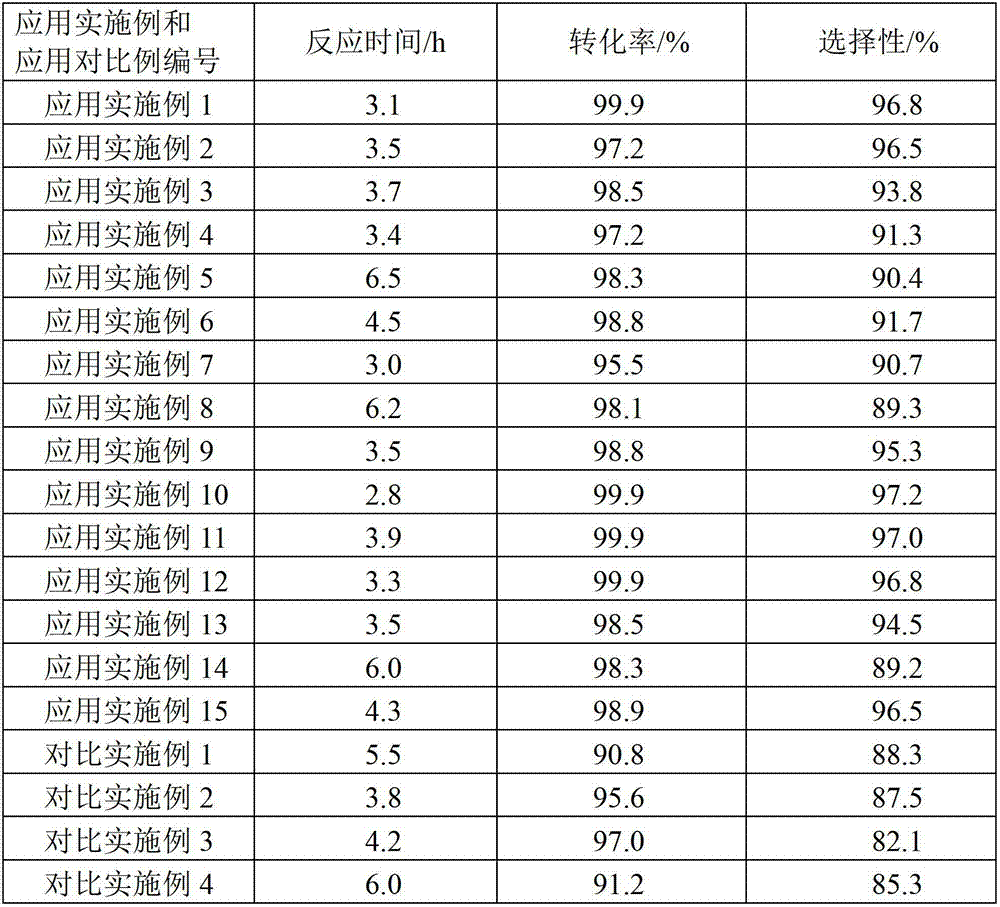

[0024] According to the present invention, the preparation method of the hydrogenation catalyst comprises: combining a soluble compound of hydrogenation active component ruthenium, Mn or Mn with at least one metal component selected from Group IB, Group IIB, Group IIIB and Group VIII The combination of soluble compounds with ZrO as auxiliary2 The composite carrier of ZnO is uniformly mixed in water to obtain a mixture, and the mixture is contacted with a reducing agent capable of reducing ruthenium ions in the soluble compound of ruthenium and metal ions in the soluble compound of the auxiliary agent, and filtered to obtain a solid precipitate . The method of uniformly mixing the soluble compound of ruthenium and the soluble compound of the auxiliary agent with the carrier in water can be carried out in the following two ways: (1) the soluble compound of ruthenium and the soluble compound of the auxiliary agent can be mixed with the carrier, and then uniformly mixed in water M...

Embodiment 1

[0057] (1) Carrier preparation

[0058] At 40°C, 100g of zirconium oxychloride octahydrate and 132g of zinc nitrate hexahydrate were dissolved in 500mL of water, stirred to dissolve completely, and 1400g of 12% by weight sodium carbonate solution was added dropwise to the solution to adjust the pH to 9.6; Raise the temperature to 95°C and age for 2h. Filter and wash with deionized water until no chloride ions are detected by silver nitrate; the filter cake is dried at 100°C and calcined at 600°C for 3.5h to obtain 70g of solid.

[0059] (2) Catalyst preparation

[0060] Mix 1.5 g of an aqueous ruthenium chloride solution with a metal ruthenium concentration of 10% by weight, 1.6 g of a 50% by weight manganese nitrate aqueous solution, and 50 mL of distilled water, and stir for 30 min. Then add 5 g of the carrier prepared in the above step (1), and stir for 1 h. Under stirring condition, add dropwise 33mL of 0.5mol / LKBH 4 The aqueous solution was added dropwise within 10-15...

Embodiment 2

[0062] (1) Carrier preparation

[0063] At 30°C, 200g of zirconium oxychloride octahydrate and 132g of zinc nitrate hexahydrate were dissolved in 500mL of water, and stirred to completely dissolve it; 2000g of 12% by weight sodium carbonate solution was added dropwise to the solution, and the terminal pH was 9.4; Raise the temperature to 90°C and age for 2.5 hours. Filter and wash with deionized water until no chloride ions are detected by silver nitrate; the filter cake is dried at 110°C and calcined at 550°C for 4.5h to obtain 107g of solid.

[0064] (2) Catalyst preparation

[0065] Prepare according to the catalyst preparation method of Example 1, the difference is that the carrier prepared in Example 2 is used. The hydrogenation catalyst C2 was obtained, the composition of which is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com